Casing and manufacturing method thereof

A manufacturing method and shell technology, which are used in electrical equipment shells/cabinets/drawers, ion implantation coating, decorative arts, etc., can solve the problem of difficult precision control, reduce competitiveness in the field of decorative coating, plastic shells and painted shells cannot be displayed. Metal texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

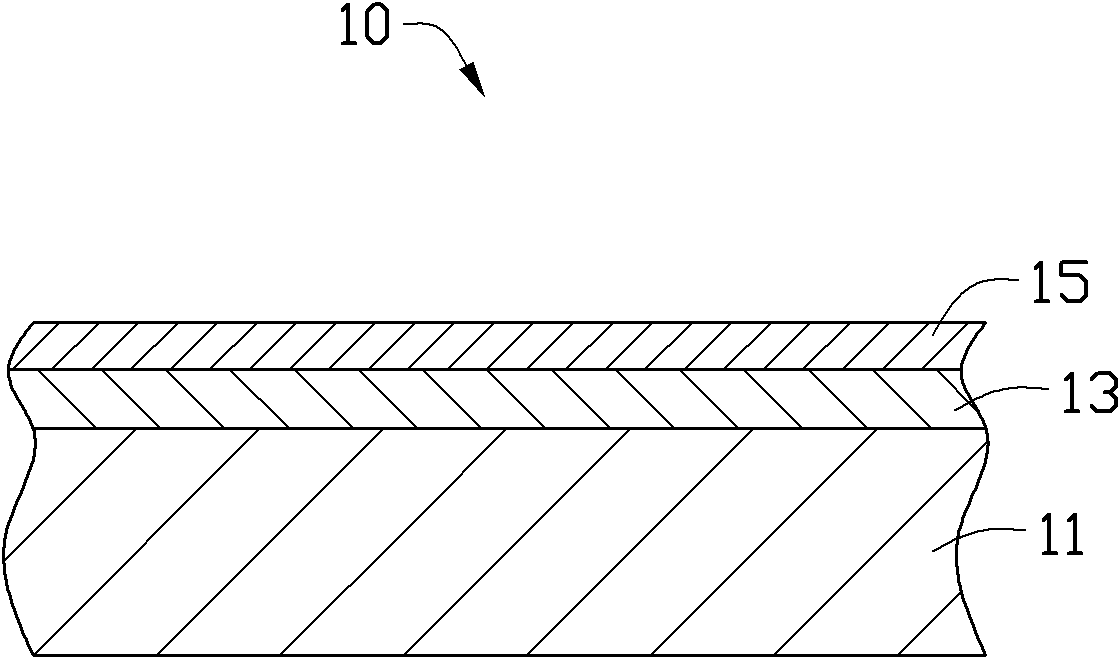

[0024] see figure 1 , the housing 10 of a preferred embodiment of the present invention is described by taking a mobile phone housing as an example. The casing 10 includes a base 11 , a bonding layer 13 and a color layer 15 . The combination layer 13 is disposed on the surface of the substrate 11 , and the color layer 15 is disposed on the surface of the combination layer 13 .

[0025] The substrate 11 may be metal material or non-metallic material such as glass or plastic.

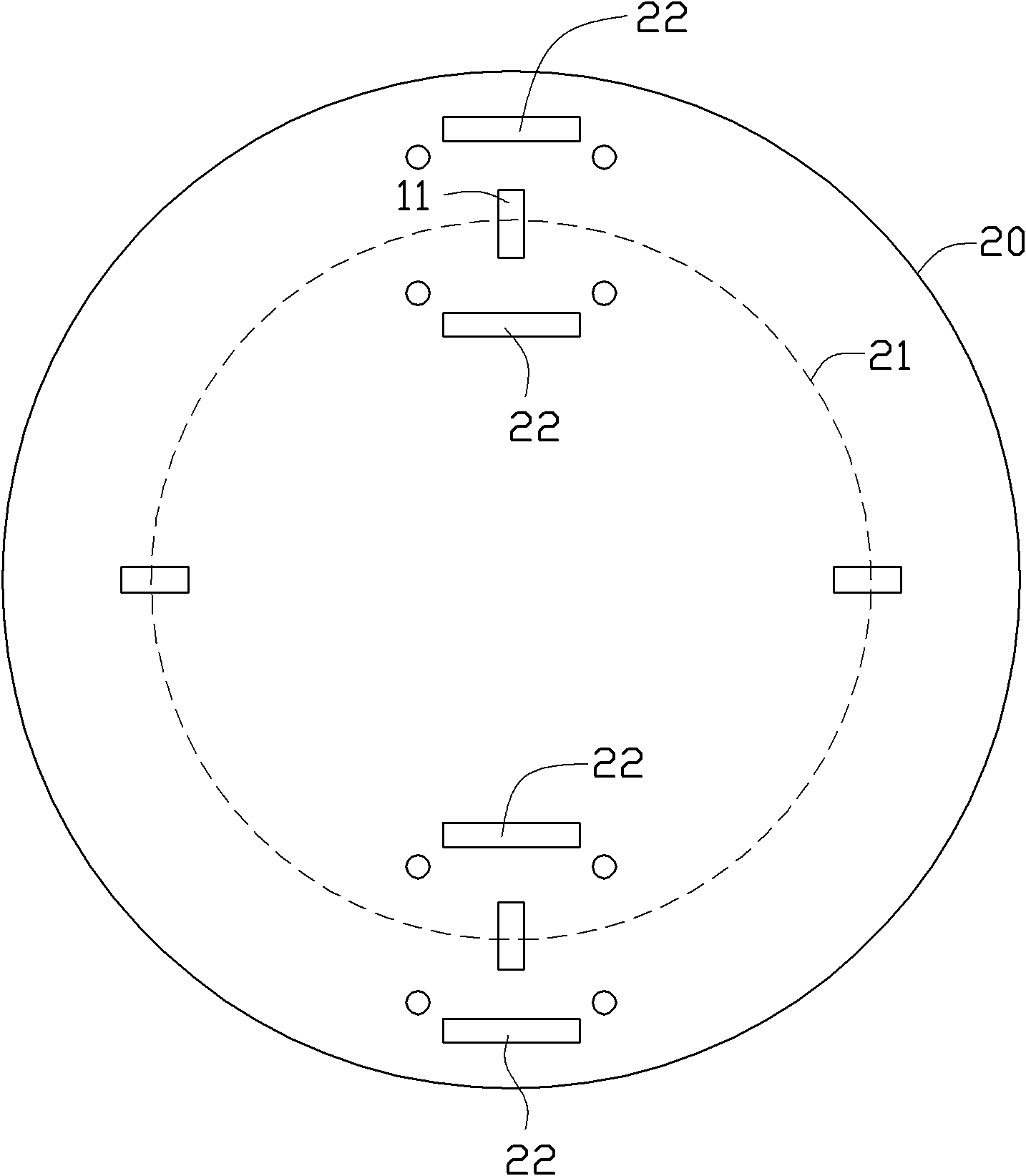

[0026] combined reference figure 2 , provide a coating machine 100, the coating machine 100 includes a coating chamber 20 and a vacuum pump 30 connected to the coating chamber 20, the vacuum pump 30 is used to evacuate the coating chamber 20. The coating chamber 20 is provided with a turret (not shown) and a titanium target 22 arranged symmetrically in the center. The turret drives the substrate 11 to revolve along the circular trajectory 21 , and the substrate 11 also rotates when revolving along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com