Outdoor weather resistant SMC (Sheet Molding Compound) material and preparation method thereof

A weather-resistant, outdoor technology, applied in the field of composite insulation materials, can solve the problems of SMC materials such as lack of weather resistance, poor UV stability and hydrolysis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

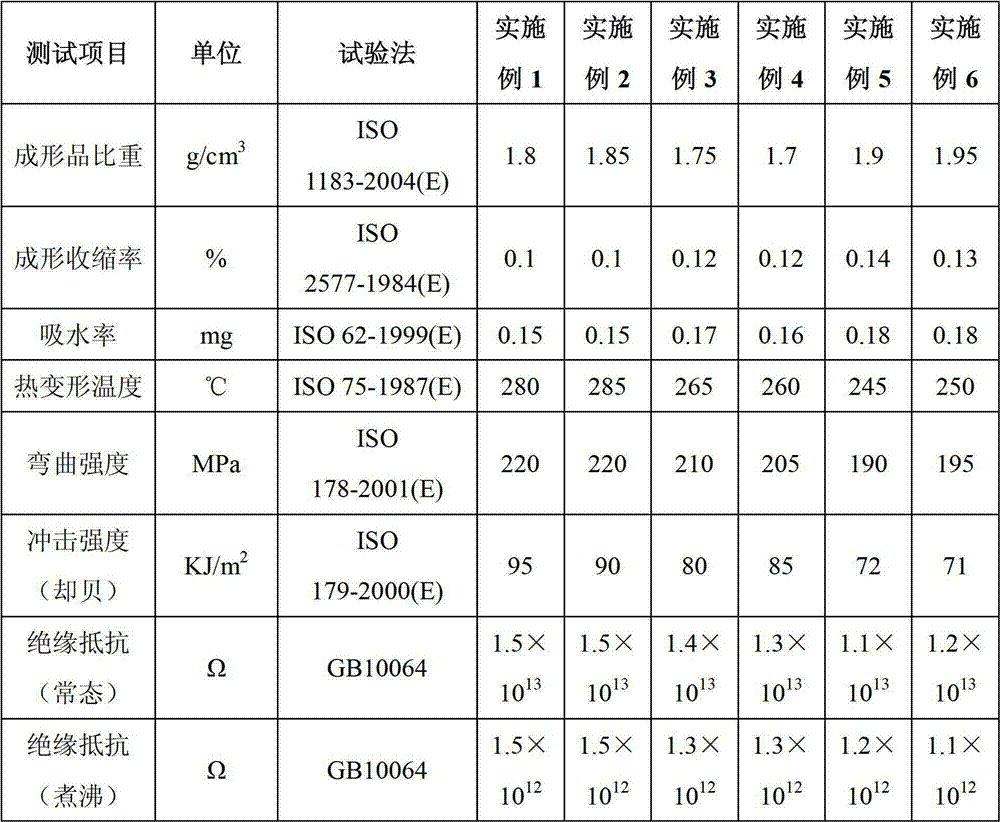

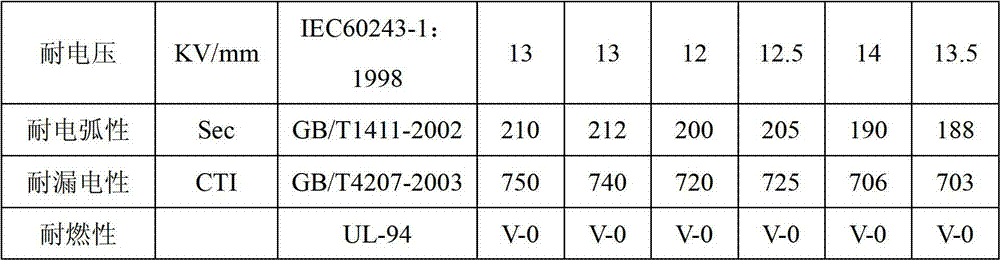

Examples

Embodiment 1

[0095] Prepare the weather-resistant SMC material for outdoor use as follows:

[0096] (1) Prepare raw materials according to the following mass percentages: 16.5wt% weather-resistant unsaturated polyester resin, 6wt% weather-resistant low-shrinkage additive, 2wt% weather-resistant color paste, 0.3wt% ultraviolet light absorber, and 0.5wt% process additive , Filling material 55wt%, curing agent 0.4wt%, release agent 0.8wt%, thickener 0.4wt%, antioxidant 0.1wt%, non-alkali continuous filament glass fiber 18wt%;

[0097] The weather-resistant unsaturated polyester resin is a product of Nanjing Jinling DSM Resin Co., Ltd., and the model is P19-901;

[0098] The weather-resistant low-shrinkage additive is a product of Nanjing Jinling DSM Co., Ltd., and the model is H851-02;

[0099] The weather-resistant color paste is a color paste made by mixing and grinding weather-resistant toner and weather-resistant monomer-free unsaturated polyester resin according to a weight ratio of 1:9...

Embodiment 2

[0114] (1) Prepare raw materials according to the following mass percentages: 22wt% weather-resistant unsaturated polyester resin, 4wt% weather-resistant low-shrinkage additive, 4wt% weather-resistant colorant, 0.1wt% ultraviolet light absorber, 1.0wt% process additive, Filling material 52wt%, curing agent 0.2wt%, release agent 1.2wt%, thickener 0.2wt%, antioxidant 0.3wt%, non-alkali continuous filament glass fiber 15wt%;

[0115] The weather-resistant unsaturated polyester resin is a product of Nanjing Jinling DSM Resin Co., Ltd., and the model is P19-901;

[0116] The weather-resistant low-shrinkage additive is a product of Nanjing Jinling DSM Co., Ltd., and the model is H851-02;

[0117] The weather-resistant color paste is a color paste made by mixing and grinding weather-resistant toner and weather-resistant monomer-free unsaturated polyester resin according to a weight ratio of 1:9; the weather-resistant toner is titanium blue, The mixture of Titanium Green, Red 254, an...

Embodiment 3

[0132] (1) Prepare raw materials according to the following mass percentages: 15wt% weather-resistant unsaturated polyester resin, 8wt% weather-resistant low-shrinkage additive, 1wt% weather-resistant colorant, 0.4wt% ultraviolet light absorber, 0.4wt% process additive, Filling material 53.7wt%, curing agent 0.5wt%, release agent 0.5wt%, thickener 0.45wt%, antioxidant 0.05wt%, non-alkali continuous filament glass fiber 20wt%;

[0133] The weather-resistant unsaturated polyester resin is a product of Nanjing Jinling DSM Resin Co., Ltd., and the model is P19-901;

[0134]The weather-resistant low-shrinkage additive is a product of Nanjing Jinling DSM Co., Ltd., and the model is H851-02;

[0135] The weather-resistant color paste is a product of Shanghai Baomeishi Chemical Co., Ltd., and the model is 062-3M0050;

[0136] The ultraviolet absorber is made of nano-sized TiO 2 Composite powder mixed with ZnO at a weight ratio of 2:1 is a product of Nanjing Huali Mingke Industry and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com