Construction method for preventing polyurethane clear lacquer film from blushing

A construction method and polyurethane technology, which can be used in polyurea/polyurethane coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of easy whitening of polyurethane clear paint films, and achieve a full and mild feel. , the effect of preventing whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The material is a decorative material composed of medium density boards. The construction method for preventing the whitening of the polyurethane transparent paint film on the material comprises the following steps:

[0019] (1) Material sanding: sand the burr of the material with sandpaper, and sand it smooth;

[0020] (2) Material coloring: use the filler Gaglis, wipe it evenly, and dry for 1 hour;

[0021] (3) Sanding: use sandpaper to sand flat and smooth;

[0022] (4) Anti-blushing sealing primer brushing: adjust the viscosity of the anti-blushing sealing primer to 8 seconds with the anti-blushing sealing primer thinner, brush evenly once, and dry for 4 hours;

[0023] (5) Sanding: use sandpaper to sand flat and smooth;

[0024] (6) Polyurethane transparent primer brushing: adjust the viscosity of polyurethane transparent primer to 18 seconds with polyurethane transparent primer diluent, evenly brush a "ten" character, and dry for 6 hours;

[0025] (7) Sanding:...

Embodiment 2

[0032] The material is a decorative material composed of solid wood. The construction method for preventing the whitening of the polyurethane transparent paint film on the material comprises the following steps:

[0033] (1) Material sanding: sand the burr of the material with sandpaper, and sand it smooth;

[0034] (2) Material coloring: use the filler Gaglis, wipe it evenly, and dry for 2 hours;

[0035] (3) Sanding: use sandpaper to sand flat and smooth;

[0036] (4) Anti-blushing sealing primer spraying: adjust the viscosity of the anti-blushing sealing primer to 10 seconds with the anti-blushing sealing primer thinner, spray a "ten" evenly, and dry for 6 hours;

[0037] (5) Sanding: use sandpaper to sand flat and smooth;

[0038] (6) Spraying of polyurethane transparent primer: adjust the viscosity of polyurethane transparent primer to 16 seconds with polyurethane transparent primer thinner, and spray two "ten" characters evenly for 8 hours;

[0039] (7) Sanding: use ...

Embodiment 3

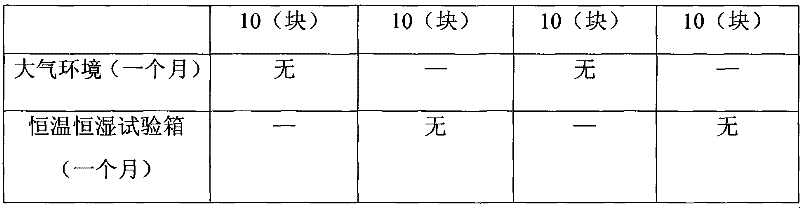

[0045] Embodiment 3 verifies that method of the present invention can effectively prevent the experiment that polyurethane transparent paint paint film turns white

[0046] Randomly select 20 pieces of materials of embodiment 1 and 2 construction treatment respectively, adopt construction method of the present invention to carry out construction, randomly select 10 pieces of products of embodiment 1 and 2 after spraying and be placed in room temperature, humidity is 55%-65% Under atmospheric environment, place one month; Other 10 products of embodiment 1,2 are placed in the constant temperature and humidity test box that temperature is room temperature, humidity is 80%, place one month; During one month, observe and record paint film development White situation. The experimental results are shown in Table 1.

[0047] Table 1

[0048]

[0049]

[0050] Note: "-" indicates that no experiment was performed.

[0051] As can be seen from Table 1, the materials processed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com