A wire mesh decorative glaze and the technique used on the surface of the mosaic

A glass mosaic and wire mesh technology, applied in the field of mosaic, can solve the problem that the surface effect of inkjet mosaic products is not enough to meet people's aesthetic needs, and achieve the effect of rich surface decoration effect, rich color and strong anti-fouling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation technology of above-mentioned glass mosaic comprises the following steps:

[0043] (1) preparing the mosaic body, biscuit burning the mosaic body;

[0044] (2) the above-mentioned silk screen decorative glaze glaze slurry is applied on the mosaic green body after bisque firing through the screen cloth;

[0045] (3) Send the glazed green body into the roller kiln for sintering.

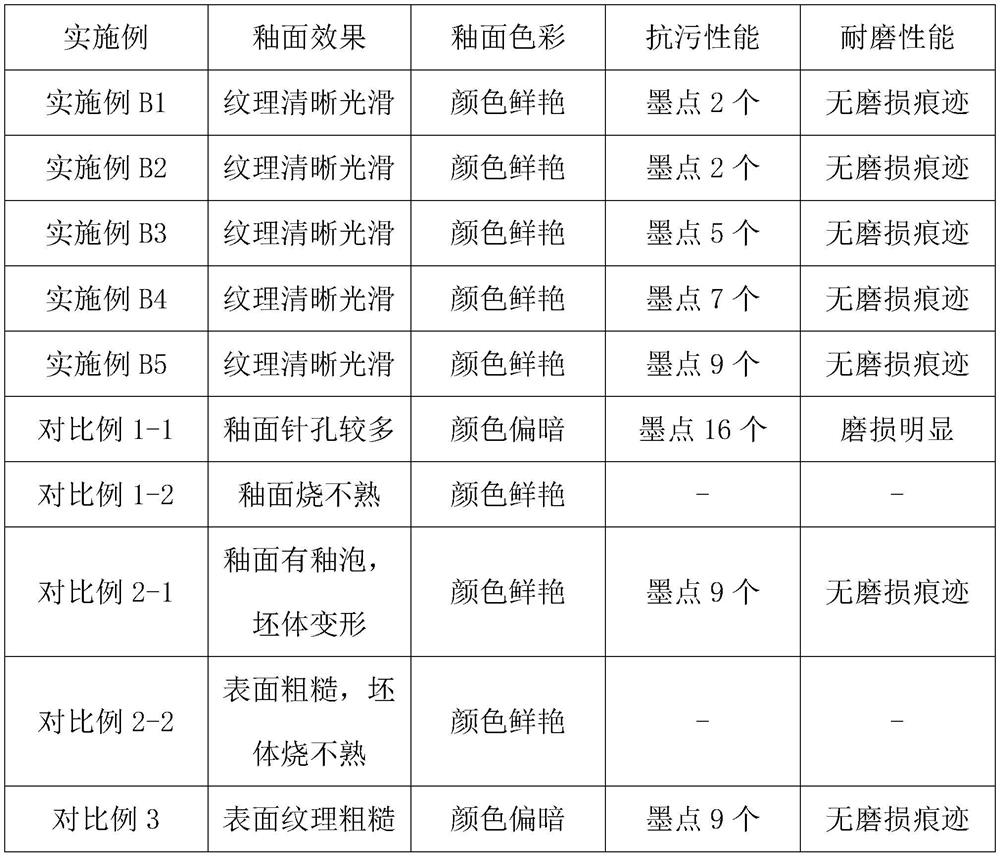

[0046] The present invention proposes a process for preparing glass mosaics. The existing mosaic body formula is used to prepare the mosaic body, and the screen decorative glaze slurry is applied to the bisque fired mosaic body through a wire mesh, and finally the mosaic body is fired at a low temperature. In other words, the surface of the mosaic can form a glaze layer with clear and smooth texture, rich colors, strong anti-fouling ability and good wear resistance. Compared with the existing mosaic products with pattern and texture formed by inkjet printing, the surface decora...

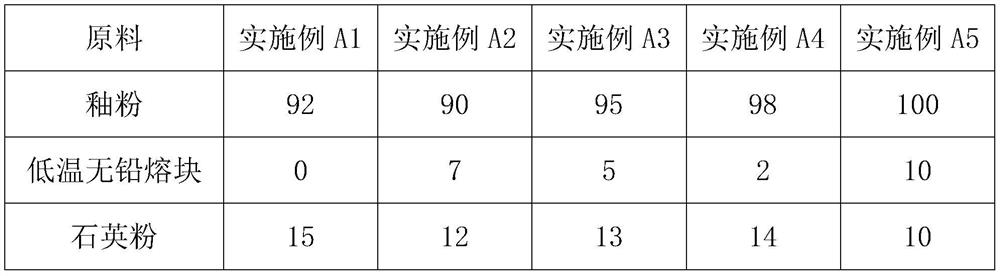

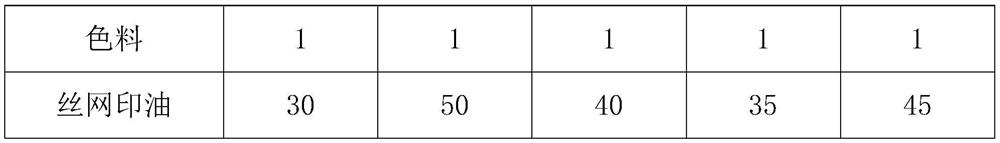

Embodiment

[0068] Example group B is a glass mosaic

[0069] The glass mosaic of the embodiment B1-B5 comprises a mosaic body and a glaze layer on the surface of the mosaic body, and the glaze layer is fired from the glaze slurry of one of the embodiments A1-A5. The preparation technology of this glass mosaic comprises the following steps:

[0070] (1) preparing the mosaic green body, bisque firing the mosaic green body at 650-780°C for 80-100min;

[0071] (2) The silk screen decorative glaze glaze slurry made by one of the embodiments A1-A5 is applied on the mosaic green body after bisque firing through a screen cloth, and the amount of glaze application is (0.6-1.0) kg / m 2 ;

[0072] (3) Send the glazed body into a roller kiln for sintering to obtain a glass mosaic.

[0073] In embodiment B1-B5, the cracked glaze glaze slurry and preparation process parameters of glass mosaic are as shown in table 4:

[0074] Table 4

[0075] project Example B1 Example B2 Example B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com