Coated member and preparation method thereof

A technology for coating parts and magnesium alloys, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of insufficient film compactness and inability to effectively delay the erosion of salt spray, so as to improve the resistance Corrosion performance, high hardness and wear resistance, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

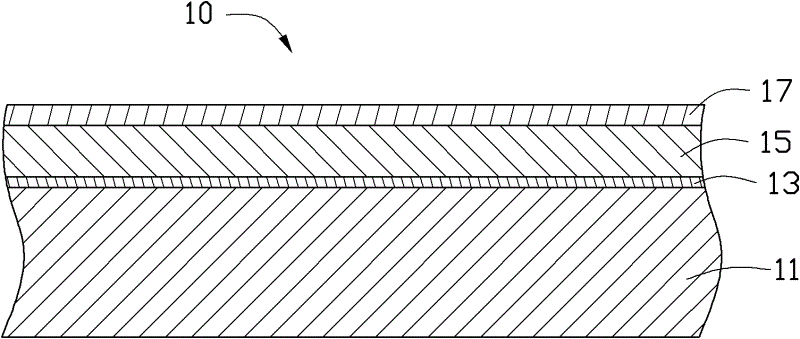

[0031] The preparation method of the coating member 10 of a preferred embodiment of the present invention, it comprises the following steps:

[0032] (a) A magnesium alloy substrate 11 is provided.

[0033] (b) Put the magnesium alloy substrate 11 into absolute ethanol for ultrasonic cleaning to remove stains on the surface of the magnesium alloy substrate 11, and the cleaning time may be 5-20 minutes.

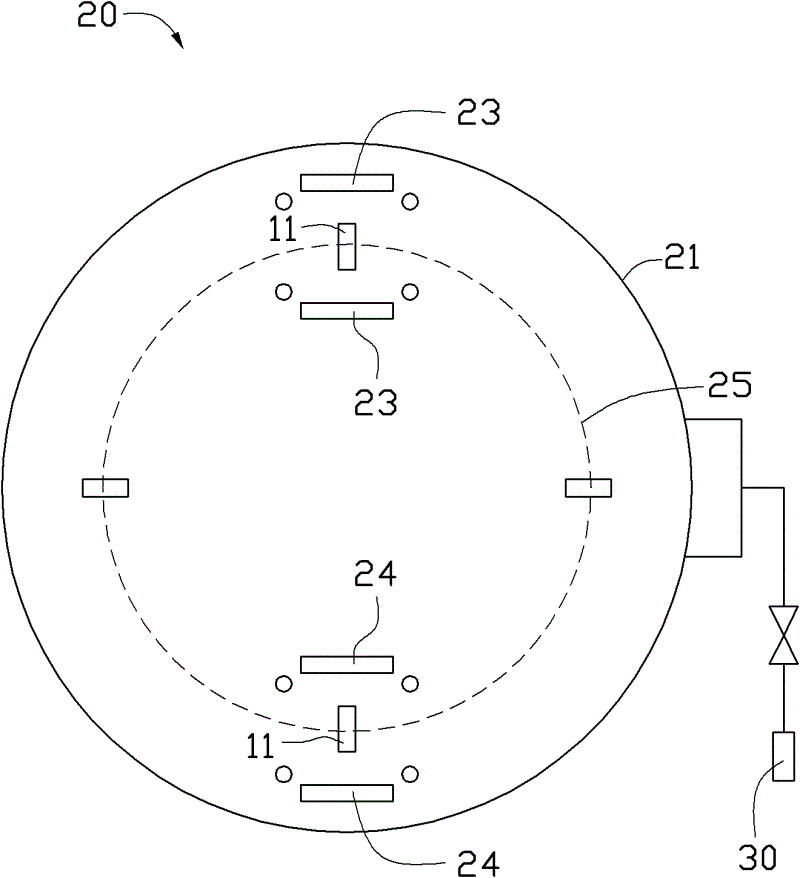

[0034] (c) Perform argon plasma cleaning on the surface of the magnesium alloy substrate 11 after the above treatment to further remove the oil stain on the surface of the magnesium alloy substrate 11 and improve the bonding force between the surface of the magnesium alloy substrate 11 and the subsequent coating. combined reference figure 2 , provide a vacuum coating machine 20, the vacuum coating machine 20 includes a coating chamber 21 and a vacuum pump 30 connected to the coating chamber 21, the vacuum pump 30 is used to evacuate the coating chamber 21. The coating chamb...

Embodiment 1

[0041] The vacuum coating machine 20 used in this embodiment is an intermediate frequency magnetron sputtering coating machine.

[0042] Plasma cleaning: the argon gas flow rate is 500 sccm, the bias voltage of the magnesium alloy substrate 11 is -500V, and the plasma cleaning time is 5 minutes.

[0043] Magnesium layer 13 is sputtered: the flow rate of argon gas is 100 sccm, the power of the magnesium target 23 is 3kW, the bias voltage of the magnesium alloy substrate 11 is -100V, the coating temperature is 80°C, and the coating time is 10min; the thickness of the magnesium layer 13 is 20nm .

[0044] Sputtering magnesium oxynitride layer 15: the oxygen flow rate is 80 sccm, the nitrogen gas flow rate is 50 sccm, other process parameters are the same as those for depositing the magnesium layer 13, the coating time is 60 min, and the thickness of the magnesium oxynitride layer 15 is 200 nm.

[0045] Sputtering titanium nitride layer 17: the flow rate of nitrogen gas is 50 scc...

Embodiment 2

[0047] The vacuum coating machine 20 used in this embodiment is the same as that in Embodiment 1.

[0048] Plasma cleaning: the argon gas flow rate is 500 sccm, the bias voltage of the magnesium alloy substrate 11 is -500V, and the plasma cleaning time is 5 minutes.

[0049] Magnesium layer 13 is sputtered: the flow rate of argon gas is 300sccm, the power of magnesium target 23 is 10kW, the bias voltage of magnesium alloy substrate 11 is -300V, the coating temperature is 200°C, and the coating time is 30min; the thickness of the magnesium layer 13 is 50nm .

[0050] Sputtering magnesium oxynitride layer 15: the oxygen flow rate is 120 sccm, the nitrogen gas flow rate is 80 sccm, other process parameters are the same as those for depositing the magnesium layer 13, the coating time is 90 min, and the thickness of the magnesium oxynitride layer 15 is 300 nm.

[0051]Sputtering titanium nitride layer 17: the flow rate of nitrogen gas is 80 sccm, the flow rate of argon gas is 300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com