Heat-resisting phenolic moulding compound

A technology of phenolic molding compound and high temperature resistance, which is applied in the field of thermosetting molding compound, can solve problems such as unseen technical revelations and troubles, and achieve the effects of improving adaptability, appropriate dosage, and reasonable selection of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

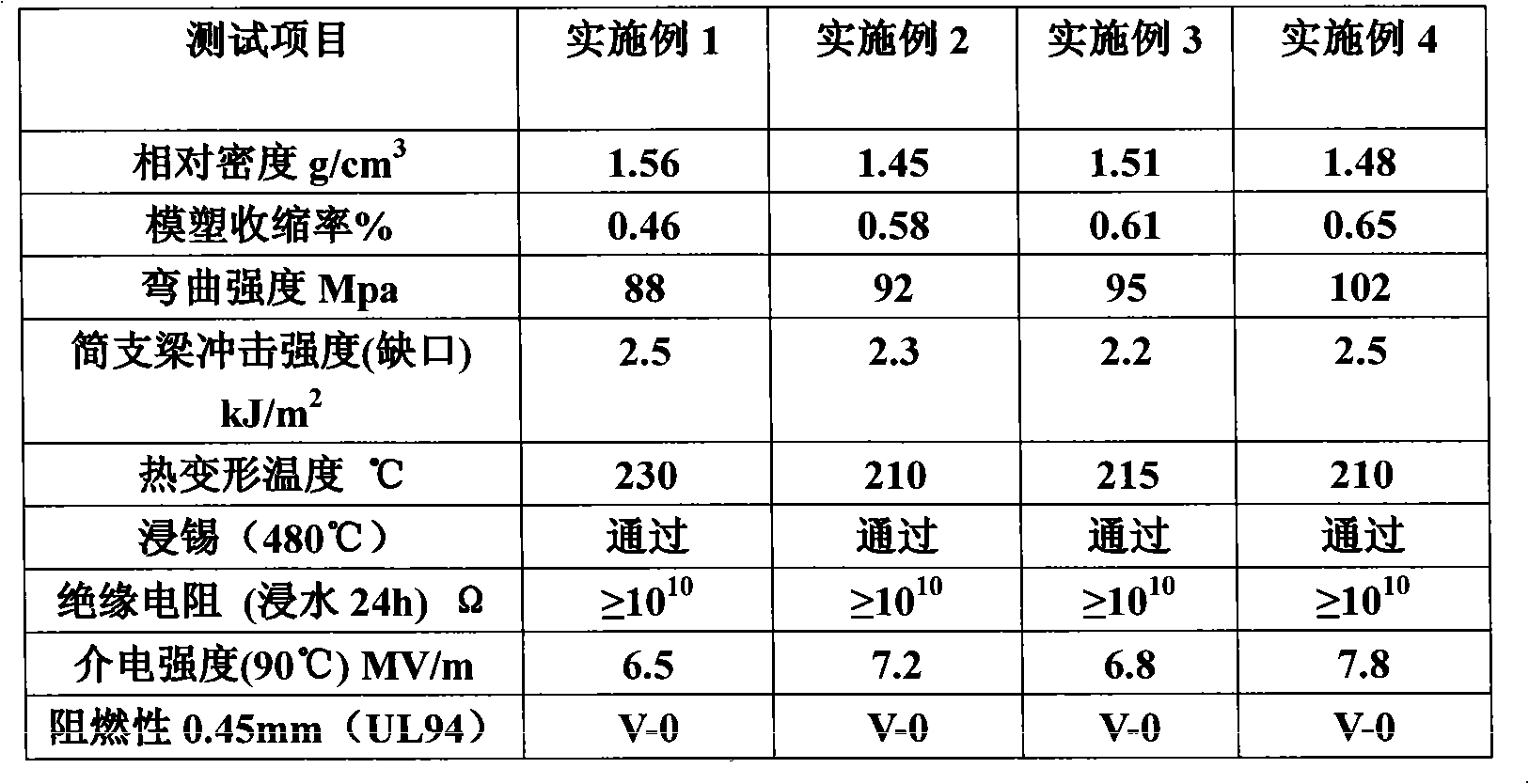

Examples

Embodiment 1

[0025] In parts by weight:

[0026] 35 parts of phenolic resin;

[0027] 5 parts of epoxy resin;

[0028] 6 parts of hexamethylenetetramine;

[0029] 15 parts of glass fiber;

[0030] 0.5 part of titanate coupling agent;

[0031] 0.5 parts of aluminum stearate;

[0033] 2 parts of magnesium oxide;

[0035] 20 parts of stone powder;

[0036] Talcum powder 6 parts.

[0037] During preparation, the above-mentioned various raw materials are crushed, passed through a 60-200 mesh screen, fed into the kneader according to the formula requirements and mixed evenly to obtain a mixture, and then the mixture is heated on a rubber mixer, rolled, and masticated Gel forming, plasticizing roller temperature 70-150°C, plasticizing time 5-10 minutes, roller spacing 2-6mm, cooling the glue, and then crushing and granulating for packaging. The high-temperature-resistant phenolic molding compound of the present invention obta...

Embodiment 2

[0039] Each raw material is by weight ratio:

[0040] 40 parts of phenolic resin;

[0041] 5 parts of epoxy resin;

[0042] 5 parts of unsaturated resin;

[0043] 8 parts of hexamethylenetetramine;

[0044] 20 parts wood flour;

[0045] 0.8 part of silane coupling agent;

[0046] 1 part calcium stearate;

[0047] 1.0 parts of stearic acid;

[0048] Kaolin 5 parts;

[0049] 15 parts of high temperature resistant mineral powder;

[0050] Calcium Hydroxide 3 parts.

[0051] 0.5 parts of magnesium hydroxide;

[0052] All the other are the same as the description to embodiment 1.

Embodiment 3

[0054] Each raw material is calculated by weight:

[0055] 25 parts of phenolic resin;

[0056] 8 parts of melamine formaldehyde resin;

[0057] 3 parts of hexamethylenetetramine;

[0058] 40 parts of bamboo powder;

[0059] 1 part of titanate coupling agent;

[0060] 0.5 parts of aluminate coupling agent;

[0061] Borate coupling agent 0.5 parts

[0062] 0.3 parts of calcium stearate;

[0063] 0.3 parts of ethylene bis stearic acid amide;

[0064] 0.5 parts of magnesium oxide;

[0065] 20 parts of calcium carbonate;

[0066] 20 parts of asbestos powder.

[0067] All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com