Plated piece and preparation method thereof

A technology for coating parts and metal substrates, which is applied in the field of coating parts with relatively high hardness film layers and its preparation, and can solve problems such as easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

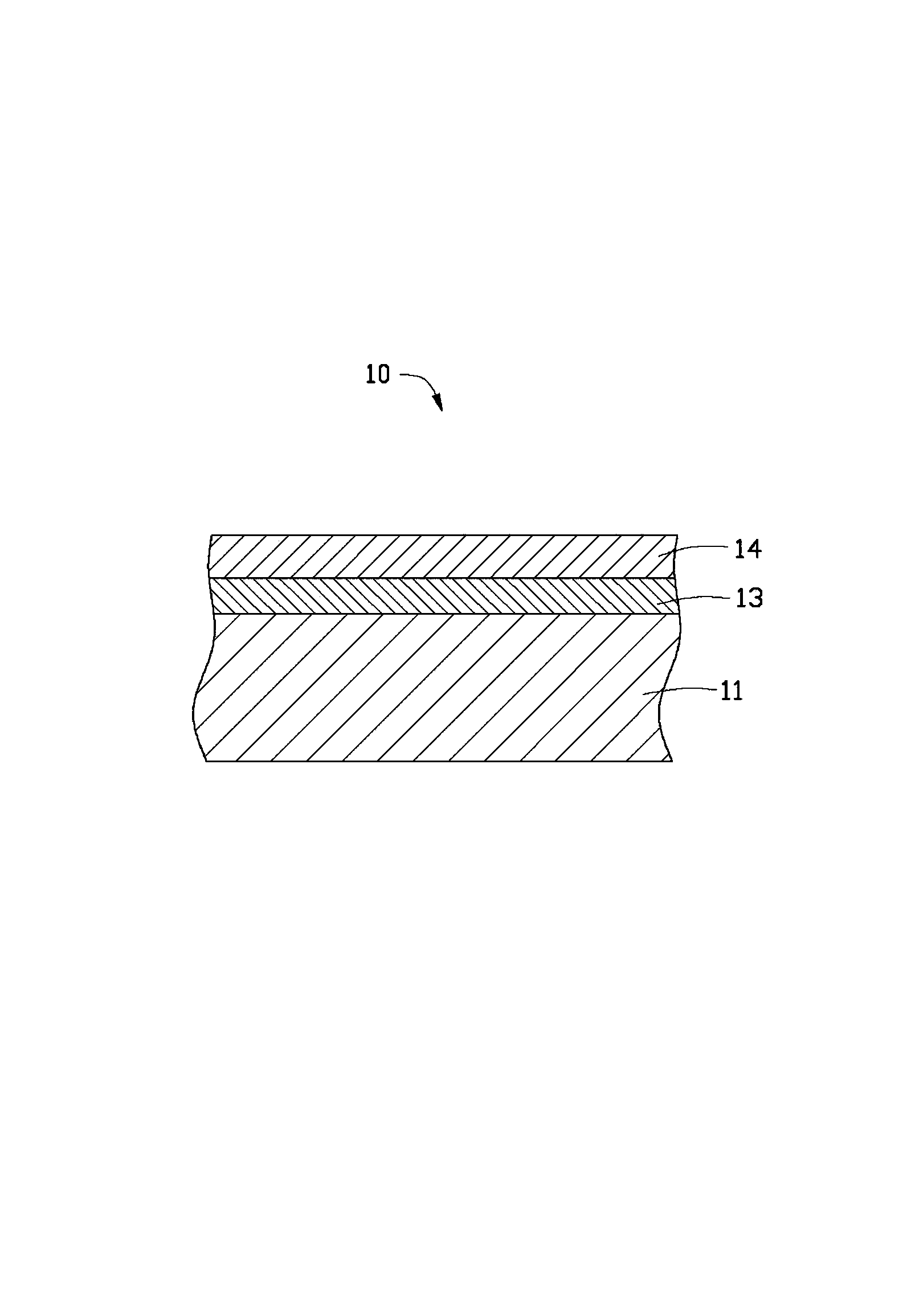

[0022] The preparation method of the above-mentioned coated part 10 mainly includes depositing a TiSiN layer 13 on the metal base 11 and depositing a TiN layer 14 on the TiSiN layer 13 by magnetron sputtering.

[0023] Depositing this TiSiN layer 13 is under sputtering conditions, with titanium as the target material, with silane (SiH 4 ) and nitrogen (N 2 ) is the reactive gas, and the target material is sputtered and deposited on the surface of the metal substrate 11 by applying power to the target to form the TiSiN layer 13 . During the sputtering process, the flow rate of the silane gas gradually decreases from an initial value to 0 sccm (standard state milliliter / minute), and the initial value can be 40-30 sccm; the flow rate of the nitrogen gas gradually increases from 0-10 sccm to A maximum value, which may be 100-90 sccm.

[0024] The TiN layer 14 is deposited under sputtering conditions, with titanium as the target and nitrogen as the reactive gas, applying power to...

Embodiment 1

[0030] 1. Ultrasonic cleaning

[0031] Put the metal substrate 11 made of 304 stainless steel into an ethanol solution for ultrasonic cleaning to remove impurities and oil stains on the surface of the metal substrate 11 , and dry it for later use after cleaning.

[0032] 2. Coating

[0033] Magnetron sputtering equipment (produced by Shenzhen Nanfang Innovation Vacuum Technology Co., Ltd., model SM-1100H) is used. The magnetron sputtering equipment includes a vacuum chamber, a turntable, a magnetron target and a bias power supply. The magnetron target is a pair target structure, including two pairs of titanium targets, and a certain distance is formed between the two targets of each pair of titanium targets. The metal base 11 is fixed on the turntable, and when the turntable rotates, the metal base 11 is driven to pass between each pair of titanium targets.

[0034] Target washing: adjust the absolute pressure in the vacuum chamber to 6.0×10 -3 Pa, heat the vacuum chamber ...

Embodiment 2

[0041] 1. Ultrasonic cleaning

[0042]Put the metal substrate 11 made of 304 stainless steel into an ethanol solution for ultrasonic cleaning to remove impurities and oil stains on the surface of the metal substrate 11 , and dry it for later use after cleaning.

[0043] 2. Coating

[0044] Magnetron sputtering equipment (produced by Shenzhen Nanfang Innovation Vacuum Technology Co., Ltd., model SM-1100H) is used. The magnetron sputtering equipment includes a vacuum chamber, a turntable, a magnetron target and a bias power supply. The magnetron target is a pair target structure, including two pairs of titanium targets, and a certain distance is formed between the two targets of each pair of titanium targets. The metal base 11 is fixed on the turntable, and when the turntable rotates, the metal base 11 is driven to pass between each pair of titanium targets.

[0045] Target washing: adjust the absolute pressure in the vacuum chamber to 5.0×10 -3 Pa, heat the vacuum chamber s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com