A composite light-weight thermal insulation decorative ceramic exterior wall brick and its preparation method

A composite and lightweight technology, applied in ceramic forming machines, manufacturing tools, sustainable waste treatment, etc., can solve the problems of heavy pollution, pollution control and haze reduction, high energy consumption, etc., achieve rich surface decoration effects, reduce pollution, Improve the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

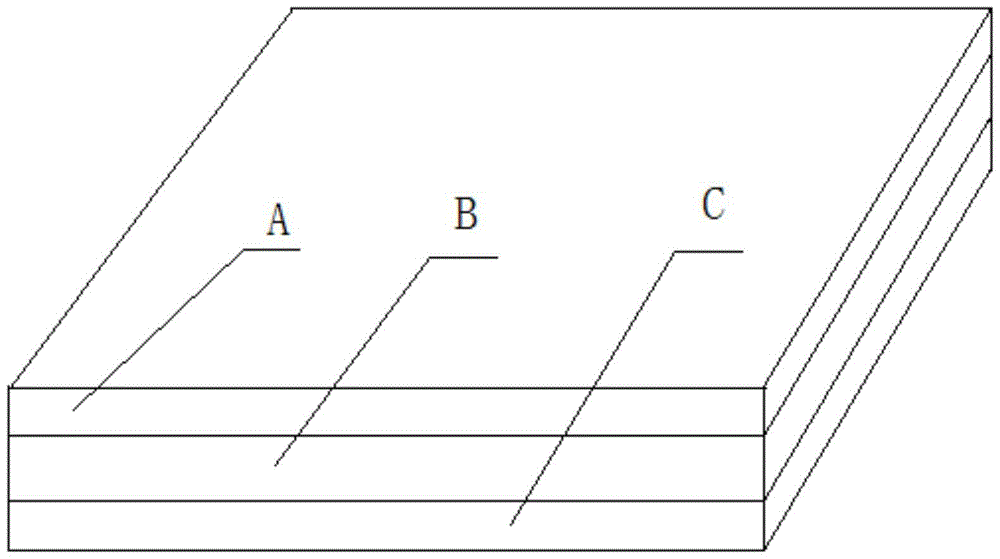

Image

Examples

Embodiment 1

[0047] (1) Put the used raw materials into a ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of the ball and the raw material to 2:1, grind for 2 hours and pass through a 325 mesh sieve to obtain red pages Rock waste, gold tailings, waste glass, limestone, talc; in addition, Al in alumina powder 2 o 3 The content is ≥98%, and the particle size is 3-5 μm.

[0048] (2) Get sieved red shale waste, gold tailings, limestone, talc, red shale waste in parts by mass: gold tailings: limestone: talc=30:50:10:10 ingredients, mix the Put the materials together into a ball mill for dry grinding, use alumina balls as the grinding medium, control the mass ratio of the balls and raw materials to 2:1, grind for 1 hour, add 6wt% binder (PVA), and dry mix And cross 80 mesh sieves to form mixture A;

[0049] (3) Get screened red shale waste, gold tailings, waste glass, limestone and alumina powder that meets the requirements, in parts by mass: ...

Embodiment 2

[0056] (1) Put the used raw materials into a ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of the ball and the raw material to be 3:1, and pass through a 325 mesh sieve after grinding for 0.5h respectively to obtain red Shale waste, lead-zinc ore tailings, waste glass, limestone, talc; in addition, Al in alumina powder is required 2 o 3 The content is ≥98%, and the particle size is 3-5 μm.

[0057] (2) Get sieved red shale waste, lead-zinc ore tailings, limestone, talc, by mass parts red shale waste: lead-zinc ore tailings: limestone: talc=15: 65: 10: 10 ingredients, Put the prepared materials together into the ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of the ball and the raw material to 3:1, grind for 0.5h, and add 6wt% binder (PVA) , dry grinding and mixing and passing through an 80-mesh sieve to form a mixture A;

[0058] (3) Take the sieved red shale waste, lead-z...

Embodiment 3

[0065] (1) Put the used raw materials into a ball mill for dry grinding respectively, use alumina ball stone as the grinding medium, control the mass ratio of the ball and the raw material to be 2.3:1, and pass through a 325 mesh sieve after grinding for 1.8 hours respectively to obtain red Shale waste, phosphate slag, waste glass, limestone, talc; in addition, Al in alumina powder 2 o 3 The content is ≥98%, and the particle size is 3-5 μm.

[0066] (2) Get sieved red shale waste, phosphate slag, limestone, talc, red shale waste in parts by mass: phosphate slag: limestone: talc=25:55:8:12 ingredients, prepare the Put the raw materials into a ball mill for dry grinding, use alumina ball stone as the grinding medium, control the mass ratio of the ball and the raw material to 2.3:1, grind for 0.8h, and add 6wt% of binder (PVA), dry grinding and mixing Homogenize and cross 80 mesh sieves to form mixture A;

[0067] (3) Get sieved red shale waste, phosphate slag, waste glass, li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com