Automatic film tearing cutting machine for SMC (sheet molding compound)

A cutting machine and sheet material technology, applied in lamination auxiliary operations, metal processing, sending objects, etc., can solve problems such as low production efficiency, high labor intensity, and polluted core materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

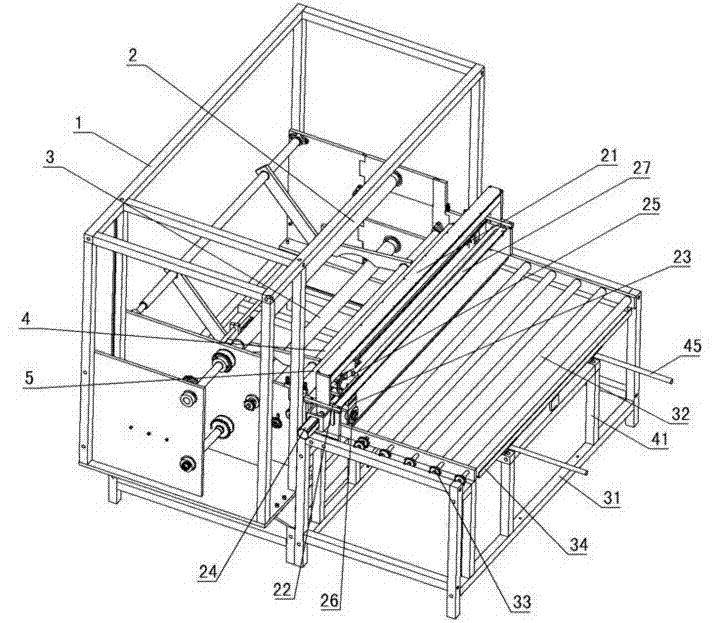

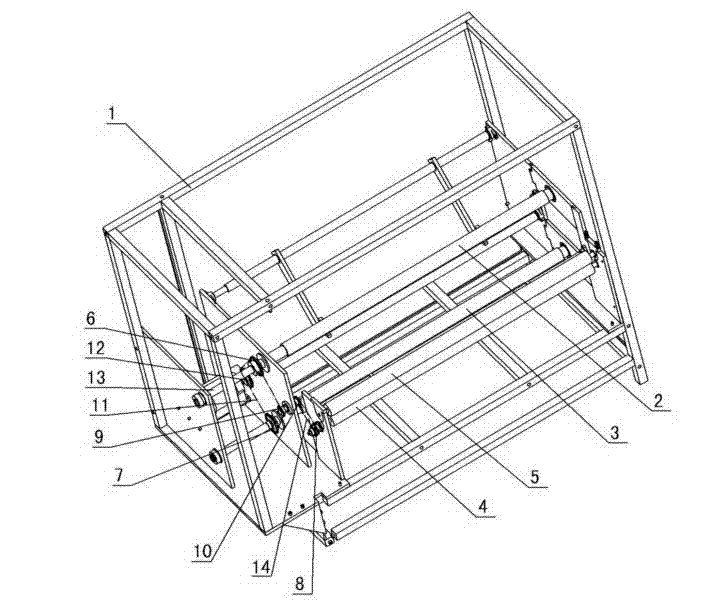

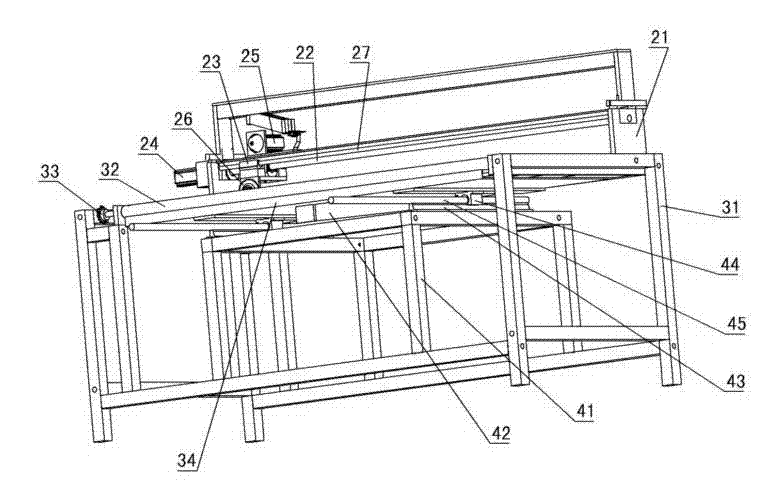

[0011] The present invention relates to a kind of SMC sheet automatic film tearing cutting machine, such as figure 1 — Figure 4 As shown, it is characterized in that it comprises a tearing film feeding device, a cutting device and a sheet taking device. The tearing film feeding device includes a tearing film feeding frame 1, and a tearing film is installed in the tearing film feeding frame. Roller 2, lower tearing film roller 3, main sheet feeding roller 4 and from sheet feeding roller 5, upper tearing film roller 2 and lower tearing film roller 3 cooperate with the upper and lower films of the SMC sheet, main sheet feeding roller 4 and Cooperate with the intermediate core material of the SMC sheet from the sheet feeding roller 5, the first gear 6, the second gear 7 and the third gear are respectively installed on one end of the upper tear film roller 2, the lower tear film roller 3 and the main sheet feeding roller 4 8. The first gear 6 and the second gear 7 are synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com