Housing and preparation method thereof

A shell and substrate technology, applied in the field of shell with purple appearance and its preparation, can solve the problems of limited film color and increased production cost, so as to improve the competitiveness of appearance, avoid wear, scratch or corrosion, and enrich the color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

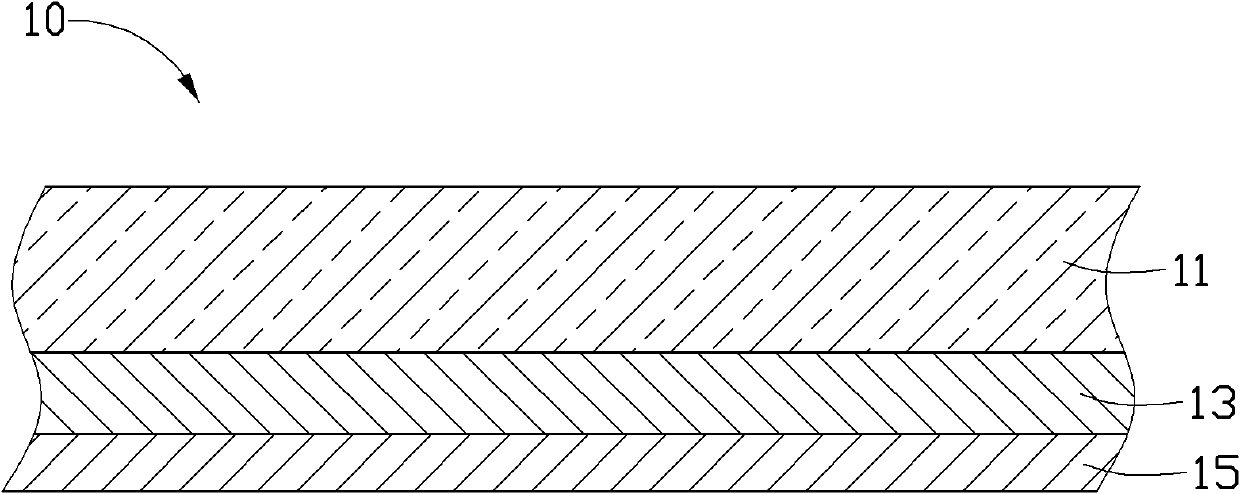

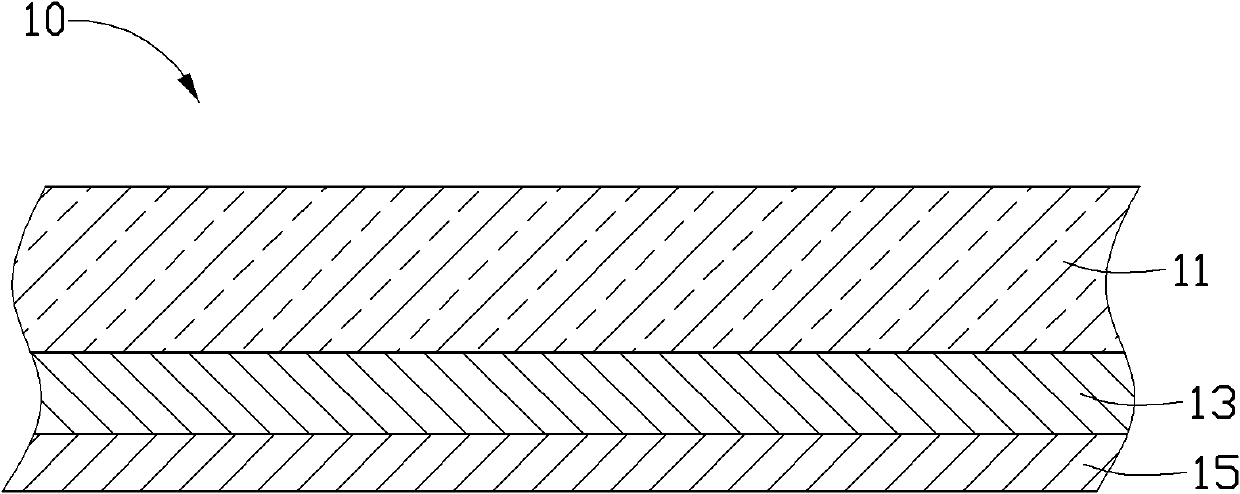

[0023] see figure 1 A housing 10 in a preferred embodiment of the present invention includes a base 11 , a color layer 13 formed on the inner surface of the base 11 , and a reflective layer 15 formed on the surface of the color layer 13 . The inner surfaces are surfaces that are not normally touched during normal use of the housing 10 .

[0024] The substrate 11 is colorless and transparent glass or plastic.

[0025] The color layer 13 can be formed on the surface of the substrate 11 by magnetron sputtering. The color layer 13 is zirconia (ZrO 2 )Floor. The color layer 13 may have a thickness of 300-500 nm. The color layer 13 appears purple.

[0026] The reflective layer 15 is formed by magnetron sputtering. The reflective layer 15 is a metal zirconium (Zr) layer. Due to the high reflectivity of metal, the reflective layer 15 can improve the vividness of the color of the color layer 13 . The reflective layer 15 may have a thickness of 100-200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com