Aluminum alloy surface treatment method and photosensitive color-change aluminum alloy obtained by same

A photosensitive discoloration and surface treatment technology, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of photosensitive discoloration on the surface of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

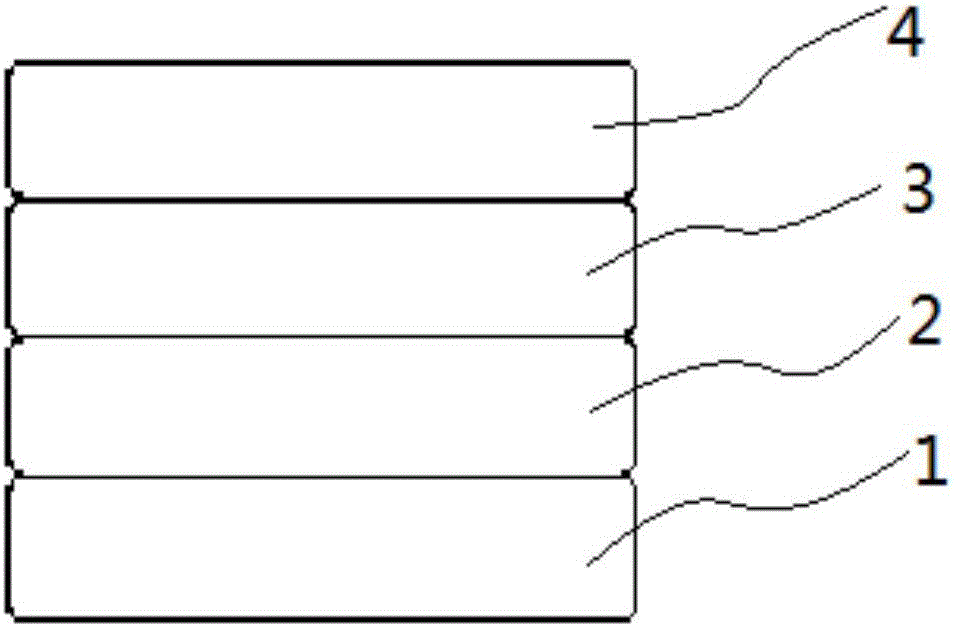

[0061] Anodizing of aluminum parts that have been mechanically pretreated and pre-anodized. Sulfuric acid is used as the electrolyte, wherein the sulfuric acid concentration is 150-200g / L. The voltage of anodizing is 11-13V, and the current density is 0.8-1.0A / mm 2 , the temperature of the anodizing tank is 18-22°C, and the anodizing time is 30-40min. The experimental parameters of anodic oxidation in Examples 1-4 are shown in Table 1.

[0062] Table 1

[0063] Example

Sulfuric acid concentration

Tank temperature

time

Example 1

150g / L

11V

0.8A / mm 2

18℃

30min

Example 2

170g / L

12V

0.9A / mm 2

20℃

35min

Example 3

200g / L

13V

1.0A / mm 2

20℃

40min

Example 4

200g / L

13V

1.0A / mm 2

22℃

40min

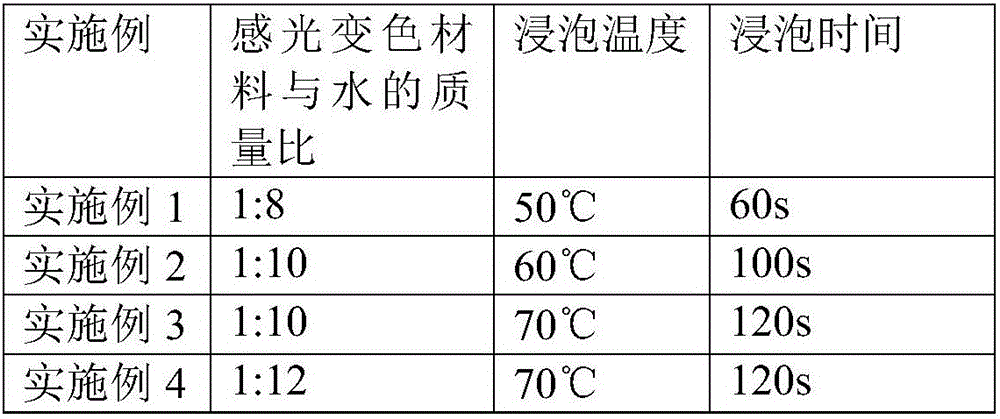

[0064] Next, the anodized aluminum parts are filled with photochromic powder. The photochromic powder N-butyl-6-nitrospiropyran is ...

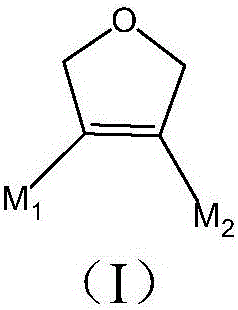

Embodiment 5

[0074] The biheterocyclic ethylene compound is selected as the photochromic material, and its chemical formula is shown in formula I, M 1 and M 2 Both are 2-methylindolyl, and other experimental procedures are the same as in Example 1. The obtained photochromic aluminum alloy has similar discoloration performance and layered structure, and will not be repeated here.

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com