Shell and method for manufacturing same

A manufacturing method and shell technology, which are applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of limiting the competitiveness of magnetron sputtering process, and achieve the improvement of appearance competitiveness and rich colors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

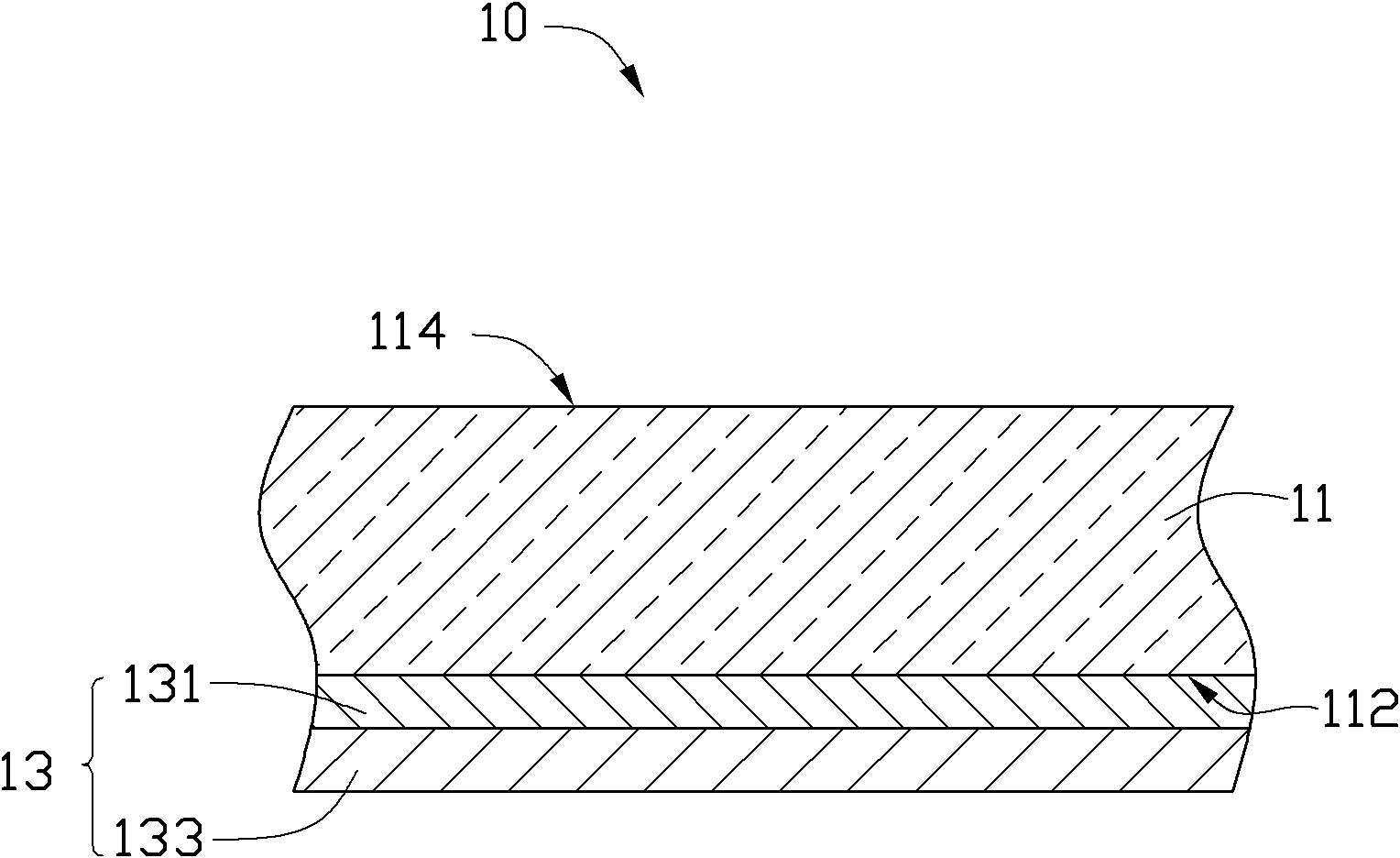

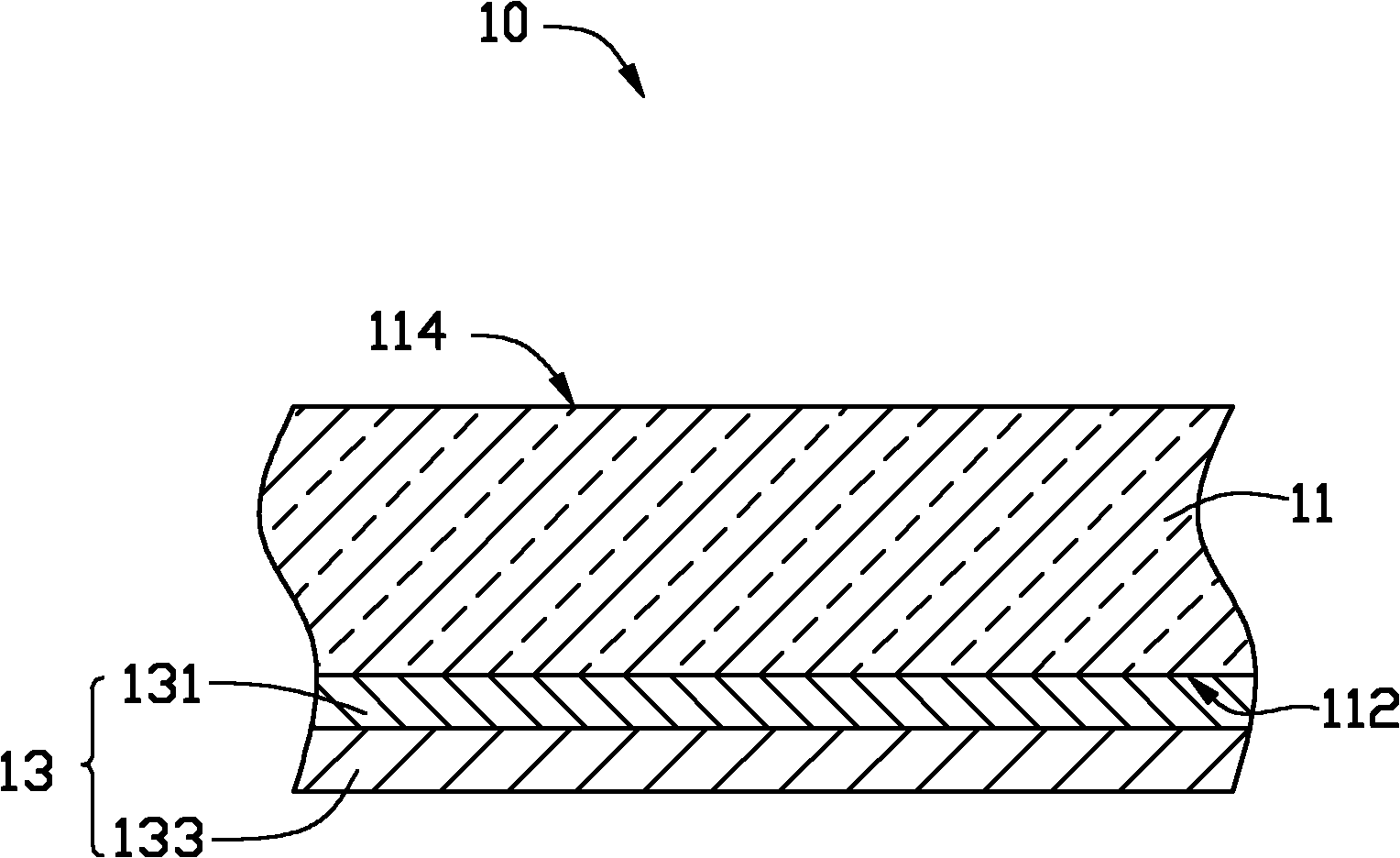

[0018] The housing 10 of a preferred embodiment of the present invention (such as figure 1 Shown) the preparation method comprises the following steps:

[0019] A transparent substrate 11 is provided, and the substrate 11 can be transparent glass or transparent plastic.

[0020] The base body 11 includes an inner surface 112 and an outer surface 114 .

[0021] Clean the surface of the substrate 11 to remove impurities and oil stains on the surface of the substrate 11, and dry it for later use after cleaning. The cleaning includes putting the substrate 11 into an ultrasonic cleaner filled with ethanol and / or acetone solution for vibration cleaning.

[0022] The outer surface 114 of the substrate 11 is shielded to prevent the outer surface 114 from being polluted when the composite film layer 13 is formed on the inner surface 112 . The outer surface 114 is masked using high temperature tape in the preferred embodiment.

[0023] The substrate 11 is fixed on the turntable of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com