Shell body and preparing method thereof

A shell and substrate technology, applied in the field of shell and its preparation, can solve the problems of not being able to present the texture, difficult to attract consumers' attention, and weak visual effects, etc., achieve good chemical stability, improve appearance competitiveness, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

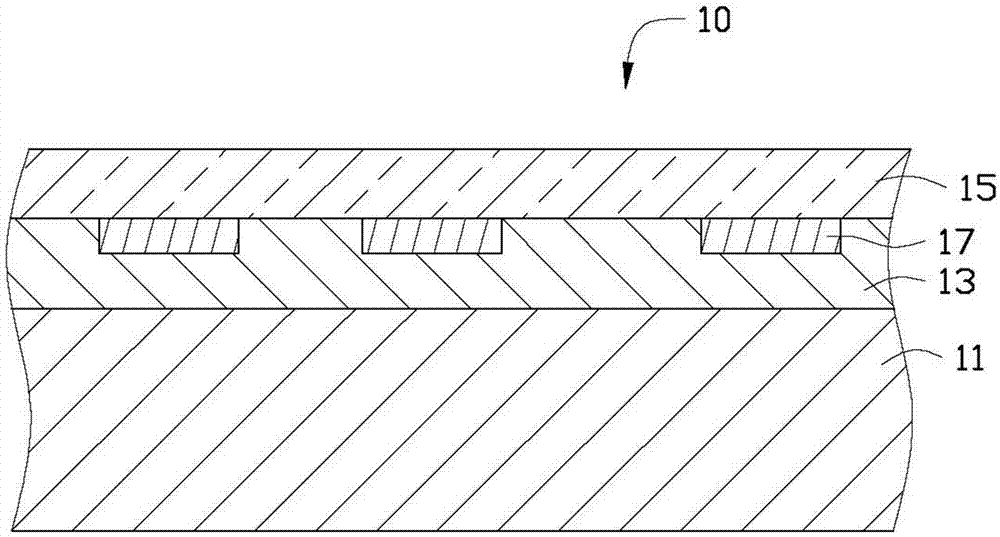

[0016] see figure 1 A housing 10 in a preferred embodiment of the present invention includes a substrate 11 and a base ceramic layer 13 and a transparent ceramic layer 15 sequentially formed on the surface of the substrate 11 . A pattern layer 17 is also provided between the base ceramic layer 13 and the transparent ceramic layer 15 , and the pattern layer 17 is embedded in the base ceramic layer 13 . The casing 10 can be a casing of an electronic device such as a mobile phone.

[0017] The base material 11 is made of stainless steel or titanium alloy.

[0018] The base ceramic layer 13 is composed of oxide ceramics, which include 60-70% by mass of silicon oxide, 15-20% of aluminum oxide, 5-10% of pigment raw materials, and 5-6% of potassium oxide. , 4-6% sodium oxide, 0.4-0.6% magnesium oxide, 0.2-0.4% iron oxide, 0.2-0.4% calcium oxide. Wherein, the pigment material is a metal compound, specifically titanium oxide, iron oxide, ferric oxide or cobalt oxide, which can respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com