Patents

Literature

58results about How to "Improve appearance competitiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

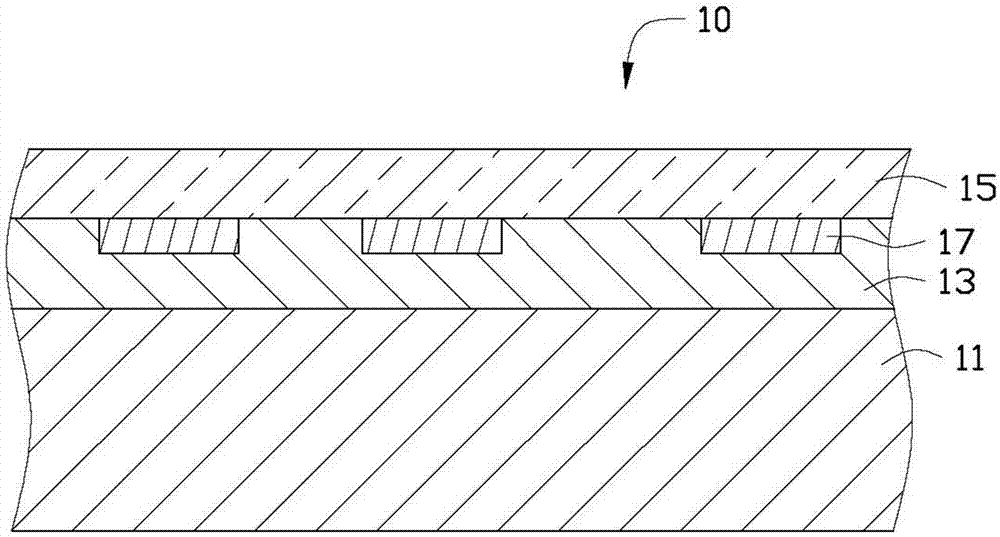

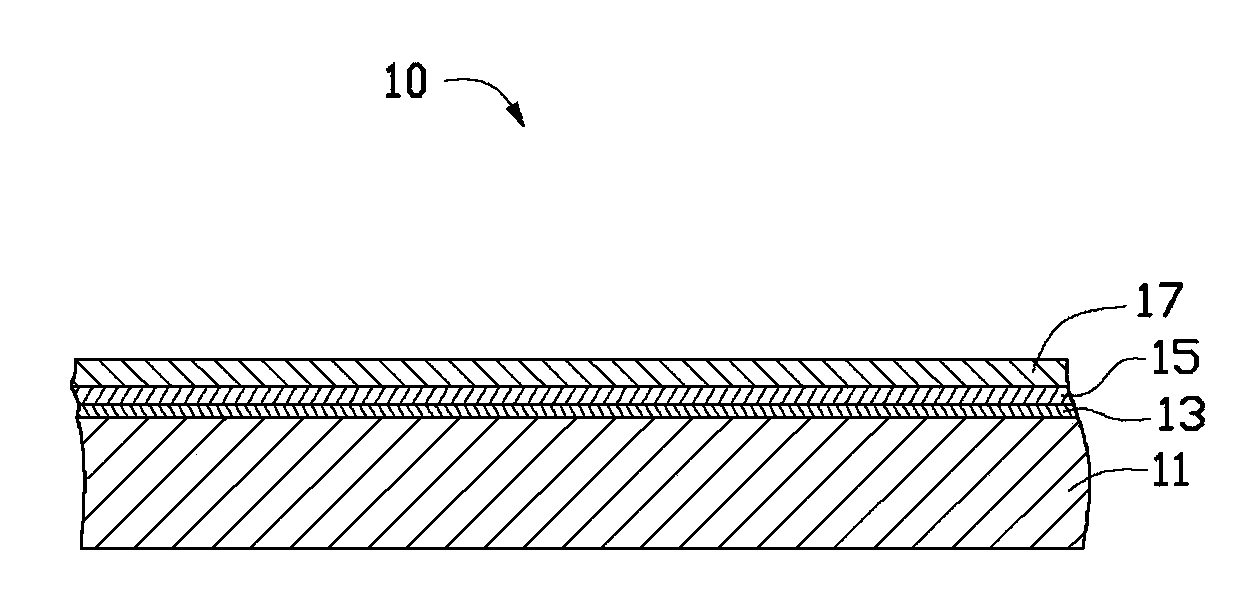

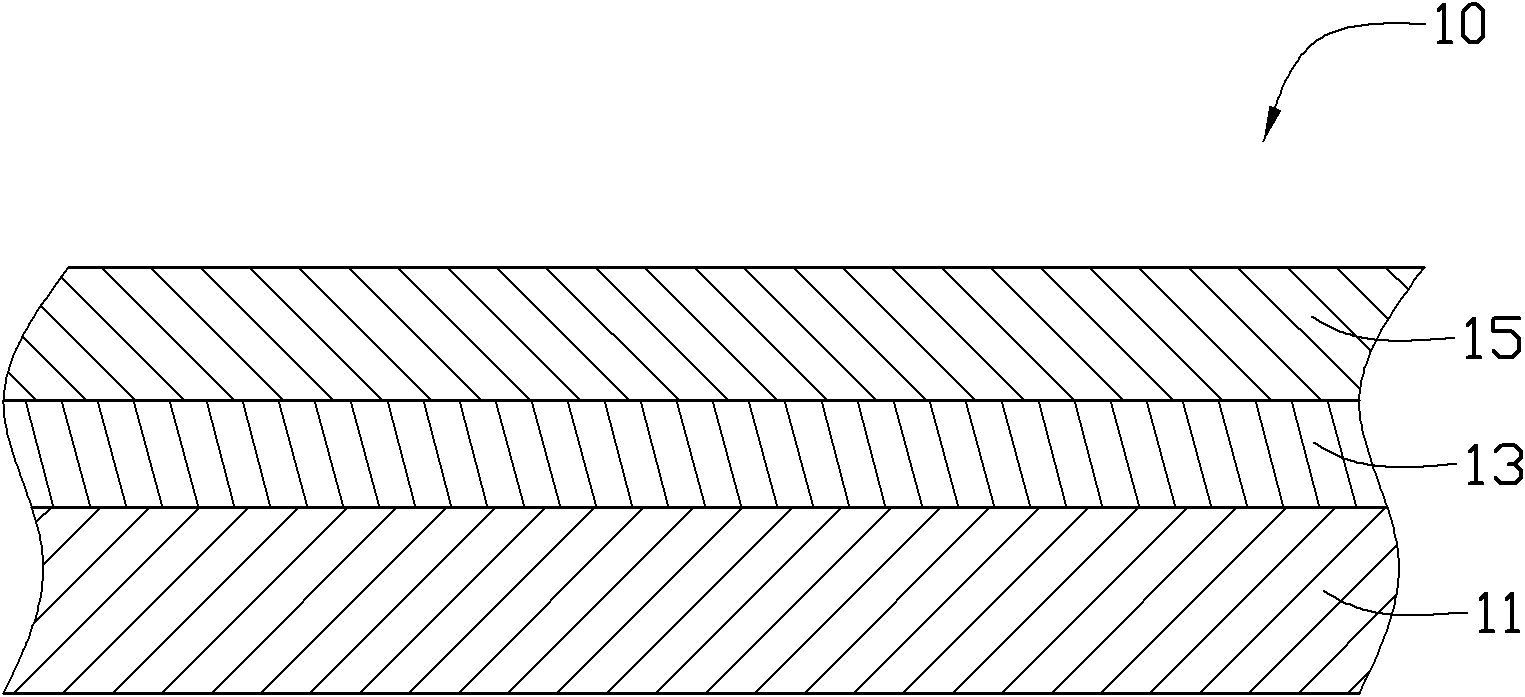

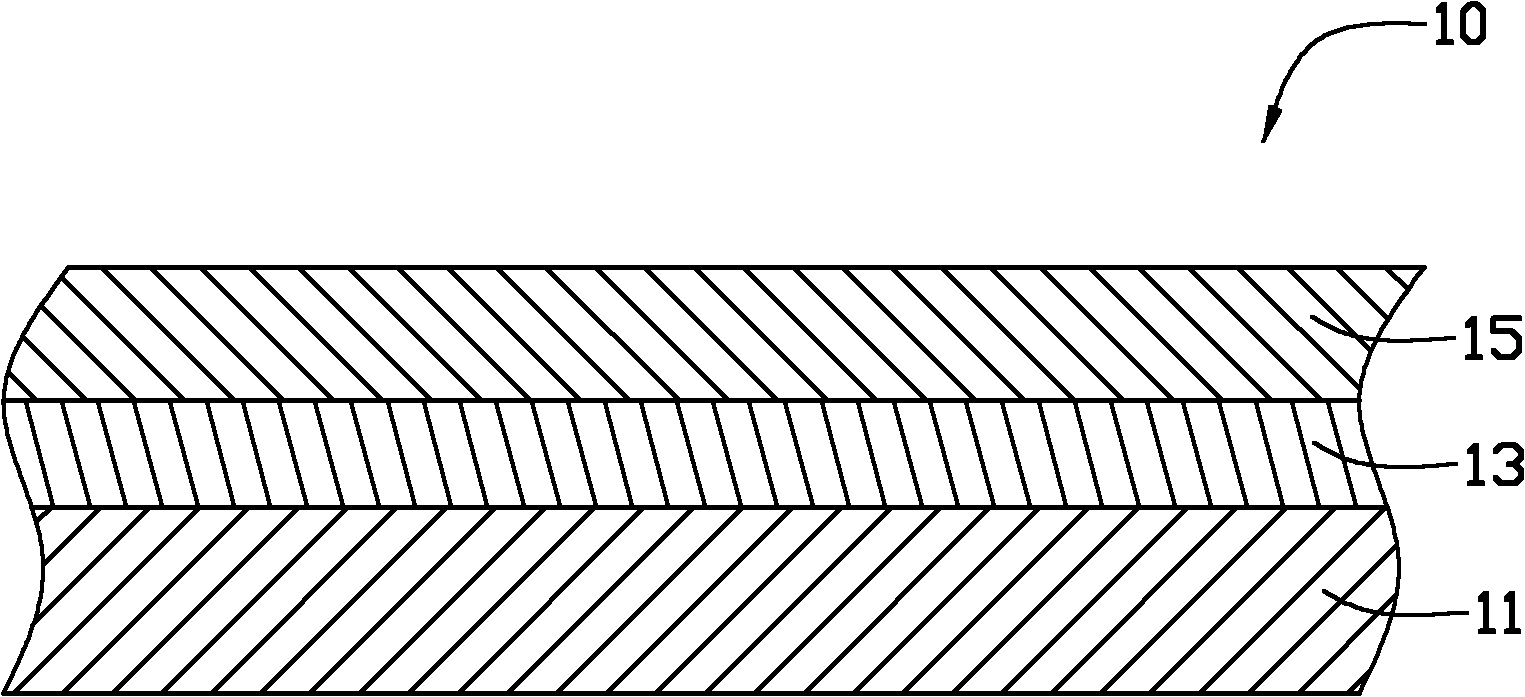

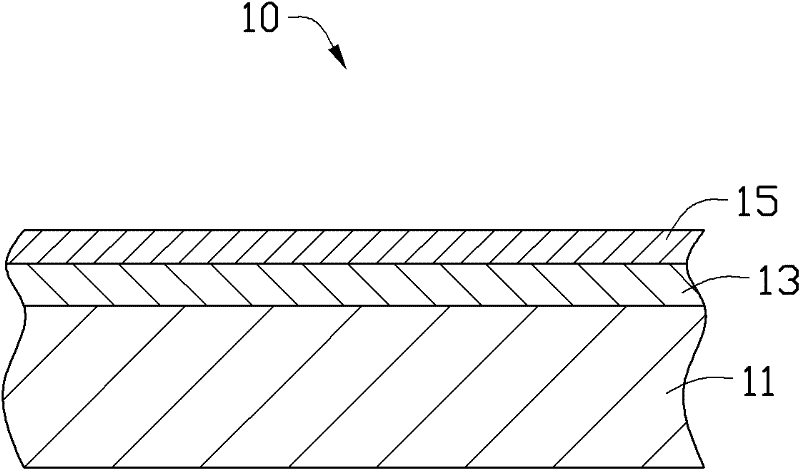

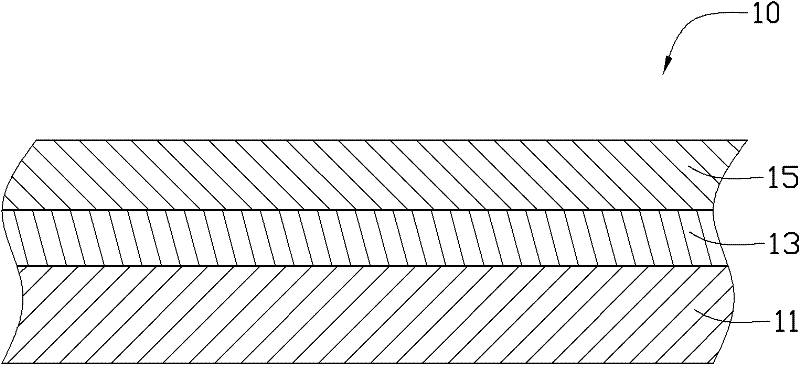

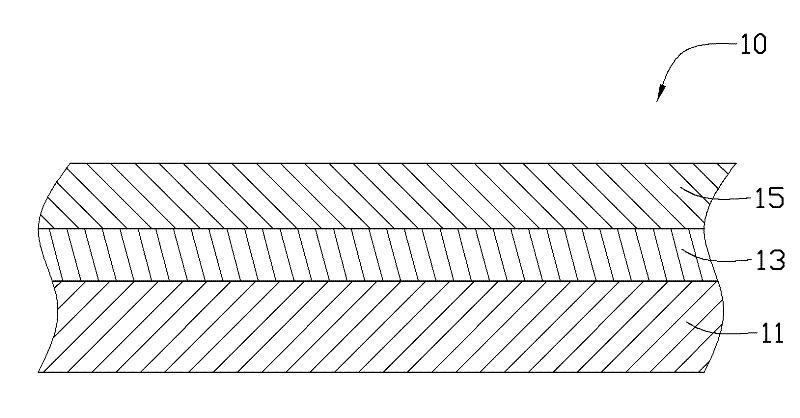

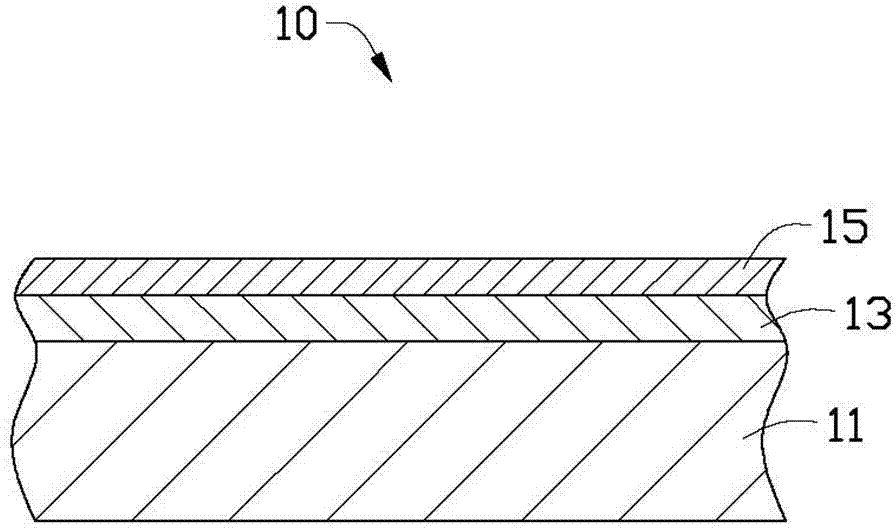

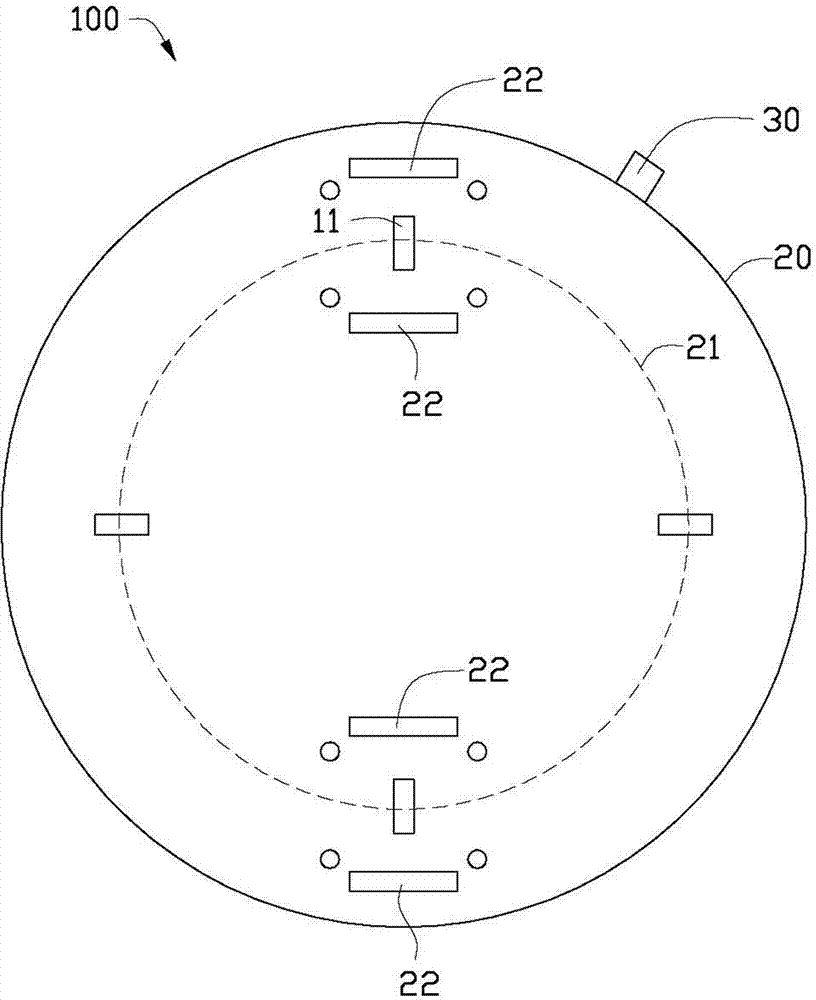

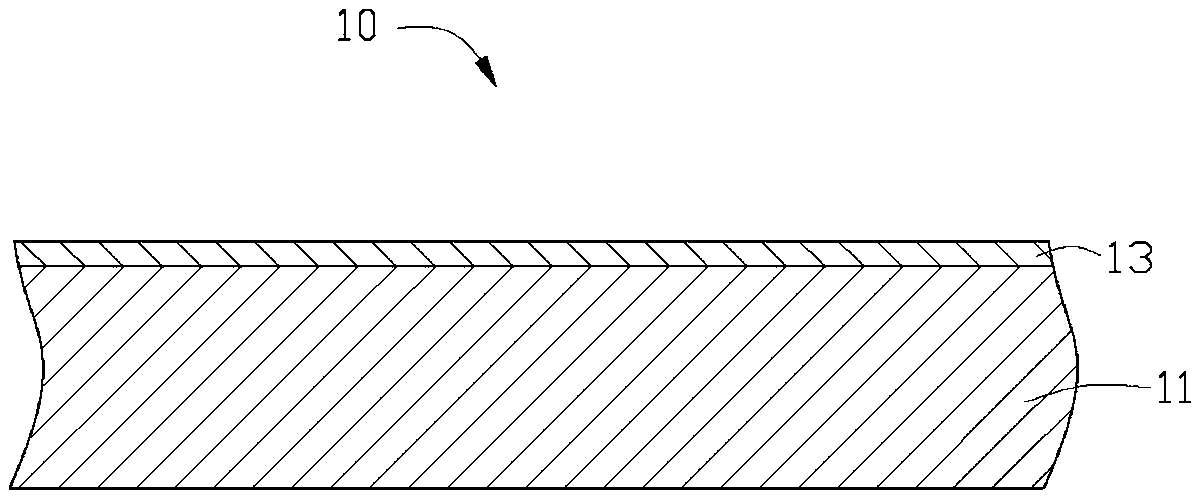

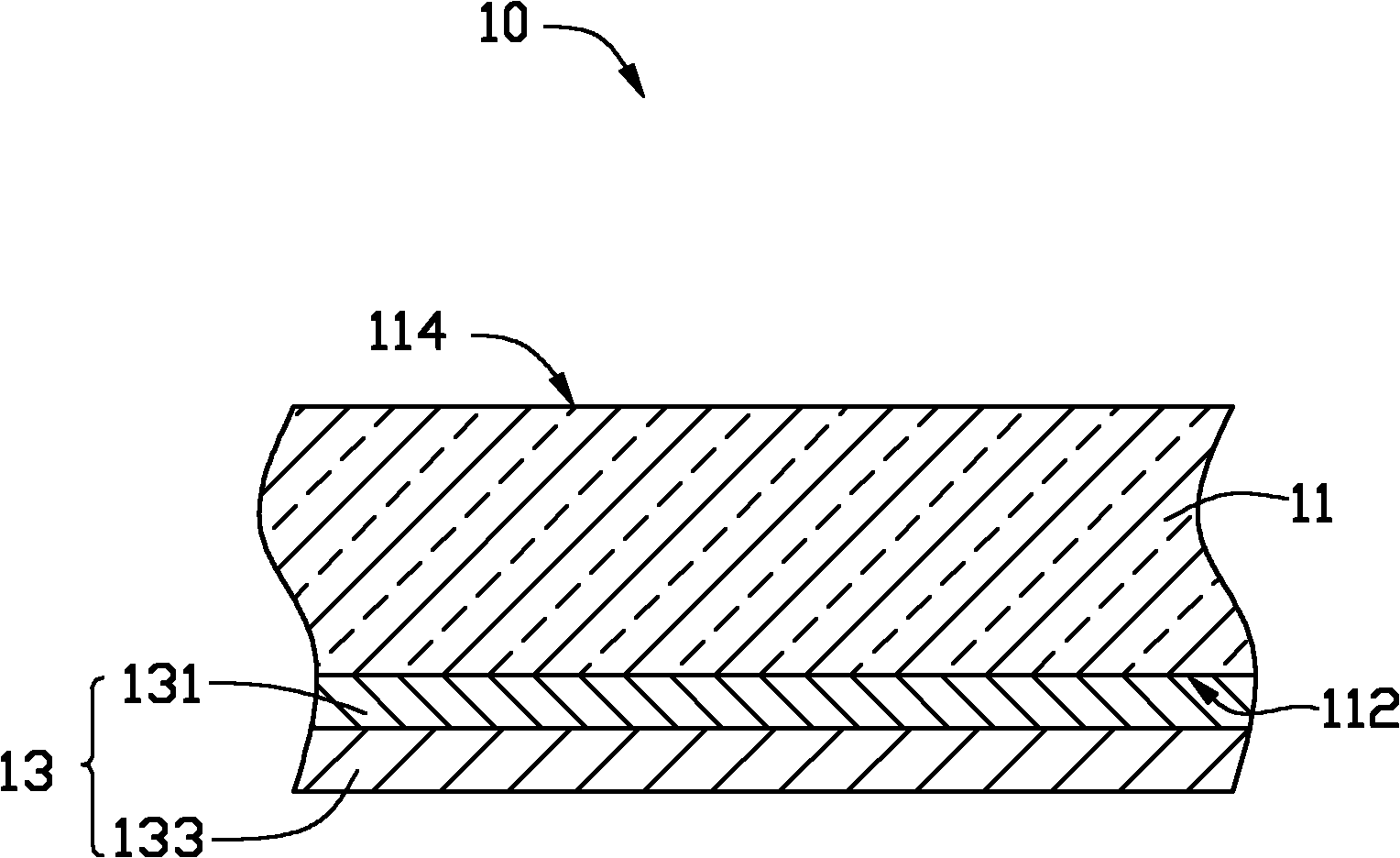

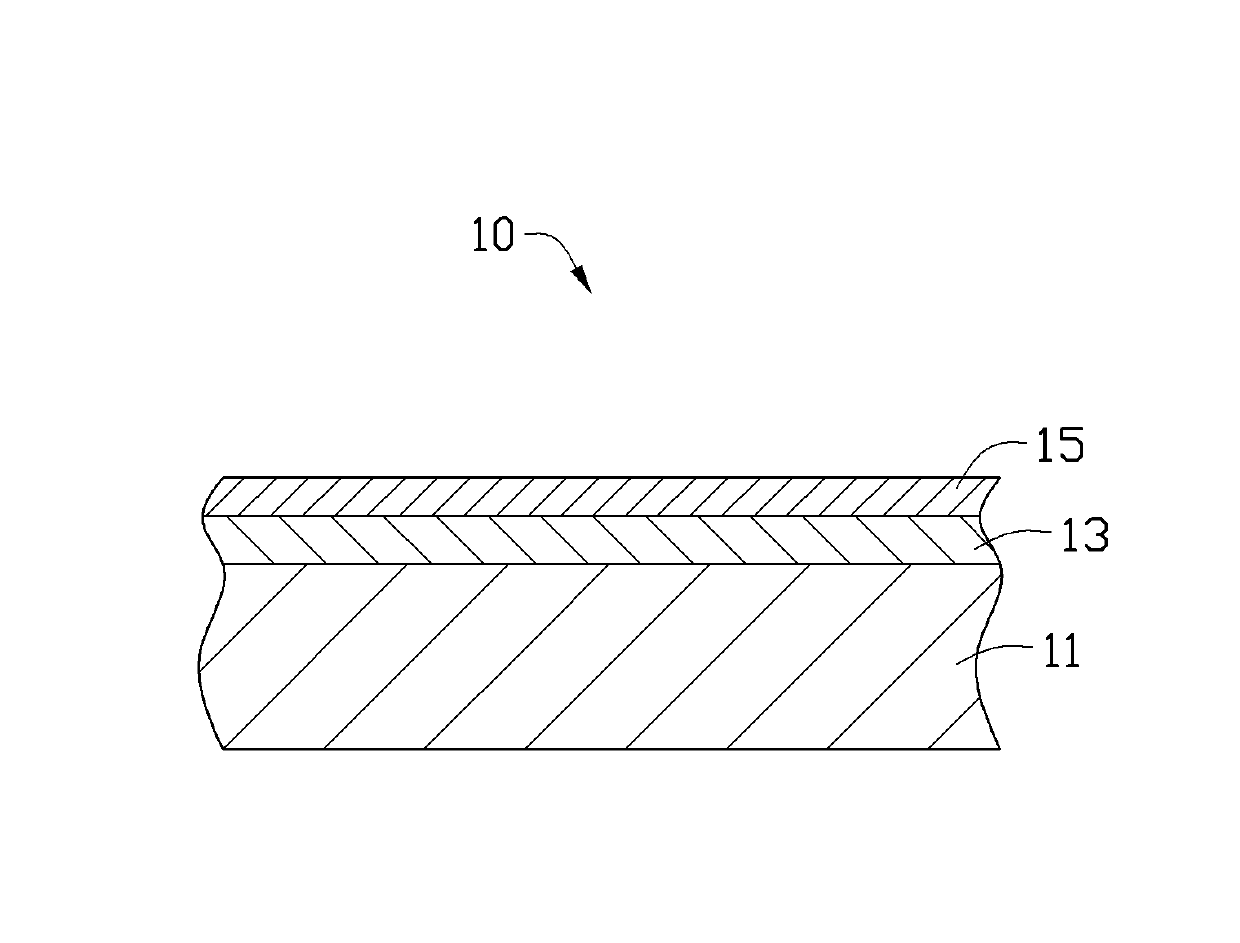

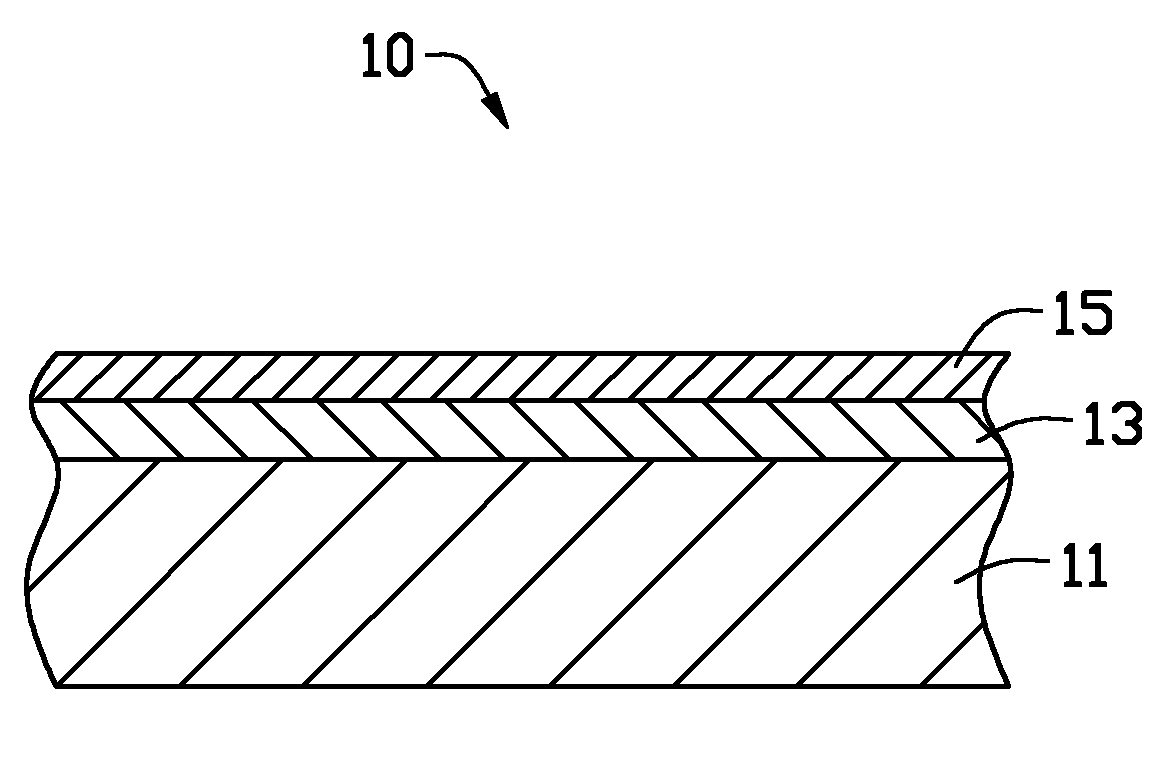

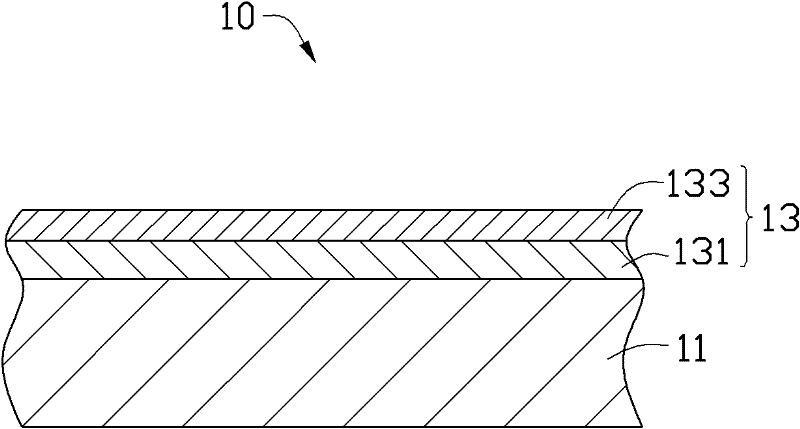

Shell body and preparing method thereof

InactiveCN103096649AImprove appearance competitivenessExtended service lifeMetal casingsThin material handlingMetallurgyTransparent ceramics

A shell body comprises base materials. The shell body is characterized by further comprising a base ceramic layer, a crystalline ceramic layer and a pattern layer, wherein the base ceramic layer is formed on the surface of the base materials, the crystalline ceramic layer is formed on the surface of the base ceramic layer, the pattern layer is arranged between the base ceramic layer and the crystalline ceramic layer, the pattern layer is embedded into the base ceramic layer, and the pattern layer is composed of ceramic. A pattern with ceramic texture is formed on the surface of the shell body, and thus the attractiveness of the appearance of the shell body is improved. Besides, the invention further provides a preparing method for the shell body.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

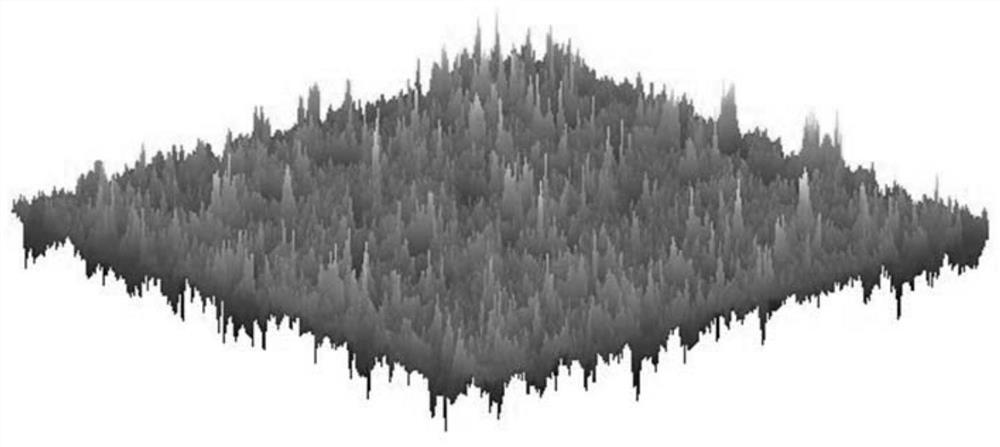

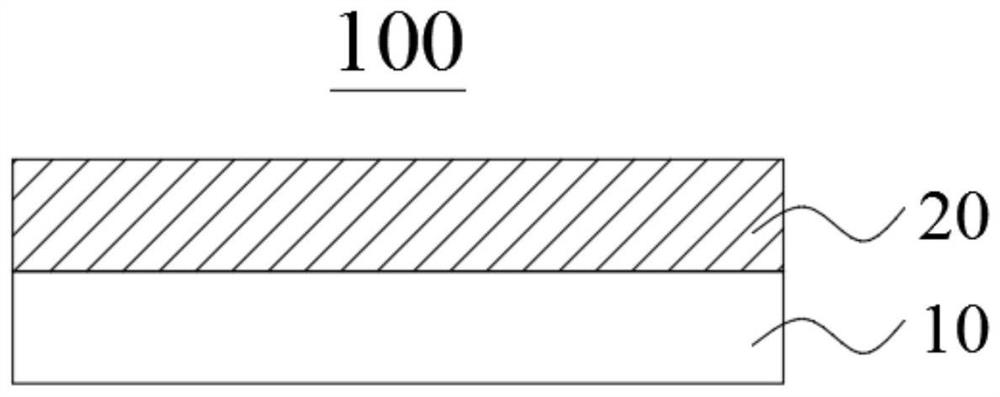

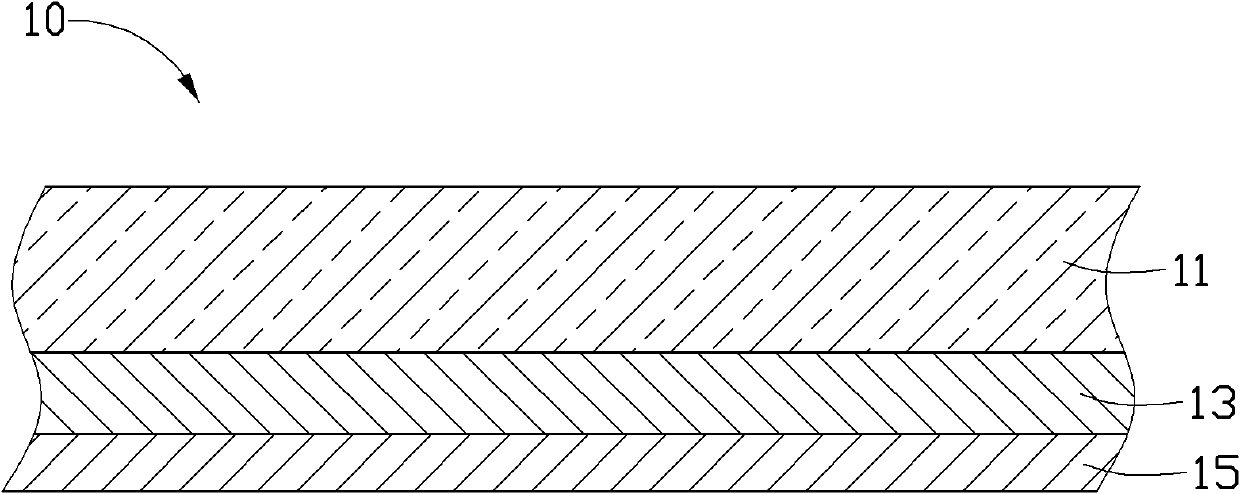

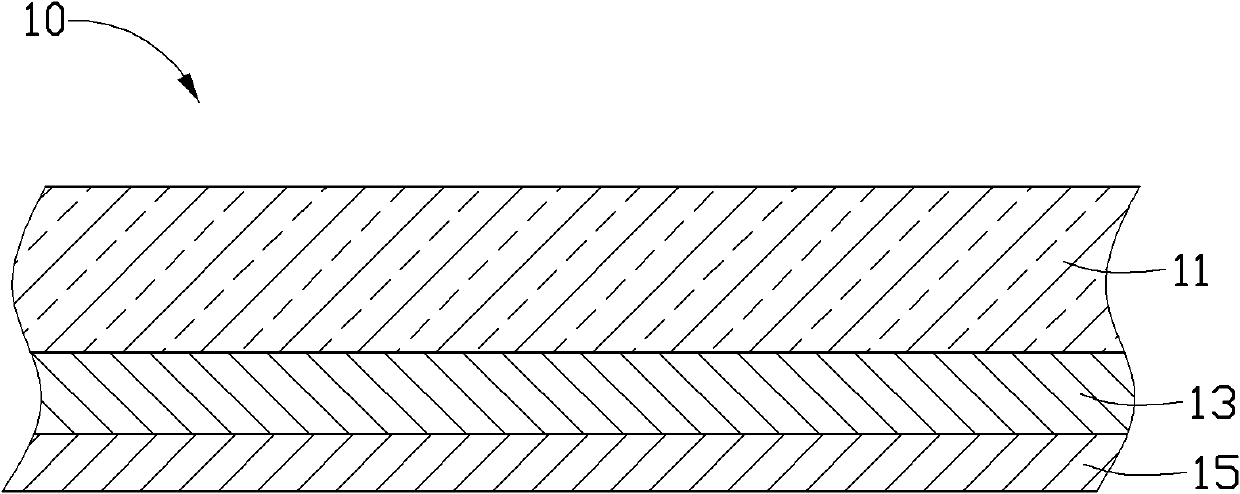

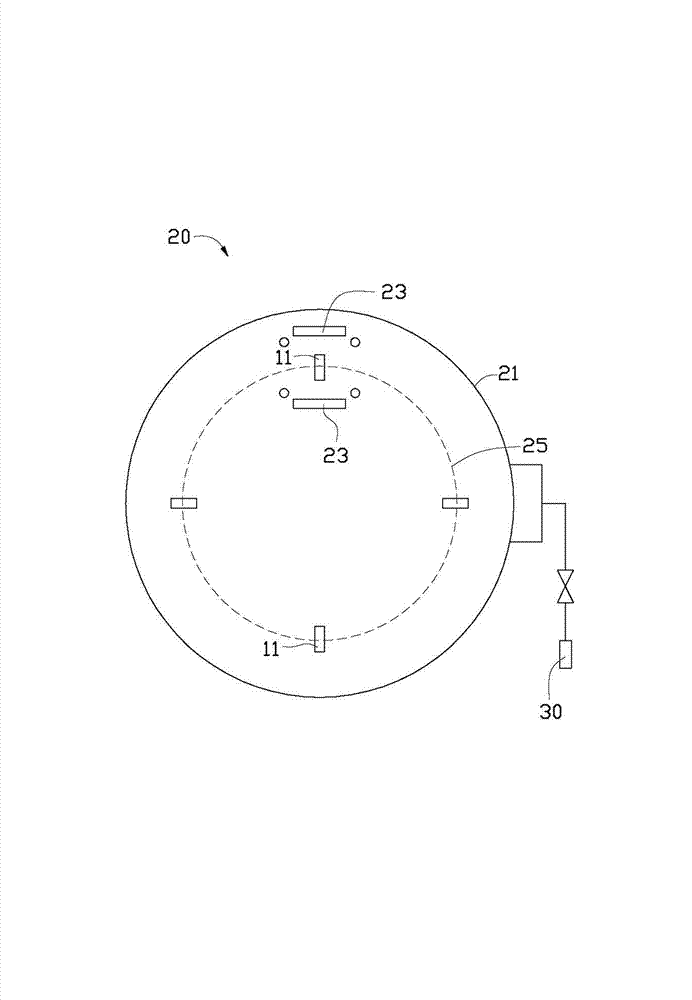

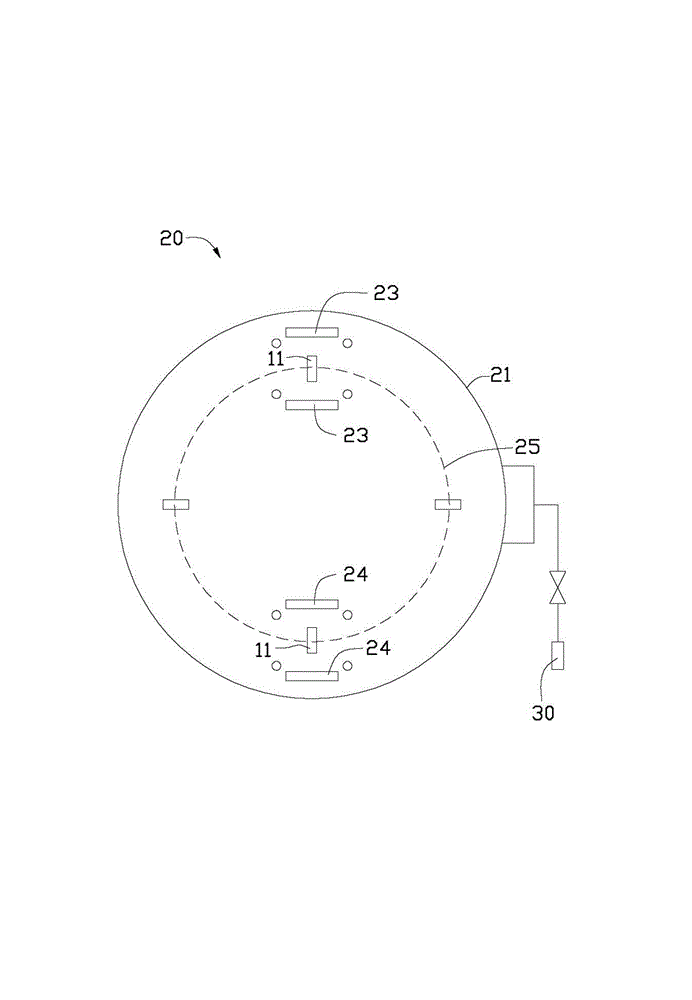

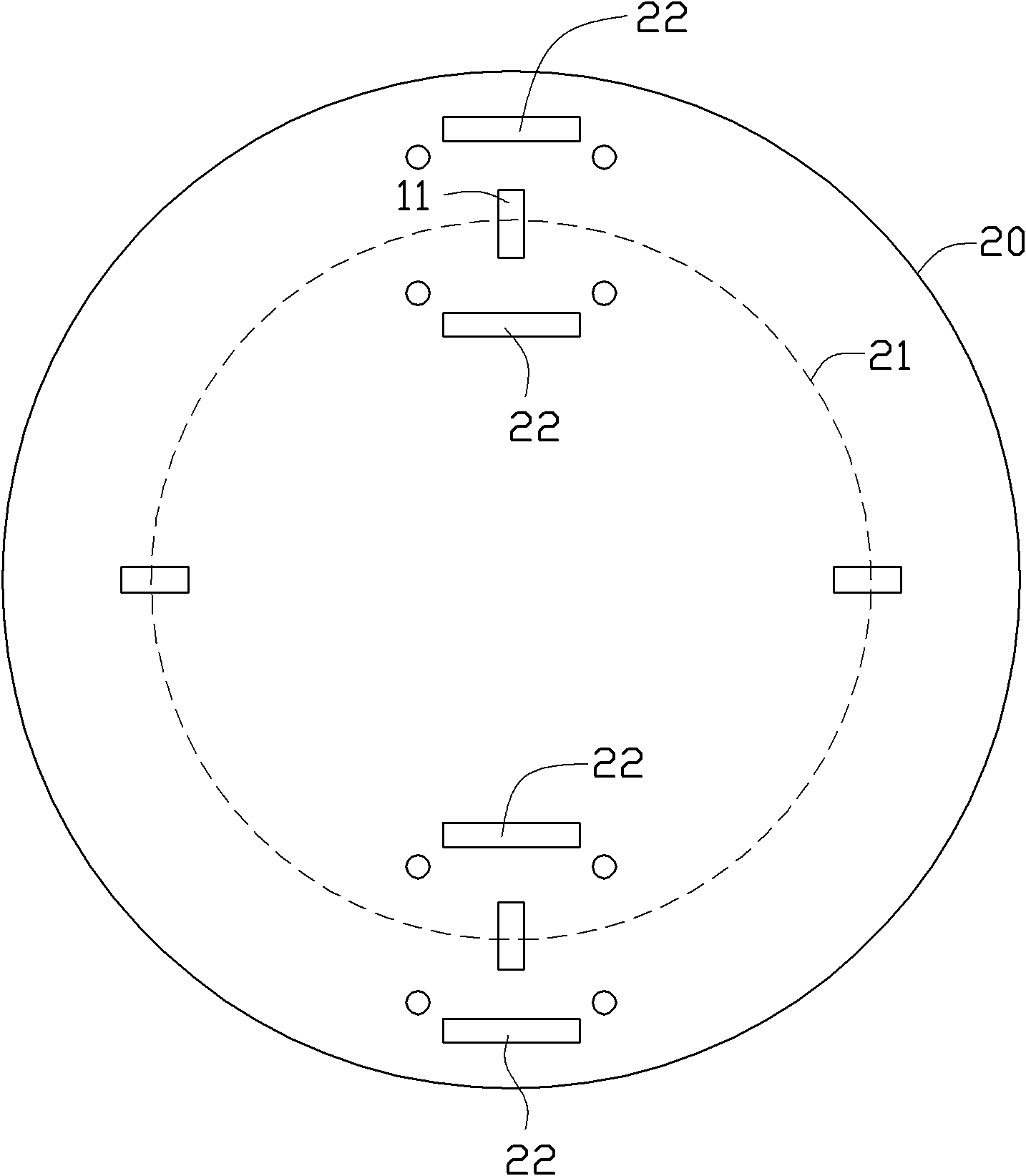

Shell, preparation method of shell and electronic device

ActiveCN111614816AEasy to prepareRich appearanceCasings/cabinets/drawers detailsTelephone set constructionsEngineeringMechanical engineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

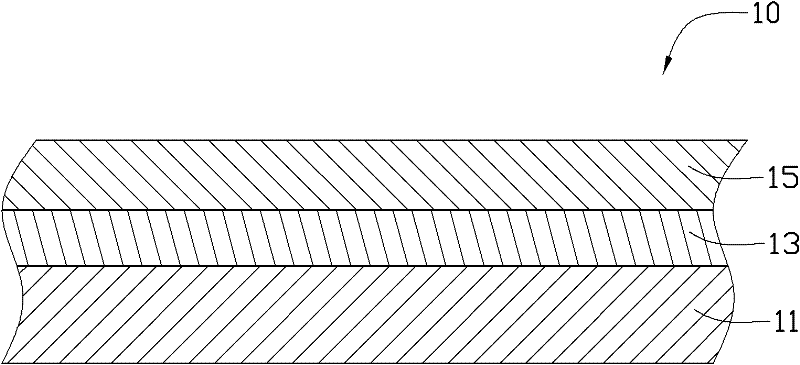

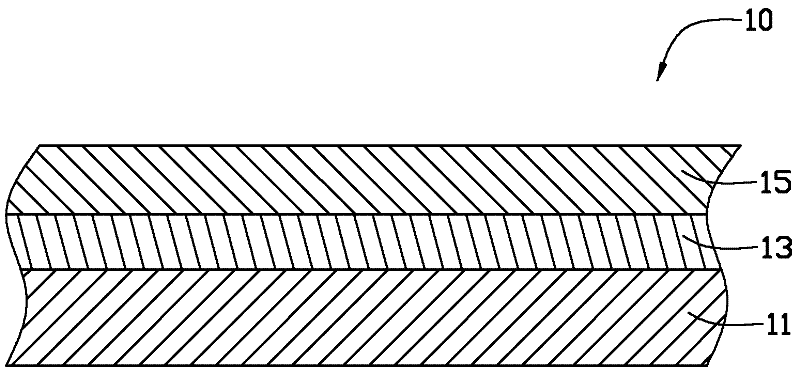

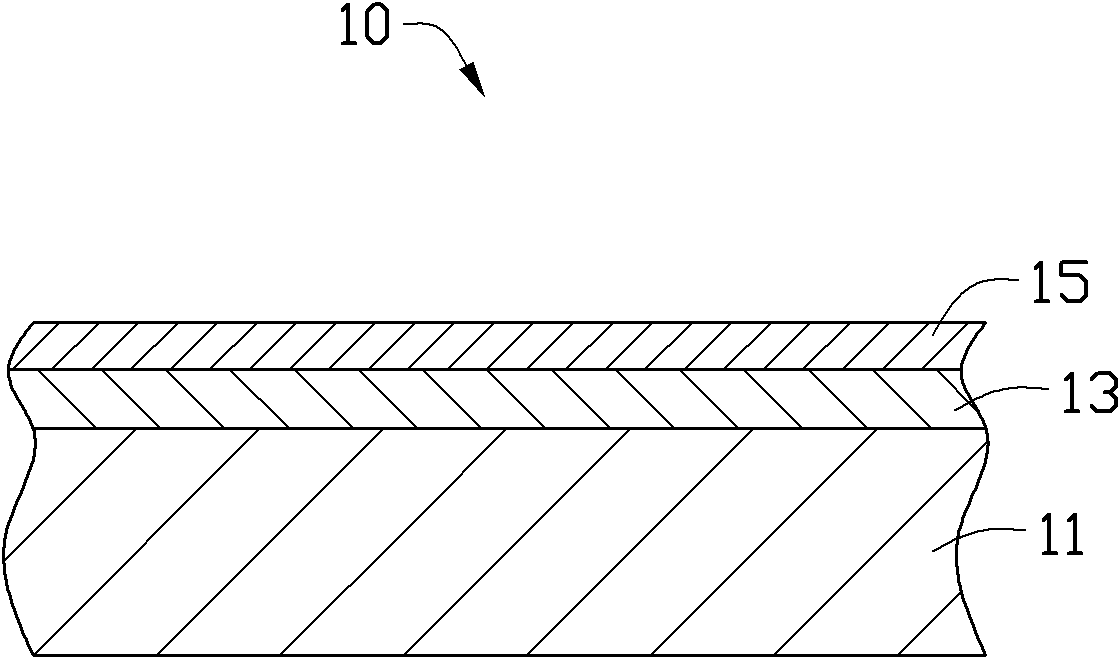

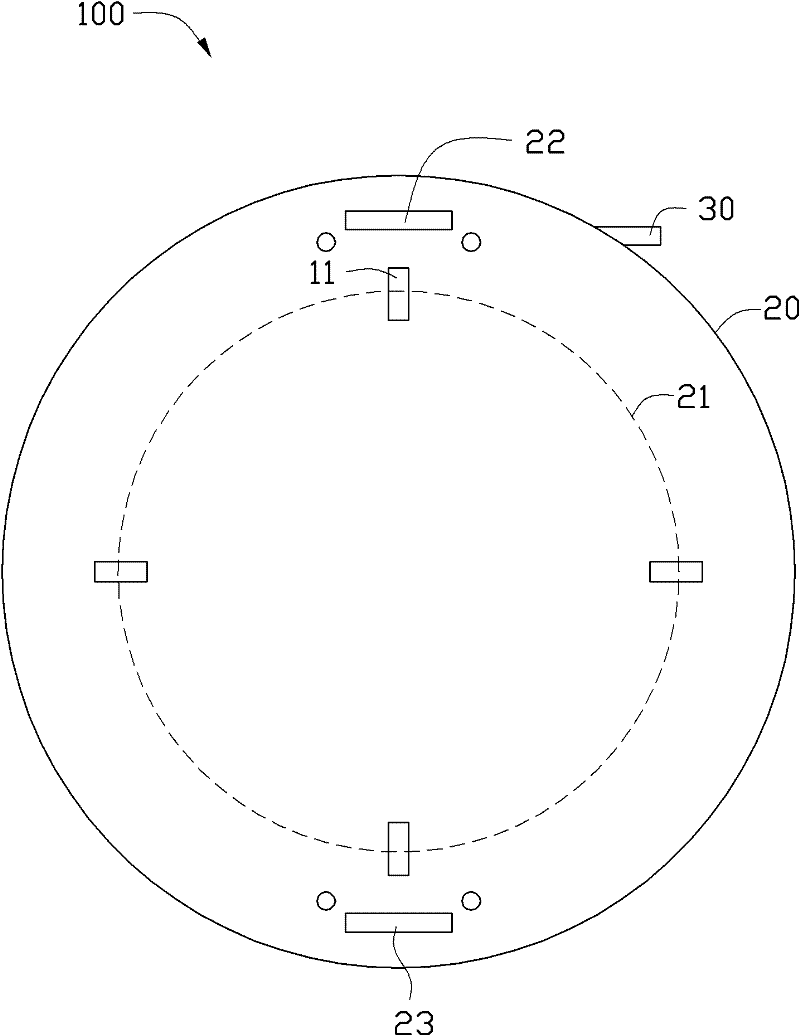

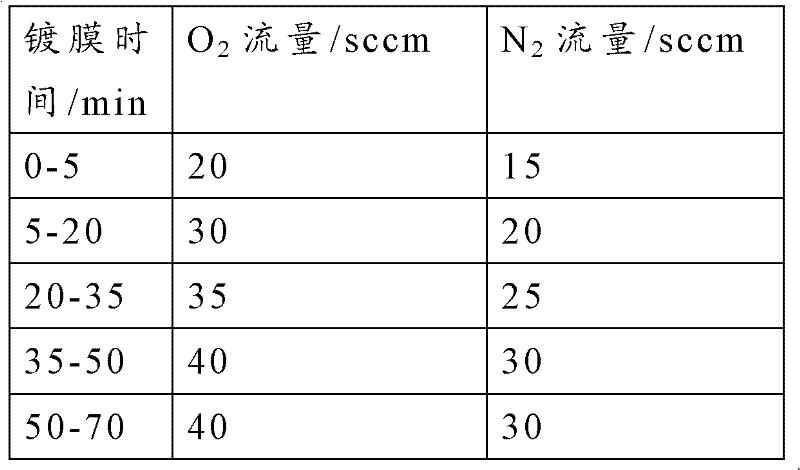

Coating piece and preparation method thereof

InactiveCN103895279AImprove appearance competitivenessVacuum evaporation coatingSputtering coatingSiliconMetal

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

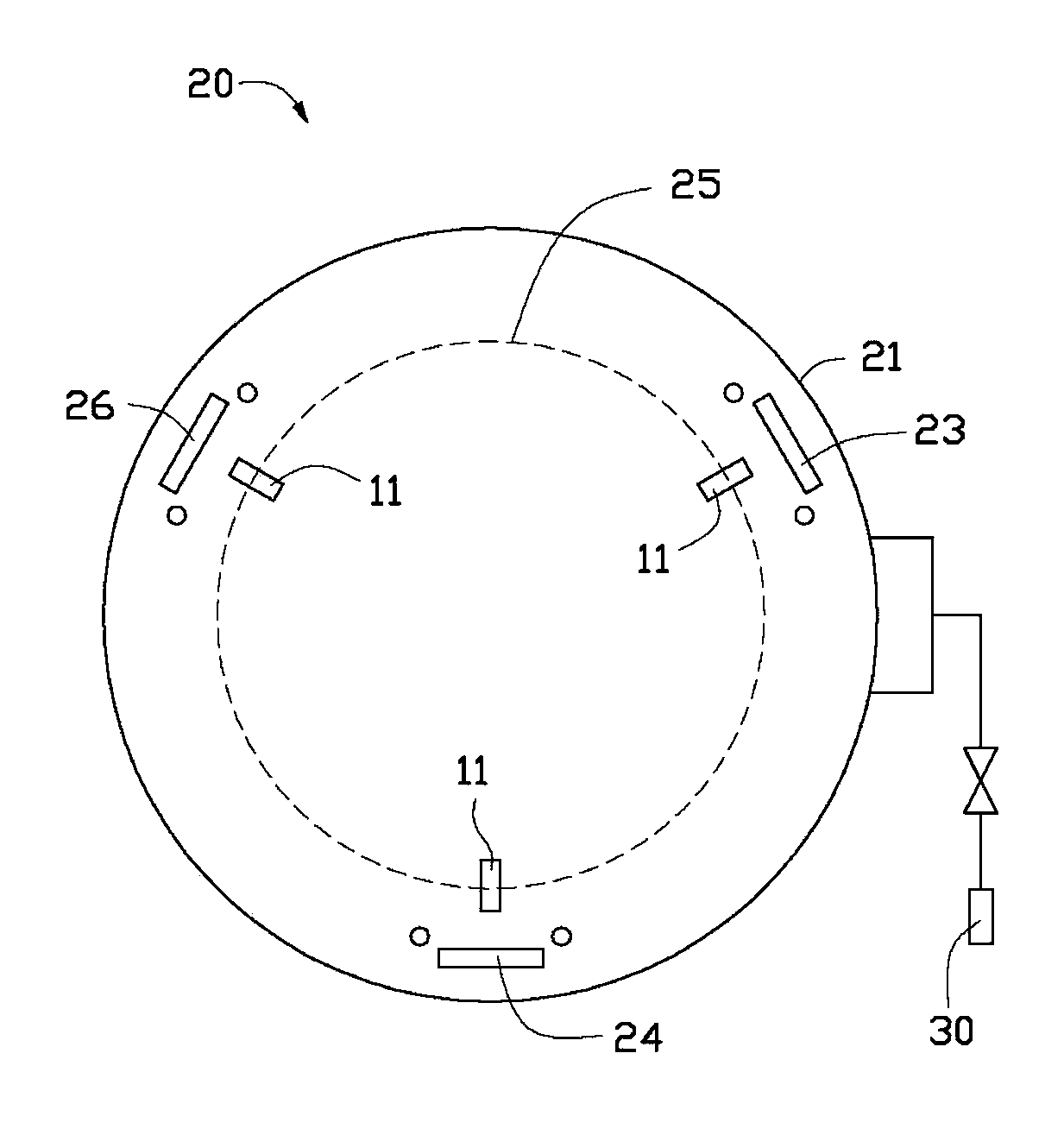

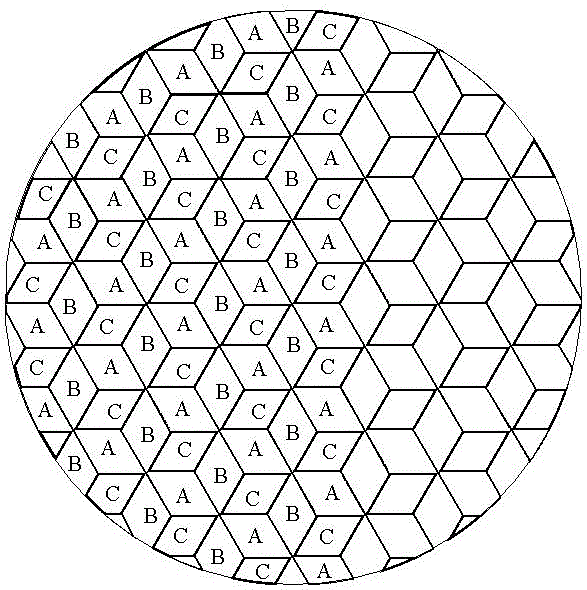

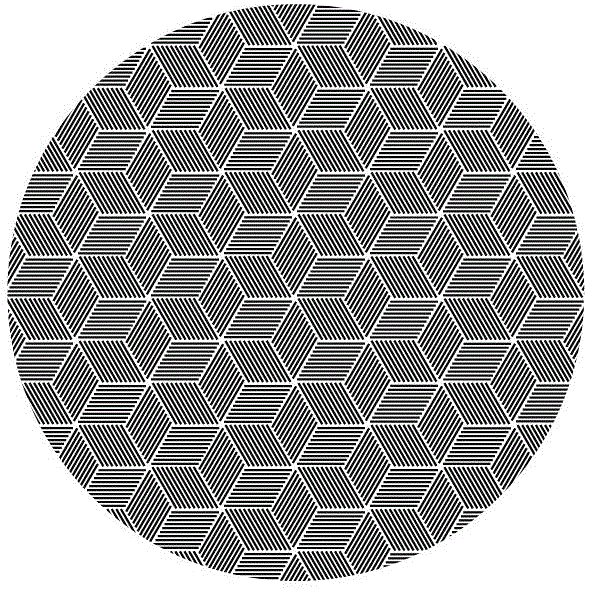

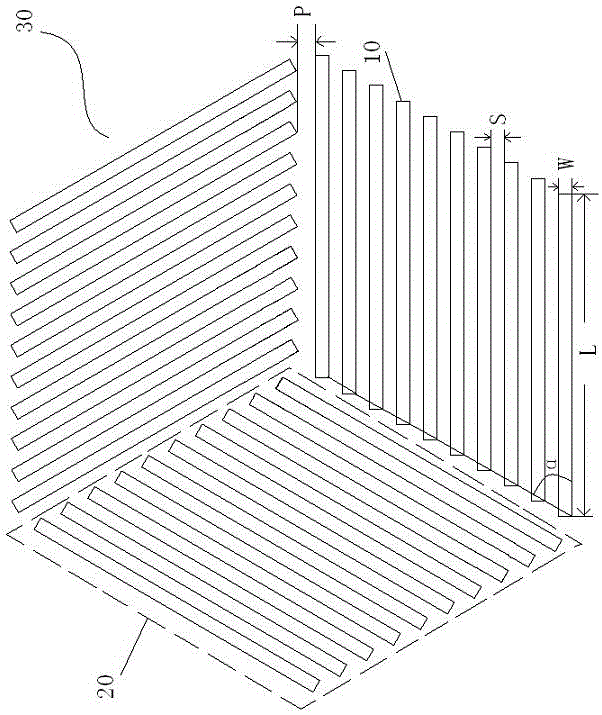

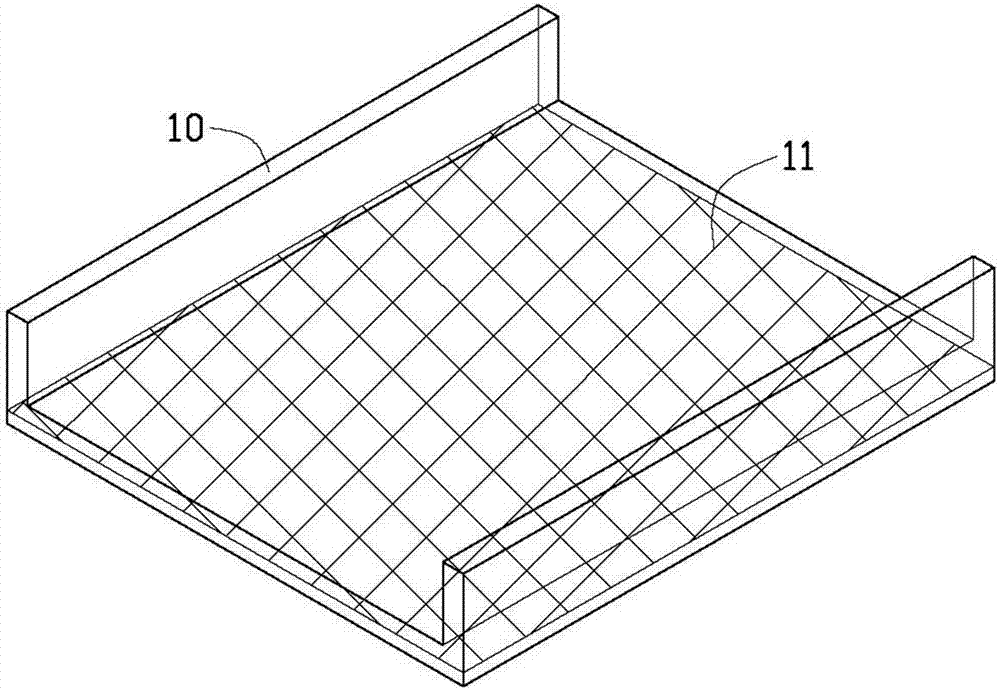

3D vision texture and processing method thereof on glass surface

ActiveCN106218196AImprove appearance competitivenessLamination ancillary operationsLamination3d visionThree stage

The invention discloses a 3D vision texture and a processing method thereof on a glass surface. The 3D vision texture comprises a plurality of three-stage units, wherein each three-stage unit consists of 3 two-stage units in an end-to-end adjacent circling manner; each two-stage unit is divided into a plurality of one-stage units which are arranged in parallel; a gap is formed between two adjacent one-stage units. As conventional color blocks are replaced by a plurality of one-stage units and are refined, light can be reflected by the one-stage units, and a 3D vision effect with false or true alternative variation can be achieved in different angles, so that a three-dimensional effect can be achieved on a two-dimensional glass surface, and the competitiveness of the product appearance can be greatly improved.

Owner:TCL COMM NINGBO

Housing and preparation method thereof

InactiveCN102560358AAvoid abrasion and scratchingAvoid corrosionVacuum evaporation coatingSputtering coatingColor effectReflective layer

The invention provides a housing with a purple appearance. The housing comprises a matrix, a color layer formed on the inner surface of the matrix and a reflective layer formed on the surface of the color layer, wherein the matrix is made of colorless transparent glass or plastic; the color layer is a zirconia layer; the reflective layer is a metal zirconium layer; and a chroma region presented by the housing has an L* coordinate between 30 to 35, an a* coordinate between 9 to 11 and a b* coordinate between minus 18 to minus 20 in a CIE Lab surface color system. The invention further provides a preparation method of the housing. The housing provided by the invention has the advantages that the color layer is formed on the inner surface of the matrix, and a color effect of the color layer is observed from the outer surface of the matrix; and under the protection of the matrix, the color layer can be effectively prevented from being abraded and scraped or corroded.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Housing and preparation method thereof

InactiveCN103096653AGood chemical stabilityImprove acid and alkali corrosion resistanceGlass shaping apparatusThin material handlingFiberHardness

The invention provides a housing. The housing body is made of colored glaze materials, the colored glaze is silica glass with lead dioxide, and fibre is embedded in the housing. The colored glaze is used for preparing housing, the housing is good in chemical stability, resistant to acid and alkali corrosion, high in hardness and wearproof, and the whole housing is crystal clear and beautiful in color. In addition, by the fact that fibre is introduced to the colored glaze, not only is the intensity of the housing greatly improved, but also the competitiveness of the housing appearance is improved. The invention further provides a preparation method of the housing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

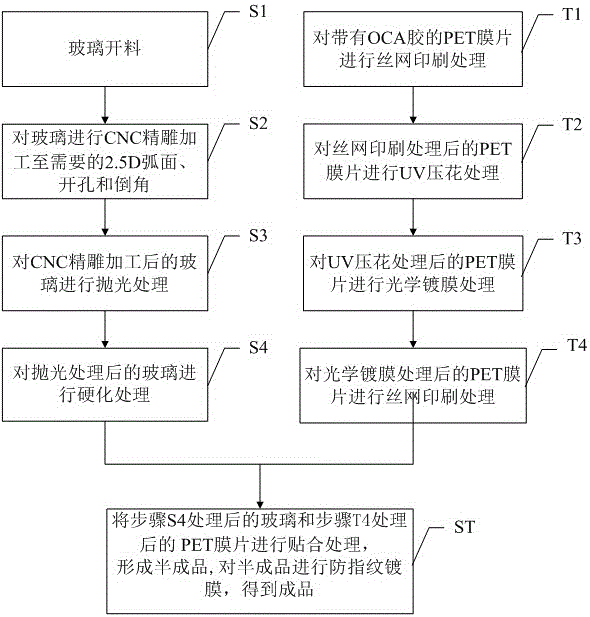

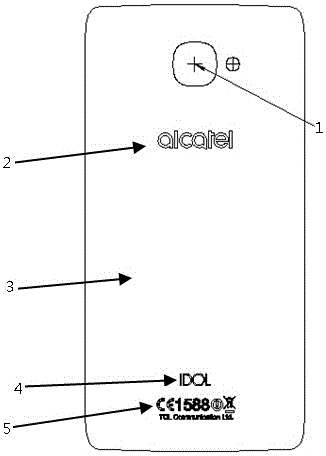

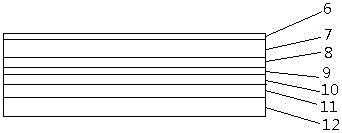

Optical coating and transfer printing combined surface treatment method

InactiveCN106218187AReduce presenceRich and varied visual effectsLamination ancillary operationsLaminationScreen printingAdhesive

The invention discloses an optical coating and transfer printing combined surface treatment method. The method comprises the steps that glass is subjected to rough shape cutting; the glass is subjected to CNC carving machining to obtain the needed 2.5 D cambered surface, tapped holes and chamfers; the glass is subjected to polishing treatment; the glass is subjected to hardening treatment; a PET membrane with an OCA adhesive is subjected to silk-screen printing treatment; the PET membrane is subjected to UV embossing treatment; the PET membrane is subjected to optical coating treatment; the PET membrane is subjected to silk-screen printing treatment; the treated glass and the treated PET membrane are subjected to laminating treatment, a semi-finished product is formed, the semi-finished product is subjected to anti-fingerprint coating, and the finished product is obtained. According to the optical coating and transfer printing combined surface treatment method, secondary machining is conducted on the periphery of the glass, certain radian is formed, ergonomics is better met, and a more comfortable touch feeling is achieved; by conducting surface treatments such as optical coating and texture transfer printing on the 2.5 D glass, the 2.5 D glass has a richer and more changeable visual effect, and the appearance competitiveness of the product is greatly promoted.

Owner:TCL COMM TECH NINGBO CO LTD

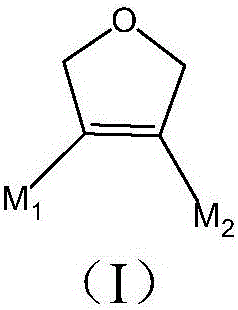

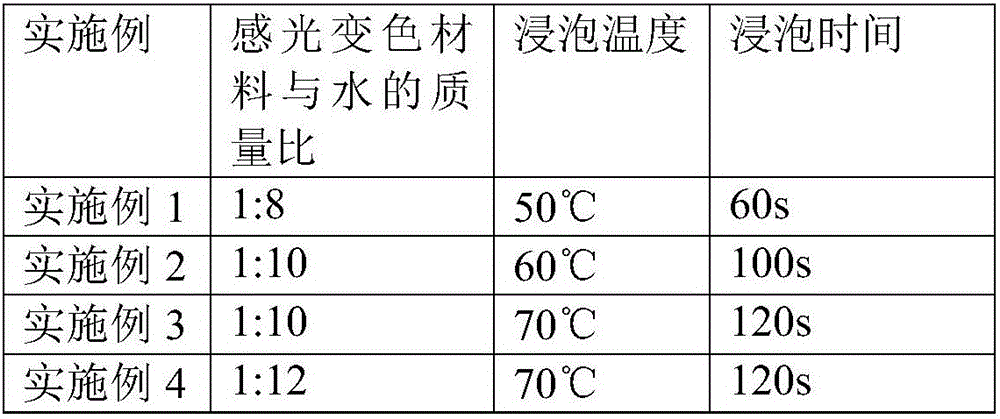

Aluminum alloy surface treatment method and photosensitive color-change aluminum alloy obtained by same

The invention relates to the technical field of aluminum alloy surface treatment, in particular to an aluminum alloy surface treatment method and a photosensitive color-change aluminum alloy workpiece obtained by the same. The aluminum alloy surface treatment method at least comprises the following steps that 1, the aluminum alloy workpiece is subjected to anodic oxidation, so that a porous alumina film layer is generated on the surface of the aluminum alloy workpiece; 2, the aluminum alloy workpiece subjected to anodic oxidation is subjected to photosensitive color-change material filling, so that the porous alumina film layer is filled with a photosensitive color-change material; 3, the aluminum alloy workpiece subjected to photosensitive color-change material filling is dyed; and 4, the dyed aluminum alloy workpiece is subjected to hole sealing. According to the aluminum alloy surface treatment method, the photosensitive color-change function and appearance effect of the aluminum alloy surface are achieved, and the appearance competitiveness of aluminum alloy materials is effectively improved.

Owner:SHENZHEN TINNO WIRELESS TECH

Housing and preparation method thereof

InactiveCN102950838AImprove appearance competitivenessColorfulVacuum evaporation coatingSputtering coatingAlloySilicon

The invention relates to a housing comprising a substrate. A primer layer, a metal layer and a topcoat layer are sequentially formed on the surface of the substrate. The primer layer is an acrylic epoxy resin layer. The metal layer is a silicon-aluminum alloy layer. Silicon atomic percentage in the metal layer is 10-90%, and aluminum atomic percentage in the metal layer is 90-10%. The topcoat layer is an acrylic polyurethane layer. The surface of the housing has a colorful effect, and has bright colors and a good metal texture. The invention also provides a preparation method of the housing.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

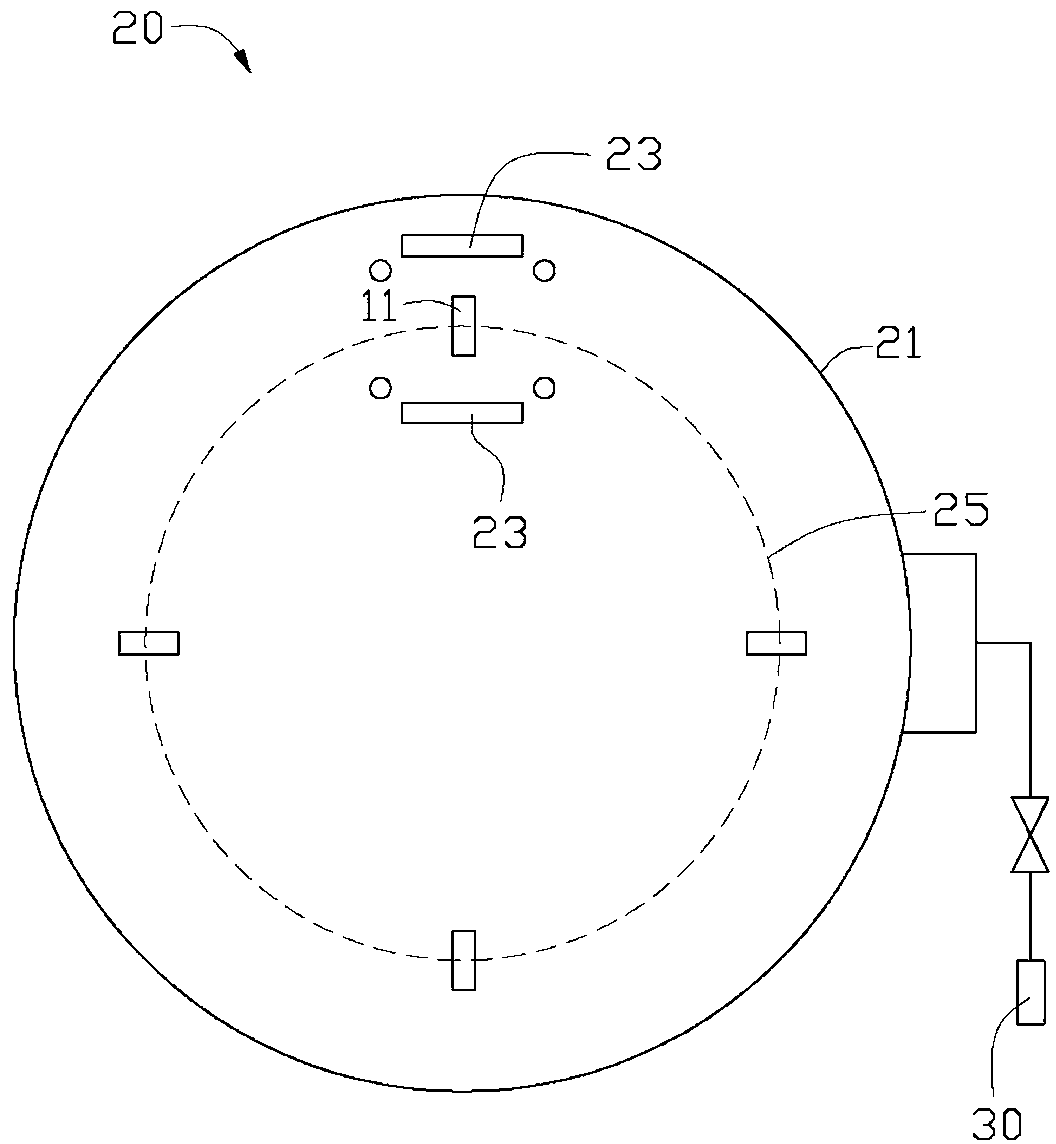

Vacuum coating part and preparation method thereof

InactiveCN102373415AImprove appearance competitivenessVacuum evaporation coatingSputtering coatingVacuum coatingPhotochemistry

The invention provides a vacuum coating part. The vacuum coating part comprises a matrix and a color layer formed on the matrix. The color layer is a chromium oxycarbide layer. An L*coordinate value of a chromaticity region shown on the color layer in a CIE LAB color system is in the range of 28 to 32, an a*coordinate value of the chromaticity region shown on the color layer in the CIE LAB color system is in the range of minus 1 to 1, and a b*coordinate value of the chromaticity region shown on the color layer in the CIE LAB color system is in the range of minus 1 to 1. The invention also provides a preparation method of the vacuum coating part.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

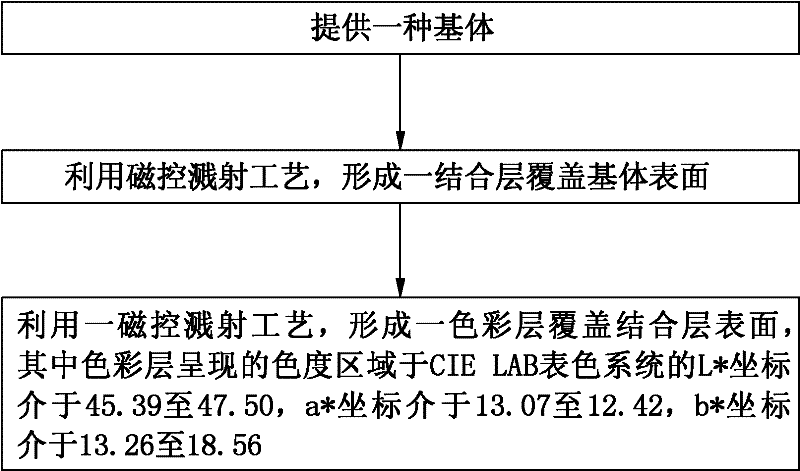

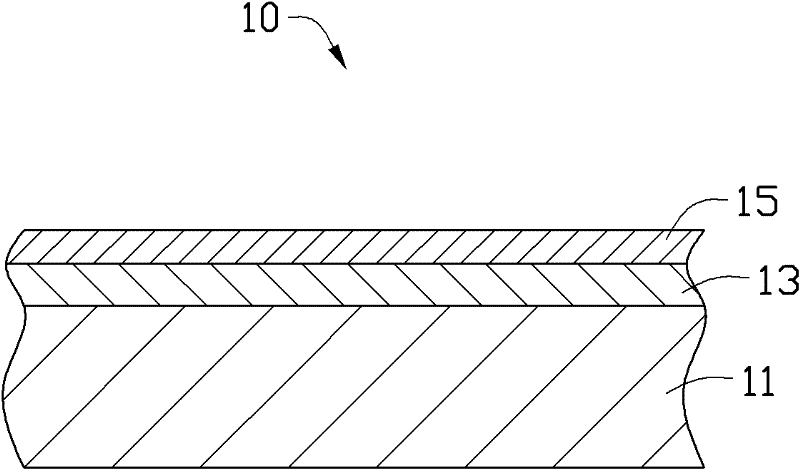

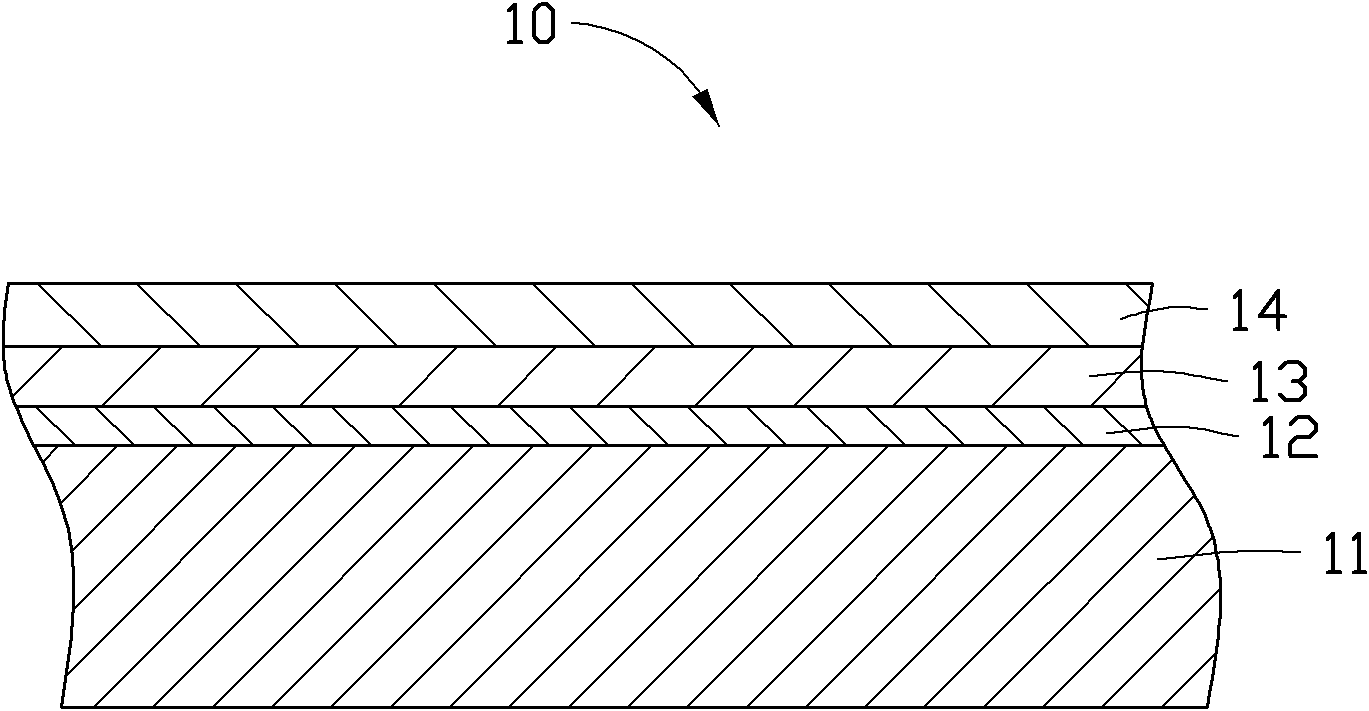

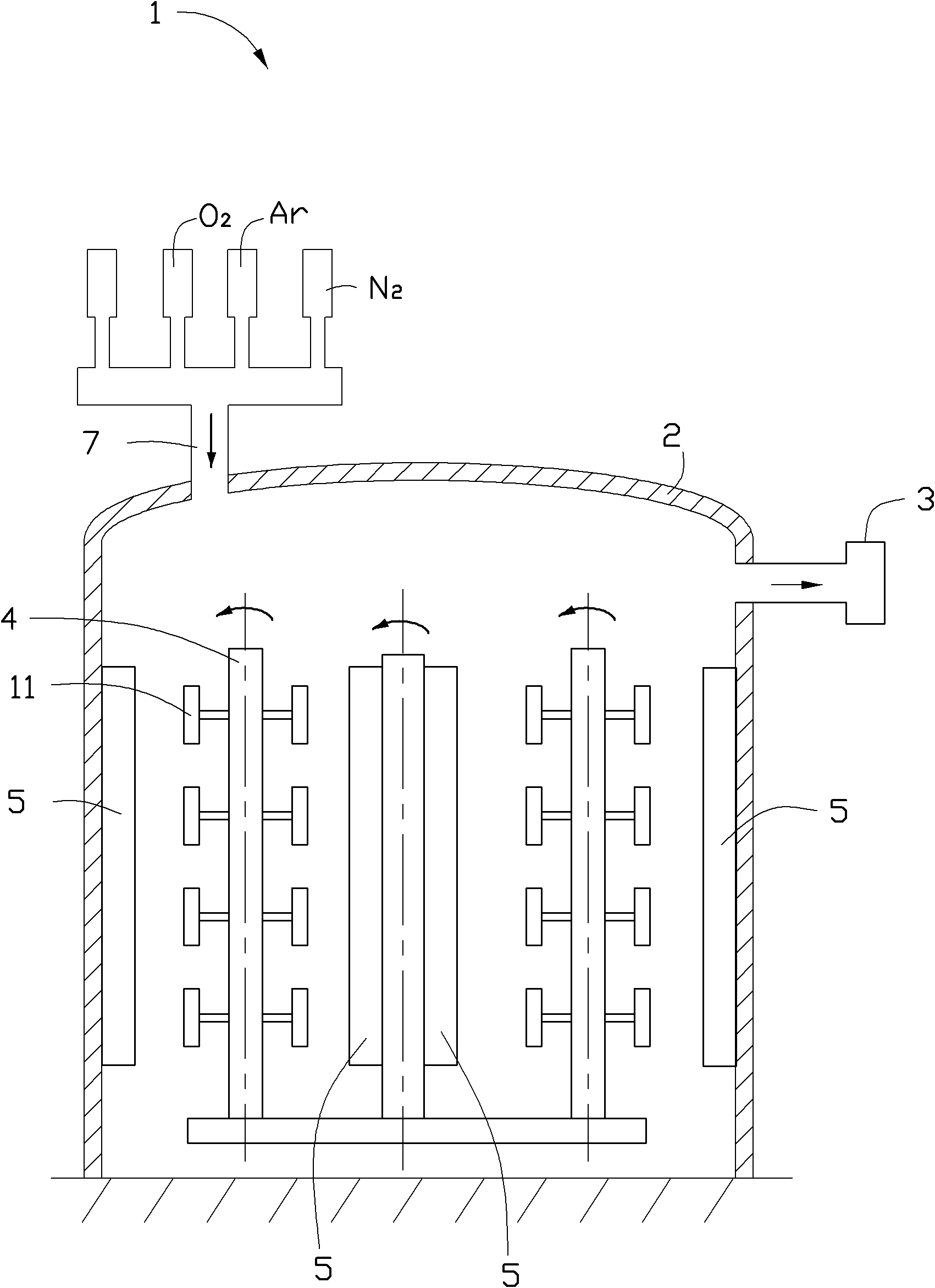

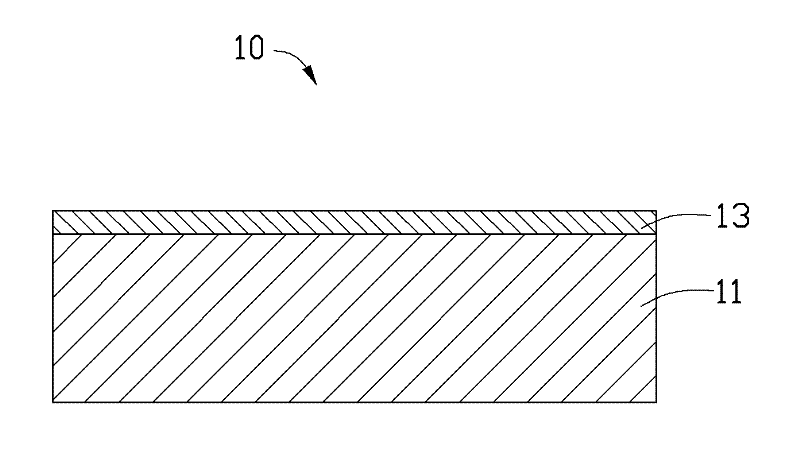

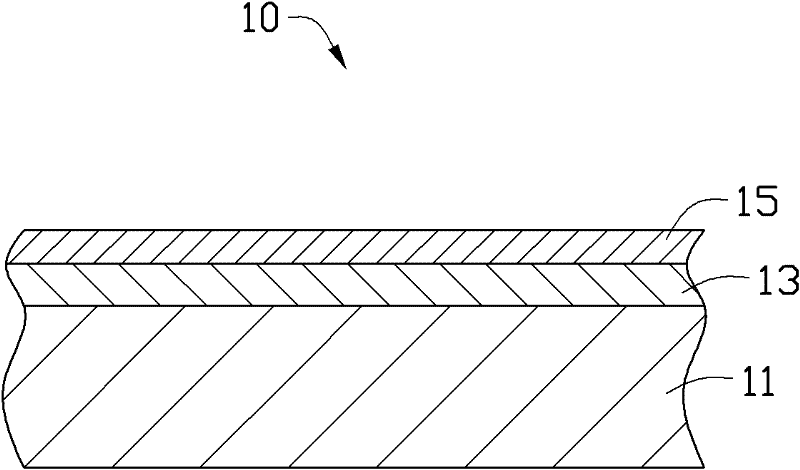

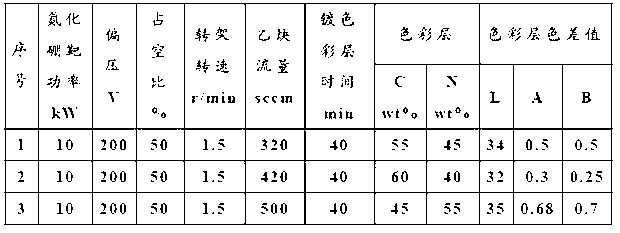

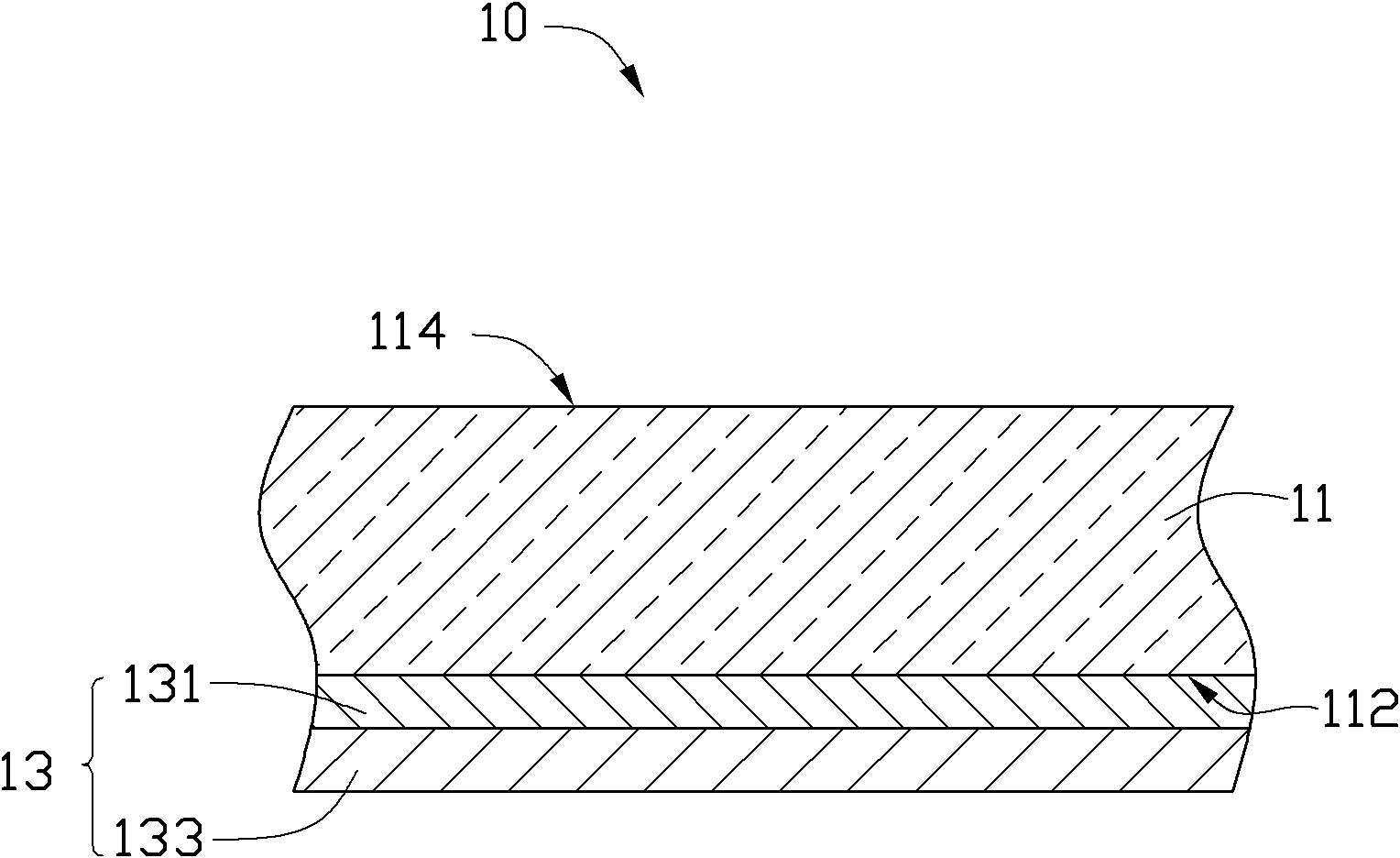

Shell and manufacturing method thereof

InactiveCN102333422ARich in colorImprove appearance competitivenessNatural patternsVacuum evaporation coatingOptoelectronicsTitanium

The invention relates to a shell and a manufacturing method thereof. The shell comprises a substrate, a bonding layer and a color layer, wherein the surface of the substrate is provided with the bonding layer, and the color layer is covered on the bonding layer of the substrate. The bonding layer is a titanium metal layer, and the color layer is a Ti-N-C membrane, wherein a chromaticity area presented on the color layer is between 45.39 and 47.50 at the L* coordinate of a CIE LAB color system, between 13.07 and 12.42 at the a* coordinate of the CIE LAB color system, and between 13.26 and 18.56 at the b* coordinate of the CIE LAB color system. The invention also provides a magnetron sputtering manufacturing method of the shell. The shell and the manufacturing method can achieve the effect that the color layer presents a bronze color, so the color of a vacuum plating layer is enriched.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

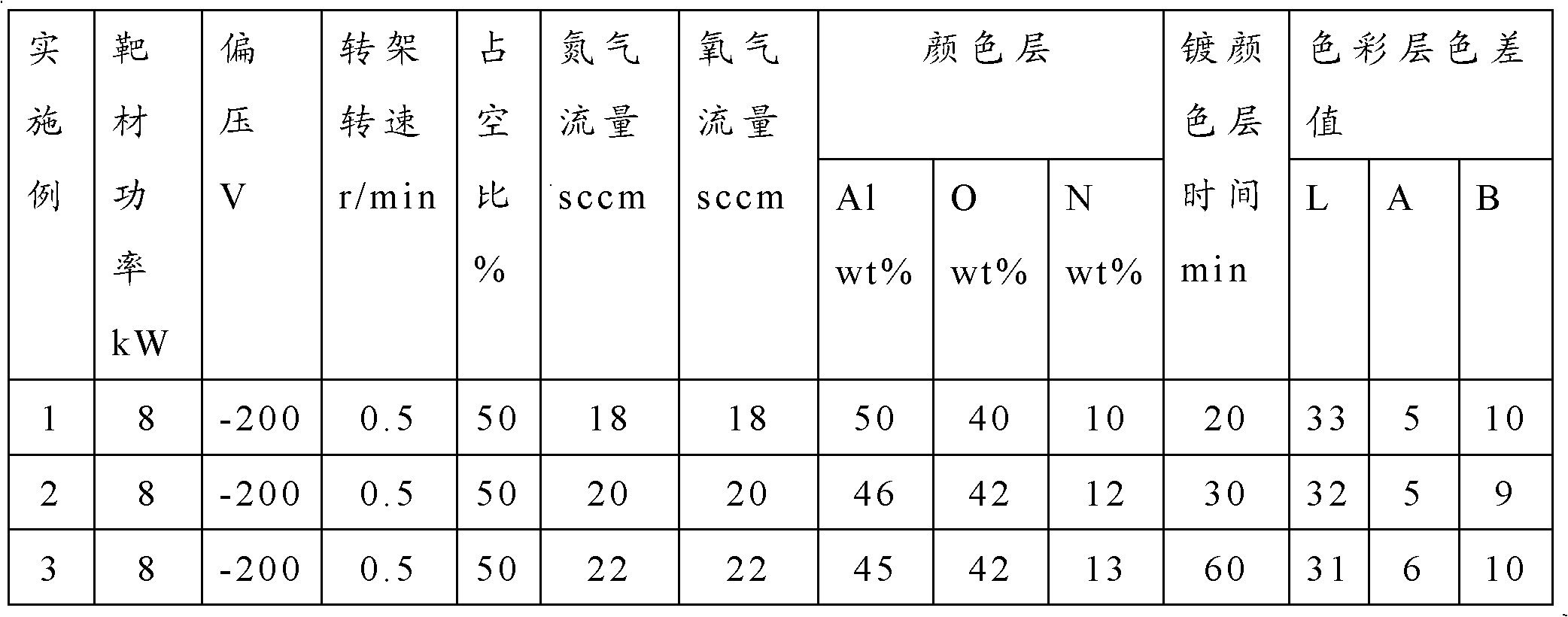

Shell and manufacturing method thereof

InactiveCN102612281ARich in colorImprove appearance competitivenessSpecial ornamental structuresMetal layered productsComputer graphics (images)Nitrogen

The invention provides a shell with a yellowish-brown appearance, comprising a color layer. The color layer is made of an aluminum oxynitride compound; the color layer comprises the following element in mass percent of 45-50% of aluminum, 40-45% of oxygen, and 10-15% of nitrogen; and an L* coordinate of a chroma area shown by the color layer ranges from 28 to 35 in a LAB color specification system of the CIE (International Commission on Illumination), an a* coordinate of the chroma area shown by the color layer ranges from 4 to 6, and a b* coordinate of the chroma area shown by the color layer ranges from 9 to 11. The invention further provides a manufacturing method of the shell. The color layer of the shell enables the shell to be yellowish-brown which is difficult to show in vacuum plating, so as to enrich the color of the vacuum plating.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

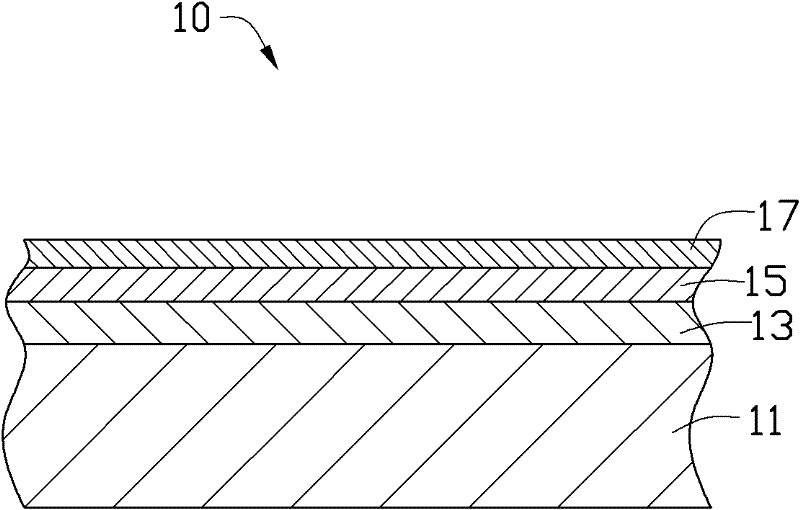

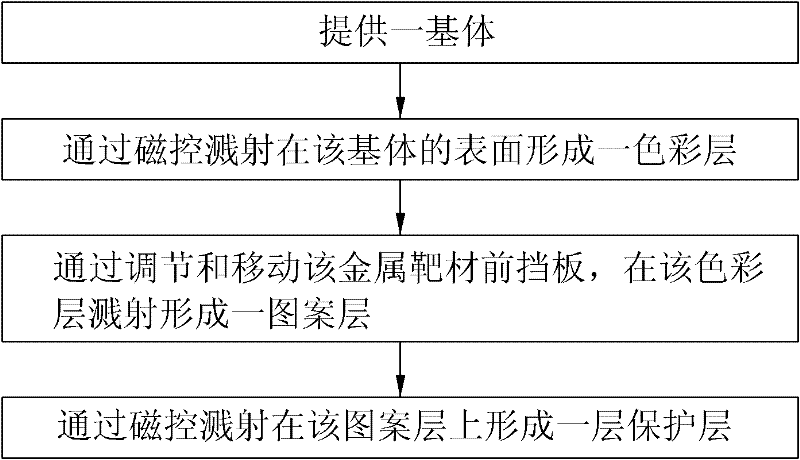

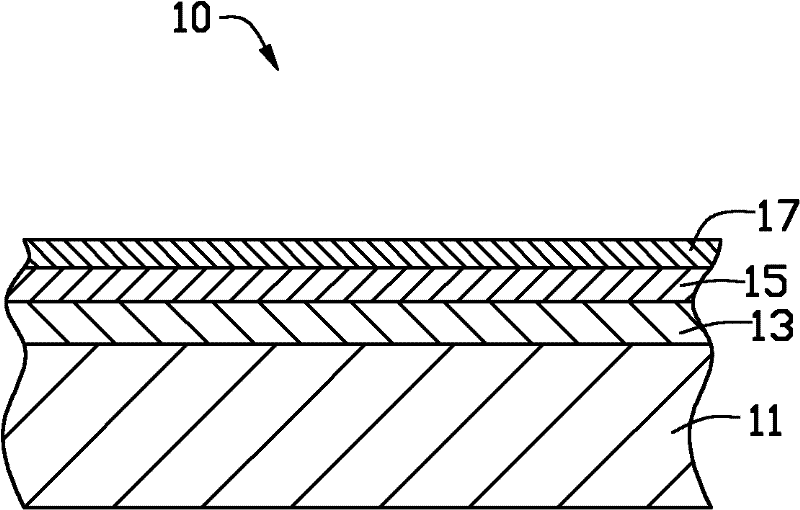

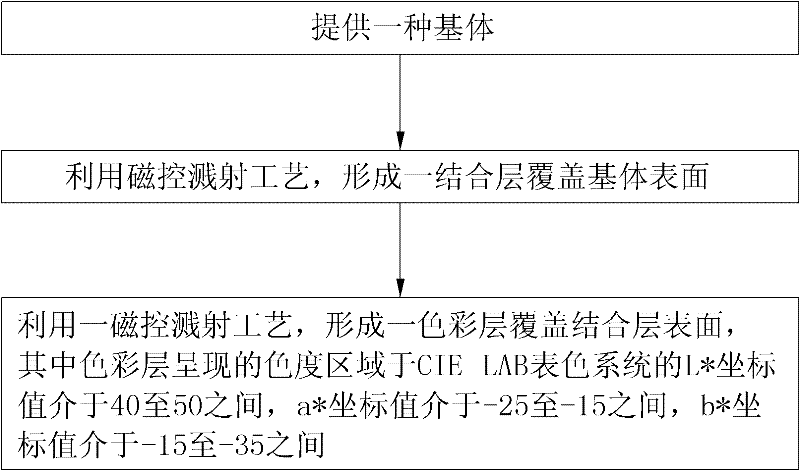

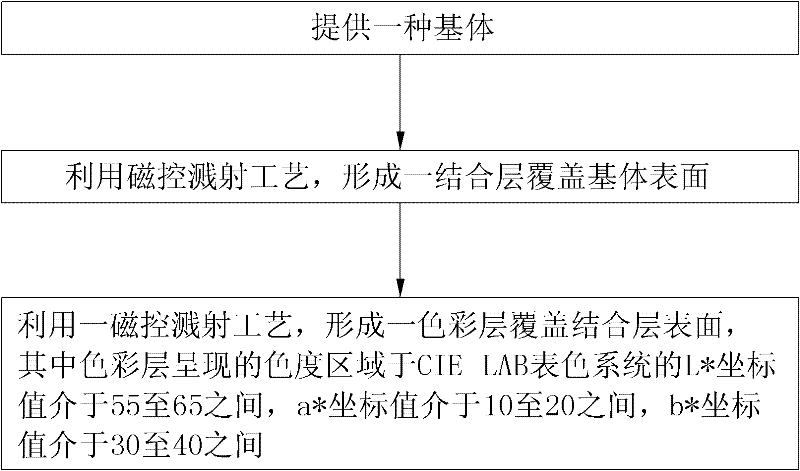

Manufacture method of shell and shell manufactured by method

ActiveCN102477527ARich surface decoration effectImprove appearance competitivenessVacuum evaporation coatingSputtering coatingOptoelectronicsNucleation

The invention provides a manufacture method of a shell, which comprises the steps of: providing a substrate; forming a color layer on the surface of the substrate by a magnetic sputtering method; then arranging a moveable baffle at the front end of a metal target, and powering on the power supply of the target, wherein the target is any one of a titanium target, a chromium target or a zirconium target; adjusting the baffle right ahead the target, and depositing for a certain time; sputtering target atoms on the baffle and removing the baffle when the number of atoms sputtered on the target and the sputtering speed are stable, so that the target atoms are sputtered on the substrate; after continuously sputtering for a period of time, powering off the power supply of the target; depositing and remaining a pattern layer on the surface of the color layer in the nucleation stage to form the pattern layer on the color layer. The shell manufactured by the manufacture method disclosed by the invention comprises the substrate, the color layer and the pattern layer, wherein the color layer is formed on the surface of the substrate, the pattern layer is formed on the surface of the color layer, and the pattern layer is a Ti, Cr or Zr film layer.

Owner:NANTONG DONGFANG SCI & TECH

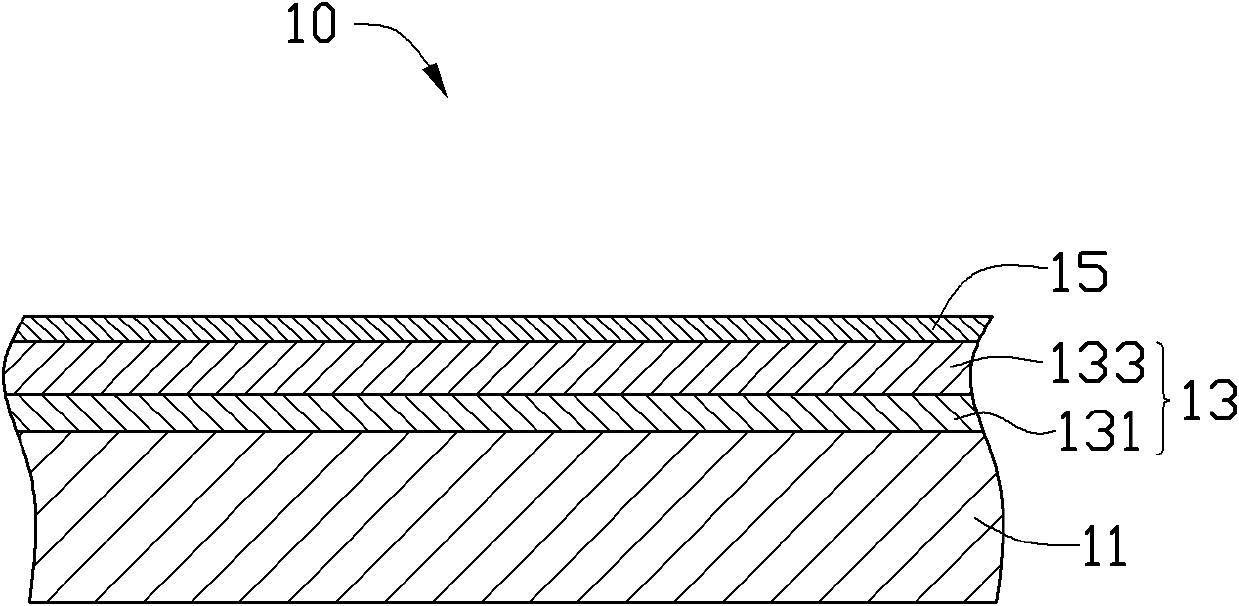

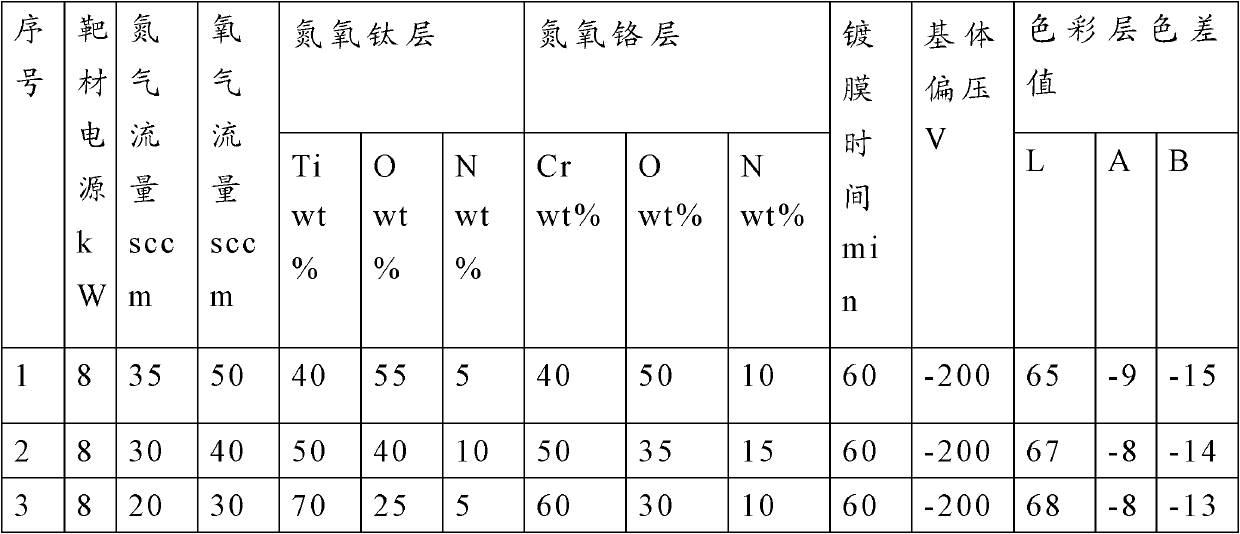

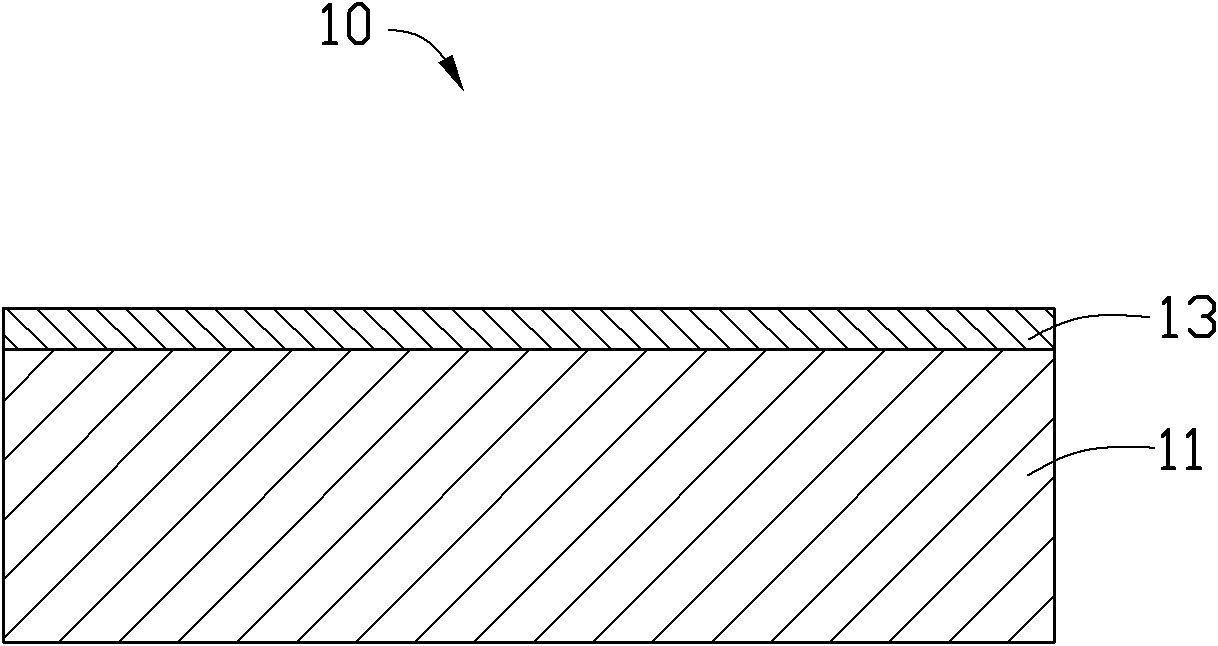

Housing and manufacturing method thereof

InactiveCN102560340ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingTitaniumTitanium oxide

The invention provides a housing with a light blue appearance. The housing comprises a matrix and a color layer formed on the surface of the matrix, wherein the color layer comprises a nitrogen titanium oxide layer and a nitrogen chromium oxide layer which are formed on the surface of the matrix in sequence; and a chroma region presented by the color layer has an L* coordinate between 60 to 100, an a* coordinate between minus 10 to minus 8 and a b* coordinate between minus 15 to minus 13 in a CIE LAB surface color system. The invention further provides a manufacturing method of the housing. By adopting the color layer, the housing can present a light blue color, thereby enriching the color of a vacuum coating layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shell and manufacturing method thereof

InactiveCN102458068AImprove appearance competitivenessVacuum evaporation coatingSputtering coatingAluminum fluorideComputer science

The invention provides a shell provided with a purple surface, and the shell comprises a base body and a color layer formed on the surface of the base body, wherein the color layer is a layer made from aluminum fluoride and aluminum oxide, an L*coordinate of a chroma area presented by the color layer to a CIE LAB color system is arranged between 35 and 55, an a*coordinate is arranged between 5 and 15, and a b*coordinate is arranged between 25 and 28. The invention also provides a manufacturing method for the shell. The shell can be presented to be a purple effect by the color layer, therefore, colors of a vacuum coating layer can be abundant.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shell and manufacturing process thereof

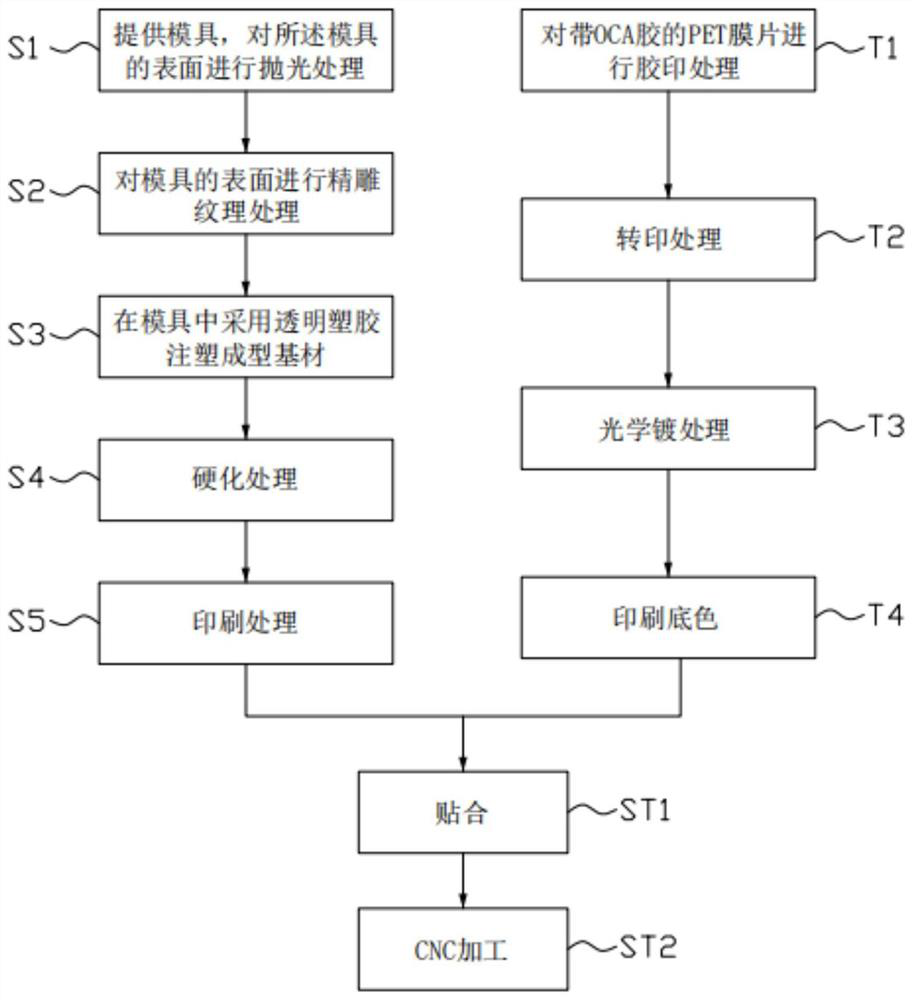

PendingCN113022073AAvoid uneven stepsAvoid hardnessLamination ancillary operationsSynthetic resin layered productsPolishingColor film

The invention provides a shell and a manufacturing process which comprises the steps of base material manufacturing, color film manufacturing, attaching and CNC machining, and the step of base material manufacturing comprises the steps that adopting transparent plastic d in a mold subjected to polishing and fine carving texture treatment for injection molding of the base material; the step of color film manufacturing comprises the following steps: carrying out printing treatment on a PET film with optical cement, carrying out texture treatment on the PET film subjected to printing treatment, and carrying out coating treatment on the PET film subjected to texture treatment to obtain the color film; then attaching the base material and the color film to remove bubbles, and finally obtaining a finished product through CNC machining. The invention further provides a shell. According to the manufacturing process of the shell, the color texture and the touch flatness of the transparent plastic shell are improved, the smooth and matte integrated effect can be achieved, the shell has the richer visual effect, and the appearance competitiveness is greatly improved.

Owner:SHENZHEN TRANSSION MFG LTD

Vacuum coated component and production method thereof

ActiveCN102477529ARich in colorAchieving Micro Bonding StructuresVacuum evaporation coatingSputtering coatingColor representationChromaticity

The invention discloses a vacuum coated component, comprising a matrix and a color layer formed on the matrix, wherein the color layer is a Ti-O-N film, the chroma of the color layer is described by using L*, a*, b* coordinates of a CIE LAB color representation system, wherein the L* coordinate value ranges from 50 to 60, the a* coordinate value ranges from -3 to -2, and the b* coordinate value ranges from -6 to -10. The invention further provides a production method of the vacuum coated component. The vacuum coated component takes on a sky blue appearance, thus the color of vacuum coating layer is enriched.

Owner:南通旺鑫新材料有限公司

Shell and its making method

InactiveCN102774072ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingTO-18Computer science

The invention provides a shell, which comprises a matrix, a bonding layer and a color layer. The bonding layer is formed on the surface of the matrix. The color layer, being a Ti-O-N film, is formed on the surface of the bonding layer. A chroma region presented by the color layer has an L* coordinate value ranging from 42 to 55 in a CIELAB color system, an a* coordinate value ranging from 5 to 18, and a b* coordinate value ranging from 6 to 15. The invention also provides a making method of the shell. The shell shows an orange red appearance, and enriches vacuum coating colors.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

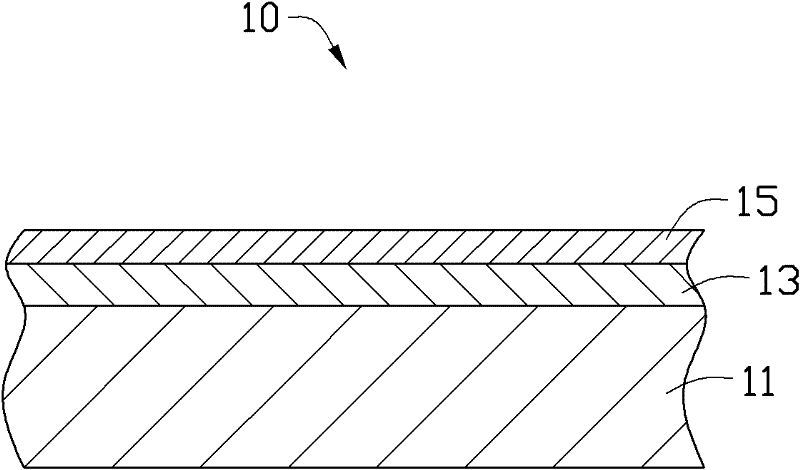

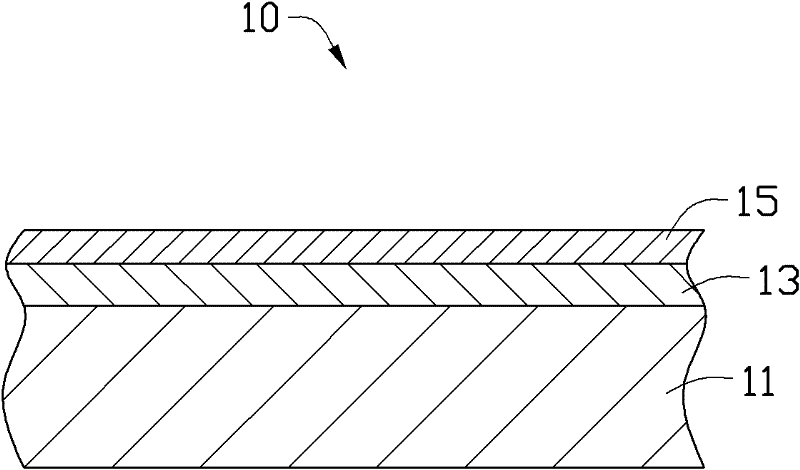

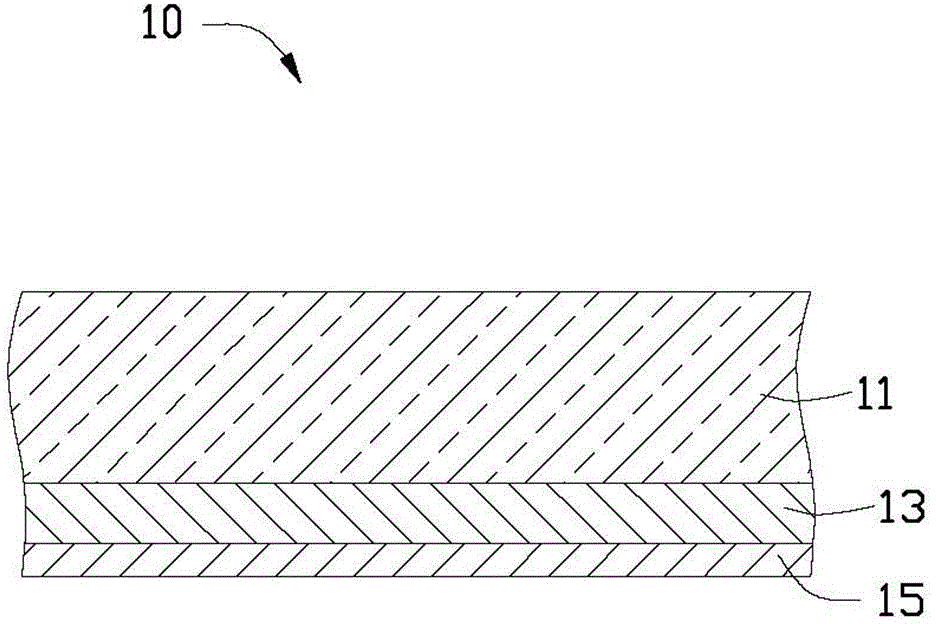

Shell and method for manufacturing same

InactiveCN102413650ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingComputer scienceVacuum coating

The invention discloses a shell which comprises a base body, a bonding layer and a color layer, wherein the bonding layer is formed on the surface of the base body; the color layer is formed on the surface of the bonding layer; the color layer is a Zr-N film; L*coordinate value of a chromaticity area which is displayed by the color layer in a CIE LAB color system is 40 to 50, a*coordinate value of the chromaticity area which is displayed by the color layer in the CIE LAB color system is -25 to -15, and b*coordinate value of the chromaticity area which is displayed by the color layer in the CIE LAB color system is -45 to -35. The invention also provides a method for manufacturing the shell. The shell has a blue appearance, so that the color of a vacuum coating film is enriched.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of plated film member and plated film member prepared by method thereof

InactiveCN102747322AImprove performanceAvoid abrasion and scratchingVacuum evaporation coatingSputtering coatingTitaniumNitride

The invention provides a preparation method of a plated film member, which comprises the following steps: providing a base material, wherein the base material is a transparent glass; using a sputtering method and forming a prefabricated layer A on the surface of the base material, wherein the prefabricated layer A is the alumina layer or aluminum nitride layer; continuously employing the sputtering method to form a prefabricated layer B on the surface of the prefabricated layer A, wherein the prefabricated layer B is aluminum layer, chromium layer or titanium layer; performing bombardment on the plated film surface of the base material by using argon plasma until the prefabricated layer B is completely stripped; repeating the above steps of plating the prefabricated layer B and argon plasma bombardment to form a color layer of the prefabricated layer A, wherein the color layer permeates the base material and the color layer presents white color. The preparation method of the plated film member enables stabilization, reliability and environmental protection. The invention also provides the plated film member prepared by the above method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

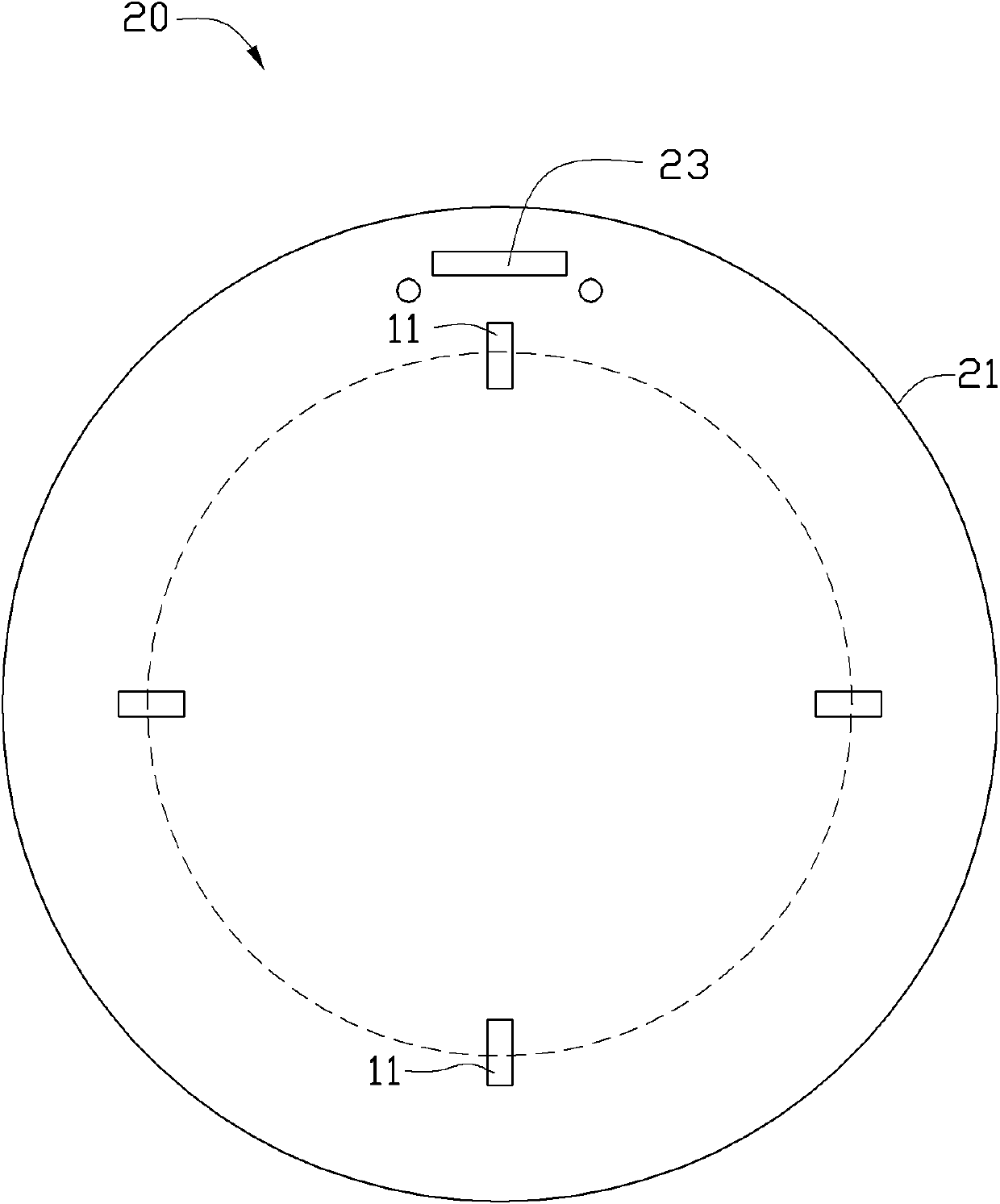

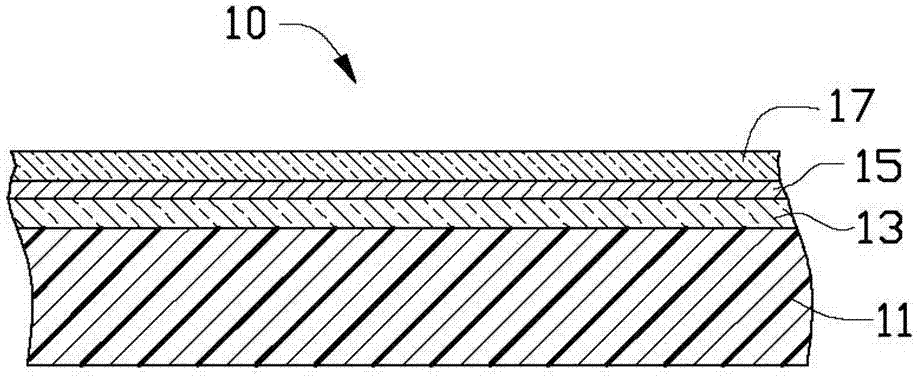

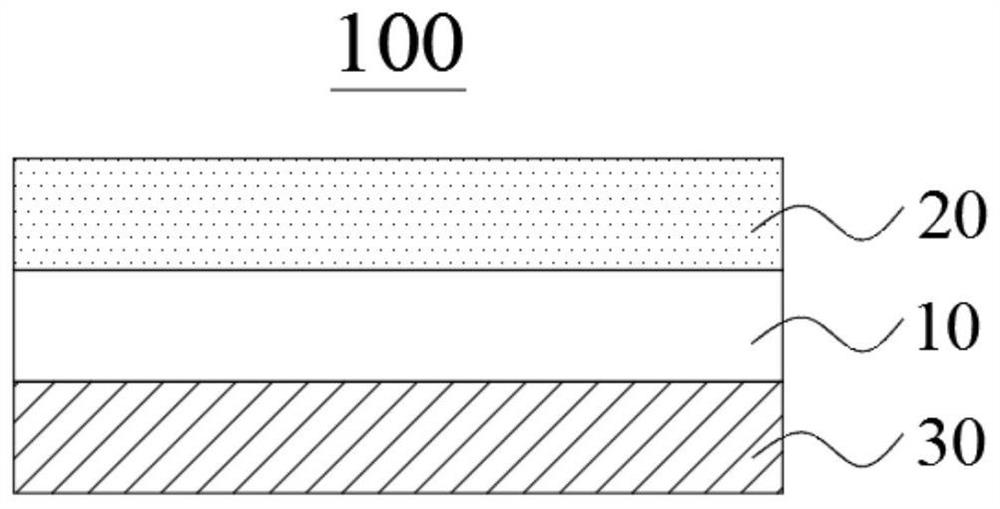

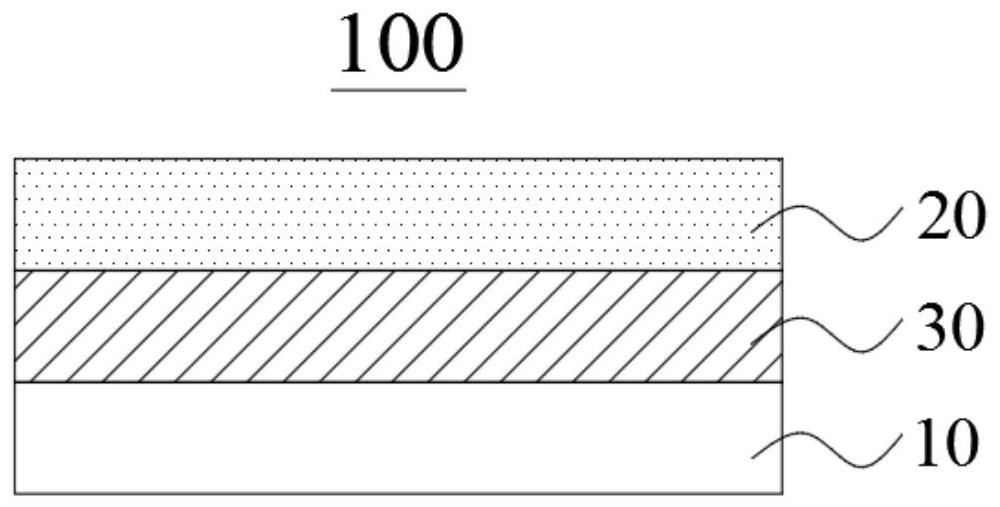

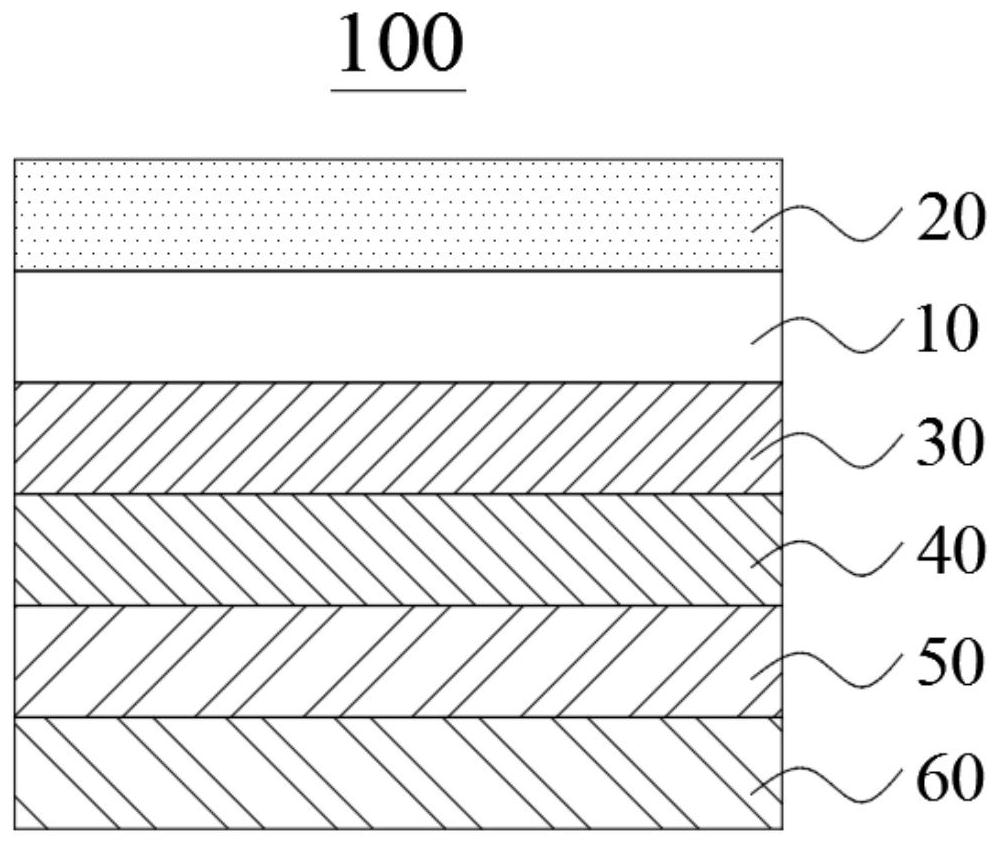

Shell assembly, preparation method of shell assembly and electronic equipment

ActiveCN113498281AEasy to prepareIncrease variabilityCasings/cabinets/drawers detailsEngineeringMaterials science

The invention provides a shell assembly which comprises a transparent substrate, a light-transmitting leather layer and a semitransparent color layer, the light-transmitting leather layer and the semitransparent color layer are arranged on the two opposite sides of the transparent substrate, or the light-transmitting leather layer and the semitransparent color layer are arranged on the same side of the transparent substrate, and the semitransparent color layer is arranged between the transparent substrate and the light-transmitting leather layer. The shell assembly not only has the touch feeling of leather, but also has light transmission and transparent color appearance, so that the visual effect of the appearance of the shell assembly is improved, and homogenization is avoided. The invention further provides a preparation method of the shell assembly and electronic equipment comprising the shell assembly.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

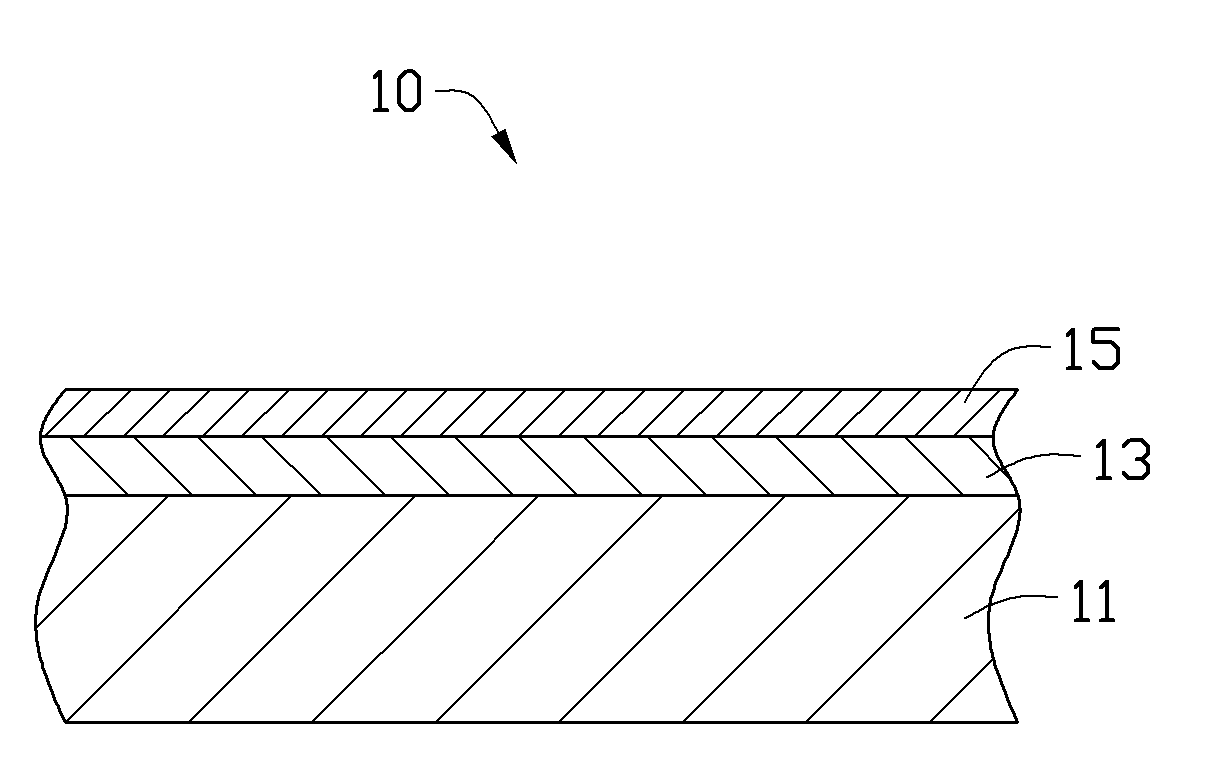

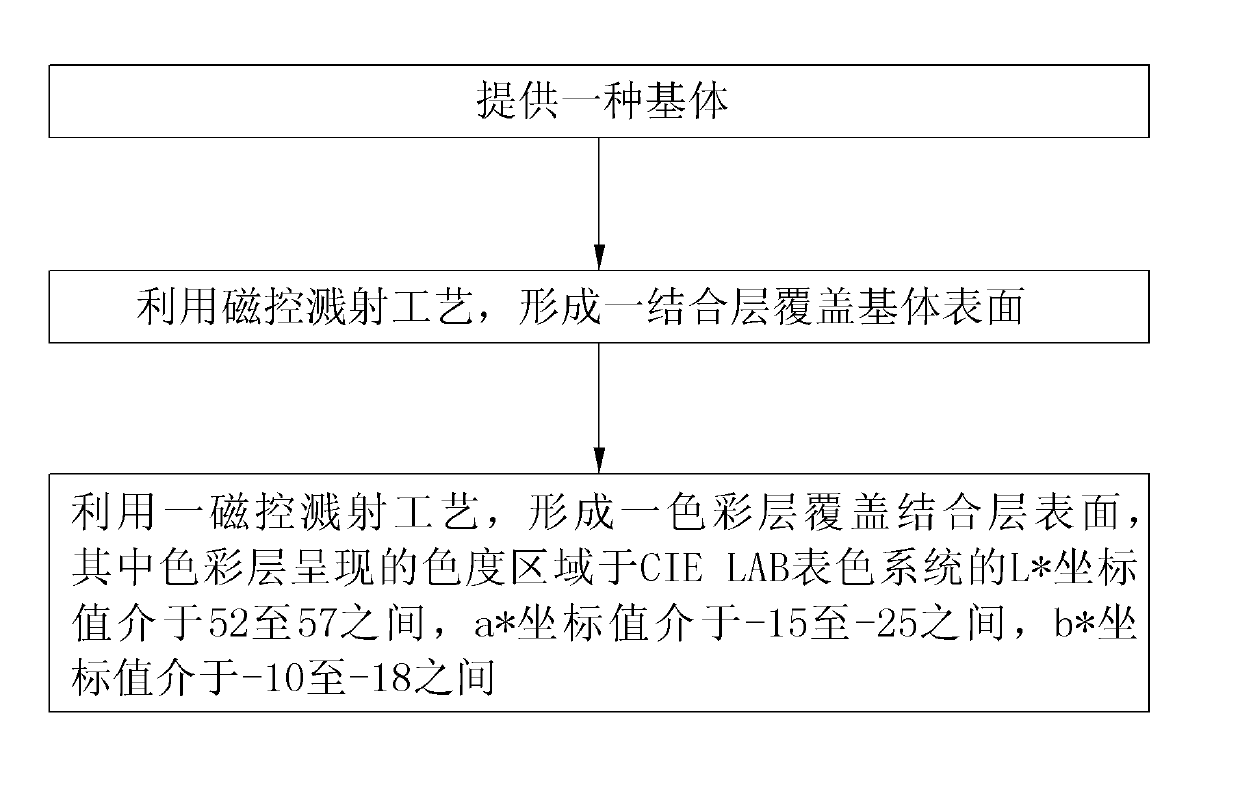

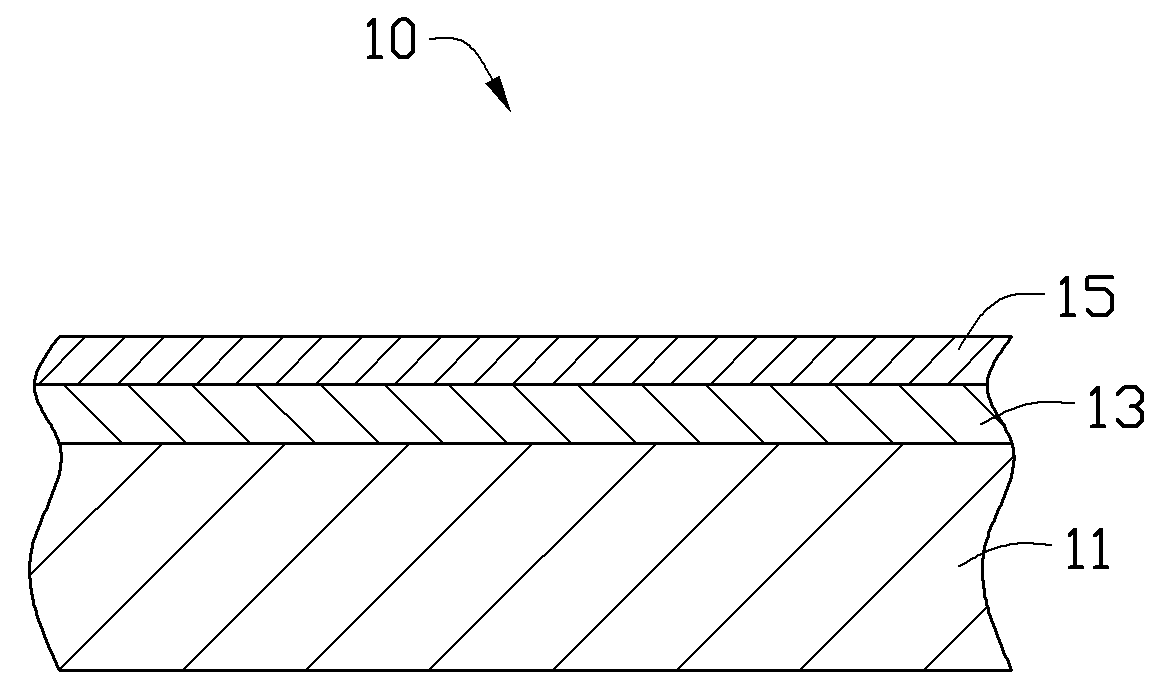

Shell and its manufacturing method

InactiveCN102443760ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingComputer scienceVacuum coating

A shell. The shell contains a matrix, an anchor coat and a color layer. The anchor coat is formed on the surface of the matrix. The color layer is formed on the surface of the anchor coat. The color layer is a Ti-O-N film. L* coordinate figure of the chromatic region presented by the color layer in the CIE LAB color system is between 52 to 57; a* coordinate figure is between -15 to -25; and b*coordinate figure is between -10 to -18. The invention also provides a manufacturing method of the above shell. The shell presents a dark blue appearance, and the color of a vacuum coating layer is abundant.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shell and manufacturing method thereof

InactiveCN102480863AImprove appearance competitivenessVacuum evaporation coatingSputtering coatingNitrogenComputer science

The invention provides a shell with blue appearance. The shell comprises a base body and a color layer formed on the surface of the base body, wherein the color layer is a nitrogen tin oxide layer; the L* coordinate of the chromaticity area presented by the color layer in a CIE LAB color system is between 35 and 38, the a* coordinate is between 3 and 4, and the b* coordinate is between -10 and -15. The invention also provides a manufacturing method of the shell. The color layer enables the shell to show blue color so as to enrich the color of a vacuum coating layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

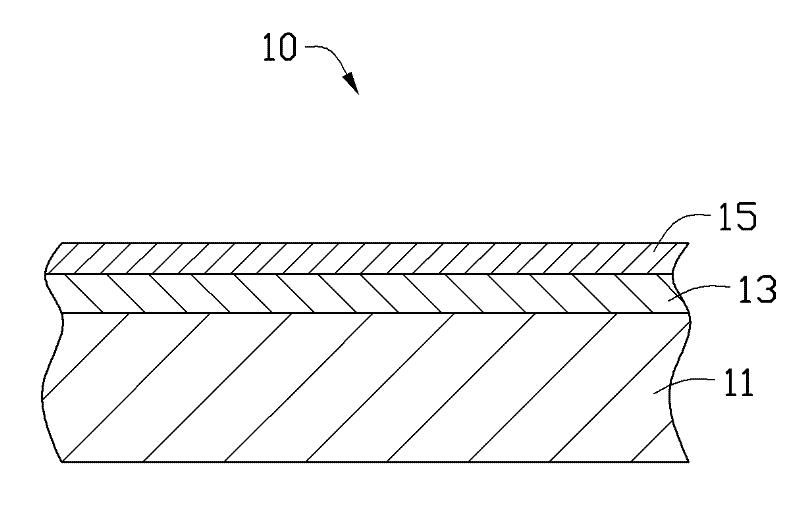

Shell and manufacture method thereof

InactiveCN102477530AAchieving Micro Bonding StructuresRich in colorVacuum evaporation coatingSputtering coatingComputer scienceVacuum coating

The invention relates to a shell. The shell comprises a substrate, a bonding layer and a color layer, wherein the bonding layer is formed on the surface of the substrate, the color layer is formed on the surface of the binding layer, the color layer is a Zr-N membrane, the L<*> coordinate value of the chromaticity area presented by the color layer on the CIE LAB surface color system is 55-65, the a<*> coordinate value is 10-20, and the b<*> coordinate value is 30-40. The present invention further provides a manufacture method for the shell. The shell presents a golden yellow appearance so as to enrich the color of the vacuum coating layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Coated member and its manufacturing method

InactiveCN102732828ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingBoronComputer science

The invention provides a coated member, which comprises a matrix and a color layer formed on the matrix. The color layer is a boron-carbon-nitrogen layer. L* coordinate of chroma area presented by the color layer in a CIELAB color system is between 32 and 35; a* coordinate is between 0.6 and 1; and b* coordinate is between 0.8 and 1. The invention also provides a manufacturing method of the above coated member. The color layer of the coated member can make the coated member show black. Therefore, the color of a vacuum coating layer is enriched.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shell and method for manufacturing same

InactiveCN102373430ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingSputteringProduct gas

The invention provides a method for manufacturing a shell. The method comprises the following steps of: providing a transparent substrate; using a titanium target, taking oxygen and nitrogen as the reaction gases, and adopting a magnetron sputtering method to carry out magnetron sputtering on the substrate for 25-35 minutes to form a titanium-oxygen-nitrogen film layer on the other surface of the substrate; and forming a chromium film layer on the titanium-oxygen-nitrogen film layer by magnetron sputtering to enable the L* coordinate value of the chroma area presented by the titanium-oxygen-nitrogen film layer in a CIE (International Commission on Illumination) LAB color system to be 45-52, the a* coordinate value to be minus 2-2 and the b* coordinate value to be minus 16-minus 18, wherein the surface of the substrate is shielded, the oxygen flow is 10-12sccm, and the nitrogen flow is 80-140sccm. The invention also provides the shell manufactured by the method. The shell has blue appearance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Vacuum coating part and preparation method thereof

InactiveCN102345102ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingMaterials scienceVacuum coating

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Casing and manufacturing method thereof

InactiveCN102762047ARich in colorImprove appearance competitivenessVacuum evaporation coatingSpecial ornamental structuresOptoelectronicsChromaticity

The invention provides a casing comprising a base body, a binding layer and a colored layer. The binding layer is formed on the surface of the base body, and the colored layer is formed on the surface of the binding layer and is a Ti-O-N film. The L* coordinate figure of the chromatic area displayed by the colored layer in the CIE (commission international eclairage) LAB surface color system ranges from 72 to 80, the a* coordinate figure thereof ranges from -12 to -6, and the b* coordinate figure thereof ranges from 22 to 28. The invention further discloses a manufacturing method of the casing. The casing is green, and the color of a vacuum film plated layer is developed.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Vacuum coating piece and manufacturing method of vacuum coating piece

InactiveCN102560389ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingMetallurgyVacuum coating

The invention relates to a vacuum coating piece. The vacuum coating piece comprises a basal body, a bonding layer and a color layer, wherein the bonding layer is formed on the surface of the basal body; the color layer is formed on the surface of the bonding layer and is an A1-N film; a chromaticity region presented by the color layer in a CIE LAB color system has an L* coordinate value of 48 to 83, an a* coordinate value of -12 to -5 and a b* coordinate value of -45 to -17. The invention also provides a manufacturing method of the vacuum coating piece. The vacuum coating piece presents a blue appearance which enriches the color of a vacuum coating layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Housing and manufacturing method thereof

InactiveCN102676988ARich in colorImprove appearance competitivenessVacuum evaporation coatingSputtering coatingNitrogenTitanium

The invention provides a housing and a manufacturing method thereof. The housing comprises a substrate and a color layer formed on a surface of the substrate, wherein the color layer comprises a nitrogen oxygen titanium layer and an aluminium oxide layer which are formed in sequence on the surface of the substrate, and a chrominance area of the color layer lies in a CIE LAB color system with an L * coordinate between 49 and 53, an a * coordinate between -10 and -9 and a b * coordinate between -39 and -37. The invention also provides a manufacturing method of the above-mentioned housing. The color layer can enable the housing to present a color of purplish blue, so that colors of vacuum coating layers are enriched.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com