Manufacture method of shell and shell manufactured by method

A manufacturing method and a casing technology, which are applied in the directions of ion implantation plating, coating, transportation and packaging, can solve the problems of restricting the competitiveness of the decoration field of electronic device casings, poor processing results, and restricting output, etc. The effect of enriching the surface decoration effect and improving the competitiveness of the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

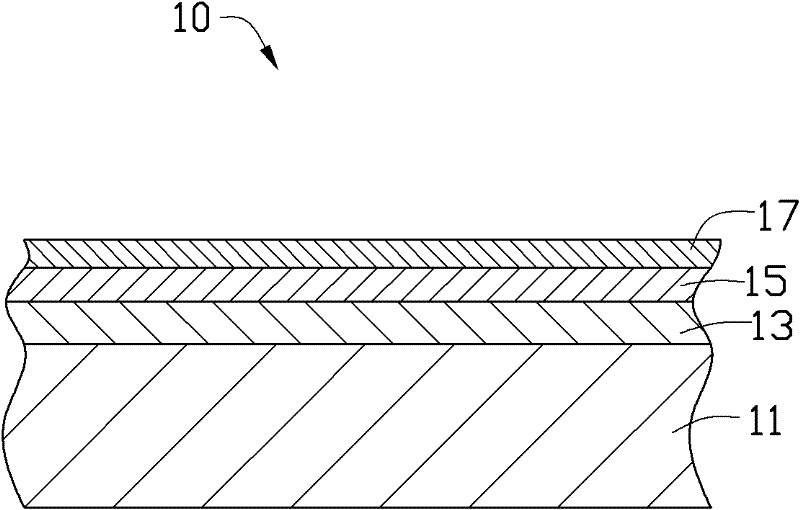

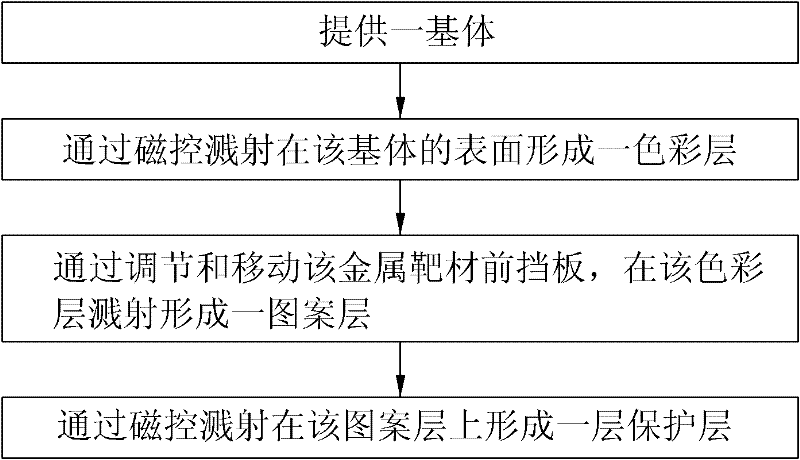

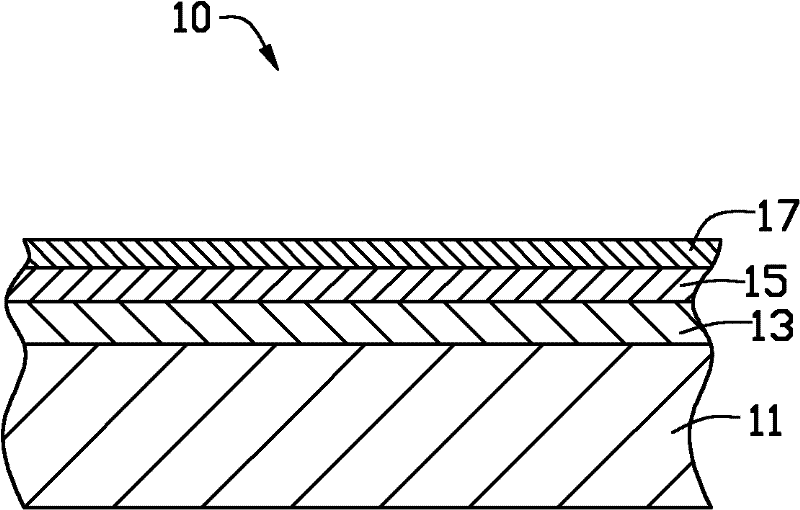

[0016] see figure 1 and figure 2 , the manufacturing method of the housing 10 in a preferred embodiment of the present invention includes the following steps:

[0017] A substrate 11 is provided, and the substrate 11 can be glass, ceramics or stainless steel.

[0018] Clean the surface of the substrate 11 to remove impurities and oil stains on the surface of the substrate 11, and dry it for later use after cleaning. The cleaning includes putting the substrate 11 into an ultrasonic cleaner filled with ethanol or acetone solution for vibration cleaning.

[0019] The substrate 11 after cleaning is fixed on the turntable of a magnetron sputtering coating machine (not shown), and the vacuum chamber of this magnetron sputtering coating machine is vacuumized so that the pressure in the vacuum chamber is 3× 10 -8 Pa, after that, argon gas (working gas) with a flow rate of 100-400 sccm (standard state ml / min) is introduced; and the temperature of the cavity is kept at about 100-20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com