Housing and preparation method thereof

A shell and metal layer technology, which is applied in the field of shell and its preparation, can solve the problems of weak product competitiveness, single color effect of decorative coating, lack of metal texture, etc., and achieve improved appearance competitiveness, colorful, good metal texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

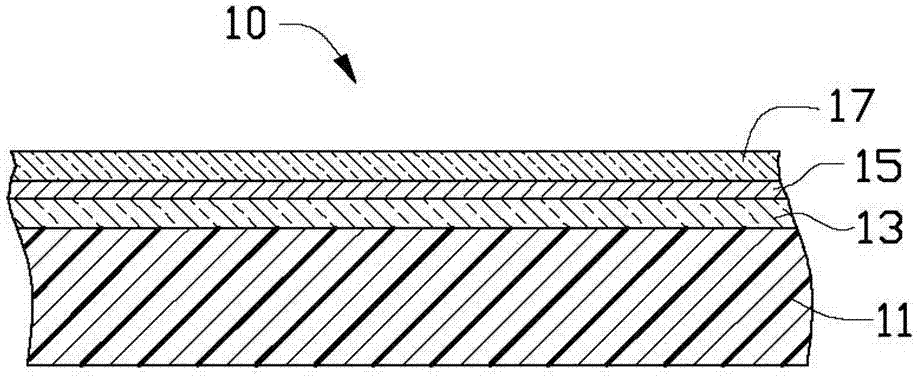

[0017] see figure 1 A housing 10 according to a preferred embodiment of the present invention includes a substrate 11 and a primer layer 13 , a metal layer 15 and a topcoat layer 17 sequentially formed on the surface of the substrate 11 .

[0018] The base material 11 is made of plastic material.

[0019] The primer layer 13 is a transparent UV-curable resin layer, specifically an acrylic epoxy resin. The curing degree of the primer layer 13 is 50%-85%, and its thickness is 5-30 μm.

[0020] The metal layer 15 is a translucent layer, which can be formed by vacuum sputtering. The metal layer 15 is a silicon aluminum alloy layer with a thickness of 10-80 nm. The atomic percentage of silicon in the metal layer 15 is 10-90%, and the atomic percentage of aluminum is 90-10%.

[0021] The topcoat layer 17 is a transparent layer, which can protect the metal layer 15 from abrasion and scratches. The specific composition of the topcoat layer 17 can be acrylic polyurethane. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com