Ceramic brightening glaze and its preparation process

A production method and a ceramic technology, which are applied to the production method and the glaze field of ceramic consecration glazes on the surface of daily-use ceramics and display ceramics, and can solve problems such as constraints, poor wear resistance, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Make a glazed effect on a flat plate. Mold a flat plate with china clay and dry. Apply a layer of red glossy bottom glaze on the flat body by dipping glaze, with a thickness of 0.2-0.3 mm; then spray a layer of 0.3-0.4 mm on the bottom glaze by spraying glaze mm white matt glaze. After entering the kiln and firing at a high temperature, a three-dimensional white glaze and a red flat plate are obtained.

[0028] The base glaze is composed of base glaze and colorant, the weight percentage of which is: base glaze 80%, colorant 20%, and colorant is commercial pigment for ceramics or iron red powder for industrial use.

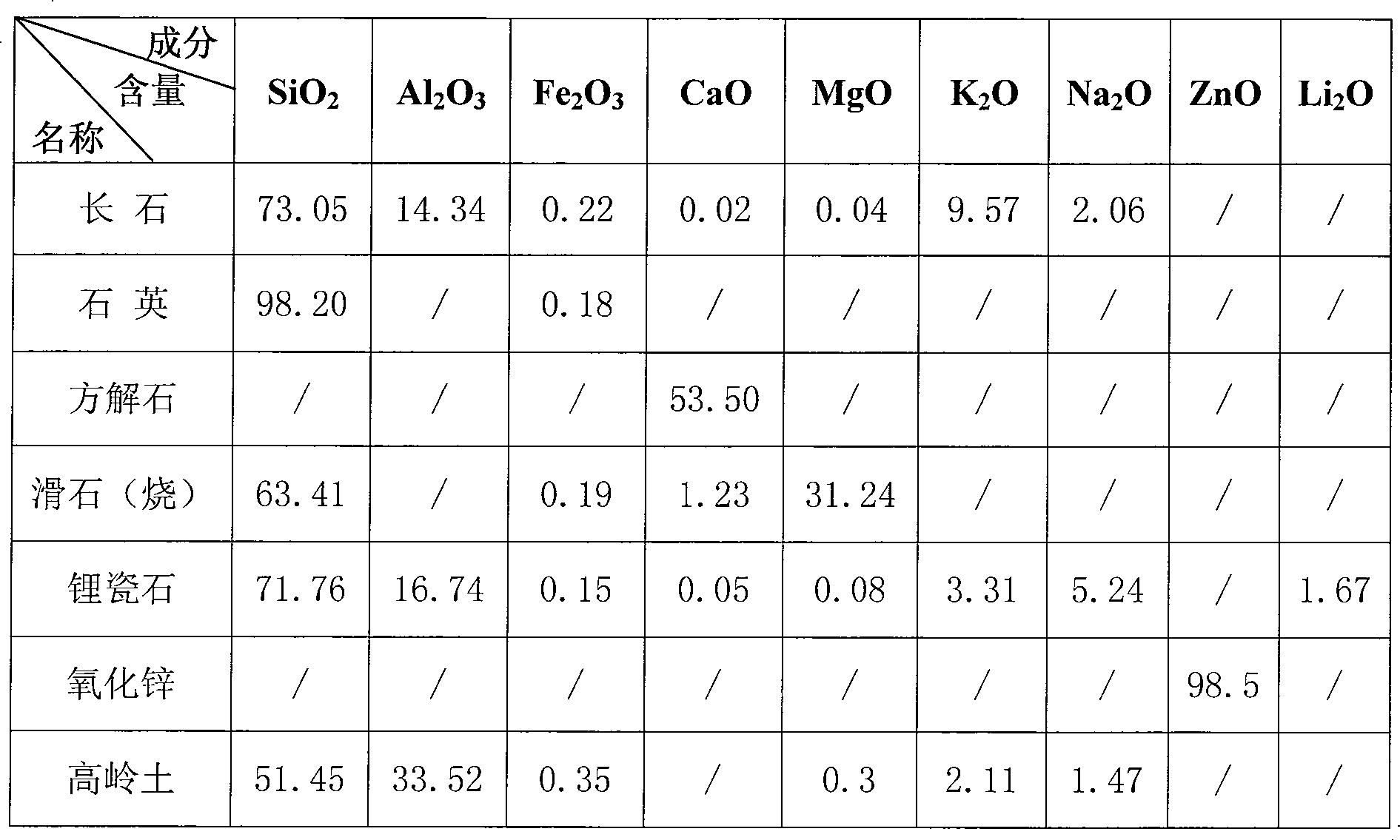

[0029] The base glaze of the bottom glaze mainly includes SiO 2 、Al 2 o 3 , CaO, ZnO, Li 2 O, MgO, K 2 O and Na 2 O, made of any combination of feldspar, quartz, calcite, talc (fired) and lithium china stone, to ensure that the chemical composition of the base glaze of the bottom glaze is as follows:

[0030] SiO 2 : 66% Al 2 o 3 : 12% CaO: 6.3% ...

Embodiment 2

[0040] Make a glazed glaze effect on the daily cup. Mold a cup out of china clay and dry. Apply a layer of black glossy bottom glaze on the cup body by glaze brushing, with a thickness of 0.2-0.3 mm; then spray a layer of 0.3-0.4 mm on the bottom glaze on the cup body by spraying Green glossy glaze. After entering the kiln and firing at a high temperature once, a three-dimensional green glazed black light cup is obtained.

[0041] The base glaze is composed of base glaze and toner, the weight percentage of which is: base glaze 90%, colorant 10%, and the colorant is commercial pigment for ceramics or black powder for industry.

[0042] The base glaze of the bottom glaze mainly includes SiO 2 、Al 2 o 3 , CaO, ZnO, Li 2 O, MgO, K 2 O and Na 2 O, made of any combination of feldspar, quartz, calcite, talc (fired) and lithium china stone, to ensure that the chemical composition of the base glaze of the bottom glaze is as follows:

[0043] SiO 2 : 66.5% Al 2 o 3 : 11.5% C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com