Patents

Literature

346 results about "Sheet moulding compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

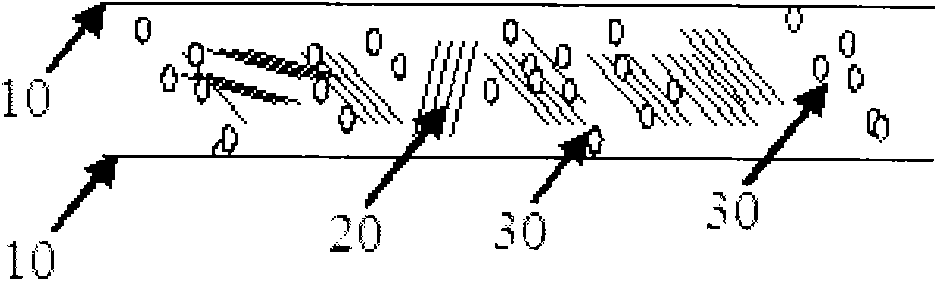

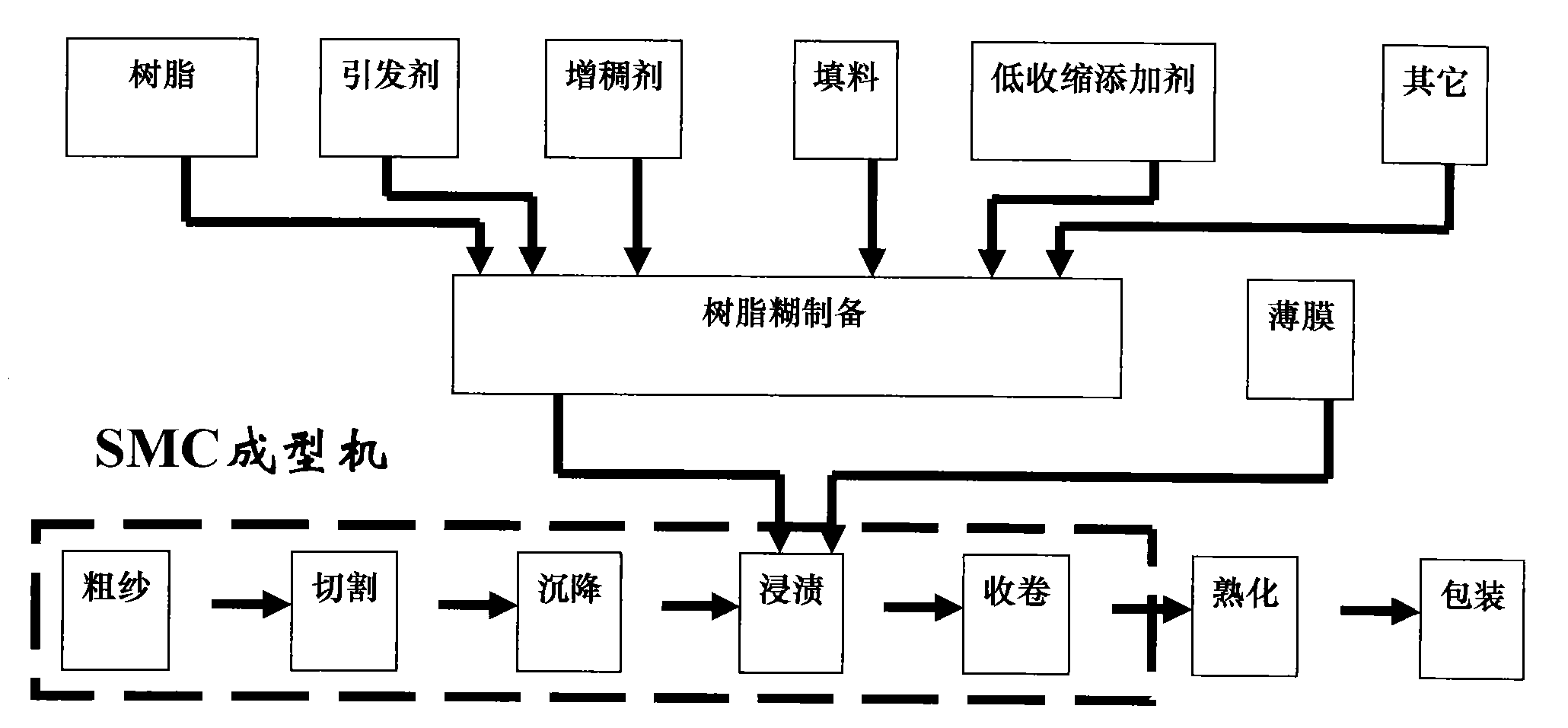

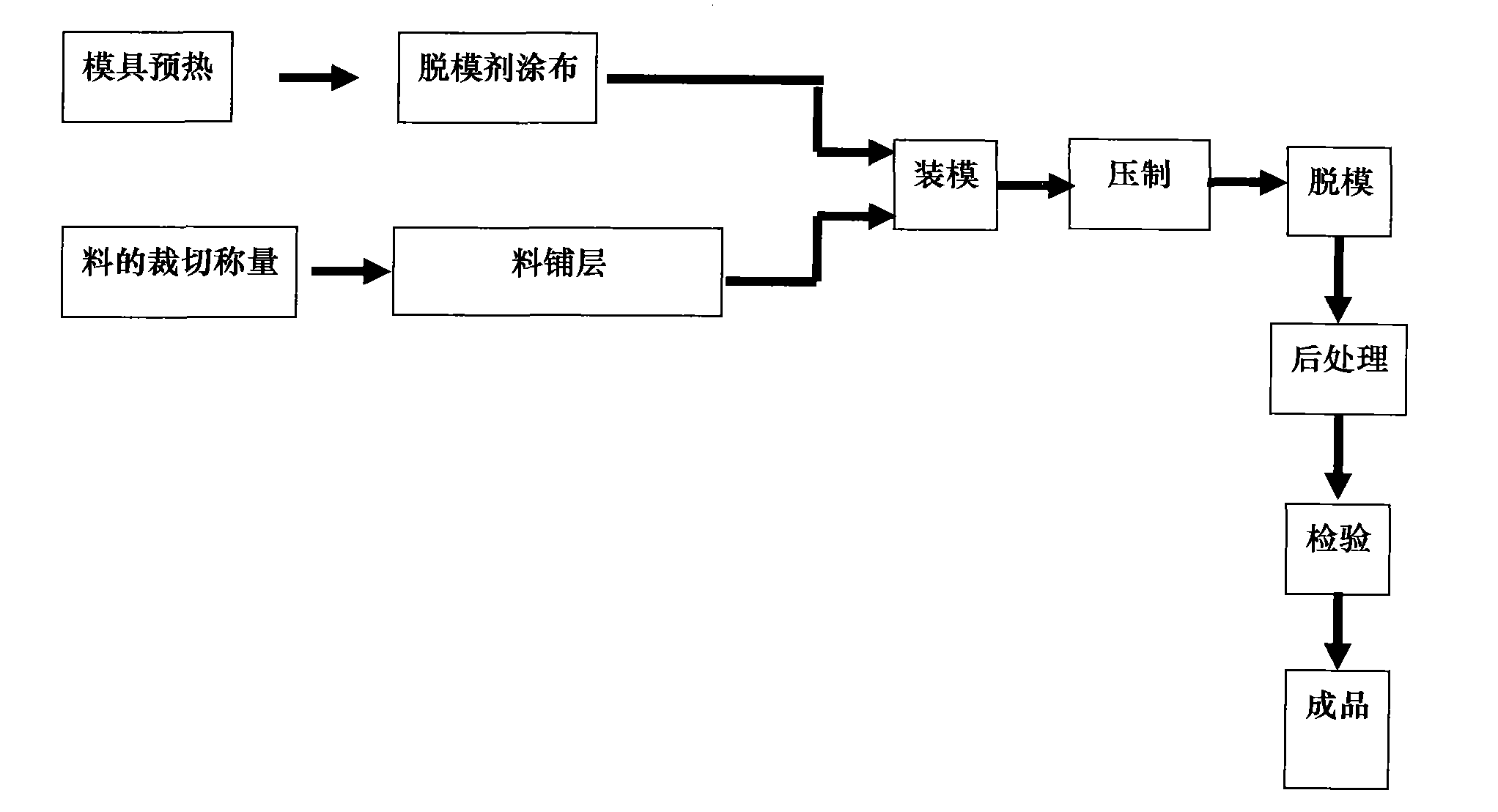

Sheet moulding compound (SMC) or sheet moulding composite is a ready to mould glass-fibre reinforced polyester material primarily used in compression moulding. The sheet is provided in rolls weighing up to 1000 kg. Alternatively the resin and related materials may be mixed on site when a producer wants greater control over the chemistry and filler.

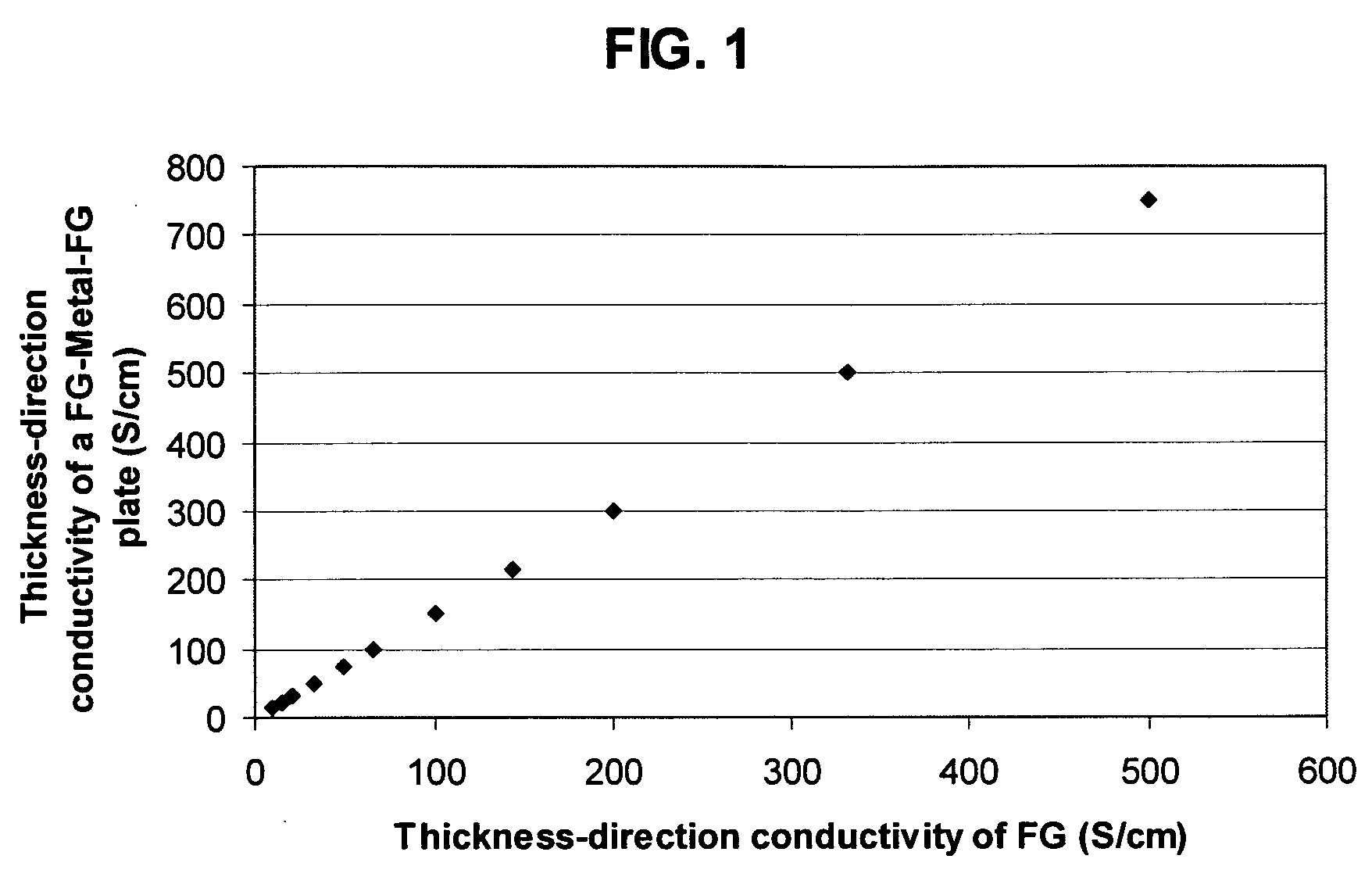

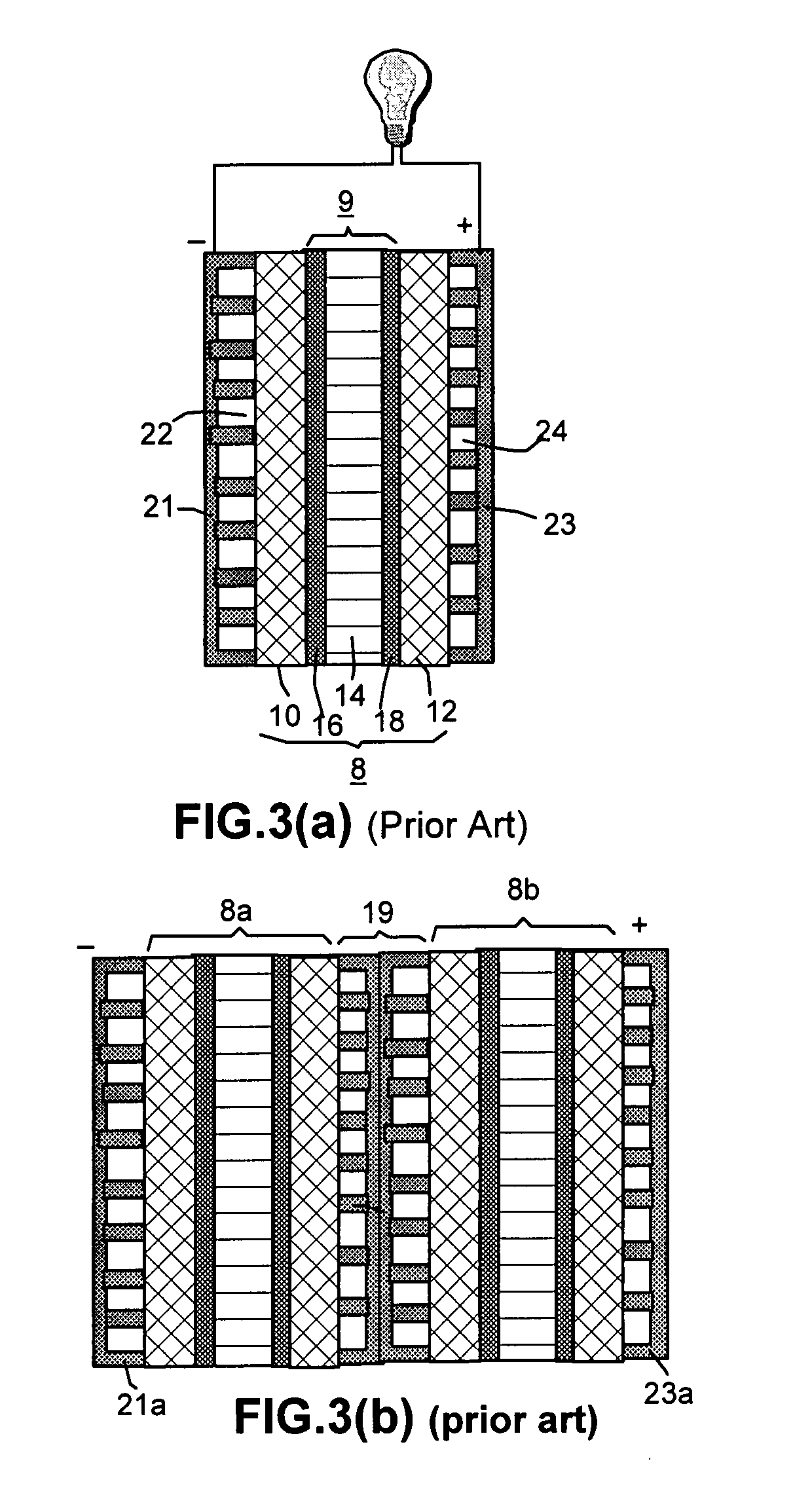

Method for producing highly conductive sheet molding compound, fuel cell flow field plate, and bipolar plate

ActiveUS20070125493A1Improves Structural IntegrityAdhesive processesMechanical working/deformationFuel cellsSheet moulding compound

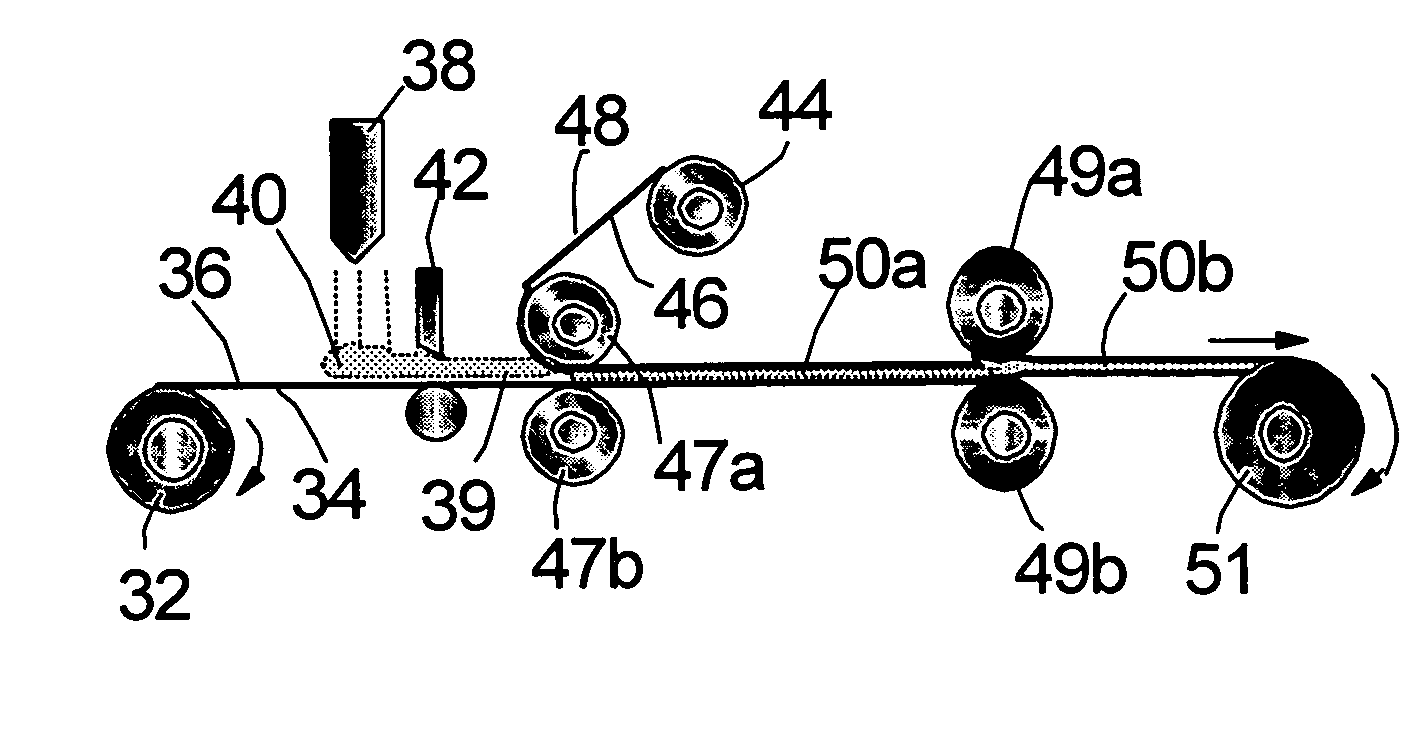

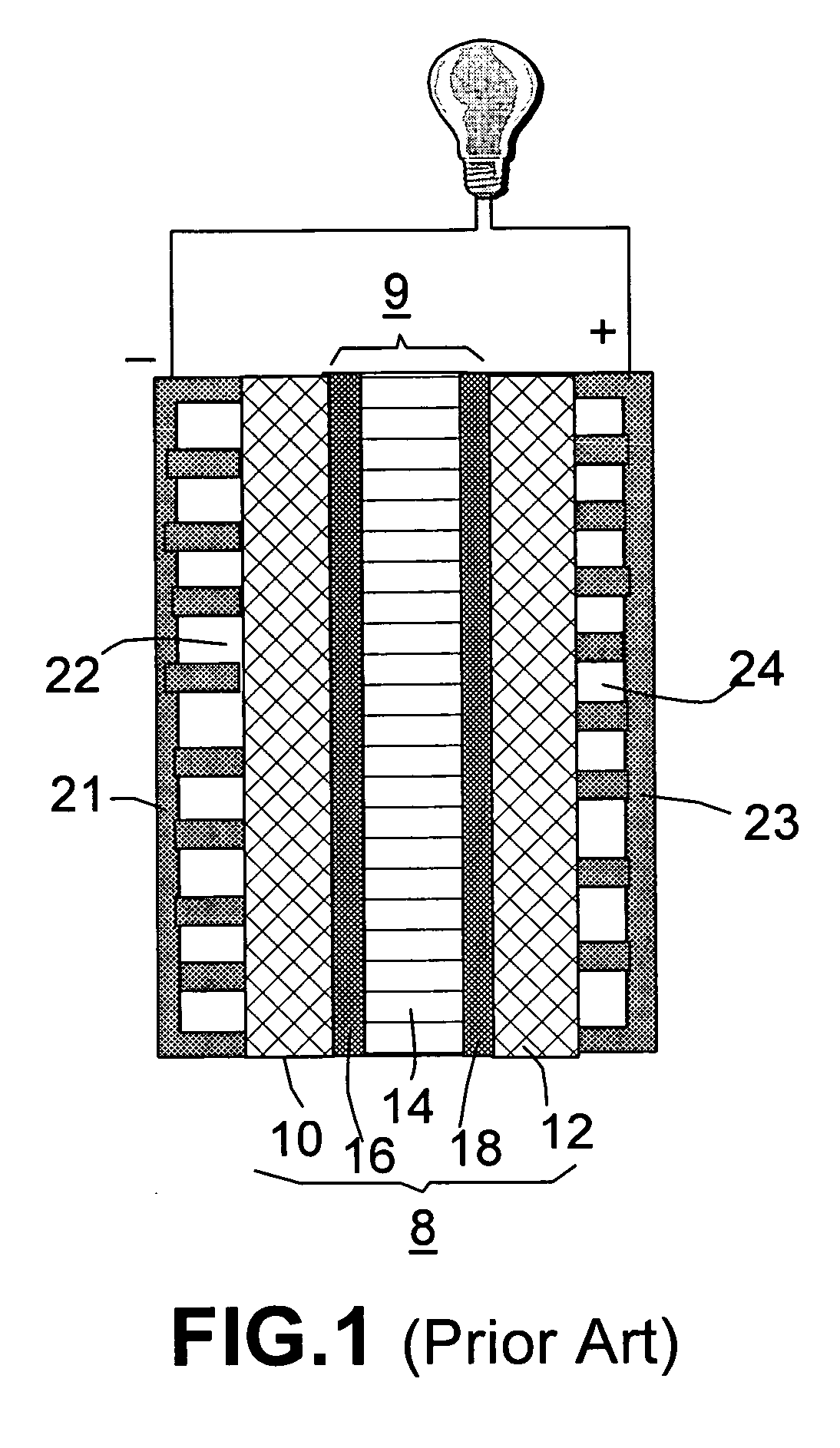

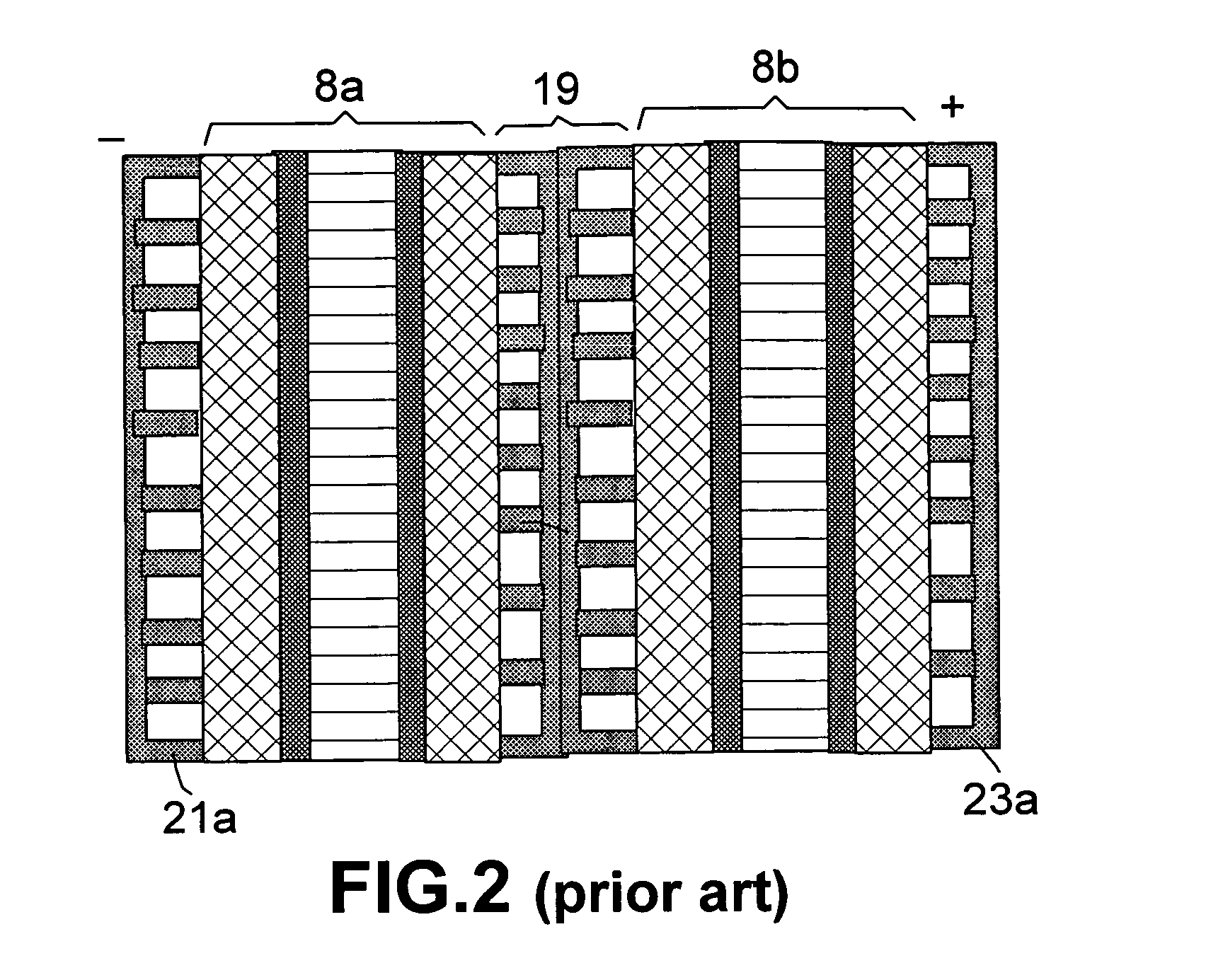

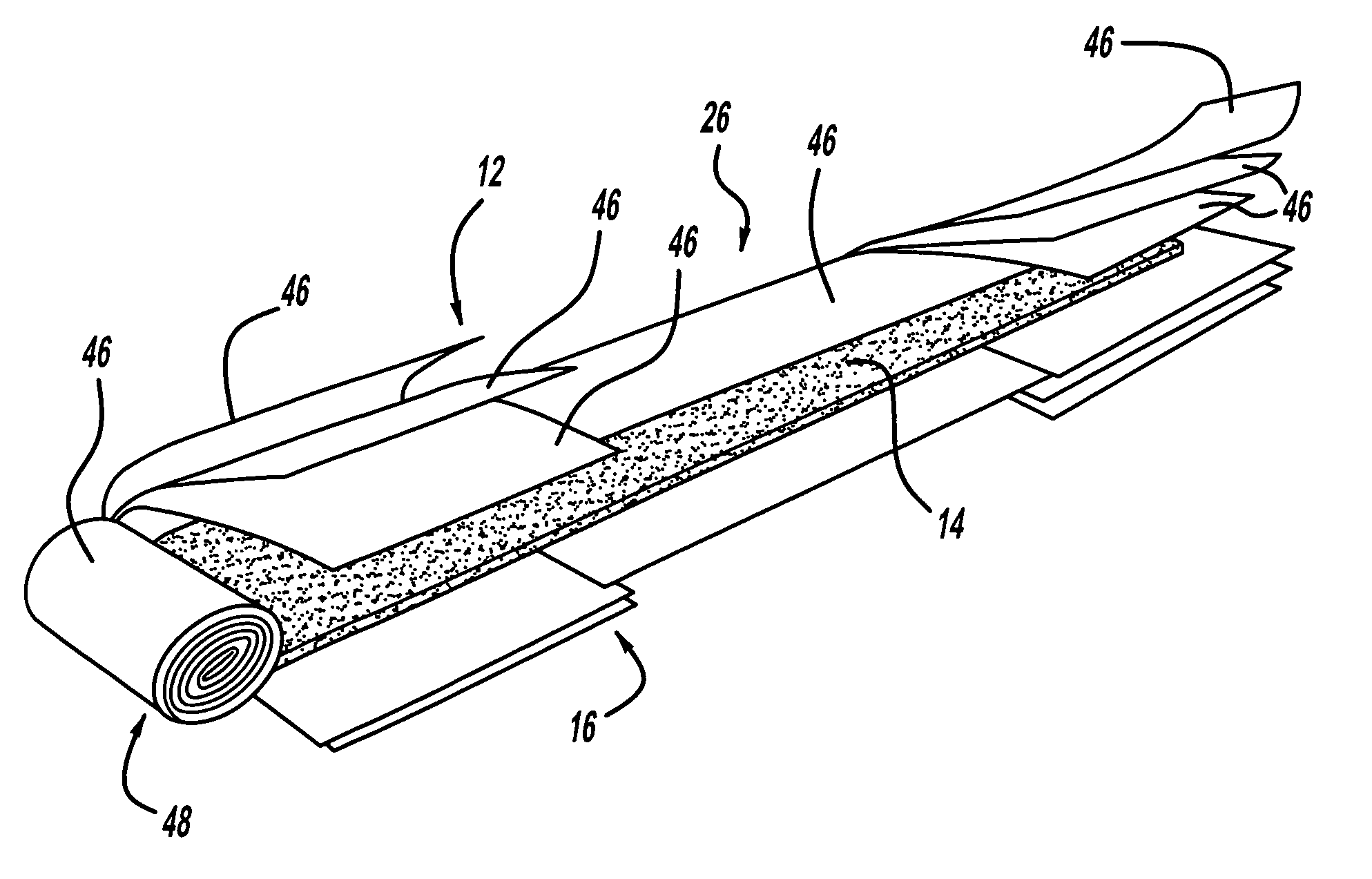

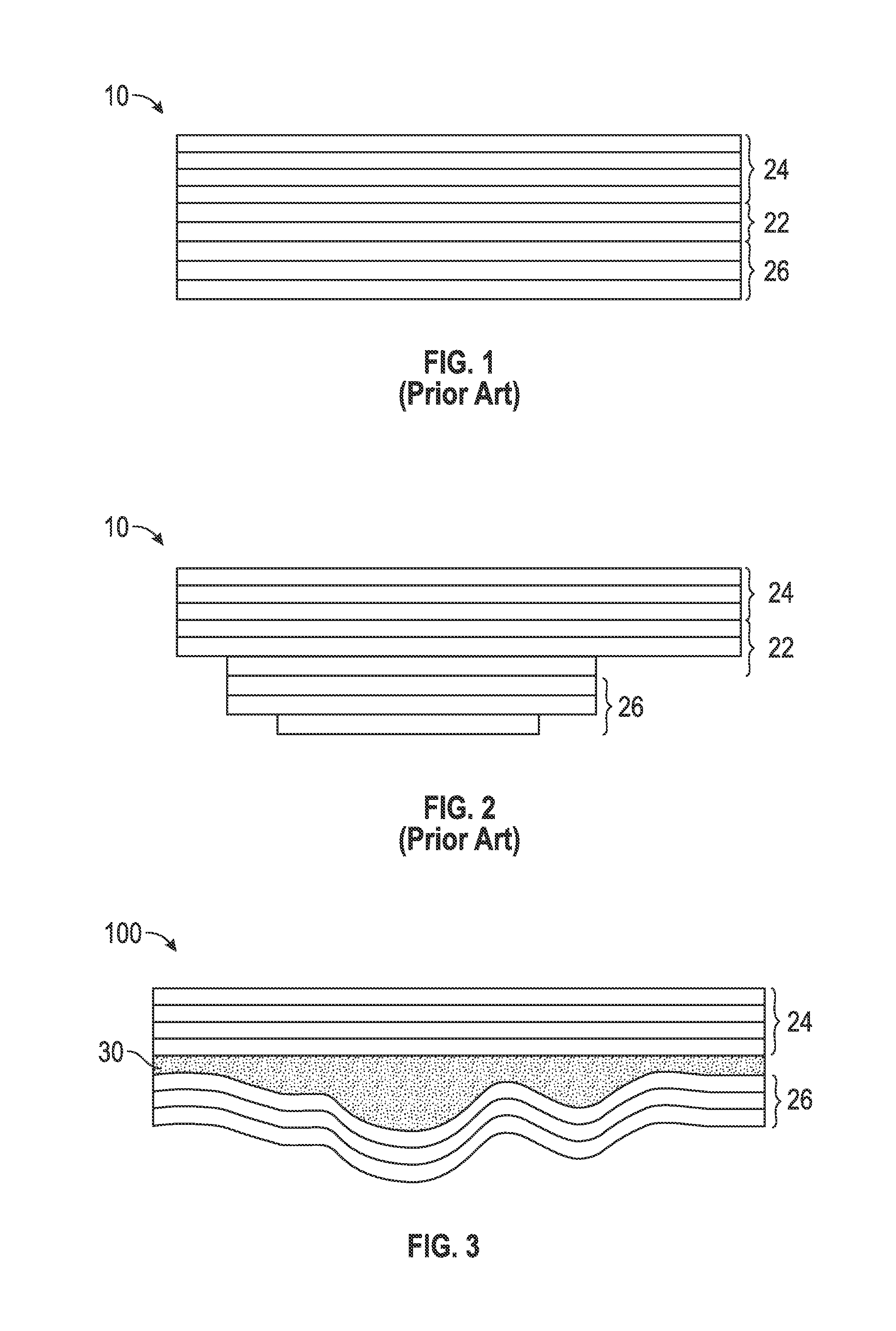

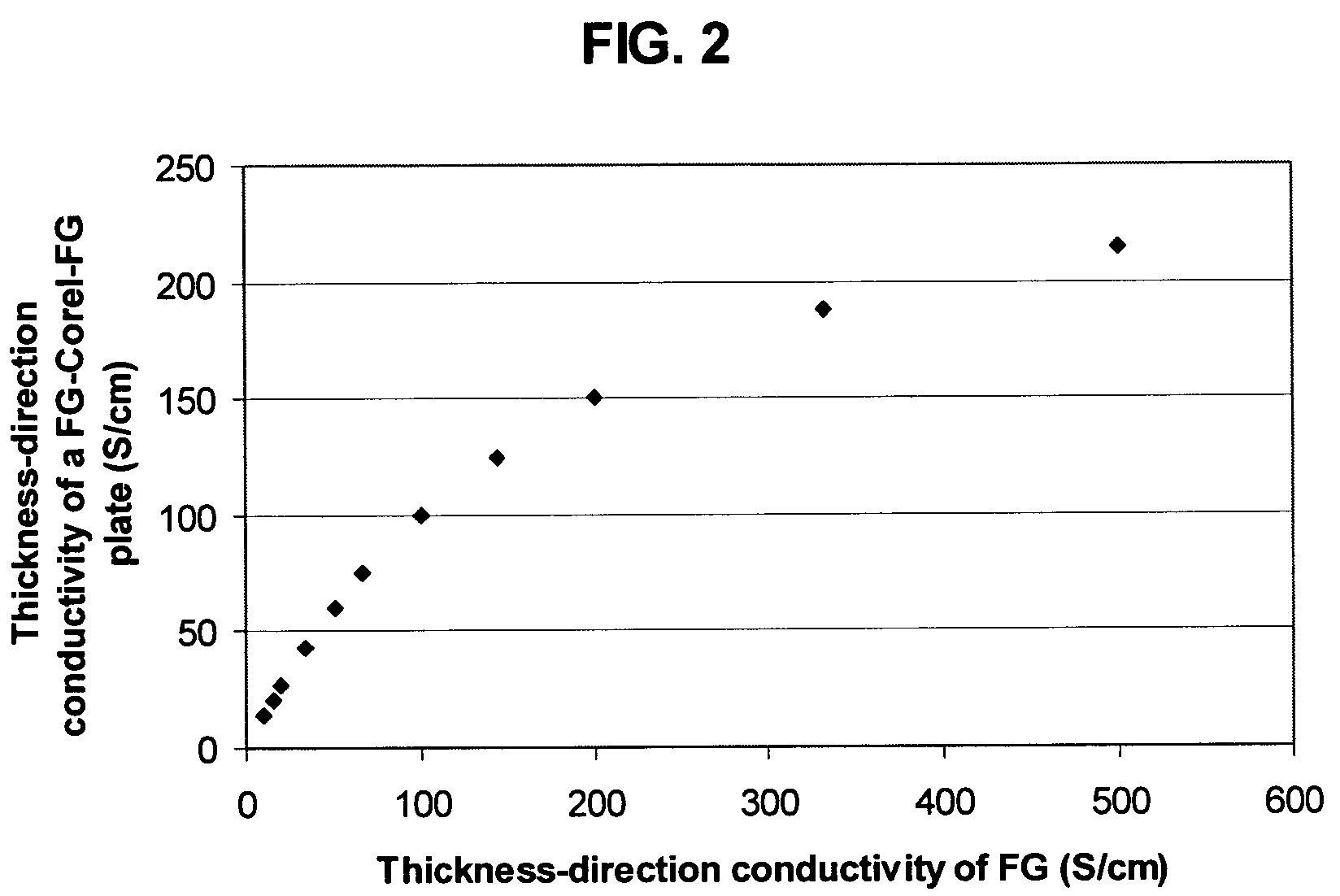

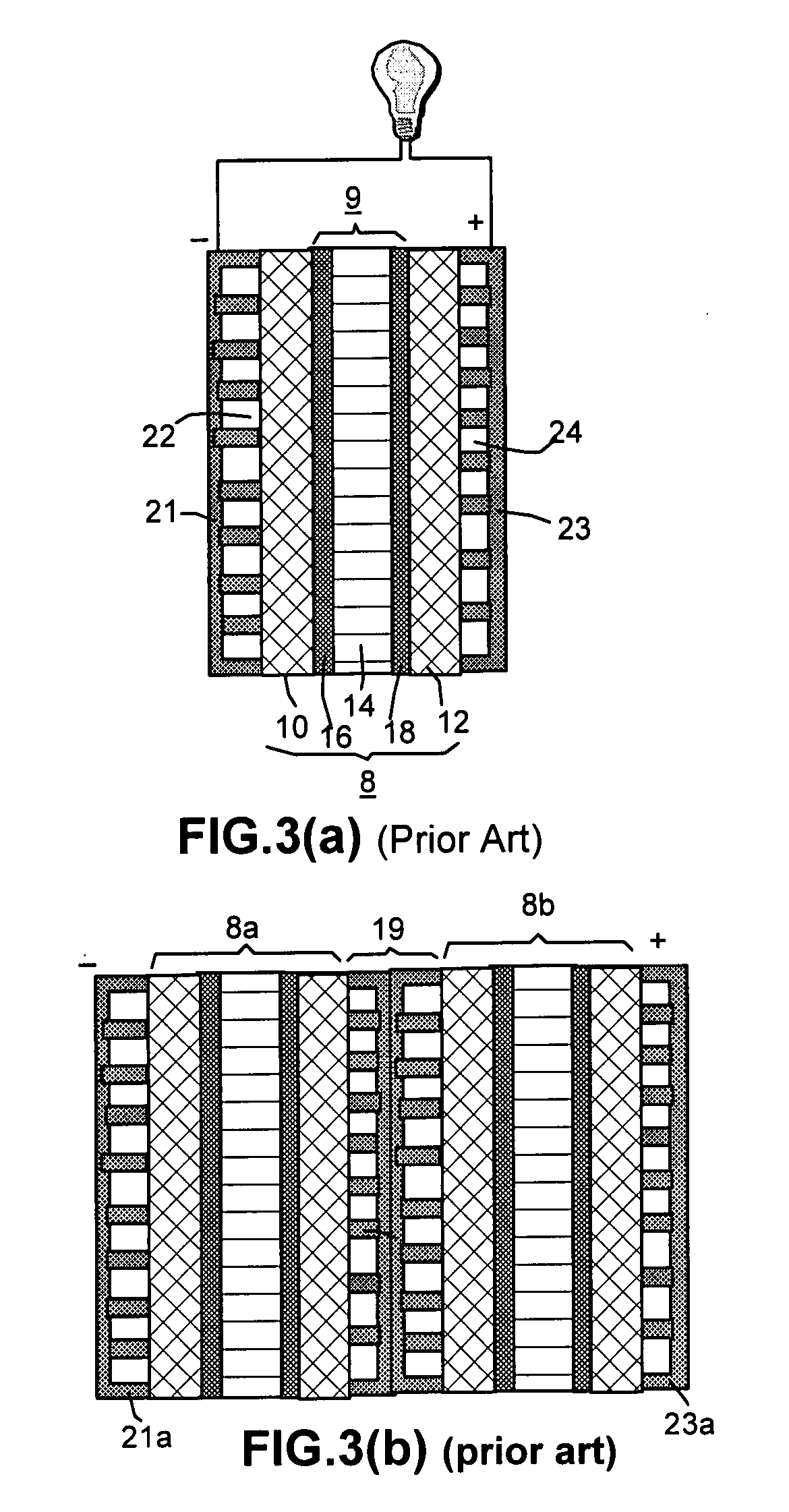

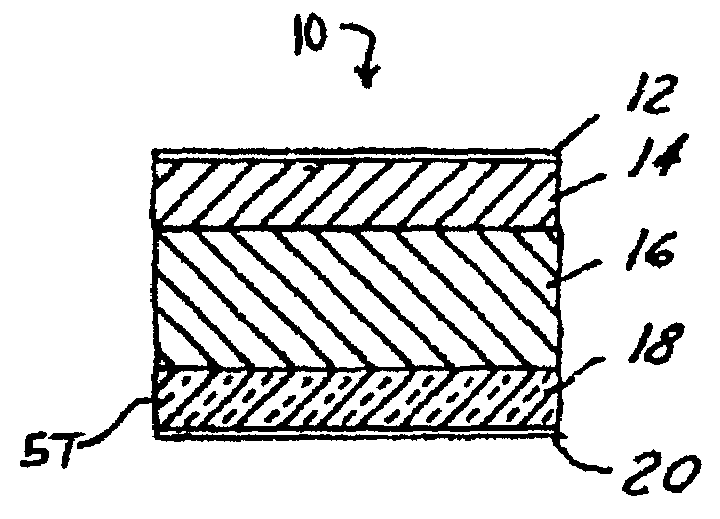

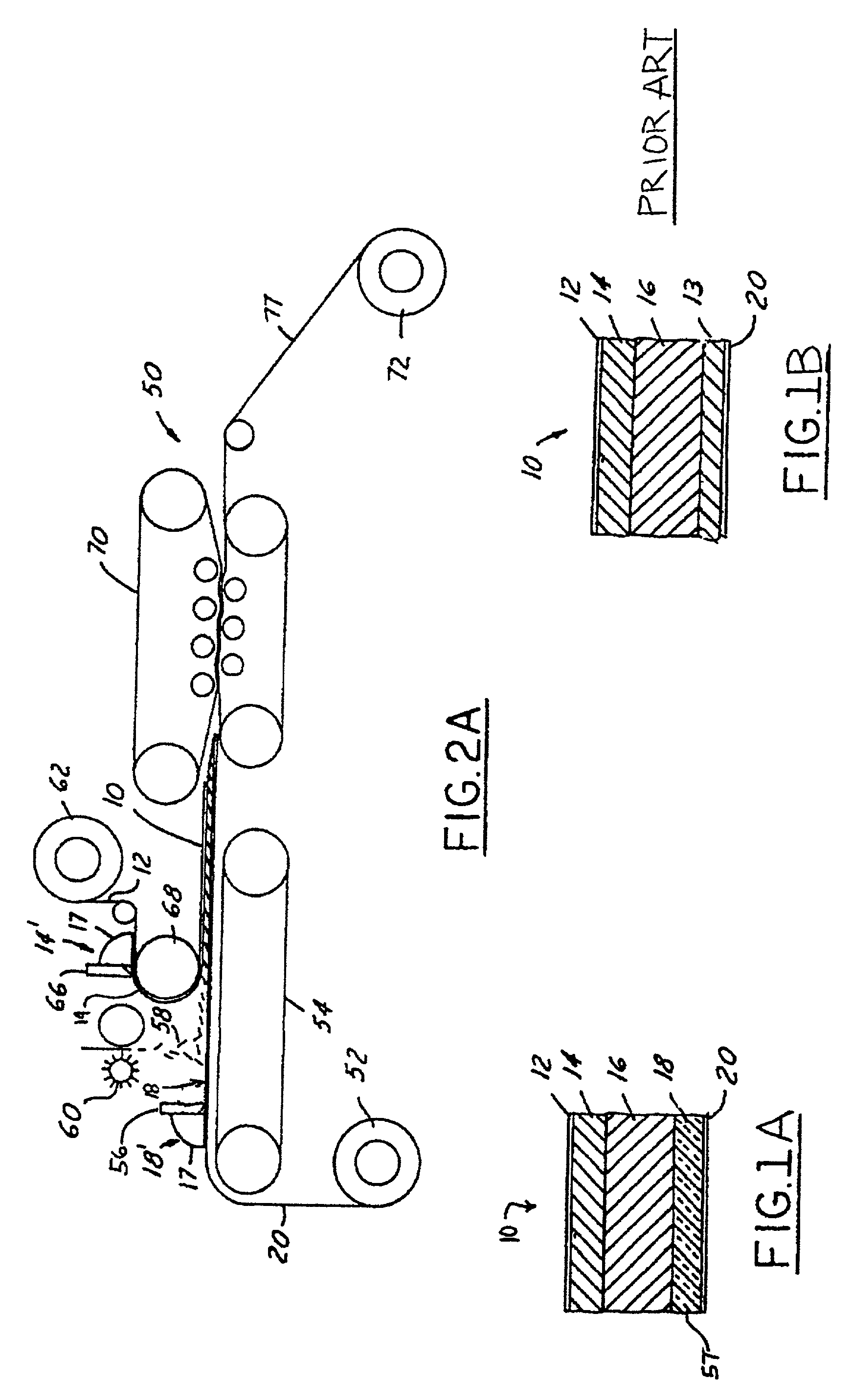

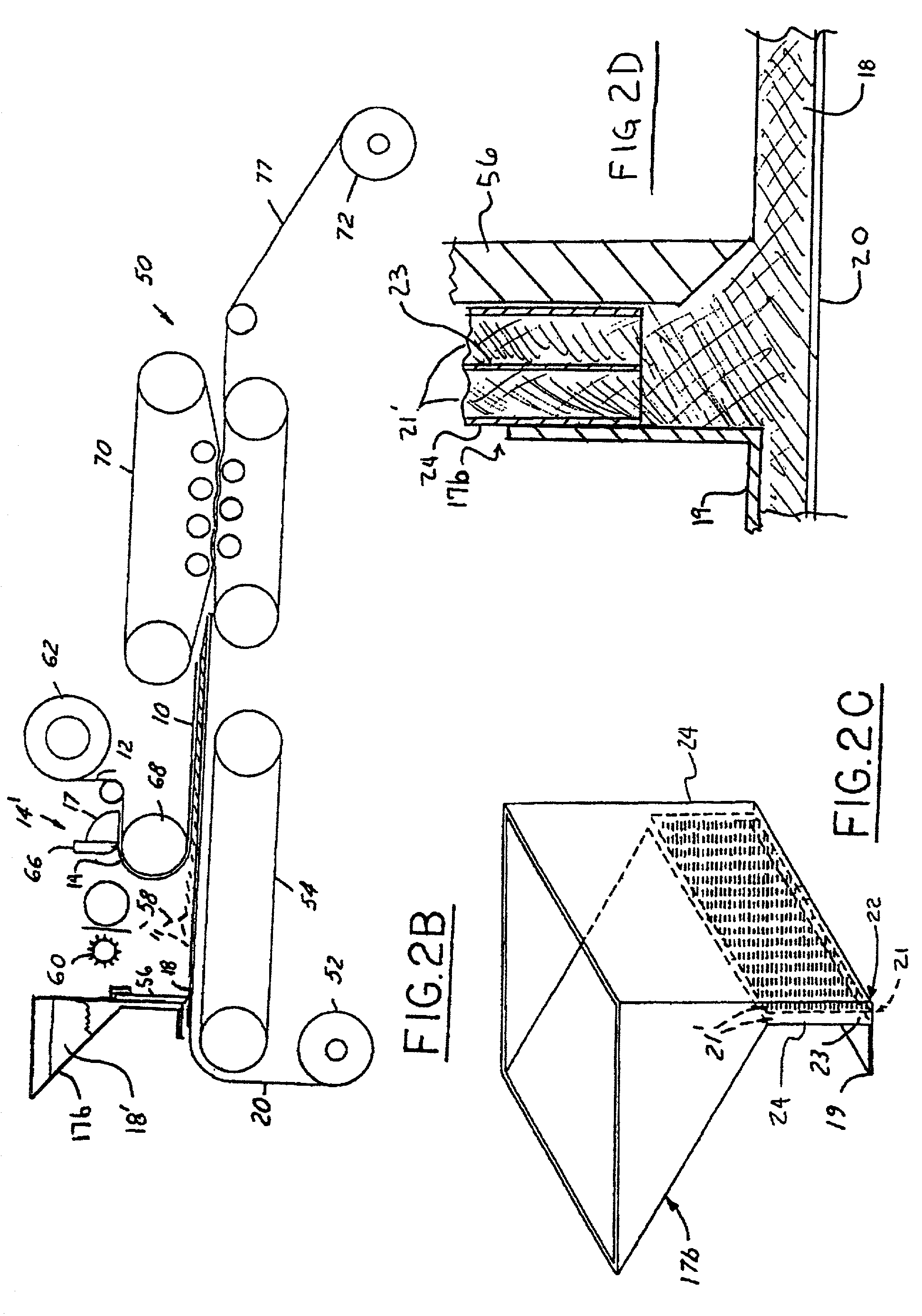

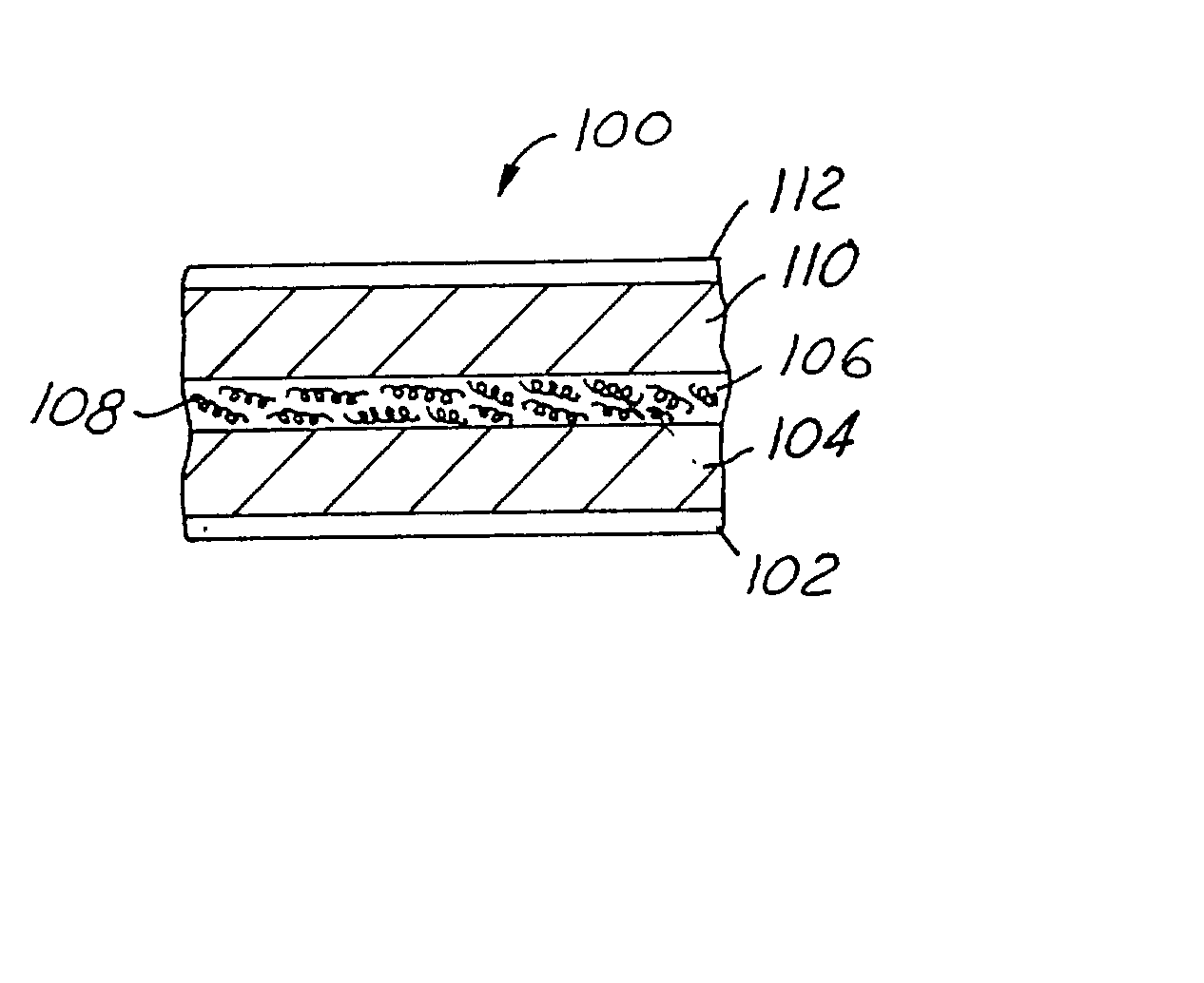

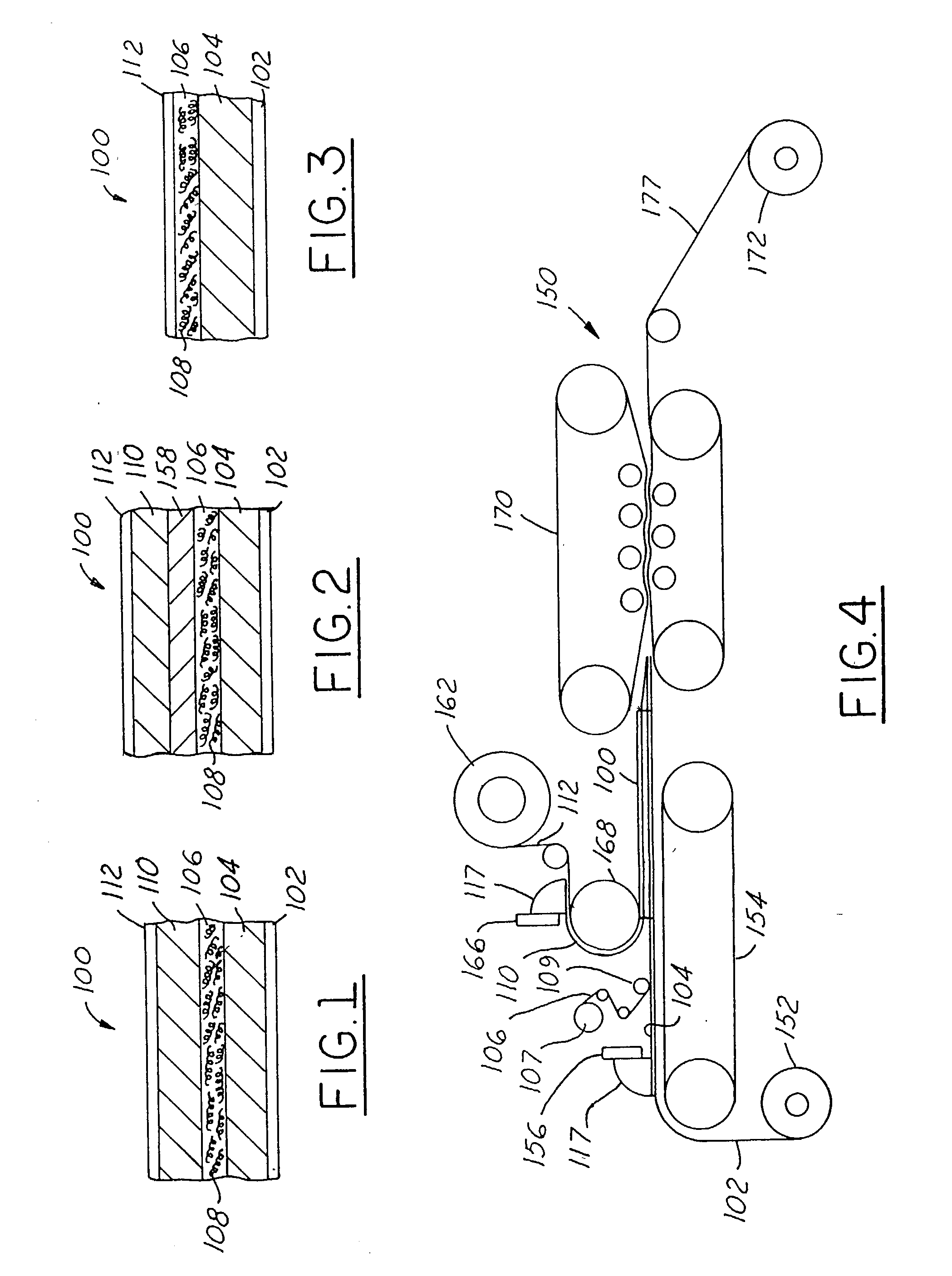

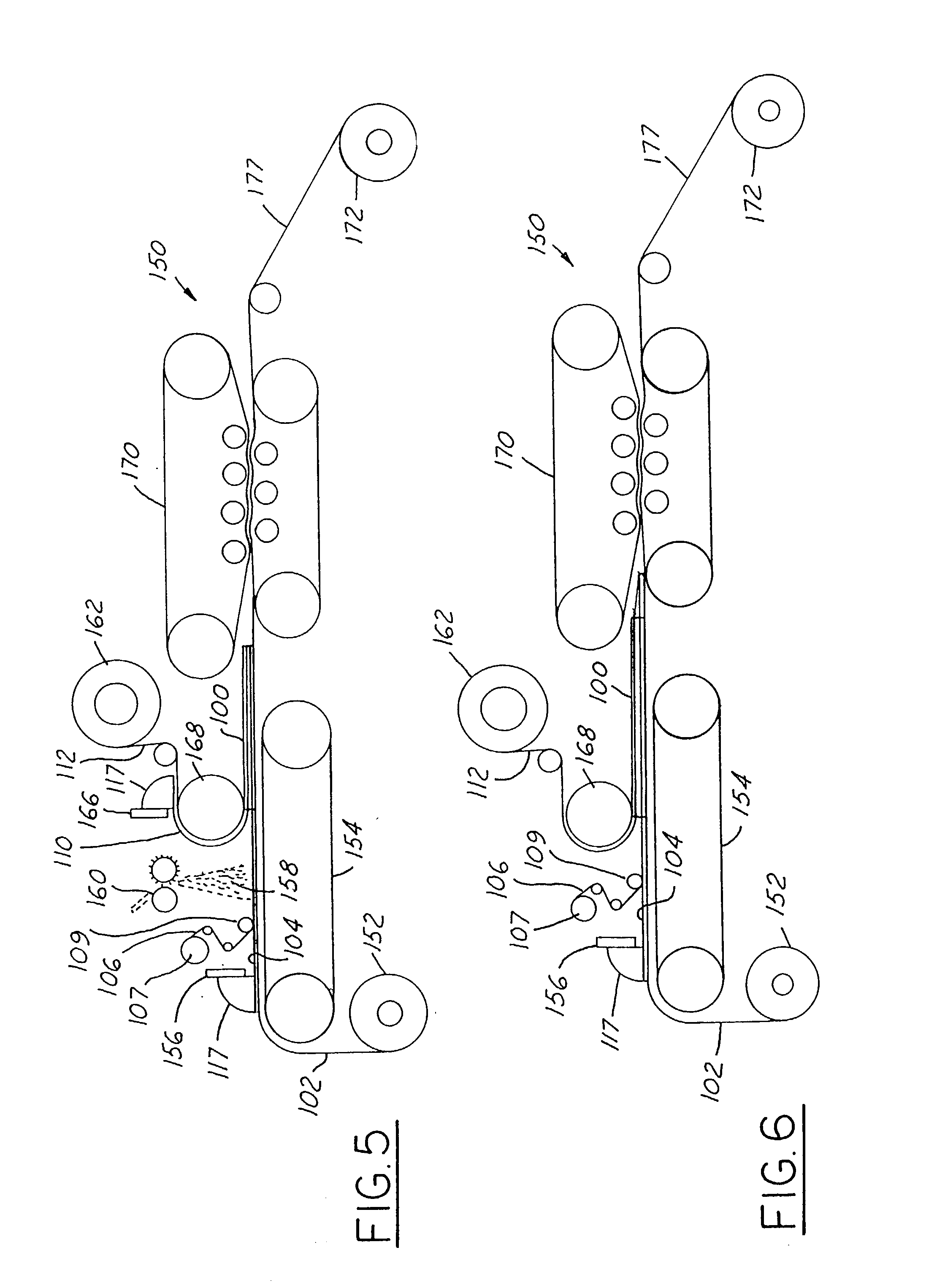

This invention provides a method of producing a highly electrically conductive sheet molding compound (SMC) composition and a fuel cell flow field plate or bipolar plate made from such a composition. The plate exhibits a conductivity typically greater than 100 S / cm and more typically greater than 200 S / cm. In one preferred embodiment, the method comprises: (a) providing a continuous sheet of a substrate material (bottom sheet) and a continuous sheet of flexible graphite (top sheet) from respective rollers; (b) feeding a resin mixture (comprising a thermoset resin and a conductive filler) to a space between the top sheet and the bottom sheet in such a way that the resin mixture forms a uniform core layer sandwiched between the two sheets to obtain a laminated structure; (c) compressing the laminated structure to obtain a SMC composition having two opposite outer surfaces; and (e) impressing a fluid flow channel to either or both of the outer surfaces (e.g., via embossing or matched-die molding) and curing the thermoset resin to obtain the plate.

Owner:NANOTEK INSTR GRP LLC

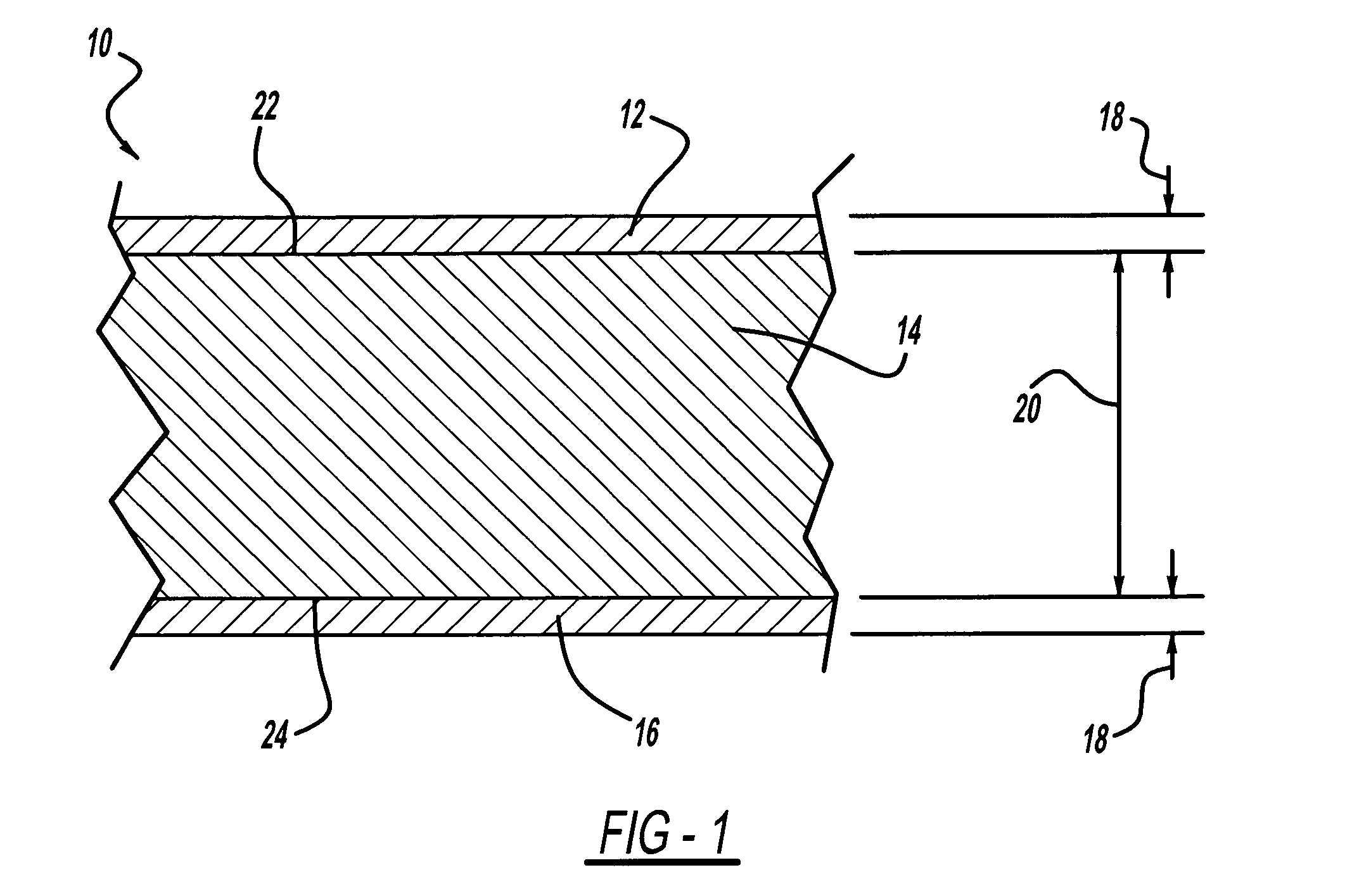

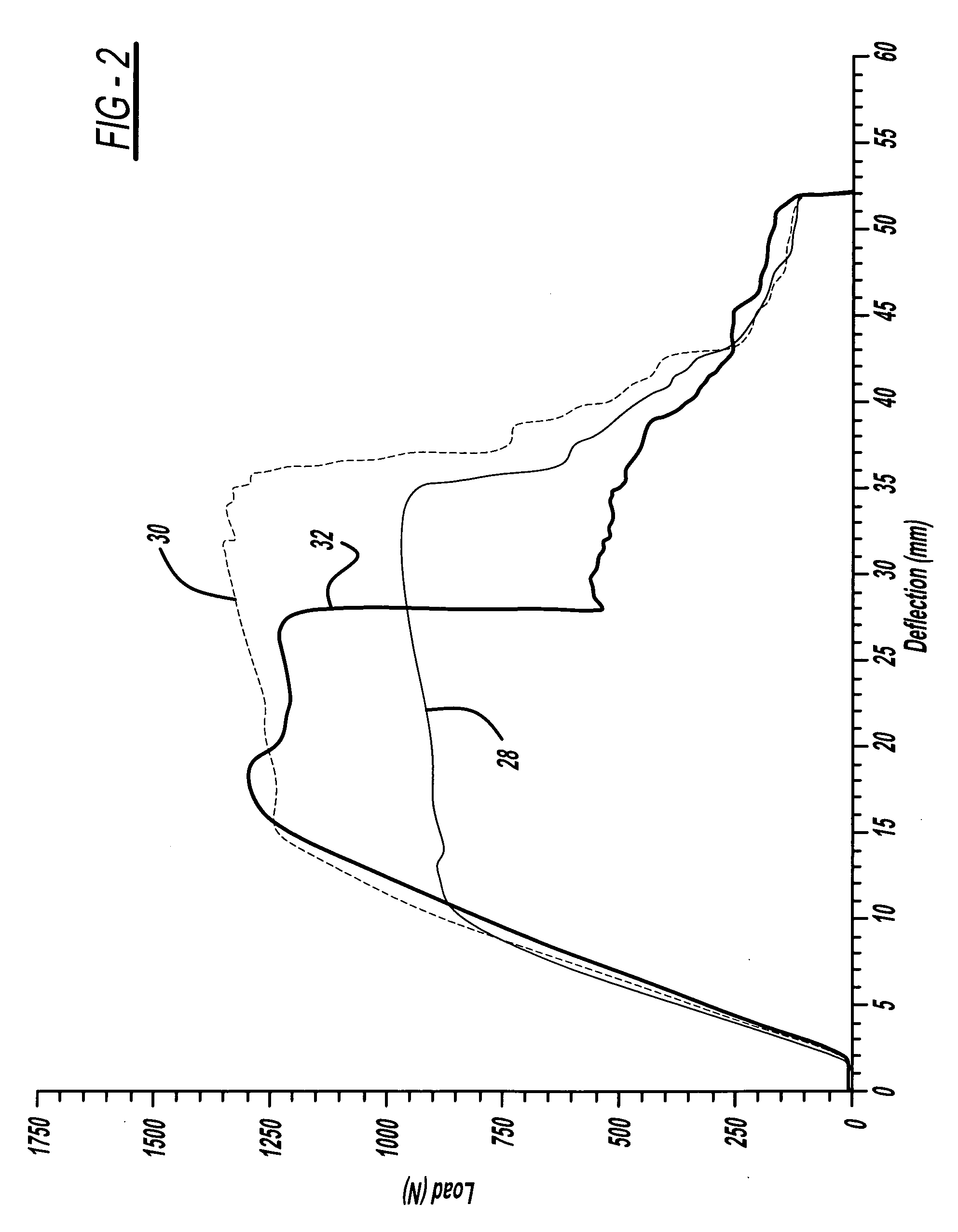

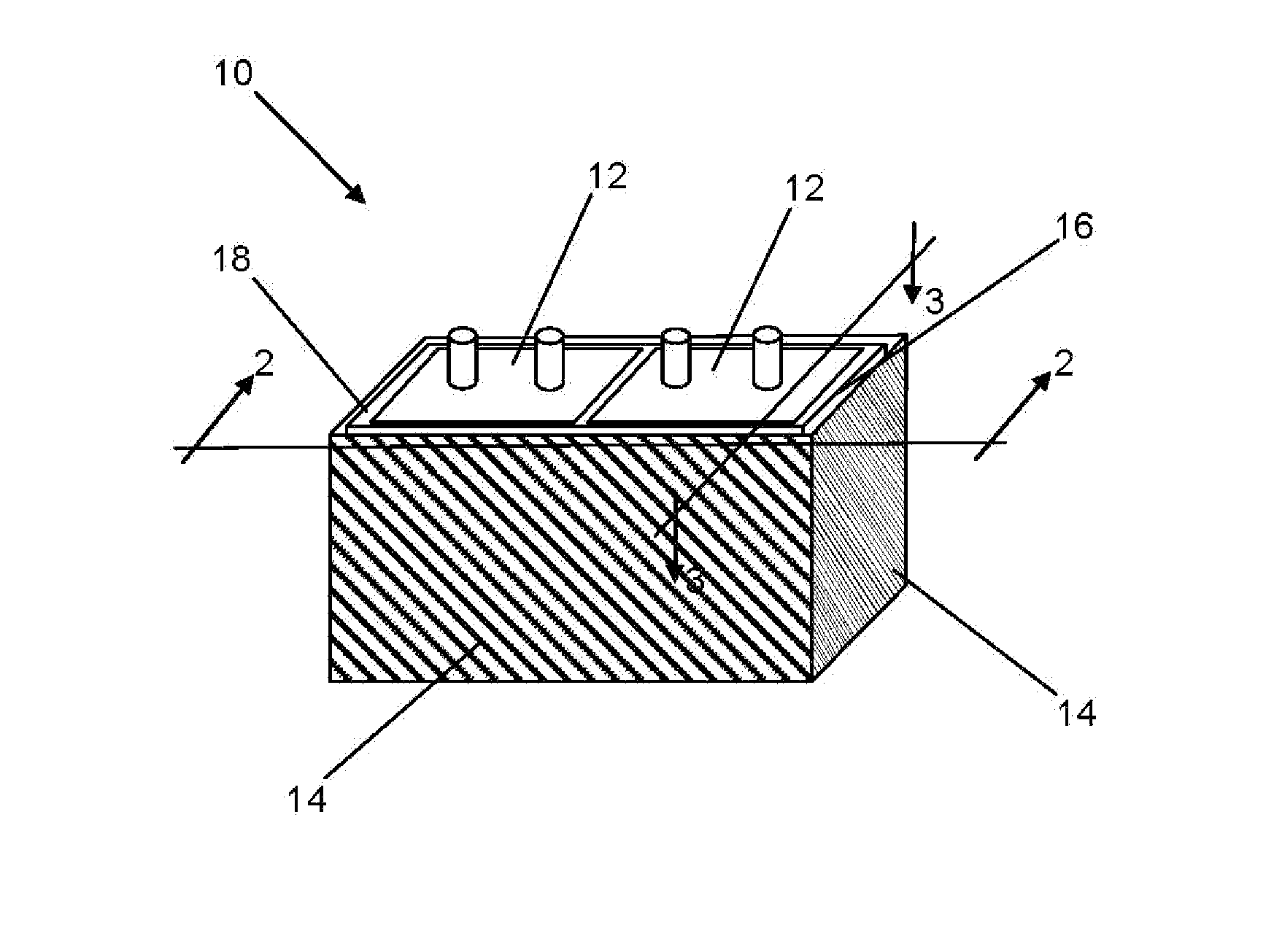

Sheet molding compound with cores

ActiveUS8992813B2Many layersStrength can be moreFinal product manufactureAnimal housingSheet moulding compoundEngineering

A component made of at least one thermoformable material, having a first layer made of a first material, a second layer made of a second material, and a third layer made of the first material. The three layers form a sheet, which is formed to various shapes, depending upon the part that is to be created. The sheet may be formed to produce the bumper of an automobile, a door panel for an automobile, a flotation device, such as a pontoon for a pontoon boat, or the like. The first and third layers are SMC, and the second layer, or “core,” is disposed between the first and third layers, allowing the strength of the first and third layers to be used more efficiently, compared to a sheet having only the first and third layers, and no core.

Owner:MAGNA INTERNATIONAL INC

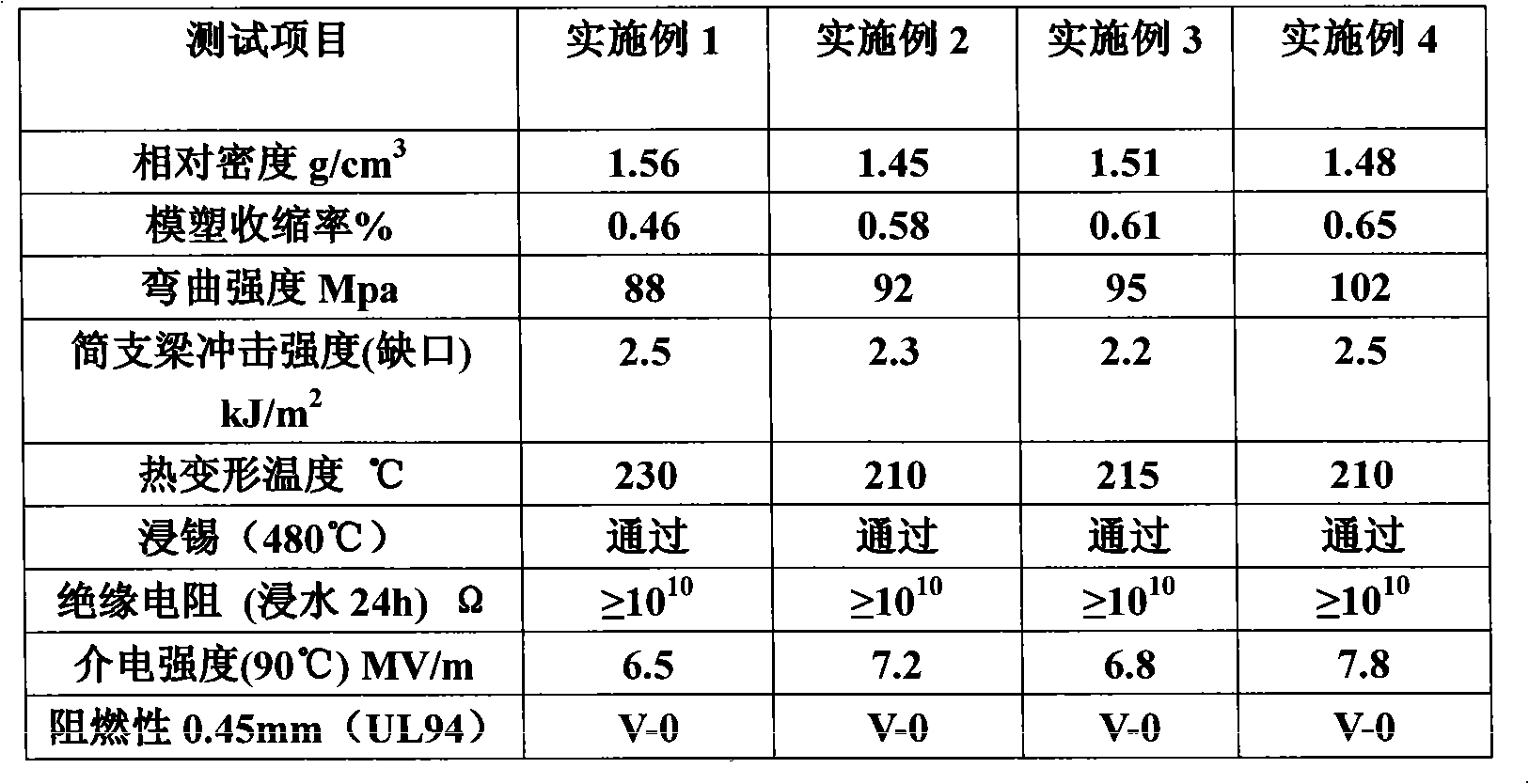

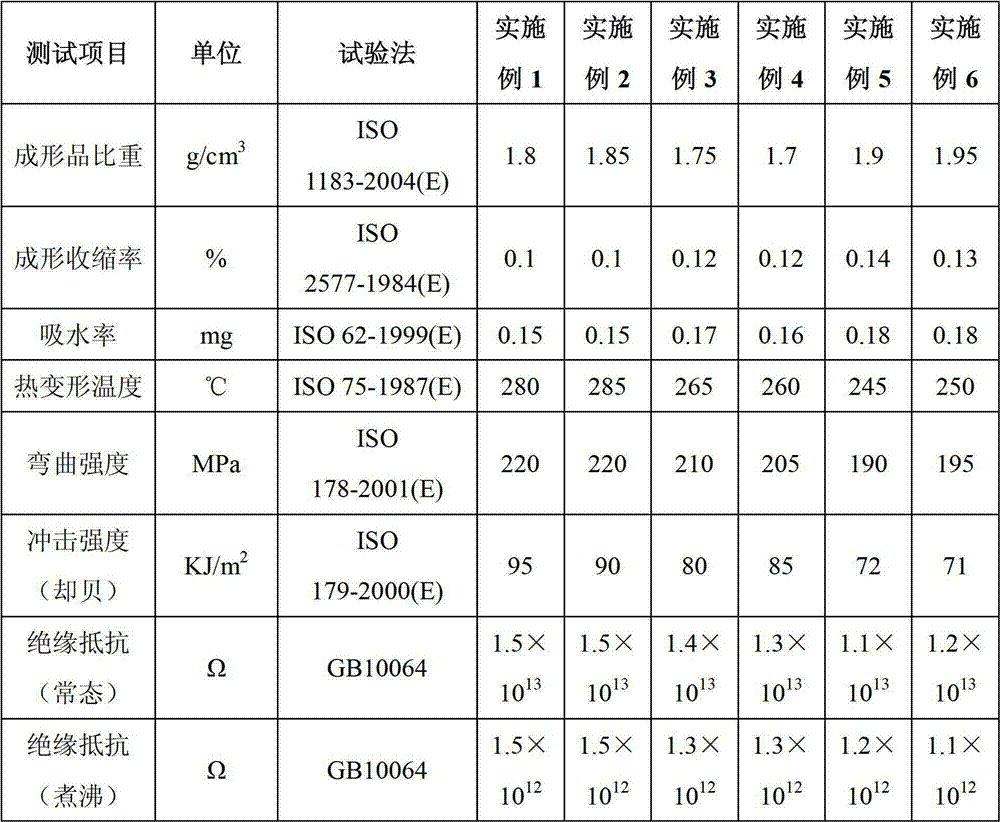

Heat-resisting phenolic moulding compound

The invention discloses a heat-resisting phenolic moulding compound belonging to the technical field of thermoset moulding compound. The heat-resisting phenolic moulding compound is composed of the following raw materials in parts by weight: 25-40 parts of phenolic resin, 2-10 parts of thermosetting resin, 3-8 parts of curing agent, 1-3 parts of accelerator, 15-40 parts of reinforcing fibre, 0.5-2 parts of interface modifier, 0.5-2.5 parts of releasing agent and 10-40 parts of inorganic filler. Because in the technical scheme of the invention, raw material selection is reasonable and the use amount of each raw material is proper, the invention can ensure that the eat-resisting phenolic moulding compound has excellent curing system and the flame retardant property reaches V-0 level. The heat-resisting phenolic moulding compound is suitable for manufacturing handles, handle knobs and the like of daily necessities, such as cookers and the like, can satisfy strict requirements on product heat resistance by electronic parts, electrical appliance parts, mechanical parts, automobile parts and the like, improves the adaptability of the moulding process, and can be moulded by injection and mould pressing.

Owner:常熟东南塑料有限公司

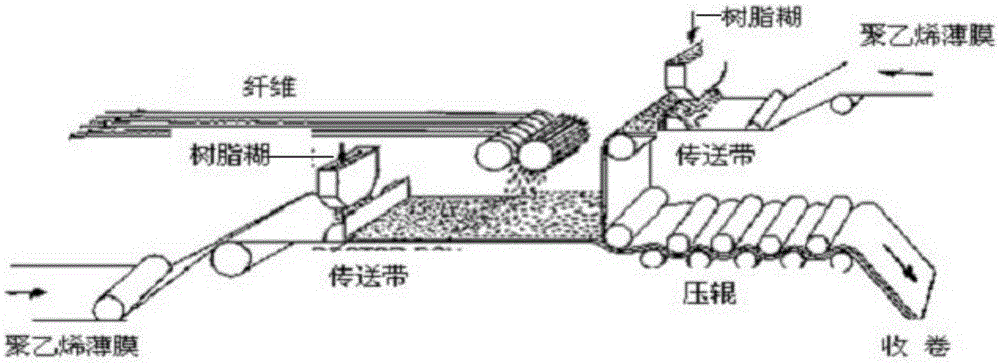

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

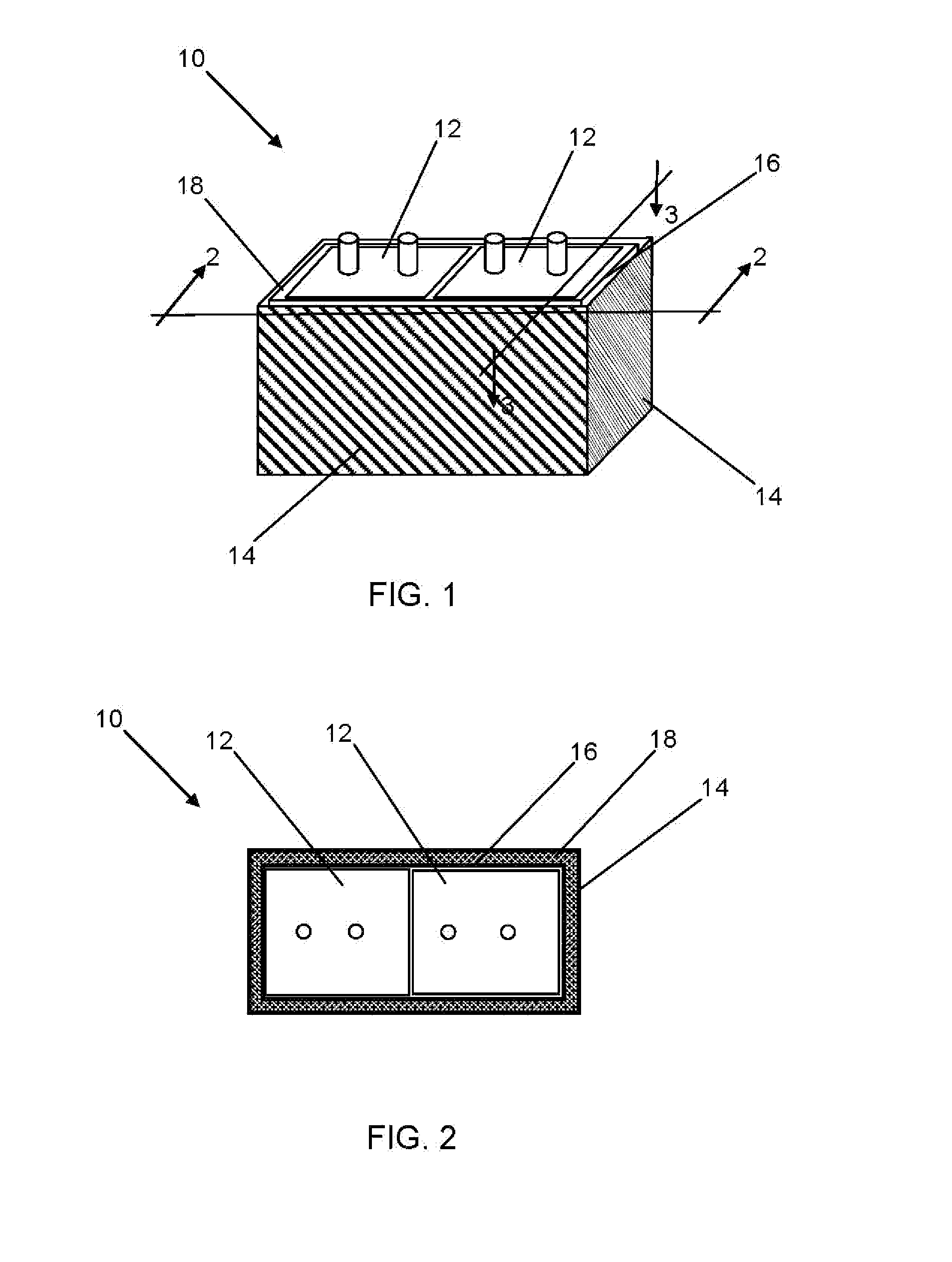

Energy cell temperature management

InactiveUS20140106198A1Heat storage plantsCell temperature controlSheet moulding compoundEngineering

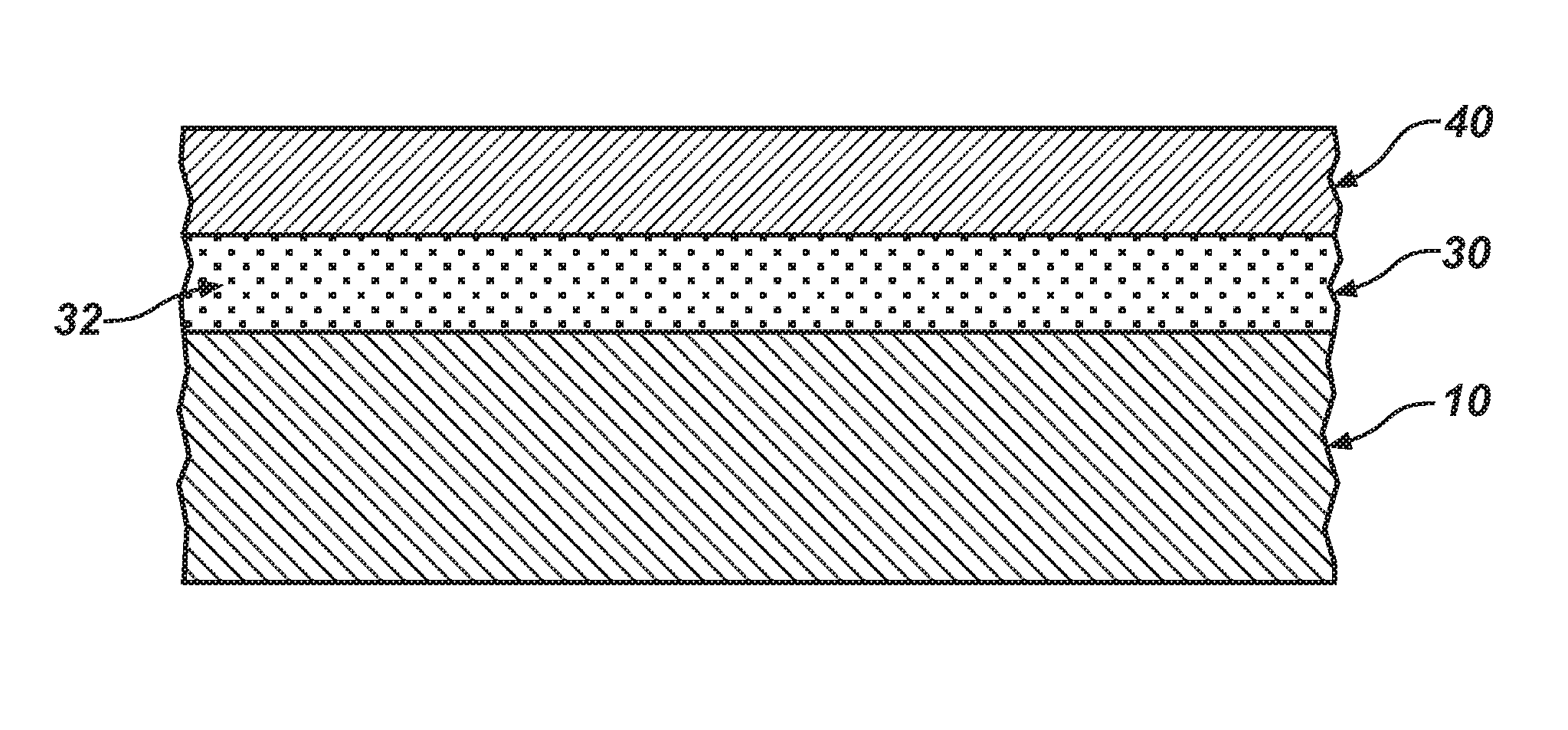

A temperature regulation and management system is provide that has an inner wall and an outer wall forming a space for accommodating a phase change material (PCM) with the space between the walls, in one or both of the walls, or a combination of such locations. The inner wall is in contact with an object that requires temperature regulation within a specified operating range, such as a vehicle battery pack. The inner wall and the outer wall are both formed from sheet molding compound (SMC), or the outer wall if formed of a filled polyurethane.

Owner:CONTINENTAL STRUCTURAL PLASTICS INC

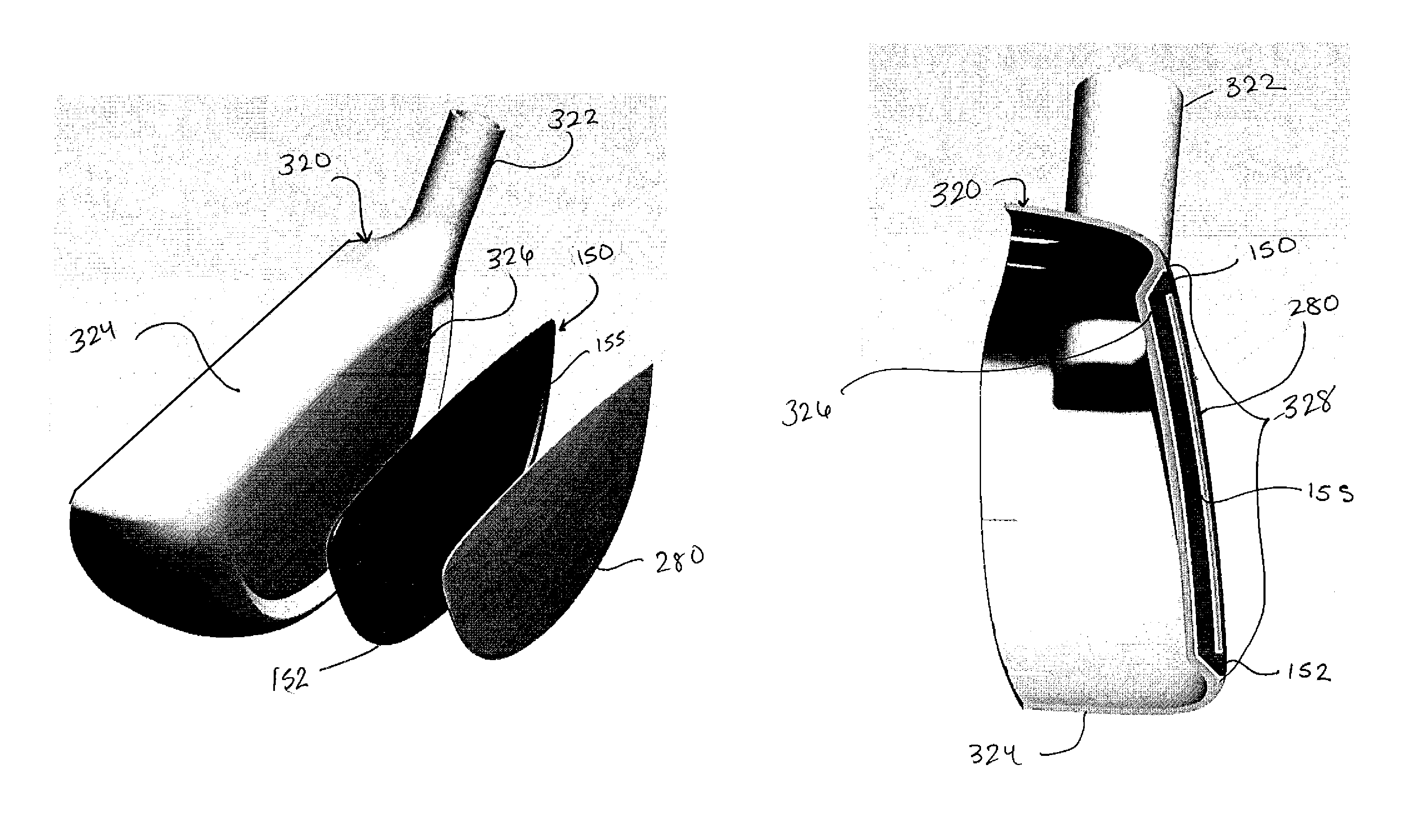

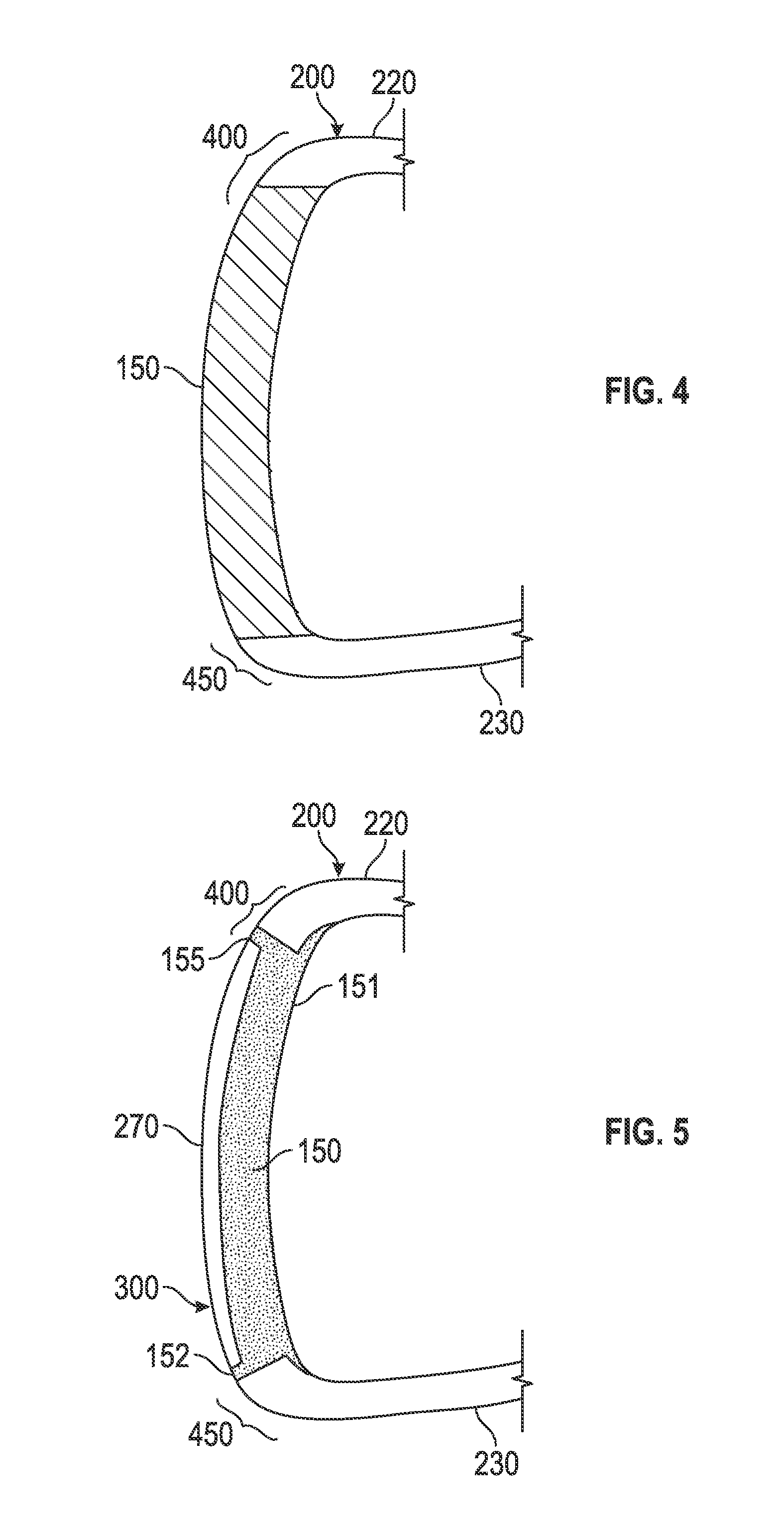

Golf club head with composite face

A novel material comprising collections of prepreg plies and a variable thickness core material such as sheet molding compound or metal, methods of forming said material, and golf clubs comprising said material are disclosed herein. Golf club heads having faces made of multiple materials, including a composite layer at least partially sandwiched between two metal layers, are also disclosed herein.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Recovering and treating method for glass fibre reinforced plastic waste

InactiveCN1554493ASmall particle sizeFix compatibility issuesSolid waste disposalGlass fiberSheet moulding compound

The recovering and treating method of waste glass fiber reinforced plastic is to treating waste glass fiber reinforced plastic into grains and to utilize the grains as the stuffing for sheet molding compound (SMC). The said method solves the problem of compatibility and adhesion of the waste with resin, reinforcing material and other components and makes SMC possess excellent mechanical performance.

Owner:TONGJI UNIV

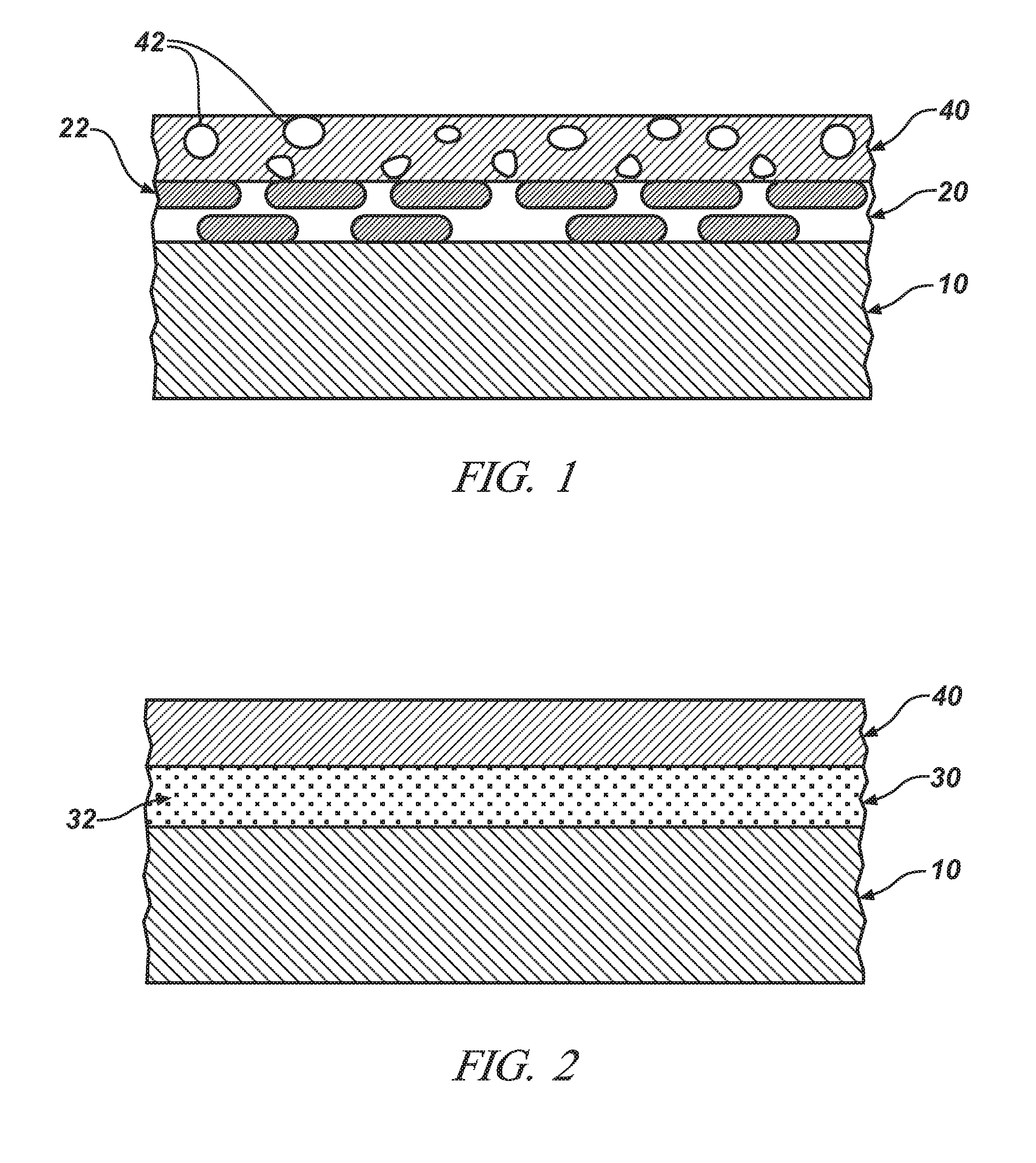

Coatings with organic polymeric fillers for molded SMC articles

Filler particles of a moisture-permeable, organic polymeric material are used in a polymeric coating composition, and this composition can be applied to a surface of a molded, fiber-reinforced polymeric material, such as sheet molding compound (SMC), to enable the electrostatic application of a layer of a powder primer to the same surface overlying the polymeric coating. And, when the molded SMC is heated to cure the powder primer layer, the out-gassing of moisture from the heated SMC does not result in defects on the surface of the molded SMC.

Owner:GM GLOBAL TECH OPERATIONS LLC

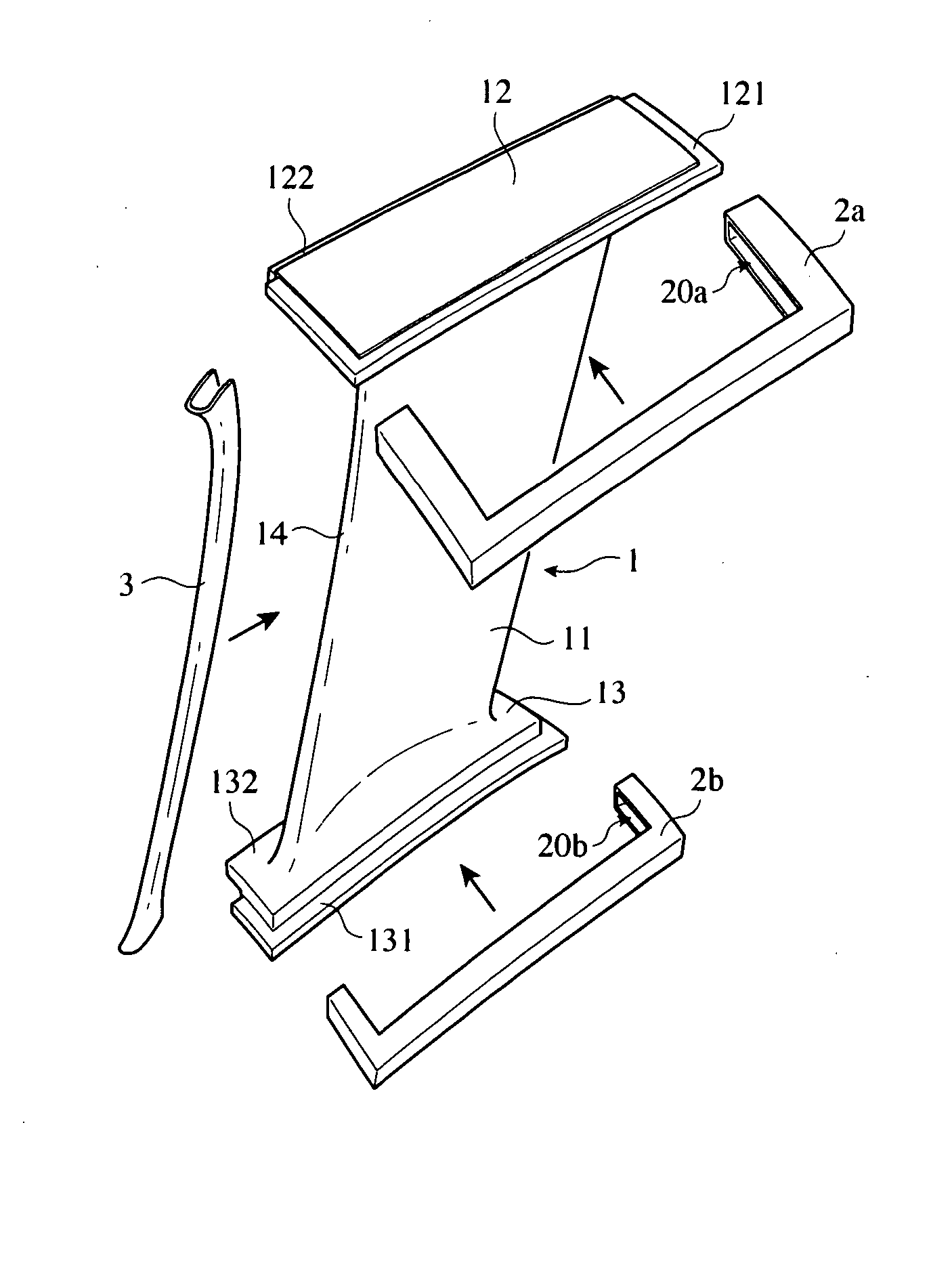

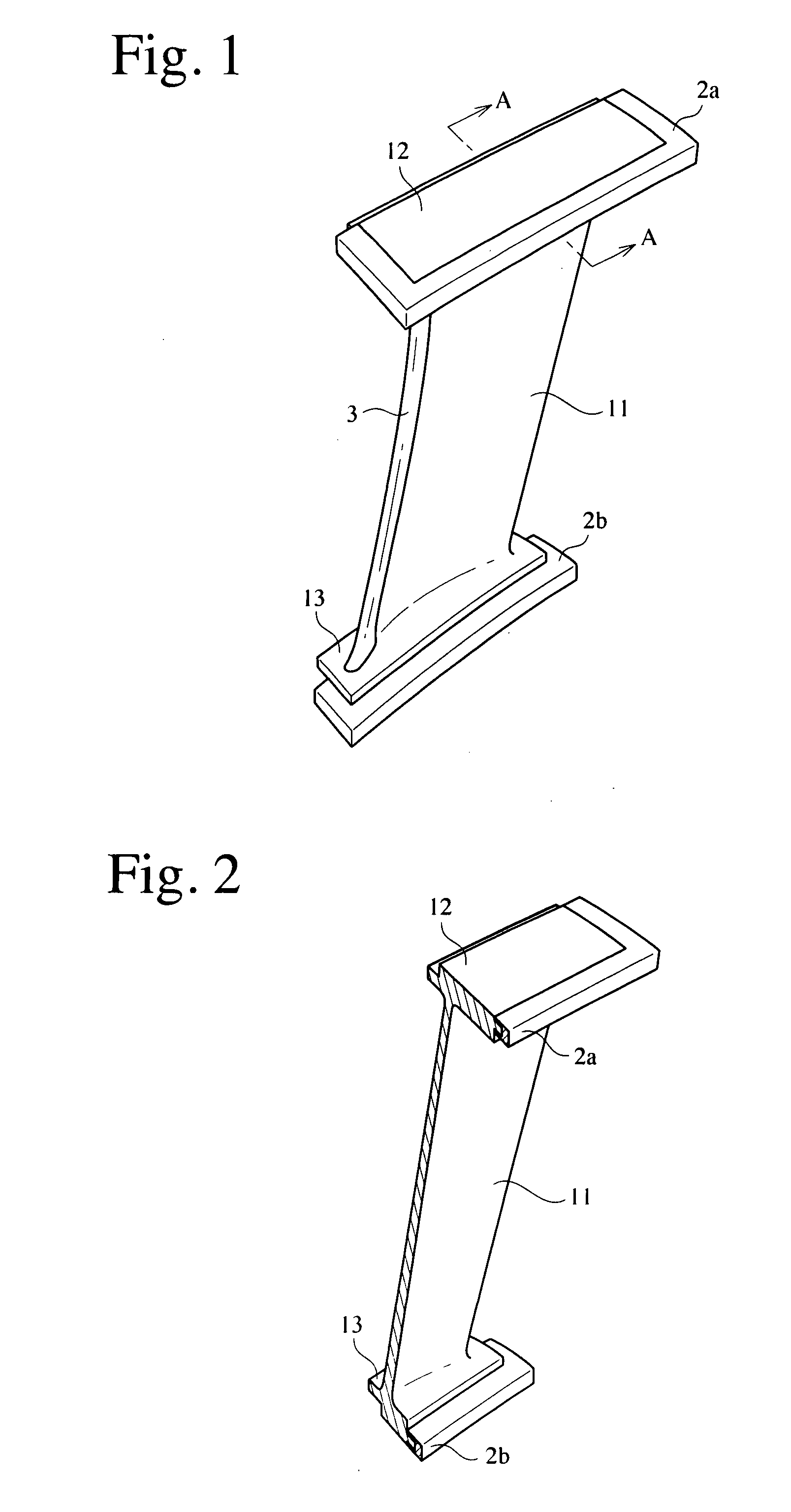

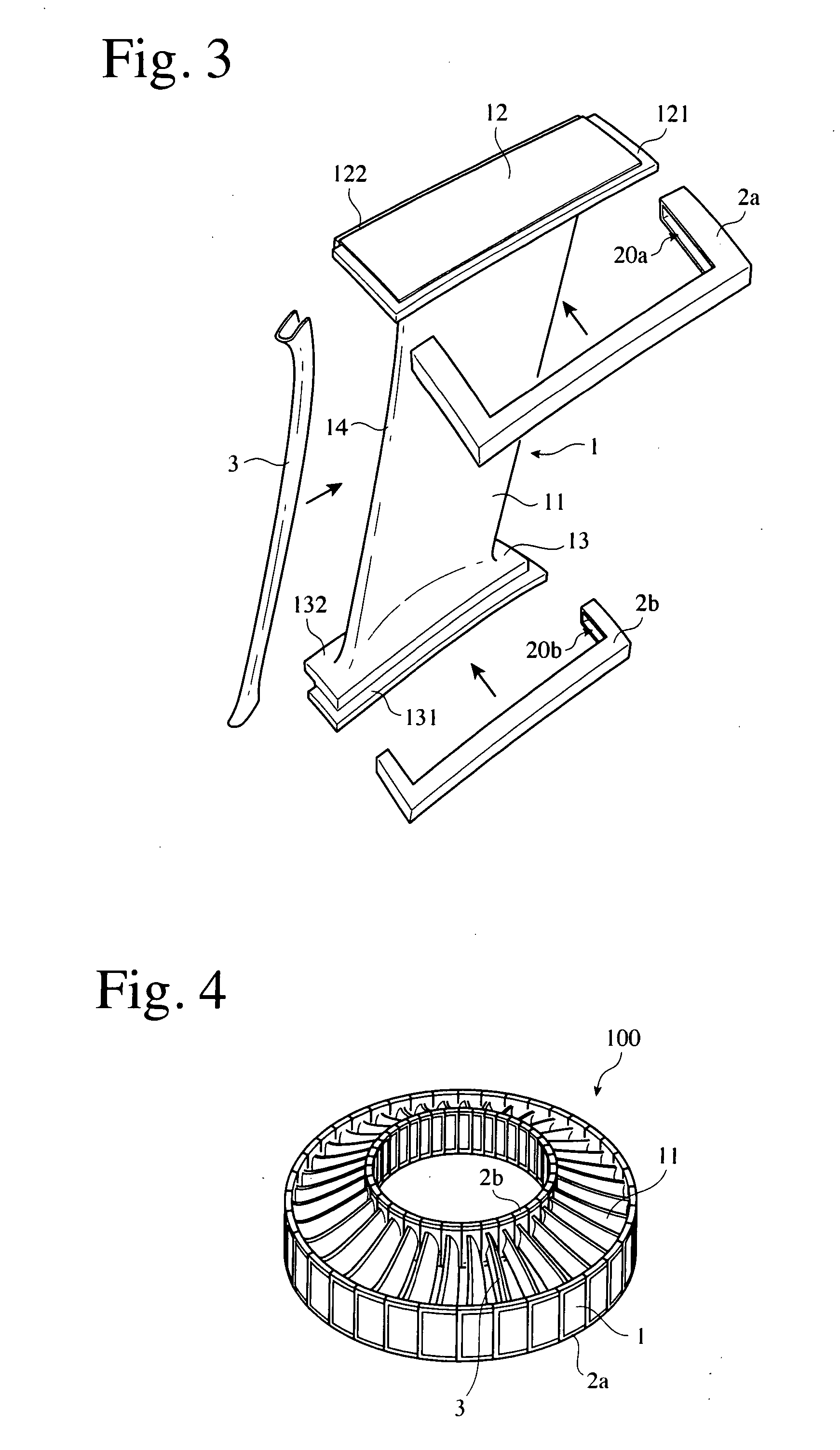

Flow-guiding member unit and its production method

ActiveUS20080038113A1High mechanical strengthEasy to replacePump componentsMouldsFiberThermoplastic elastomer

A flow-guiding member unit used for assembling a flow-guiding member comprising pluralities of vanes, an outer platform and an inner platform, the unit comprising an integral body member comprising one vane portion, an outer platform portion, and an inner platform portion, a first elastic member attached to a step of the outer platform portion, and a second elastic member attached to a step of the inner platform portion, the body member being formed by the thermal compression of sheet-molding compounds or fiber-reinforced resin pellets, and the first and second elastic members being made of a thermoplastic elastomer.

Owner:HONDA MOTOR CO LTD

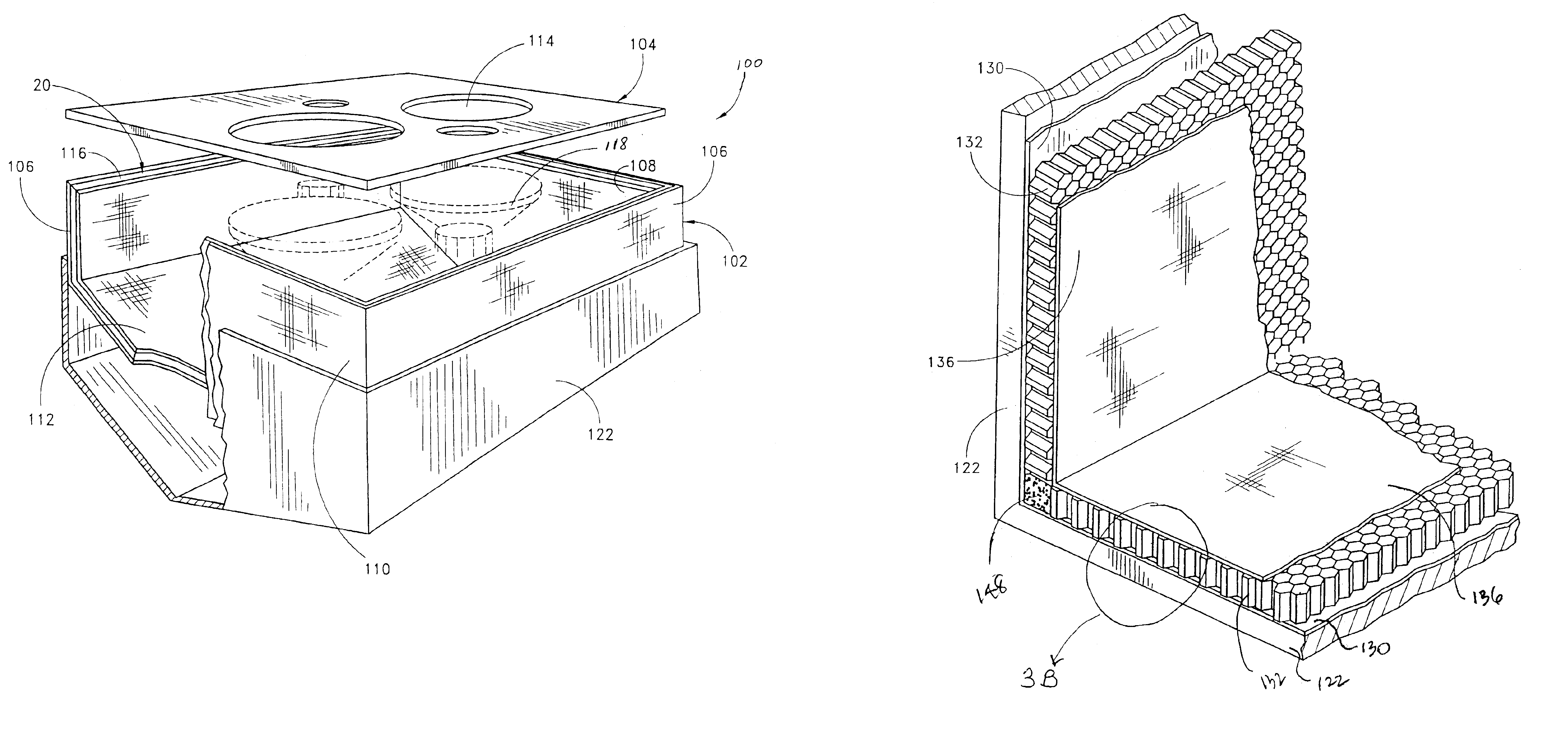

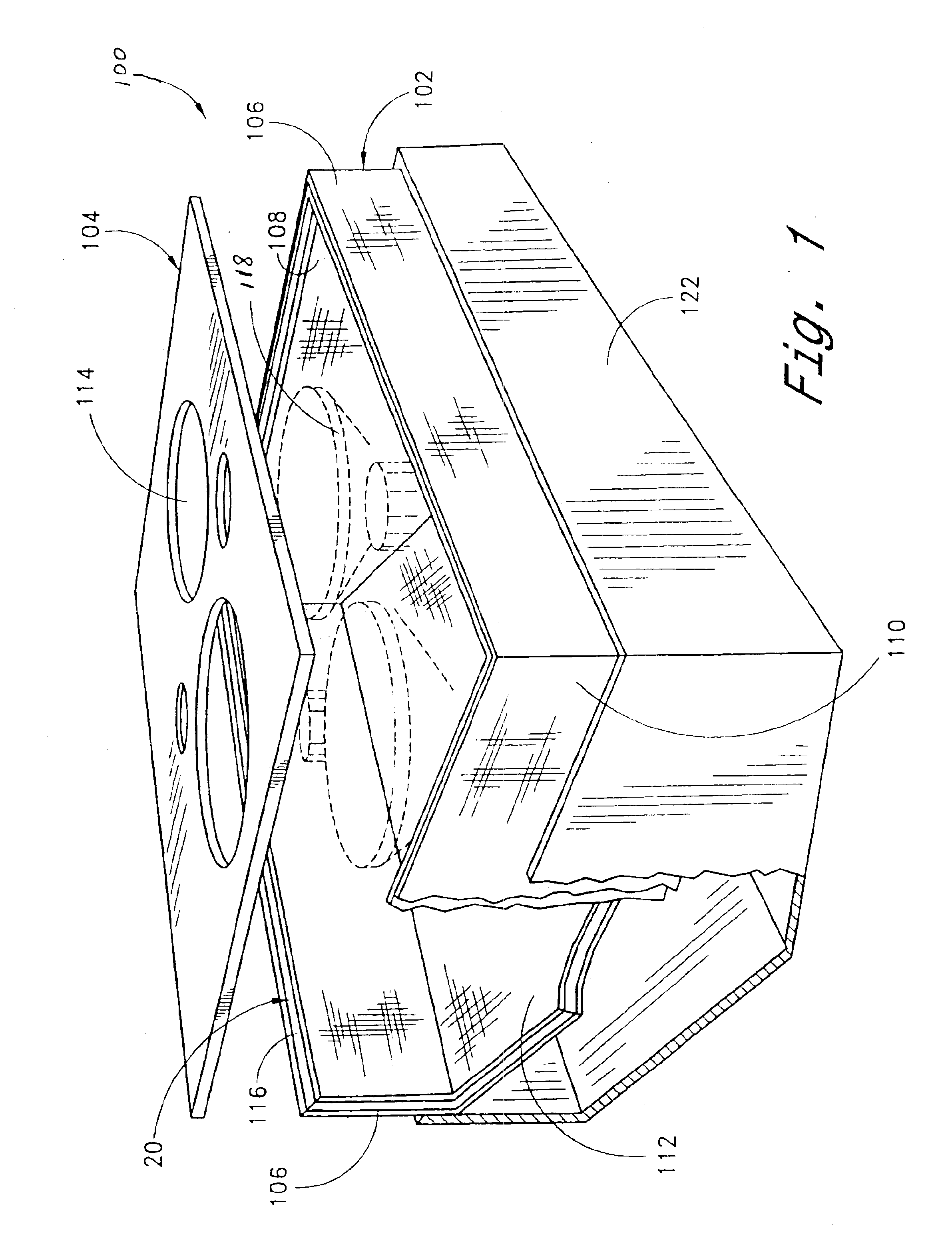

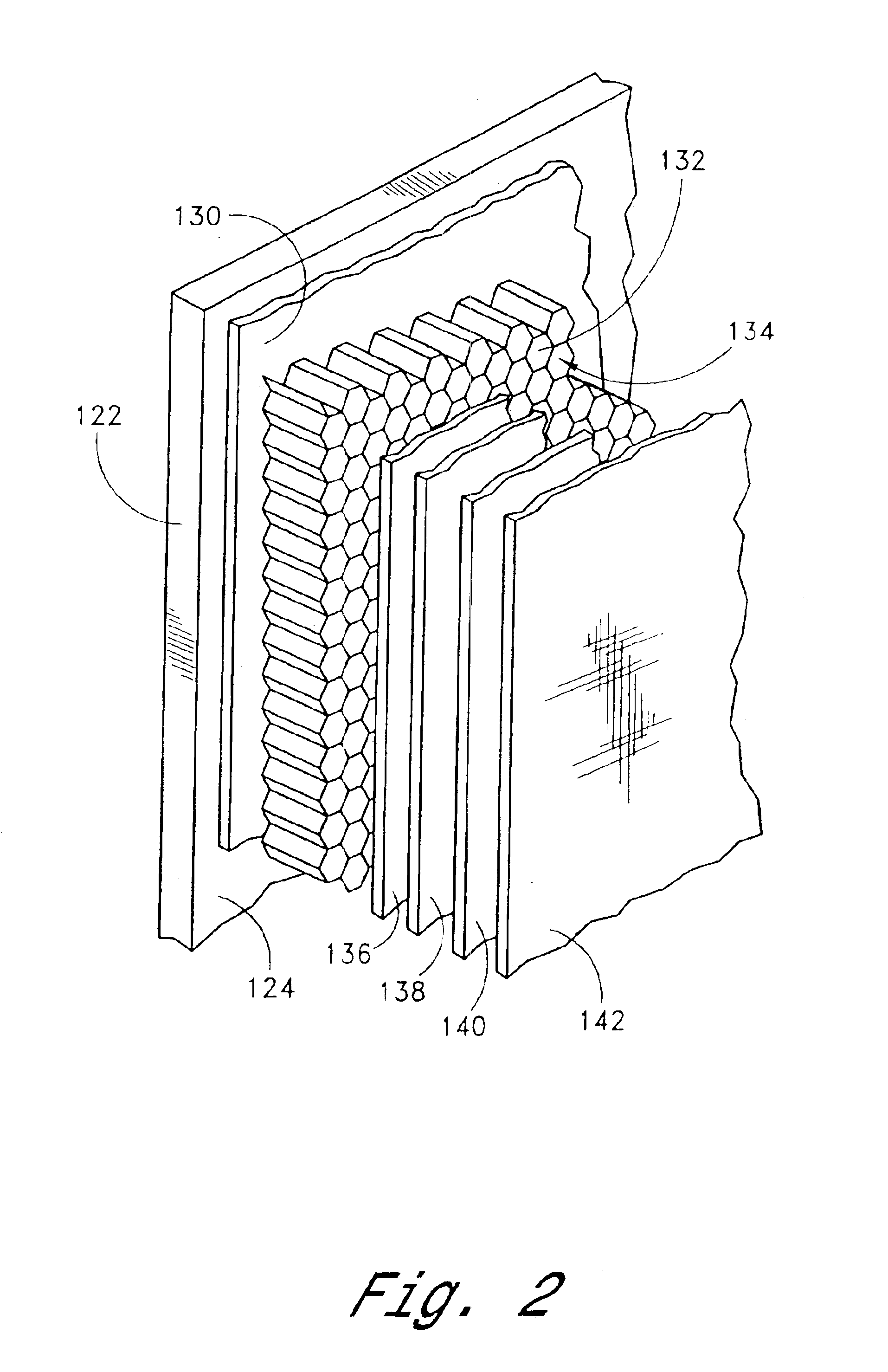

Lightweight speaker enclosure

A speaker enclosure having a substantially seamless rigid outer skin, a middle sound absorbing layer, and a substantially seamless inner skin results in a lightweight speaker having sound absorbing characteristics. The speaker enclosure is comprised of two basic parts, a box section and a baffle section where each of these sections include a rigid outer skin, the middle sound absorbing layer and a seamless inner skin and are made according to the same method. The outer skin is formed from a layer of sheet molding compound, the middle sound absorbing layer includes pieces of honeycomb material, and the inner skin is formed from a layer of sheet molding compound. The layers of material are placed into a mold and then cured through vacuum bagging and heating thereby producing a strong, lightweight speaker enclosure made of materials which attenuate the transmission and retransmission of errant sound waves in the enclosure thereby reducing distortion of the sound signal produced by the speaker.

Owner:SOUTHERN CALIFORNIA SOUND IMAGE

Sheet molding compound with high flame resistance, low smoke and non-toxic and preparation method thereof

InactiveCN101514254AFully dispersedImprove flame retardant performancePolymer scienceAluminium hydroxide

The invention relates to a sheet molding compound with high flame resistance, low smoke and non-toxic and a preparation method thereof. The formula of the sheet molding compound comprises the following substance in mass portion: 50-80 portions of unsaturated polyester resin, 15-60 portions of low shrink additive, 1-3 portions of evocating agent, 0.01-0.05 portions of polymerization inhibitor, 0.7-7 portions of wetting and dispersing agent, 3-8 potions of inner mold release agent, 1-2 potions of thickening agent, 20-50 potions of viscosity reduction filler, 100-200 portions of flame retardant A, 50-100 portions of flame retardant B and 50-250 portions of reinforced material; the flame retardant A is micron aluminum hydroxide and the grain diameter is 0.4-3.5 microns; the flame retardant B is nanometer aluminum hydroxide and the grain diameter is 30-80 nanometers. The sheet molding compound of the invention has the advantages of high flame resistance, low smoke and non-toxic, well mechanical performance and surface decorative effect.

Owner:BEIJING ZHONGTIE LONGDRAGON ADVANCED COMPOSITE MATERIAL

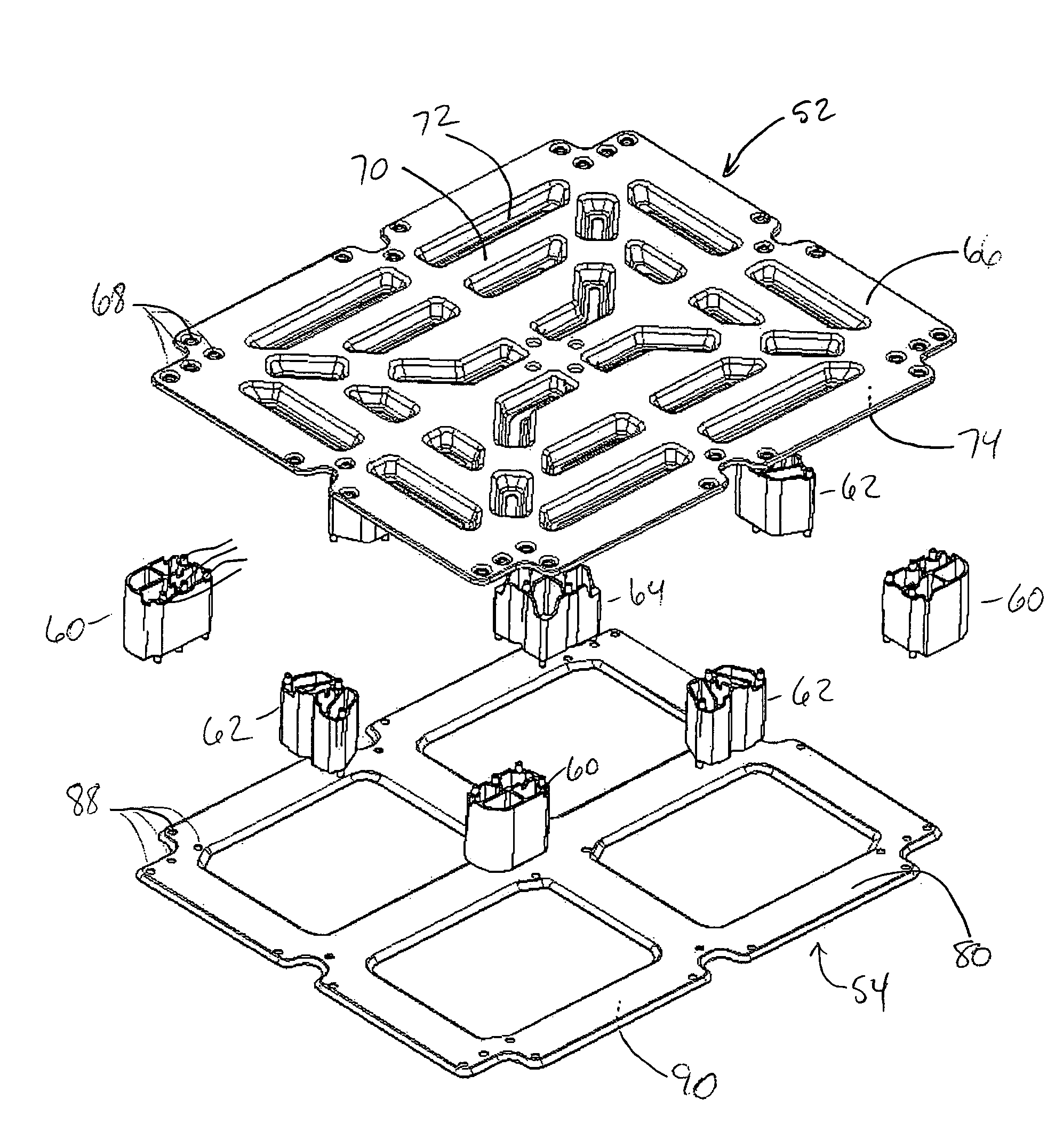

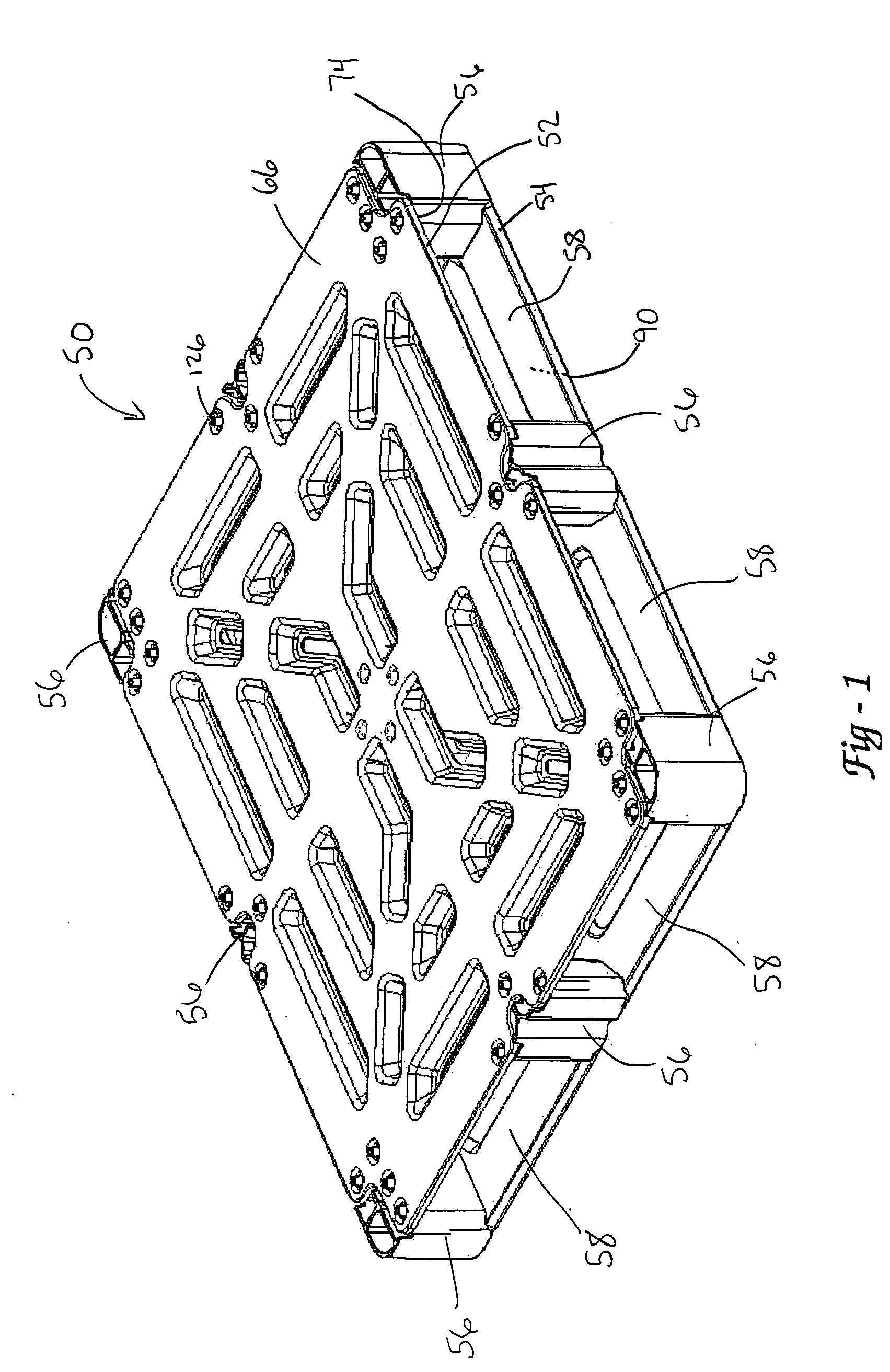

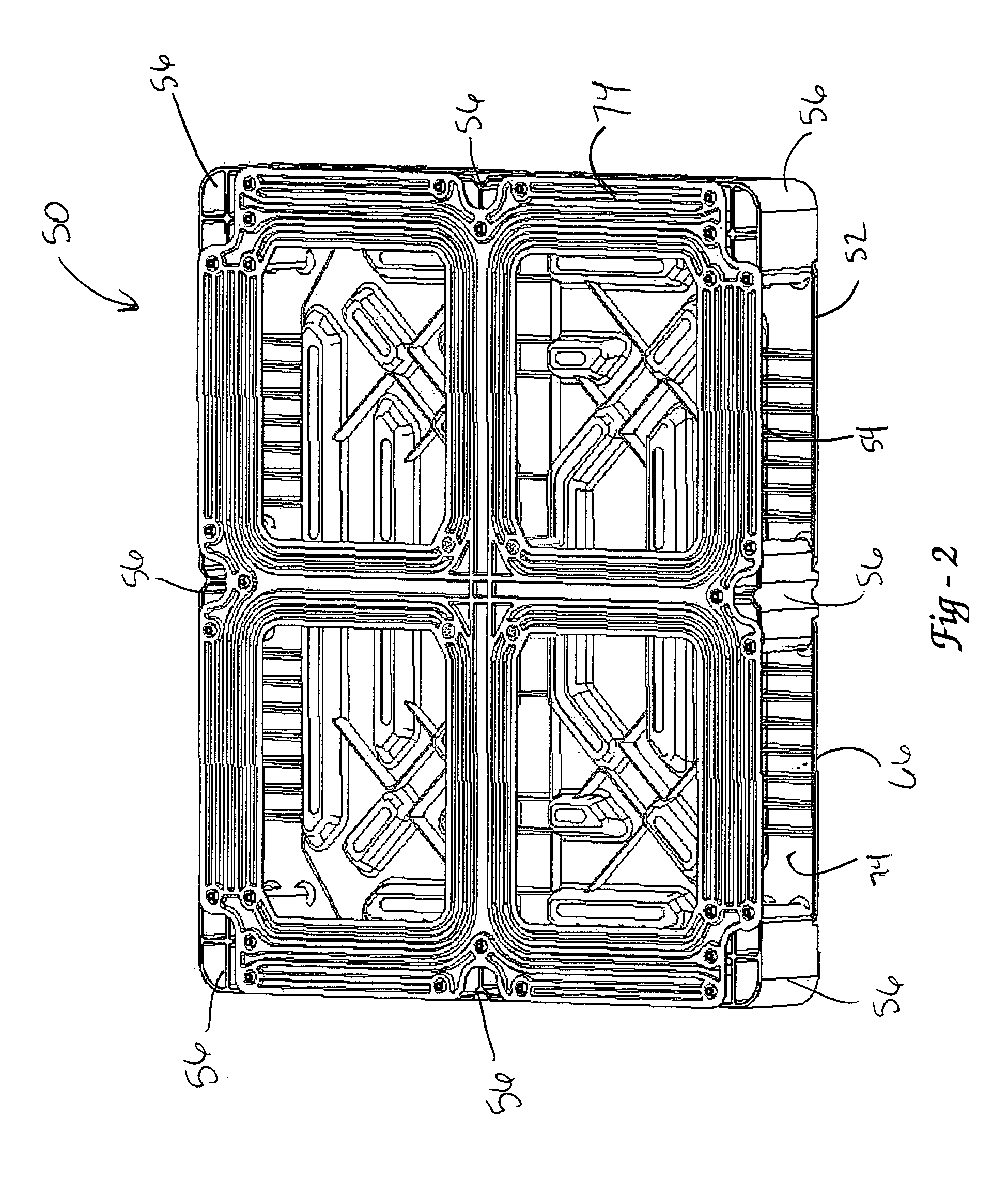

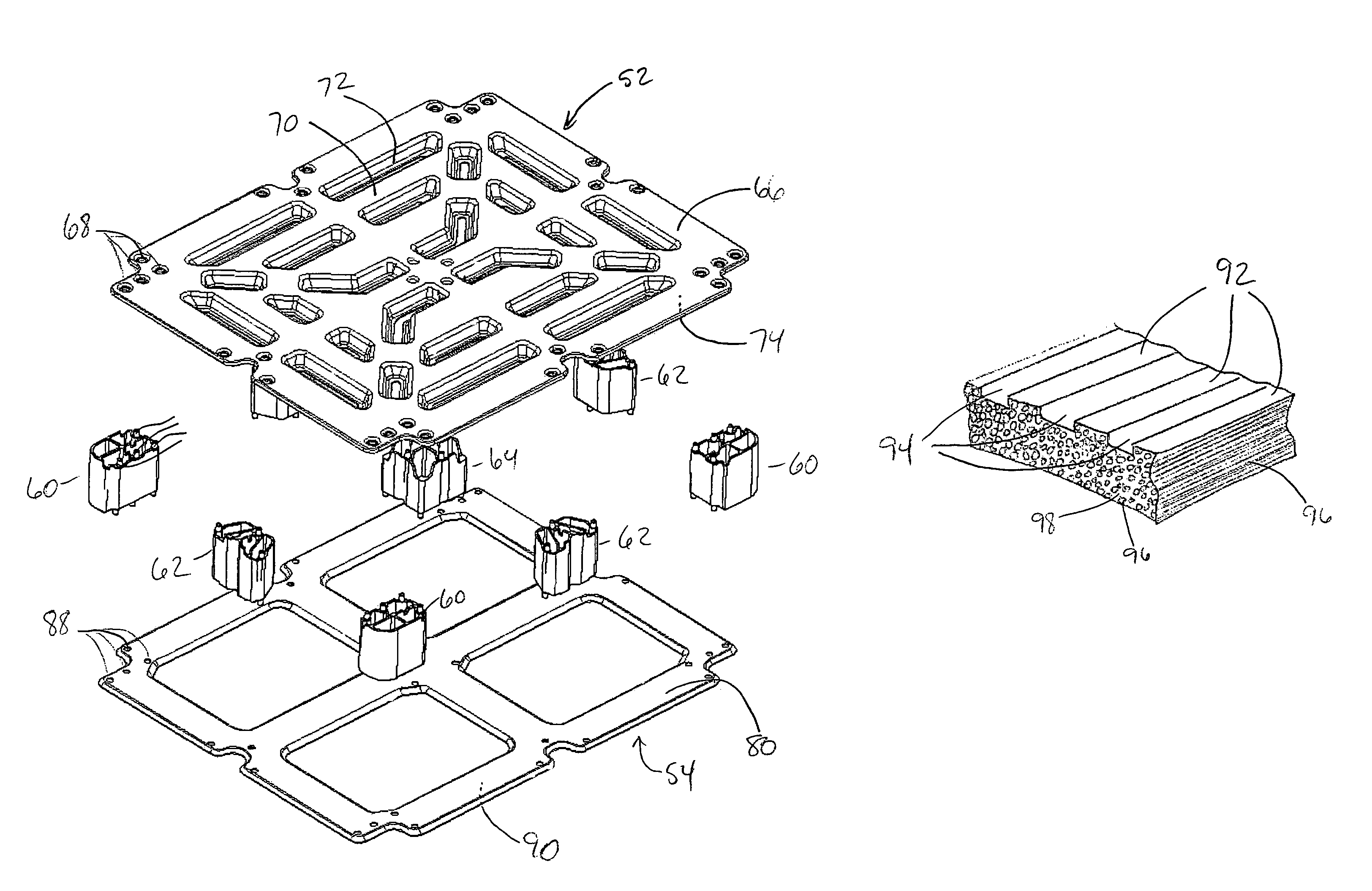

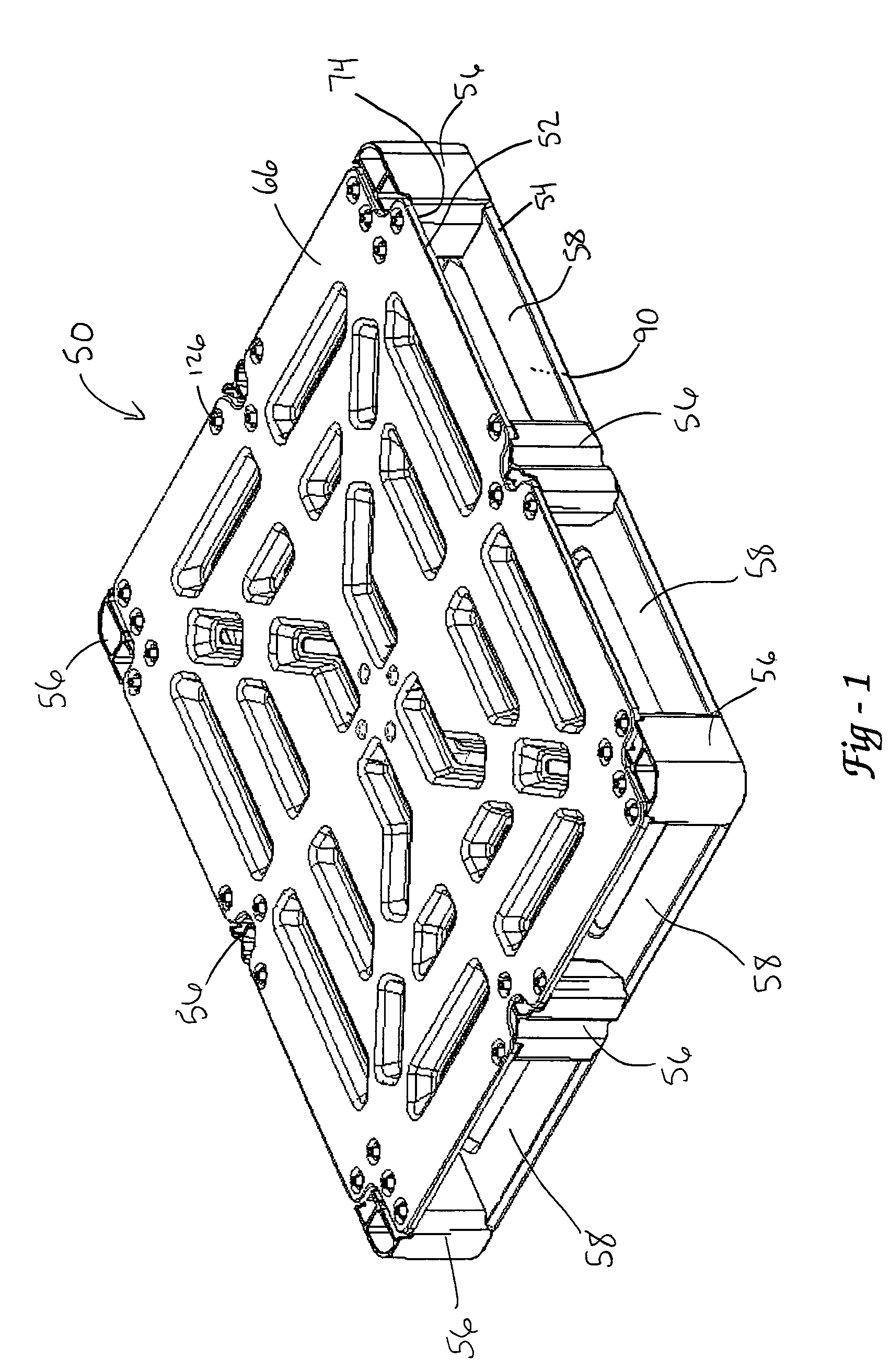

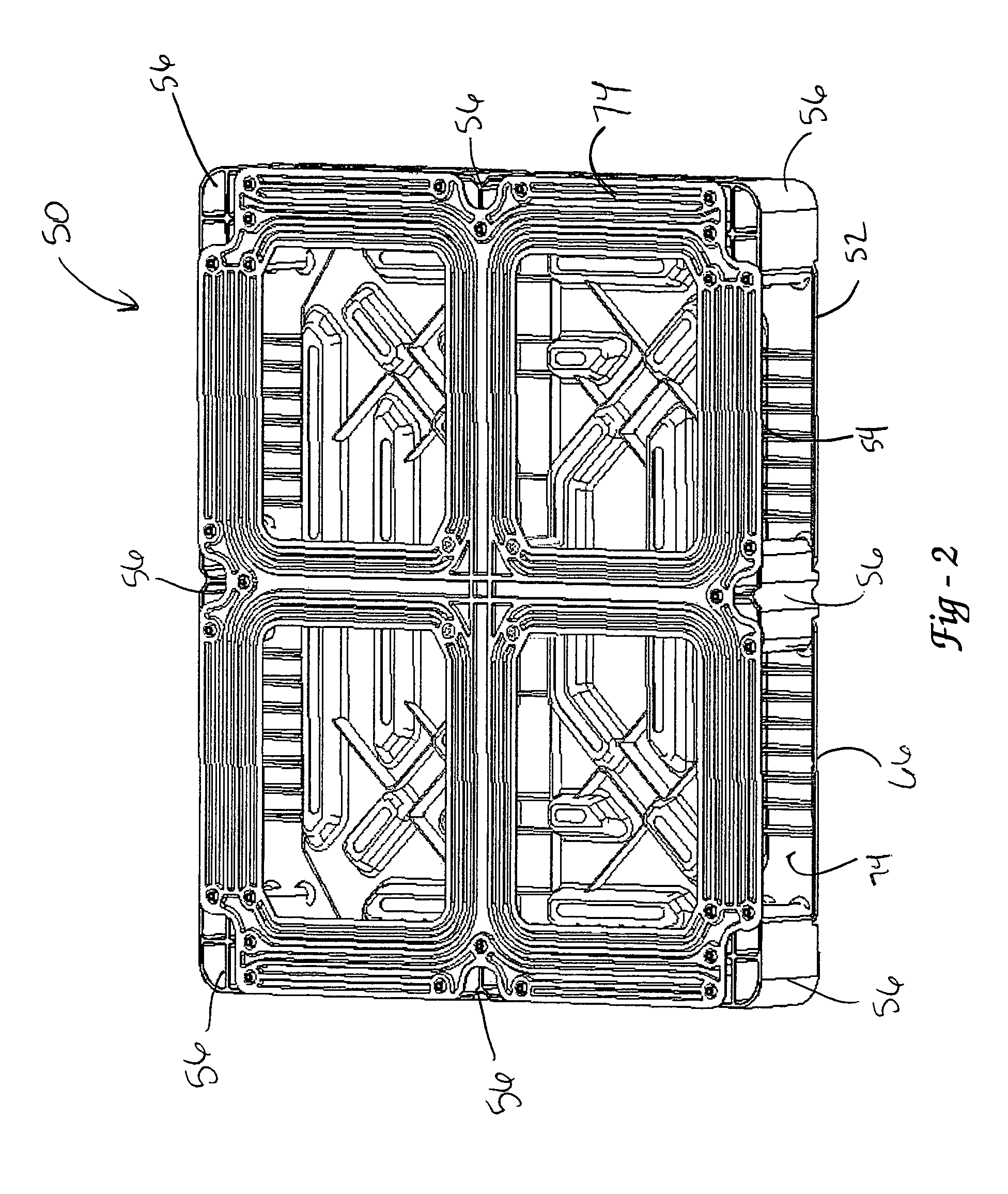

SMC pallet

InactiveUS20050193929A1Other manufacturing equipments/toolsDomestic articlesFiberSheet moulding compound

A pallet made of sheet molding compound (SMC) preferably includes a lower deck having unidirectional fibers therein and an upper deck having randomly oriented fibers therein. The upper and lower decks are assembled by heat staking the decks together with thermoplastic blocks.

Owner:FITZPATRICK TECH L L C

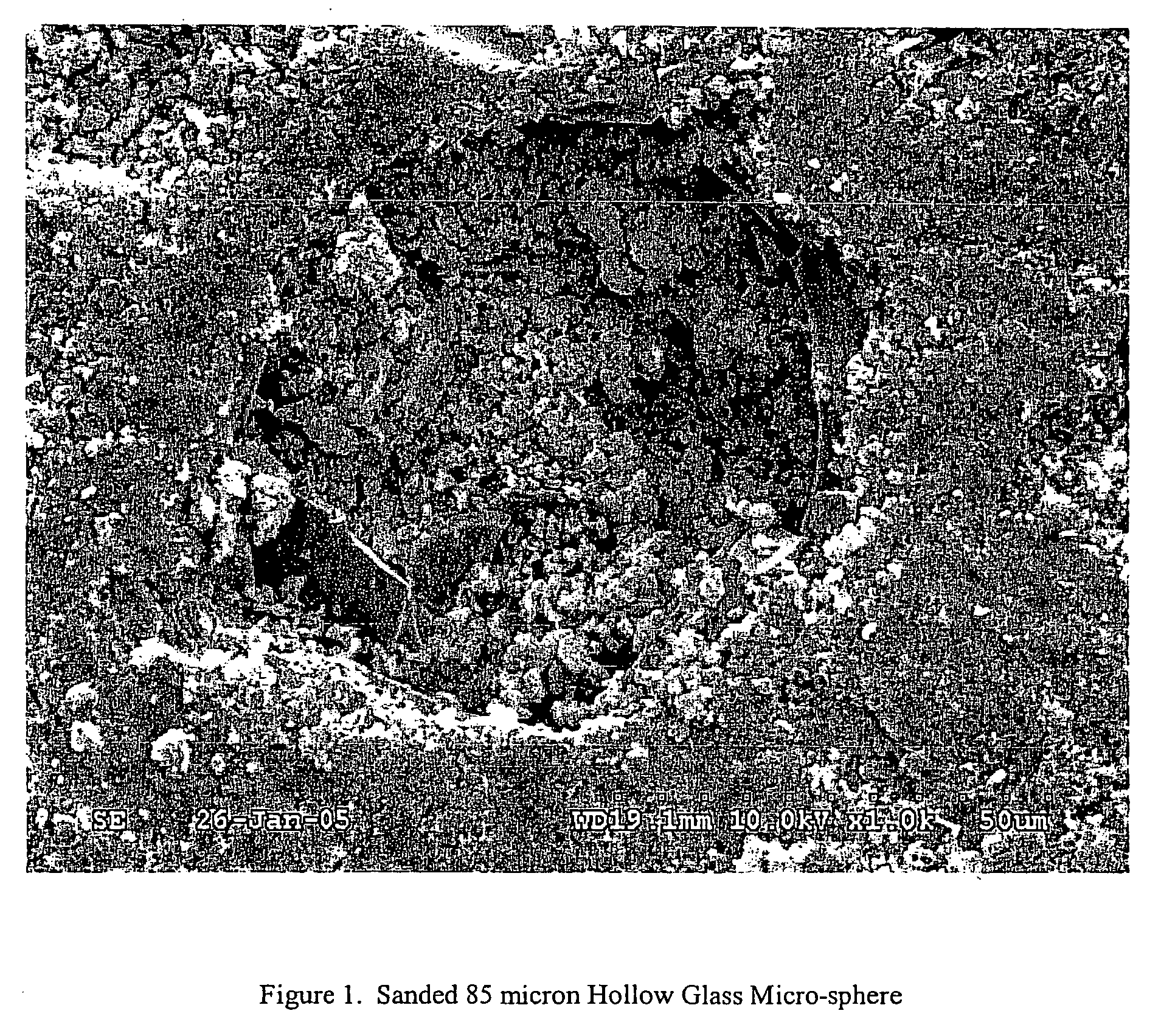

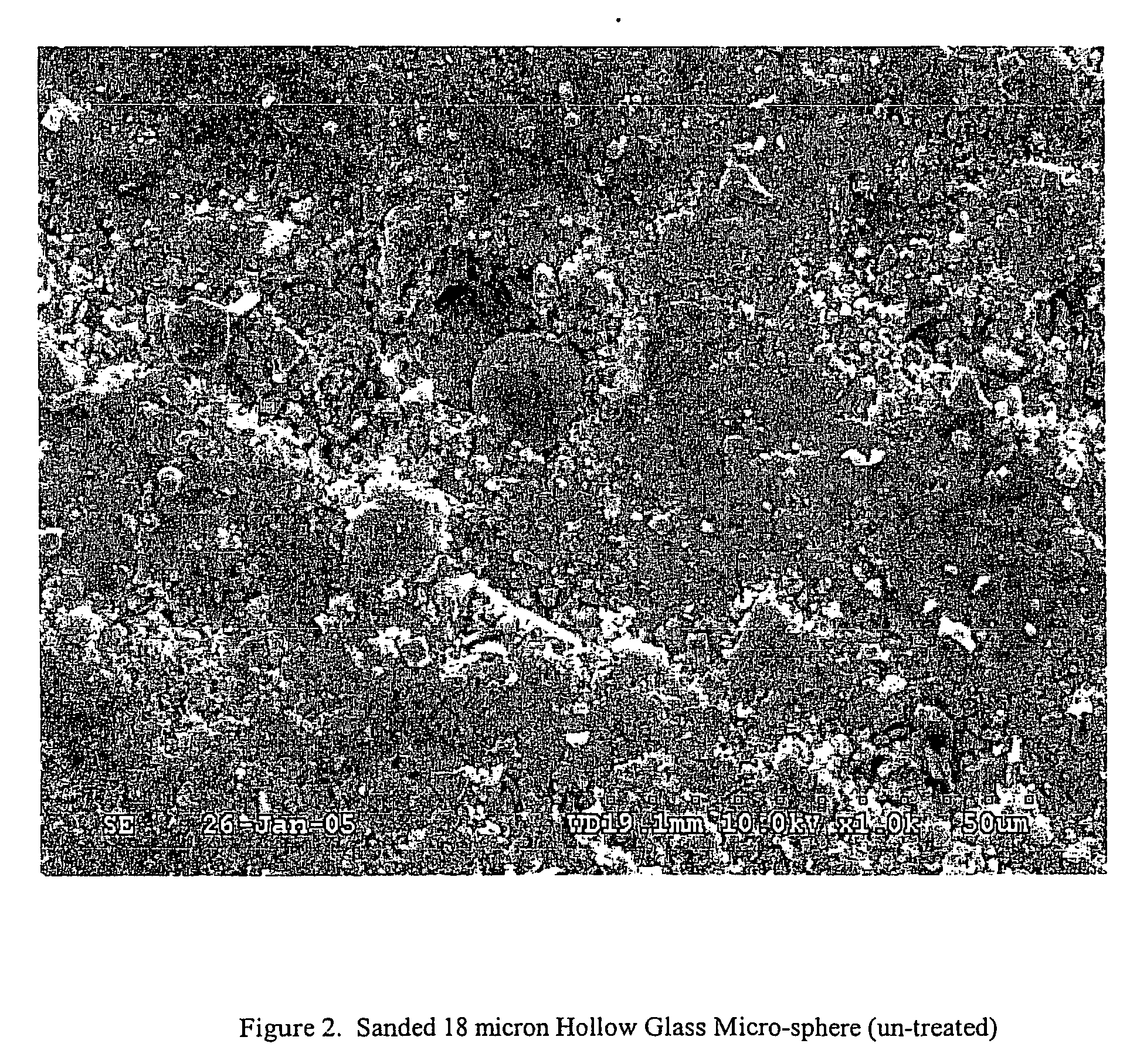

Synergistic filler compositions and low density sheet molding compounds therefrom

InactiveUS20060252869A1Improve efficiencyHigh resin contentMaterial nanotechnologySheet moulding compoundLow density

The present disclosure relates generally to resin formulations for sheet molding compounds. Particularly, but not by way of limitation, the disclosure relates to low-density thermosetting sheet molding compounds (SMC) comprising a treated inorganic clay, a thermosetting resin, a low profile agent, a reinforcing agent, a low-density filler, and substantially the absence of calcium carbonate. The thermosetting SMC are used to prepare exterior and structural thermoset articles, e.g. auto parts and panels, etc that have Class A Surface Quality.

Owner:ASHLAND LICENSING & INTPROP LLC

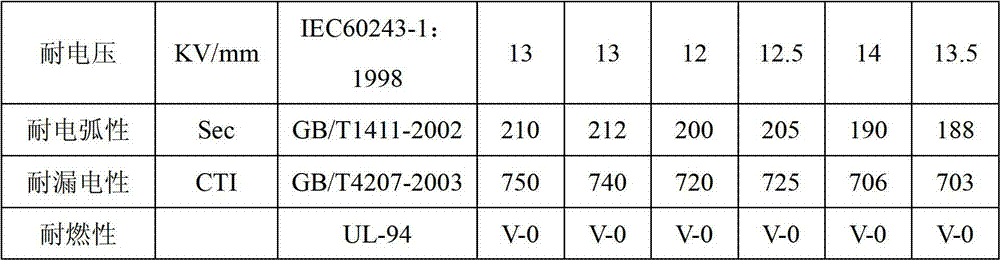

Low-density molding compound

ActiveUS20060258781A1Improve performanceSynthetic resin layered productsCellulosic plastic layered productsParticulatesCompound a

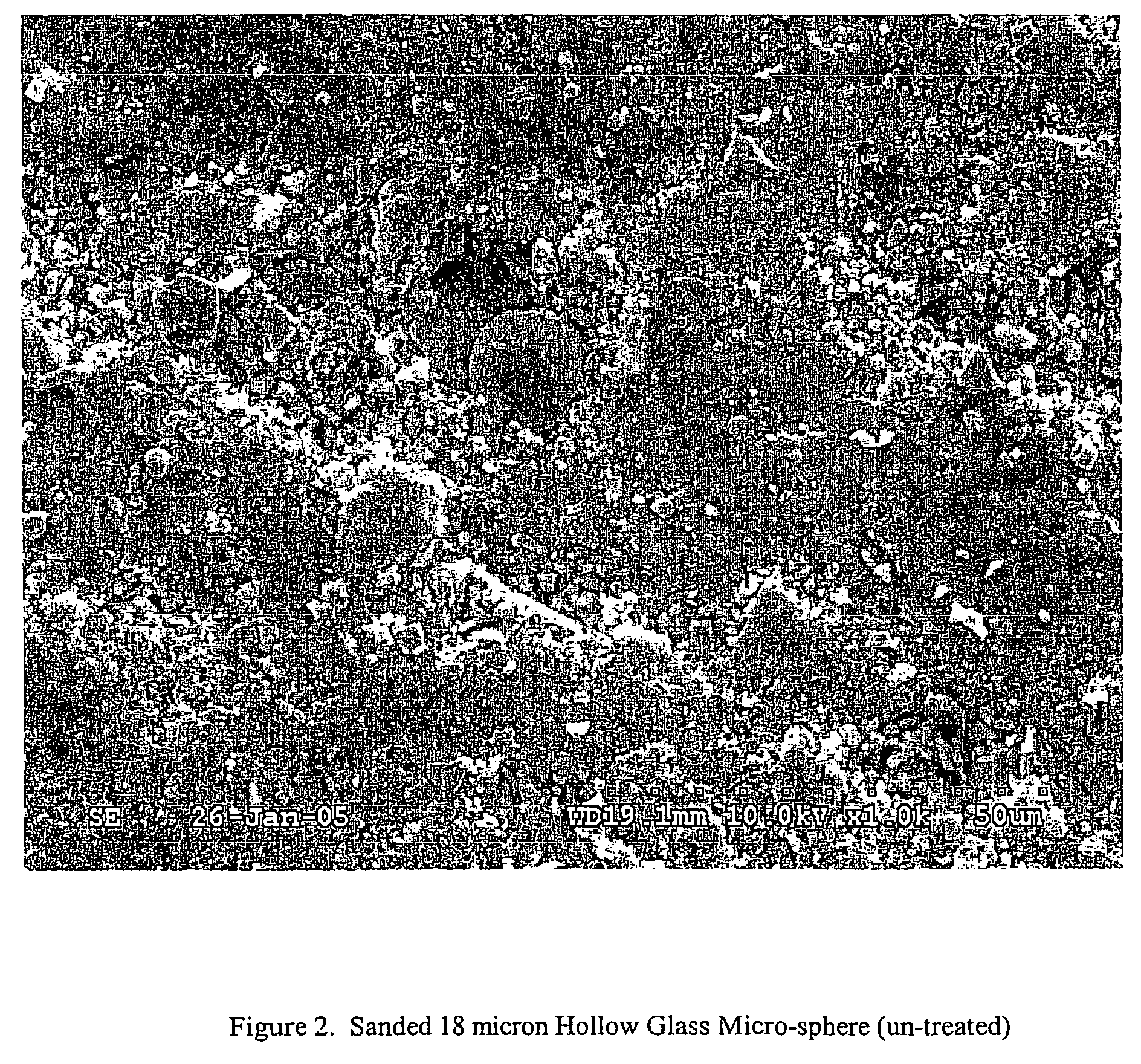

A molding composition formulation includes a thermoset cross-linkable polymeric resin. Glass microspheroids are present such that upon cure of the resin the resulting article has a linear shrinkage of less than ±0.06% and a density of less than 1.65. An article formed from such a composition is further strengthened by the addition of a surface activating agent bonded to the surface of the glass microspheroids. Conventional particulate fillers when added to an inventive formulation provide enhanced performance when the filler particle has a size sufficiently small to insert within adjacent microspheroid interstitial voids. An unsaturated polyester resin so formed is particularly well suited for the formation of sheet molding compound formulations.

Owner:CONTINENTAL STRUCTURAL PLASTICS INC

Graphene oxide reinforced vinyl ester composite material and preparation method thereof

InactiveCN103540104AImprove mechanical propertiesImprove thermal stabilityGlass fiberSheet moulding compound

The invention discloses a graphene oxide reinforced vinyl ester composite material and a preparation method thereof. The graphene oxide reinforced vinyl ester composite material disclosed by the invention comprises vinyl ester resin, glass fibre, graphene oxide powder, a low profile agent, a thickener, inorganic mineral filler and a curing agent. The graphene oxide reinforced vinyl ester composite material disclosed by the invention has excellent composite performances by utilizing the huge specific surface area of graphene oxide and the abundant functional groups on the surface; graphene oxide and a resin-based composite material are composited, and therefore, the performances in the aspects of heat, force, electric and the like of the material can be obviously improved. The composite material disclosed by the invention is in the form of a sheet moulding compound; the adopted forming process is compression moulding forming or injection forming; the preparation method disclosed by the invention is simple and easy to implement.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

SMC pallet

InactiveUS8127691B2Other manufacturing equipments/toolsDomestic articlesFiberSheet moulding compound

A pallet made of sheet molding compound (SMC) preferably includes a lower deck having unidirectional fibers therein and an upper deck having randomly oriented fibers therein. The upper and lower decks are assembled by heat staking the decks together with thermoplastic blocks.

Owner:FITZPATRICK TECH L L C

Recompressed exfoliated graphite articles

InactiveUS20090061191A1Easy to moldEasy embossingConductive materialSynthetic resin layered productsFuel cellsSheet moulding compound

This invention provides an electrically conductive, less anisotropic, recompressed exfoliated graphite article comprising a mixture of (a) expanded or exfoliated graphite flakes; and (b) particles of non-expandable graphite or carbon, wherein the non-expandable graphite or carbon particles are in the amount of between about 3% and about 70% by weight based on the total weight of the particles and the expanded graphite flakes combined; wherein the mixture is compressed to form the article having an apparent bulk density of from about 0.1 g / cm3 to about 2.0 g / cm3. The article exhibits a thickness-direction conductivity typically greater than 50 S / cm, more typically greater than 100 S / cm, and most typically greater than 200 S / cm. The article, when used in a thin foil or sheet form, can be a useful component in a sheet molding compound plate used as a fuel cell separator or flow field plate. The article may also be used as a current collector for a battery, supercapacitor, or any other electrochemical cell.

Owner:NANOTEK INSTR GRP LLC

High heat-resistant fiber reinforcement vinyl ester composite material with low expansion coefficient

InactiveCN102220029AImprove heat resistanceSmall expansion coefficientGlass fiberCompression molding

The invention discloses a high heat-resistant fiber reinforcement vinyl ester composite material with a low expansion coefficient, comprising the following ingredients by weight percentage: 10-40 of vinylite, 15-25 of glass fiber, 10-60 of carbon fiber powder, 5-25 of low profile additive, 10-70 of inorganic mineral filler, 1-4 of magnesium oxide, 1-5 of releasing agent, and 0.5-2 of curing agents. The composite material has good mechanical performance, high heat resistance and the low expansion coefficient. The composite material product prepared by the material is a sheet molding compound (SMC), the adopted molding process is compression molding forming or injection molding, and can be widely applied to a precise part under a high-heat working environment.

Owner:江苏兆新材料科技

Sheet molding compound having improved surface characteristics

InactiveUS7026043B2Improve physical and surface characteristic and electrostatic sprayabilityImprove surface propertiesSynthetic resin layered productsLaminationShell moldingSheet moulding compound

A composite part made from a sheet molding compound is disclosed as having improved characteristics over traditional sheet molding compound composite parts. The composite part may be made from a unique sheet molding compound material having a resin impregnated filamentized fiber layer and a resin impregnated fiber layer prior to compaction. The resin impregnated filamentized fiber layer side prevents the movement of partially filamentized or unfilamentized fibers to the visible surface of the composite part when the part is molded. The resin impregnated filamentized fiber layer may be contain a conductive filamentized fiber such that the surface of a sheet molding compound may be conductive and be capable of being electrostatically sprayed.

Owner:OWENS CORNING FIBERGLAS TECH INC +1

SMC (sheet molding compound) material for passenger car covering parts and preparation method thereof

The invention discloses an SMC (sheet molding compound) material for passenger car covering parts and a preparation method thereof. The SMC material comprises 60-100 parts of base resin, 80-200 parts of reinforcing fiber, 30-50 parts of low shrinkage agent, 130-220 parts of inorganic mineral filler, 20-60 parts of hollow glass microsphere, 3-8 parts of releasing agent, 1-4 parts of curing agent and 1-5 parts of thickening agent. The hollow glass microspheres, of which the average particle size is less than 40 micrometers and the compression strength is greater than 37MPa, are utilized to lower the density of the material; the novel liquid releasing agent is used instead of the traditional releasing agent, so that the product surface can be directly painted without treatment; and PVAc / St copolymer and saturated polyester are utilized to compound the low shrinkage system, so that the material has zero shrinkage and satisfies the requirements for Grade A surfaces. The invention has the advantages of low specific gravity, no need of surface treatment and Grade A surface, and can be used for passenger car covering parts instead of steel materials.

Owner:江苏兆新材料科技

Novel low-shrinkage amino moulding compound and preparation method thereof

ActiveCN101921454ADoes not affect the process cycleDoes not affect the production cycleCelluloseElastomer

The invention relates to a formula and a preparation method of a novel low-shrinkage amino moulding compound. The novel low-shrinkage amino moulding compound comprises urea, formaldehyde, melamine, lubricant, dispersant, release agent, a curing agent system, dye, filler, cellulose and low shrinkage agent. The invention is characterized in that (1) the low shrinkage agent is water-soluble isocyanate elastomer; (2) the low shrinkage agent can be uniformly dispersed in a resin system and improve the surface glossiness of the moulding compound without influencing the coloring property of the dye or other performances of the moulding compound; and (3) a relatively small amount of the low shrinkage agent can meet the shrinkage requirement of the moulding compound. The preparation method of the moulding compound comprises the following steps: proportionally mixing and uniformly stirring the urea, the formaldehyde and the curing agent to prepare resin raw pulp; then transferring the raw pulp into a reaction kettle and adding the low shrinkage agent and other auxiliaries; and performing vacuum kneading and polymerization to prepare the amino moulding compound, wherein the forming shrinkage of the amino moulding compound is less than 0.6%, and the post shrinkage is less than 0.4%.

Owner:CHANGZHOU JOEL PLASTIC +1

Bathroom chassis and manufacturing method thereof

InactiveCN101953651AResidue reductionSuitable for home decorationBathsDouchesGlass fiberSheet moulding compound

The invention relates to a bathroom chassis which is produced by a sheet molding compound (SMC), the sheet molding compound comprises resin paste and glass fiber which is fully impregnated in the resin paste, wherein the resin paste accounts for 75%-85% (by weight), and the glass fiber accounts for 20%-25% (by weight). Compared with the existing bathroom chassis, the closed molding of the bathroom chassis is carried out under high temperature and high pressure, thereby completely curing the product to the maximum extent, leading the organic monomer residue to be lower, being more environment-friendly and healthy and being applicable to home decoration.

Owner:W&M SANITARY WARE FOSHAN

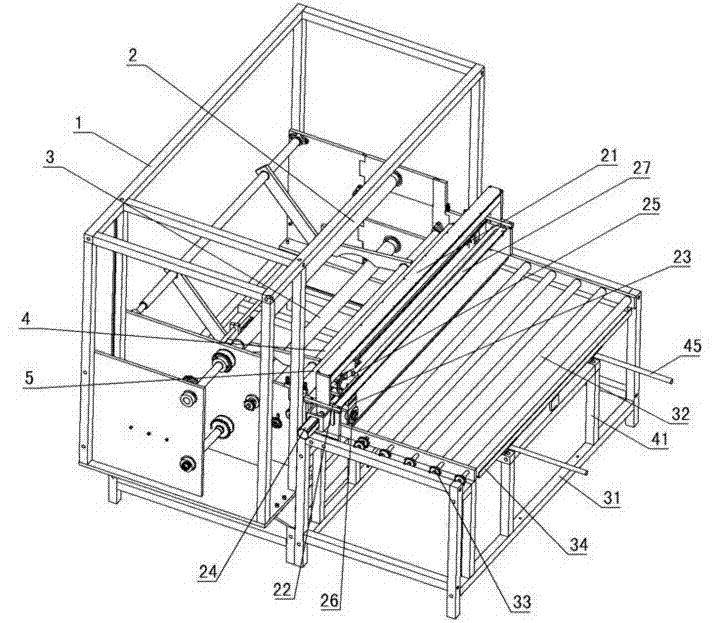

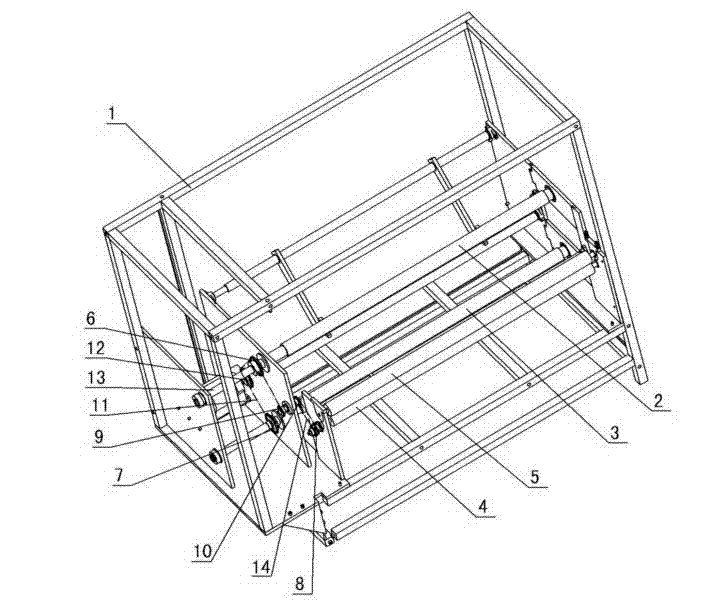

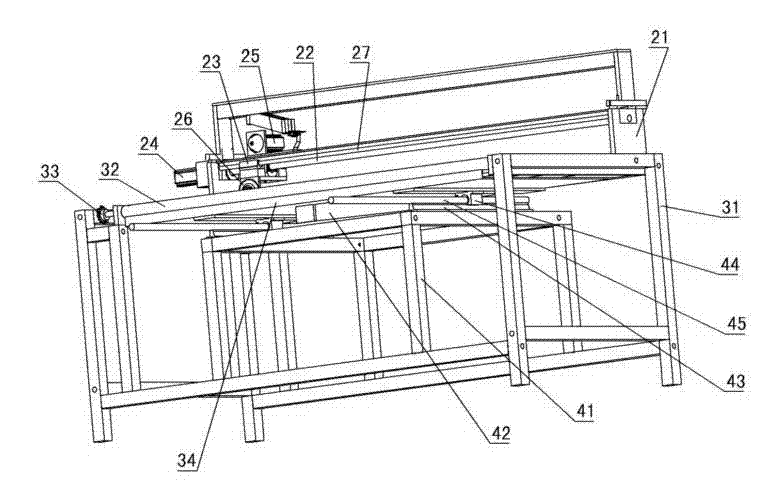

Automatic film tearing cutting machine for SMC (sheet molding compound)

InactiveCN102773873AReduce labor intensityIncrease productivityLamination ancillary operationsLaminationSheet moulding compoundEngineering

An automatic film tearing cutting machine for SMC (sheet molding compounds) comprises a film tearing and sheet feeding device, a cutting device and a sheet picking device. The film tearing and sheet feeding device comprises an upper film tearing rotary drum, a lower film tearing rotary drum, a main sheet feeding rotary drum and a driven sheet feeding rotary drum, the upper film tearing rotary drum and the lower film tearing rotary drum are respectively matched with an upper film and a lower film, the main sheet feeding rotary drum and the driven sheet feeding rotary drum are matched with a middle core, and the various rotary drums are driven by a servo motor via a transmission mechanism; the cutting device comprises a cutting support, a lead screw, a sliding rod and a slider are mounted in the cutting support, the lead screw is driven by a second servo motor, and a blade is connected to the lower side of the slider and is driven to rotate by a third motor; and the sheet tanking device comprises a sheet picking framework, more than two sheet picking rotary drums are mounted in the sheet picking framework, are matched with a cut core, and are mutually driven by a motor via a transmission chain, and sheet picking plates are arranged below the sheet picking rotary drums and are driven by a picking sliding mechanism to pick out a cut and molded core.

Owner:台州市虹靖盛塑料模具有限公司

High-fluidity flame-retardant sheet-shaped molding compound and preparation method thereof

The invention relates to a high-fluidity flame-retardant sheet-shaped molding compound and a preparation method thereof and belongs to the field of chemical engineering raw materials. A formula of the molding compound comprises, by mass parts, 15-30 parts of unsaturated polyester, 10-40 parts of glass fiber, 5-15 parts of low shrinkage agent, 30-60 parts of flame-retardant fillers, 0.2-1 part of initiator, 0.02-0.1 part of inhibitor, 0.2-1 part of thickener, 2-10 parts of styrene, 1-5 parts of internal releasing agent and 0.1-0.5 part of viscosity reduction addition agent. According to the high-fluidity flame-retardant sheet-shaped molding compound and the preparation method thereof, the high impact strength low shrinkage agent is adopted to make up for a loss of mechanical properties caused by adding of the flame-retardant fillers, the flame-retardant fillers of different diameters are utilized to play a synthetic synergic filling effect, so as to improve a flame retardant effect; and the resin paste viscosity is reduced through the viscosity reduction addition agent, so that the high-fluidity flame-retardant sheet-shaped molding compound is formed. The method for preparing the high-fluidity flame-retardant sheet-shaped molding compound is provided.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

Synergistic filler compositions and low density sheet molding compounds therefrom

InactiveCN101213245ALow costSpeed up the flowMaterial nanotechnologyPolymer scienceSheet moulding compound

The present disclosure relates generally to resin formulations for sheet molding compounds. Particularly, but not by way of limitation, the disclosure relates to low-density thermosetting sheet molding compounds (SMC) comprising a treated inorganic clay, a thermosetting resin, a low profile agent, a reinforcing agent, a low-density filler, and substantially the absence of calcium carbonate. The thermosetting SMC are used to prepare exterior and structural thermoset articles, e.g. auto parts and panels, etc that have class A surface quality.

Owner:ASHLAND LICENSING & INTPROP LLC

Sheet molding compound having improved characteristics

InactiveUS20030165670A1High surface finishReduce weightSynthetic resin layered productsLaminationPolymer scienceSheet moulding compound

Owner:OWENS CORINING COMPOSITES SPRL +1

Method of producing less anisotropic flexible graphite

InactiveUS20090057940A1Improve conductivitySmall sizeCell electrodesFuel cellsFuel cellsSheet moulding compound

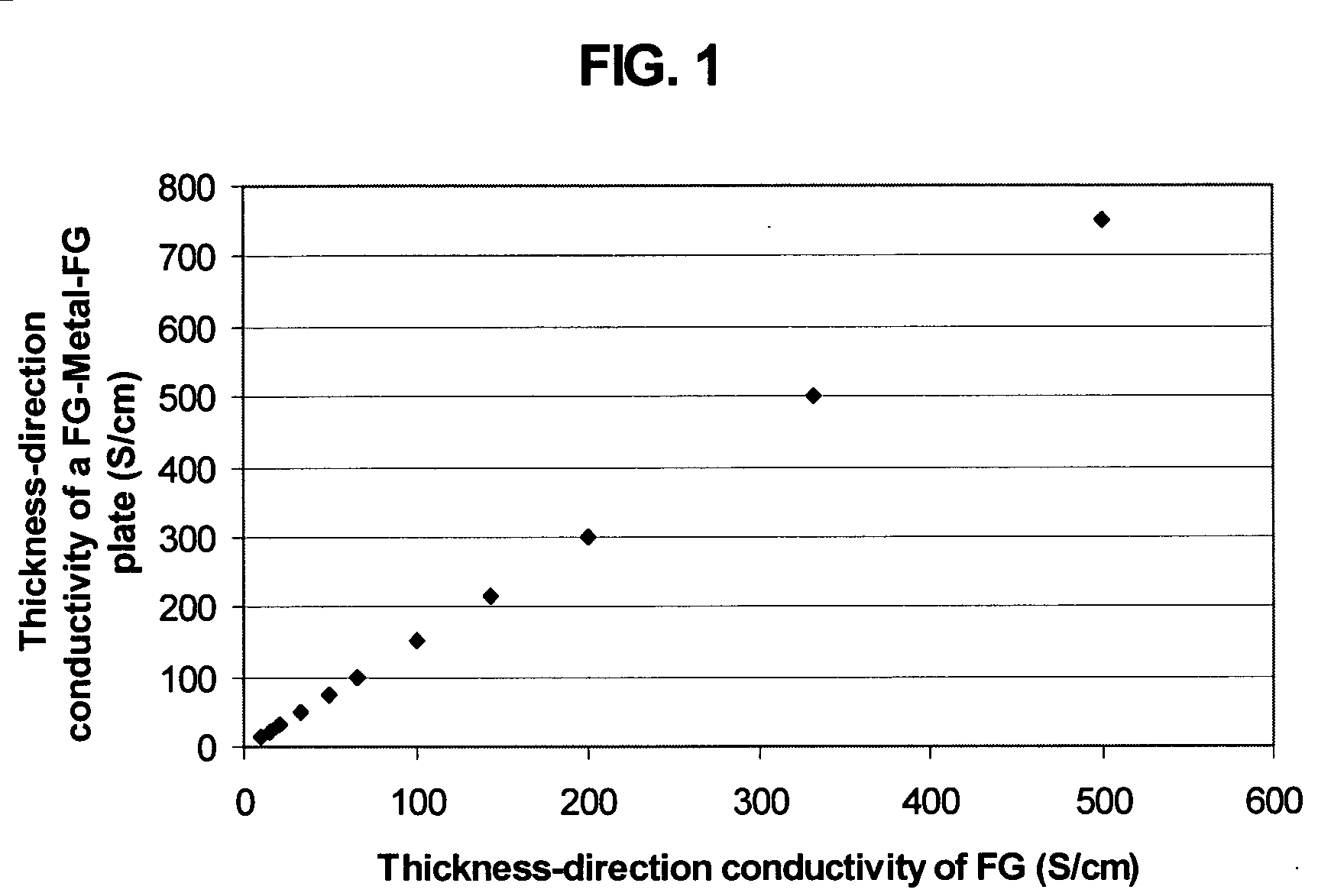

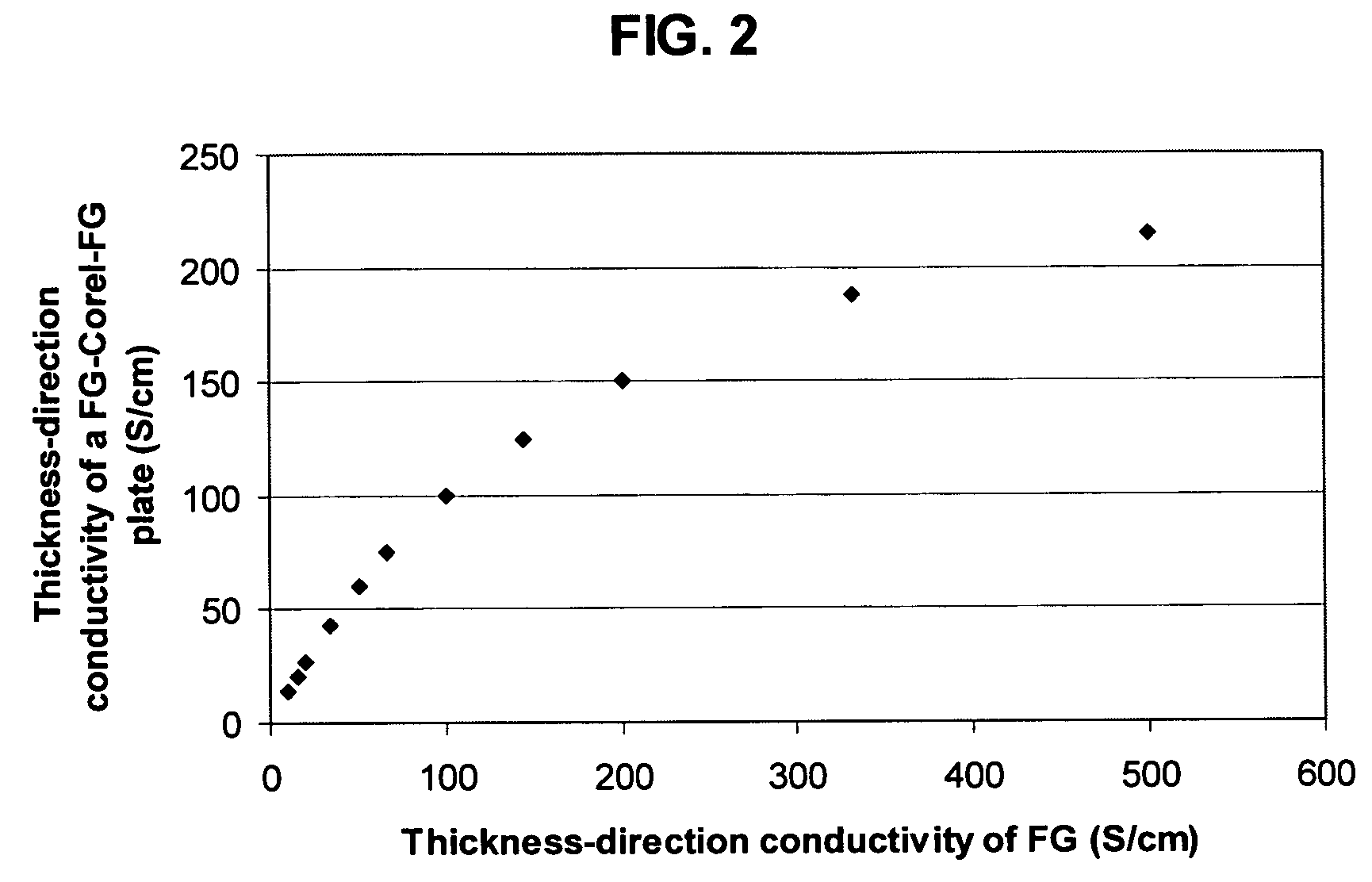

This invention provides a method for recompressing expanded or exfoliated graphite to produce a less anisotropic, flexible graphite foil having a thickness-direction electrical conductivity no less than 15 S / cm. In one preferred embodiment, the method comprises: (a) providing a mixture of expanded or exfoliated graphite flakes and particles of non-expandable graphite or carbon, wherein the non-expandable graphite or carbon particles are in the amount of between about 3% and 70% by weight based on the total weight of the particles and the exfoliated graphite; (b) compressing the mixture in at least a first direction to a pressure within the range of from about 0.04 MPa to about 350 MPa into a first cohered mixture; and (c) compressing this first cohered mixture in a second direction, different from the first direction, to a pressure sufficient to produce said flexible graphite foil having a bulk density within the range of from about 0.1 g / cm2 to about 2.0 g / cm2. All these operations are preferably conducted continuously. The foil exhibits a thickness-direction conductivity typically greater than 50 S / cm, more typically greater than 100 S / cm, and most typically greater than 200 S / cm. The foil can be used as a component in a sheet molding compound plate as a fuel cell separator or flow field plate. The foil may also be used as a current collector for a battery, supercapacitor, or any other electrochemical cell.

Owner:NANOTEK INSTR GRP LLC

Outdoor weather resistant SMC (Sheet Molding Compound) material and preparation method thereof

The invention relates to an outdoor weather resistant SMC (Sheet Molding Compound) material and a preparation method thereof. The outdoor weather resistant SMC material is prepared by adding a novel weather resistant resin, a weather resistant low-shrinkage agent, a weather resistant color paste and an ultraviolet absorber to a main body structure of the traditional SMC material, improving mold release smoothness by using a special processing additive, adding a filler, an alkali-free glass fiber and other auxiliary raw materials to the main body structure and stirring a mixture by using a special stirring process. The outdoor weather resistant SMC material provided by the invention has the advantages as follows: when original excellent performances of the SMC material are kept, ultraviolet oxidation resistance, hydrolysis resistance and high and low temperature resistance are obviously improved; and when the outdoor weather resistant SMC material is in outdoor use, time of resisting color change and color fading as well as time of resisting weather, crack, pulverization and other damages are both greatly prolonged.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

Low-density molding compound

ActiveUS7700670B2Improve performanceSynthetic resin layered productsCellulosic plastic layered productsParticulatesCompound a

A molding composition formulation includes a thermoset cross-linkable polymeric resin. Glass microspheroids are present such that upon cure of the resin the resulting article has a linear shrinkage of less than ±0.06% and a density of less than 1.65. An article formed from such a composition is further strengthened by the addition of a surface activating agent bonded to the surface of the glass microspheroids. Conventional particulate fillers when added to an inventive formulation provide enhanced performance when the filler particle has a size sufficiently small to insert within adjacent microspheroid interstitial voids. An unsaturated polyester resin so formed is particularly well suited for the formation of sheet molding compound formulations.

Owner:CONTINENTAL STRUCTURAL PLASTICS INC

Carbon fibre-reinforced flaky moulding material for shielding electromagnetic waves as well as preparation method and application

InactiveCN102675848AImprove conductivityImprove mechanical propertiesOther chemical processesCarbon fibersAutomotive battery

The invention discloses a carbon fibre-reinforced flaky moulding material for shielding electromagnetic waves as well as a preparation method and application. The flaky moulding material contains the following components according to parts by weight: 60 to 100 of matrix resin, 30 to 100 of carbon fibre, 30 to 50 of low shrinking agent, 2 to 10 of wave absorbing agent, 130 to 230 of inorganic mineral filler, 1 to 4 of curing agent, 1 to 5 of thickening agent and 2 to 10 of other components; and the carbon fibre is carbon fibre which is not treated by graphitization, and acts as the function of absorbing electromagnetic waves in the compound material. The flaky moulding material has excellent electromagnetic wave shielding performance and mechanical performance and can be used for the fields of electronic equipment, traffic, military affairs and the like. The carbon fibre-reinforced flaky moulding material for shielding the electromagnetic waves is used as materials, such as a wave absorbing material, a battery case of an electric automobile with a novel energy resource, and an invisible material.

Owner:江苏兆新材料科技

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com