Shell and manufacturing method thereof

A manufacturing method and shell technology, applied in chemical instruments and methods, electrical equipment casings/cabinets/drawers, decorative art, etc., can solve the problem of limited color of the film layer, and achieve the effect of improving appearance competitiveness and enriching colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

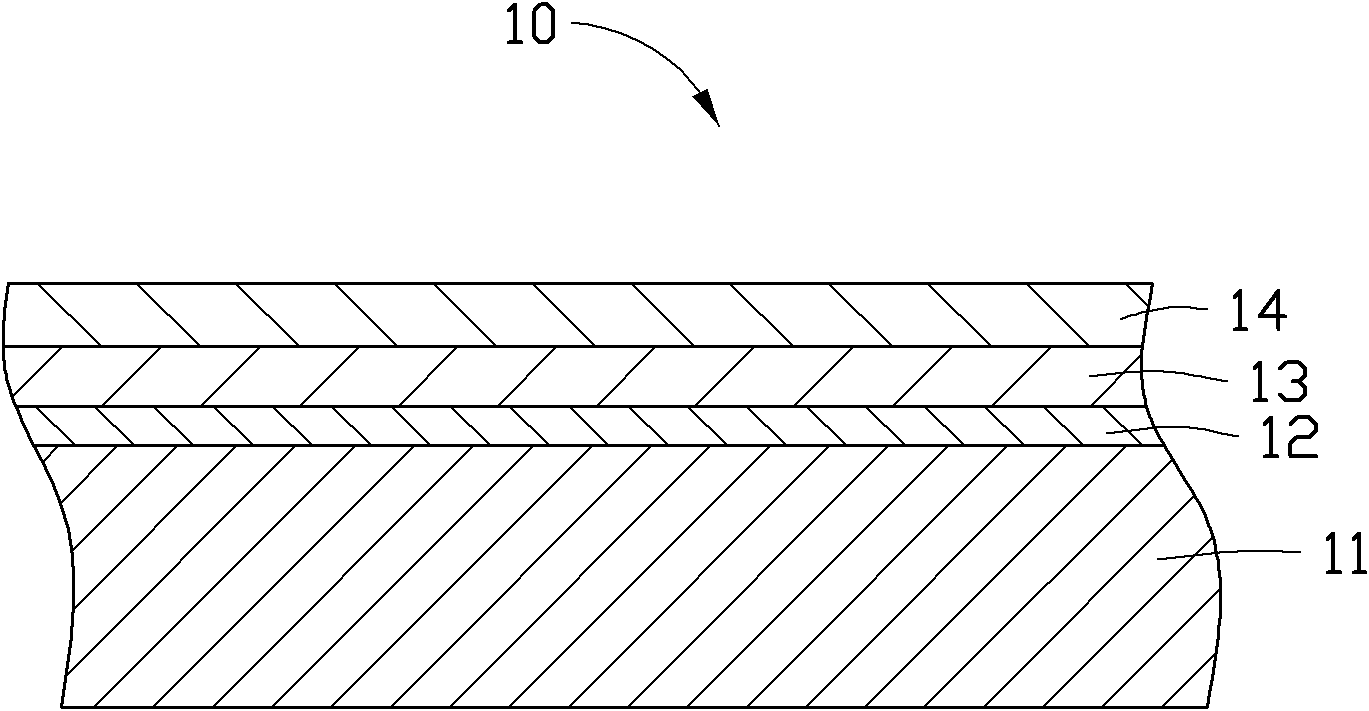

[0027] see figure 1 The housing 10 of the preferred embodiment of the present invention includes a base 11 , a base layer 12 formed on the base 11 , a transition layer 13 formed on the base layer 12 and a color layer 14 formed on the transition layer 13 . The color layer 14 is yellowish-brown visually.

[0028] The material of the substrate 11 can be one of stainless steel, glass, ceramics and plastic.

[0029] The primer layer 12 is an aluminum metal layer with a thickness of about 0.1-0.2 microns. The primer layer 11 is used to improve the bonding force of subsequent coatings.

[0030] The transition layer 13 consists of aluminum oxynitride (AlON). The mass percent content of aluminum element in the transition layer 13 is 60%-65%, the mass percent content of oxygen element is 30%-35%, and the mass percent content of nitrogen element is 5%-10%. The thickness of the transition layer 13 is about 0.2-0.6 microns. The transition layer 13 is used to better improve the binding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com