Carbon fibre-reinforced flaky moulding material for shielding electromagnetic waves as well as preparation method and application

A technology of sheet molding compound and carbon fiber, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of stripping and delamination of conductive layers, and achieve the effects of decreased resistivity, obvious shielding effect, and excellent process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

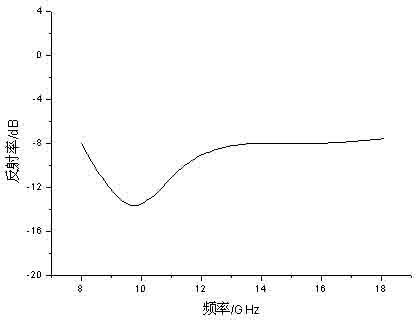

Embodiment 1

[0019] A high-strength carbon fiber reinforced sheet molding compound with excellent electromagnetic wave shielding performance. The sheet molding compound contains the following components in weight fraction ratio: matrix resin 60, carbon fiber 60, low shrinkage agent 35, wave absorbing agent 5, inorganic mineral filler 180, curing agent 2, thickener 2, mold release agent 4; wherein: matrix resin is epoxy vinyl resin; carbon fiber is carbon fiber without graphitization treatment; low shrinkage agent is PVAc; wave absorbing agent is ferrite; inorganic mineral The filler is aluminum hydroxide; the curing agent is TBPB or a composite initiation system of TBPB and TBPO, wherein the weight ratio of TBPB / TBPO is 0.7 / 0.3; the thickener is magnesium oxide; the release agent is zinc stearate.

[0020] Put the above-mentioned epoxy vinyl resin, low shrinkage agent, wave-absorbing agent, inorganic mineral filler, release agent, and curing agent into the high-speed shear mixer accordi...

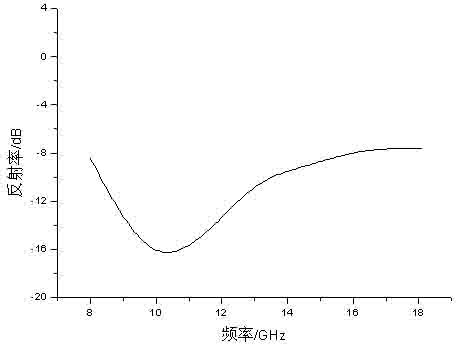

Embodiment 2

[0025] A high-strength carbon fiber reinforced sheet molding compound with excellent electromagnetic wave shielding performance. The sheet molding compound contains the following components in weight fraction ratio: matrix resin 60, carbon fiber 80, low shrinkage agent 35, wave absorbing agent 8, inorganic mineral filler 180, curing agent 2, thickener 2, mold release agent 4; wherein: matrix resin is epoxy vinyl resin; carbon fiber is carbon fiber without graphitization treatment; low shrinkage agent is PVAc; wave absorbing agent is ferrite; inorganic mineral The filler is aluminum hydroxide; the curing agent is TBPB or a composite initiation system of TBPB and TBPO, wherein the weight ratio of TBPB / TBPO is 0.7 / 0.3; the thickener is magnesium oxide; the release agent is zinc stearate.

[0026] Put the above-mentioned epoxy vinyl resin, low shrinkage agent, wave-absorbing agent, inorganic mineral filler, release agent, and curing agent into the high-speed shear mixer accordi...

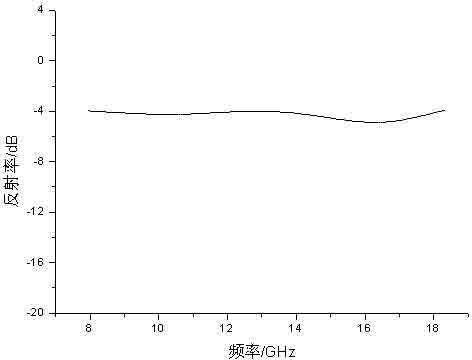

Embodiment 3

[0035] Compared with Example 1, Example 3 differs only in components. A high-strength carbon fiber reinforced sheet molding compound with excellent electromagnetic wave shielding performance. The sheet molding compound contains the following components in weight fraction ratio: matrix resin 80, carbon fiber 30, low shrinkage agent 30, wave absorbing agent 2, inorganic mineral filler 130, curing Agent 1, Thickener 1, Release Agent 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com