Patents

Literature

39results about How to "Excellent electromagnetic wave shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fiber shielding paper preparing process

InactiveCN101265676AImprove shielding effectGuaranteed lightweightDefoamers additionPaper/cardboardCarbon fibersPlant fibre

A process for preparing carbon fiber screening paper is provided. The invention includes the following steps: mixing chopped carbon fiber and plant carbon fiber in a certain proportion, adding certain amounts of a dispersant and a defoaming agent, dispersing on a fluffer, and papermaking in a paper former. While the light weight of material is guaranteed, the paper is endowed with good screening performance and easy process, which make full use of the advantages of large scale production in the papermaking industry. Furthermore, the paper electric conductive screening performance can be controlled by adjusting and quantifying the amount of the carbon fiber. The carbon fiber screening paper, which is an electric conductive material with high performance, replaces the conventional electric conductive screening material and covers the shortages thereof. The prepared screening paper has good screening performance of electromagnetic waves, the screening effectiveness at 100KHz-1500MHz is more than 30dB and the maximum is 50dB, thereby being generally applicable to radiation protection and anti-interference of common commercial or electronic products.

Owner:SHAANXI UNIV OF SCI & TECH

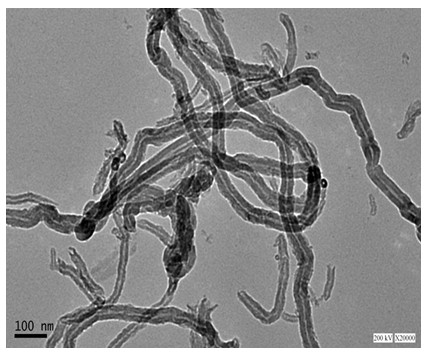

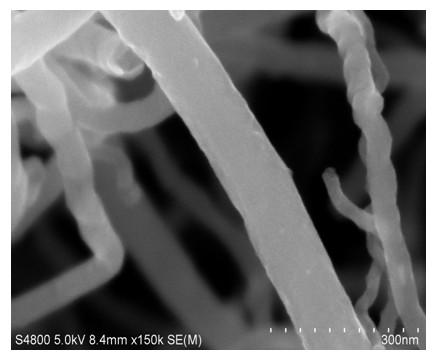

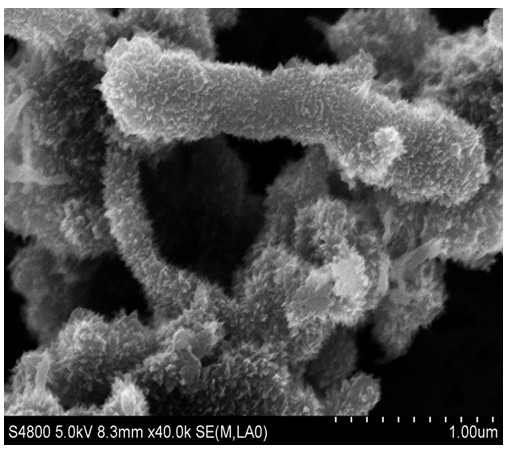

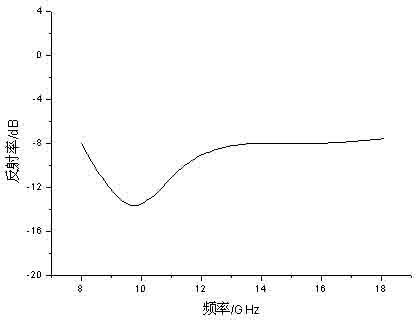

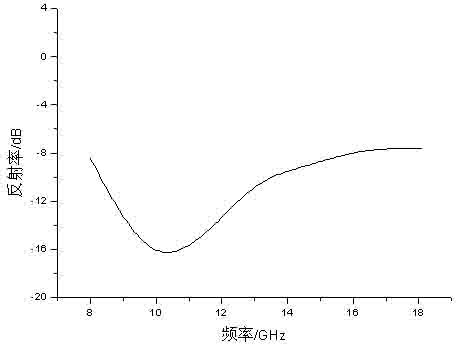

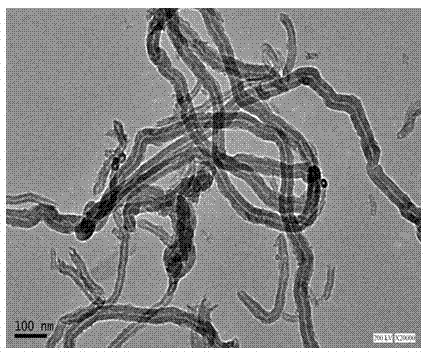

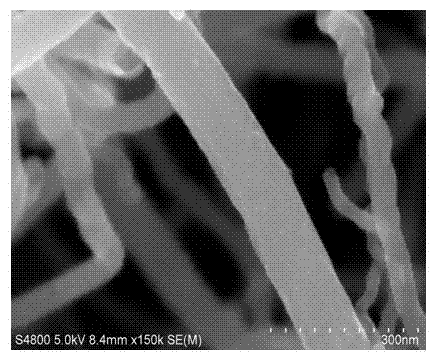

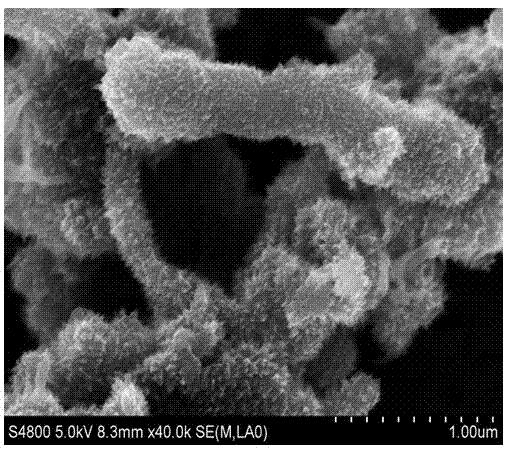

Preparation method of polyaniline/carbon nano tube compound electromagnetic shielding material

InactiveCN102153862AImprove electromagnetic wave shielding performanceIncrease the total shielding effectiveness valueCarboxylationPolyaniline nanofibers

The invention discloses a preparation method of a polyaniline / carbon nano tube compound electromagnetic shielding material. The preparation method comprises the following steps: (a) carboxylation of carbon nano tubes: adding concentrated H2SO4 into a mixture of carbon nano tubes and NaNO3 at low temperature, evenly stirring, raising the temperature, adding KMnO4, finally adding an H2O2 solution, and carrying out post-processing so as to obtain the carboxylated carbon nano tubes; and (b) preparation of the polyaniline / carbon nano tube compound shielding material. The surface of the polyaniline / carbon nano tube compound electromagnetic shielding material prepared by the method is composed of burr-shaped polyaniline nano fibers with rough surfaces. The polyaniline / carbon nano tube compound material has a large electromagnetic wave reflection section, thus the electromagnetic wave shielding property can be effectively improved; and the material has good electromagnetic shielding property in a microwave frequency band of 8-12 GHz, and can be used as a good electromagnetic shielding material.

Owner:ANHUI UNIVERSITY

Carbon fibre-reinforced flaky moulding material for shielding electromagnetic waves as well as preparation method and application

InactiveCN102675848AImprove conductivityImprove mechanical propertiesOther chemical processesCarbon fibersAutomotive battery

The invention discloses a carbon fibre-reinforced flaky moulding material for shielding electromagnetic waves as well as a preparation method and application. The flaky moulding material contains the following components according to parts by weight: 60 to 100 of matrix resin, 30 to 100 of carbon fibre, 30 to 50 of low shrinking agent, 2 to 10 of wave absorbing agent, 130 to 230 of inorganic mineral filler, 1 to 4 of curing agent, 1 to 5 of thickening agent and 2 to 10 of other components; and the carbon fibre is carbon fibre which is not treated by graphitization, and acts as the function of absorbing electromagnetic waves in the compound material. The flaky moulding material has excellent electromagnetic wave shielding performance and mechanical performance and can be used for the fields of electronic equipment, traffic, military affairs and the like. The carbon fibre-reinforced flaky moulding material for shielding the electromagnetic waves is used as materials, such as a wave absorbing material, a battery case of an electric automobile with a novel energy resource, and an invisible material.

Owner:江苏兆新材料科技

Chromium-free solution for treating metal surfaces

InactiveUS20080254315A1Lower resistanceImprove corrosion resistancePretreated surfacesAnti-corrosive paintsChromium freeOrganic acid

An acidic chromium-free solution for treating a metal surface containing: a vanadium cation source and / or a vanadyl cation source; an organic acid as an anion source; and at least one oxoacid as another anion source is provided. The oxoacid is selected from oxoacids of nitrogen, sulfur, phosphorus, boron, and chlorine. A metal component composed of, for example, aluminum or magnesium is brought into contact with the chromium-free solution to form a vanadium coating film of a surface of the metal component. A surface treating process using this chromium-free solution is useful for formation of a coating film having low corrosion resistance and low electric resistance.

Owner:NIPPON HYOMEN KAGAKU KK

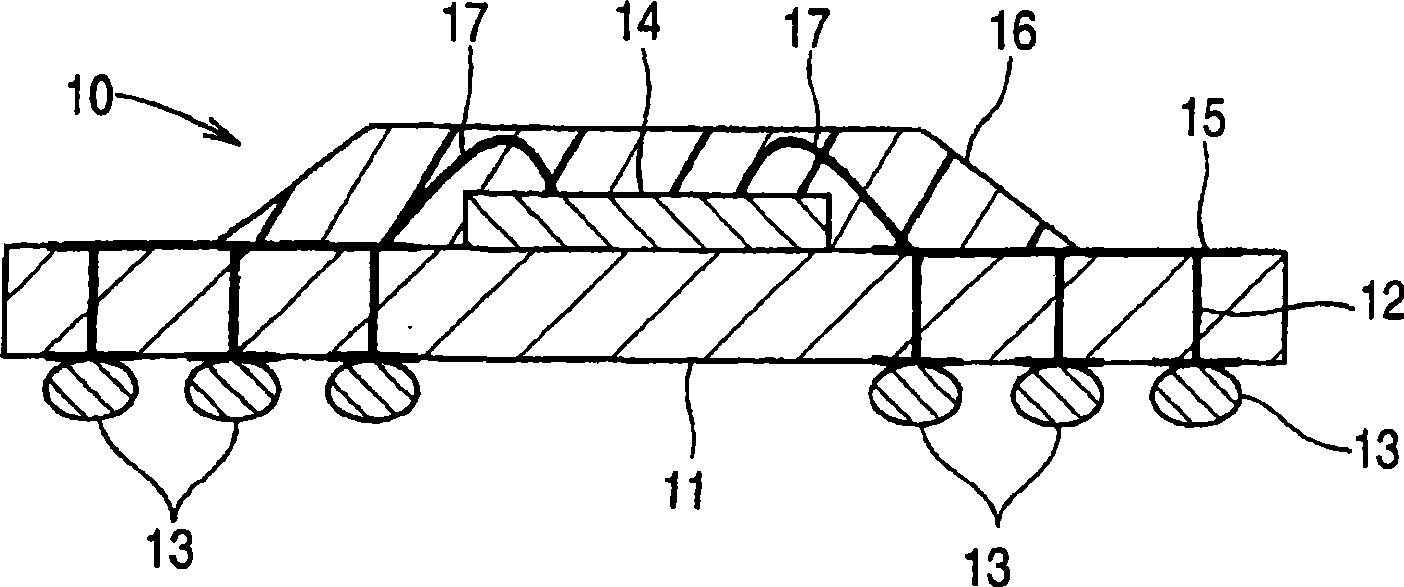

Spherical sintered ferrite particle, semiconductor sealing resin composition making use of the same and semiconductor device obtained therewith

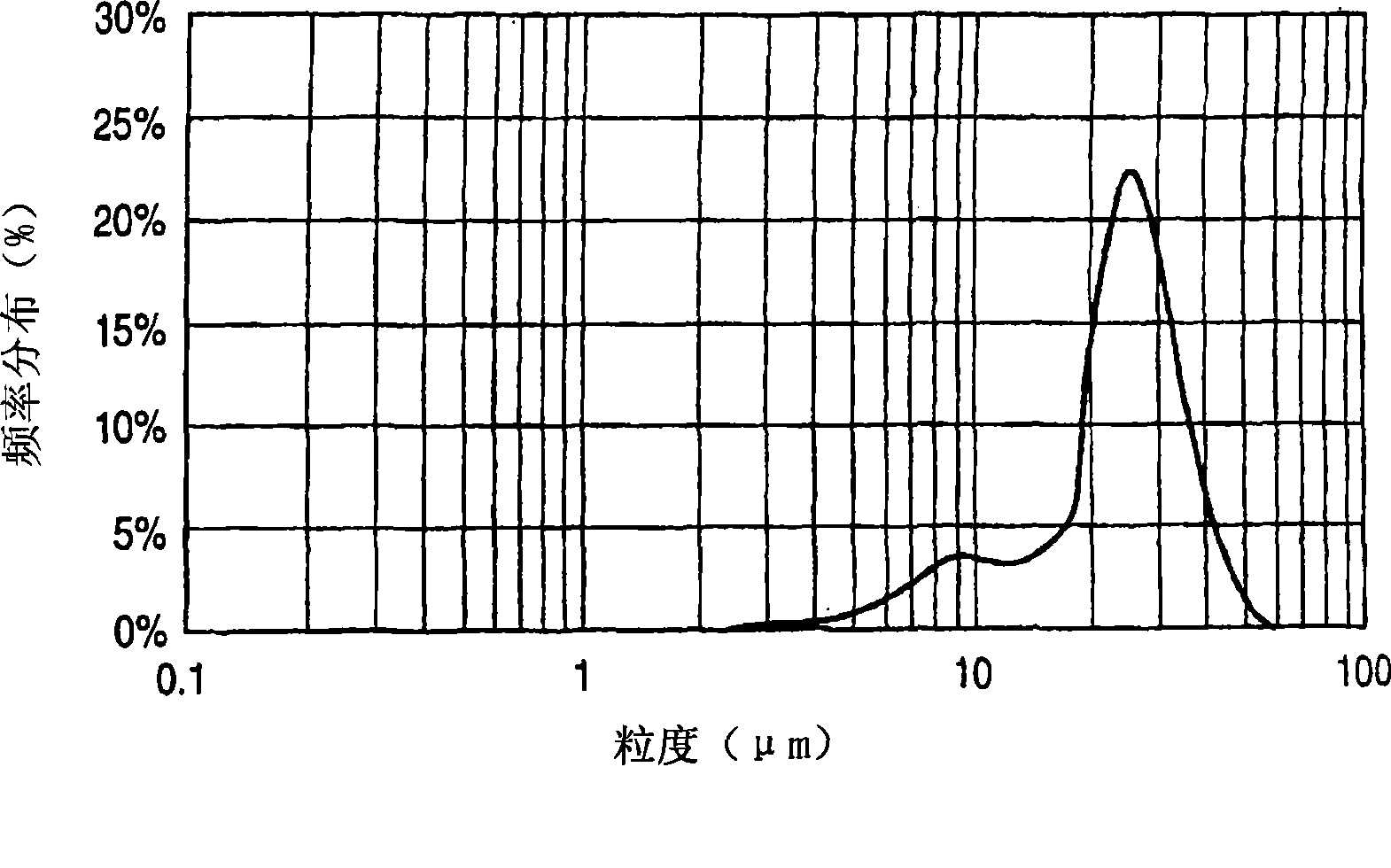

InactiveCN101460404ALow viscosityImprove liquidityPigmenting treatmentSemiconductor/solid-state device detailsIon contentCrystal structure

A resin composition for semiconductor encapsulation having goodmoldability, of which the cured product has effective electromagnetic wave shieldability, is provided. A resin composition for semiconductor encapsulation, containing spherical sintered ferrite particles having the following properties (a) to (c) : (a) the soluble ion content of the particles is at most 5 ppm; (b) the mean particle size of the particles is from 10 to 50 [mu]m; (c) the crystal structure of the particles by X-ray diffractiometry is a spinel structure.

Owner:NITTO DENKO CORP +1

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN100588743CFully activatedHigh activityMetallic material coating processesGlutaric acidGluconic acid

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloricacids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

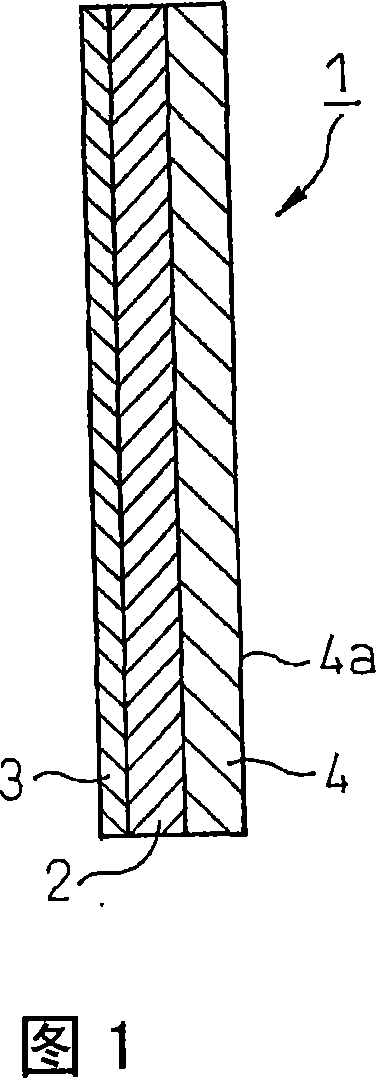

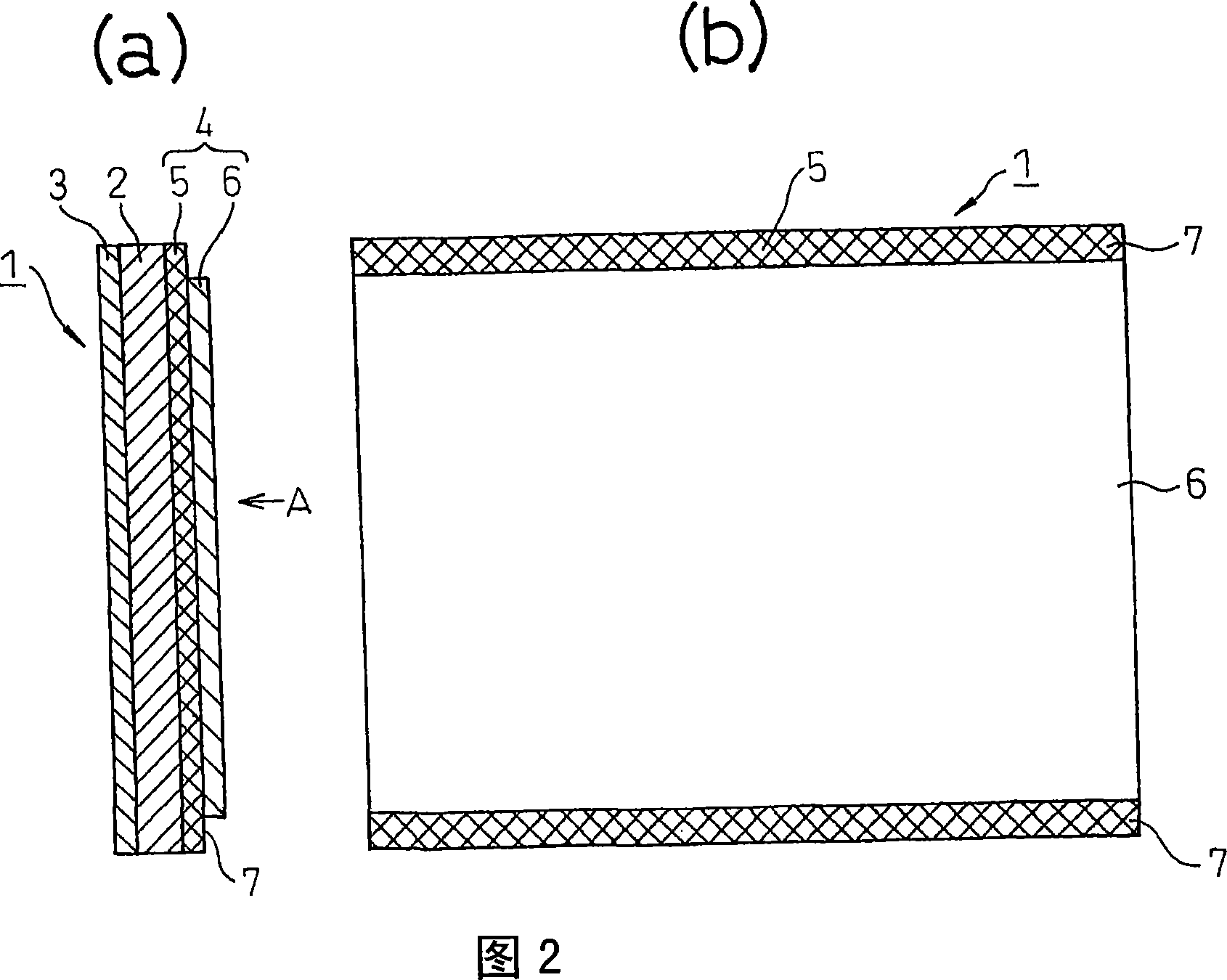

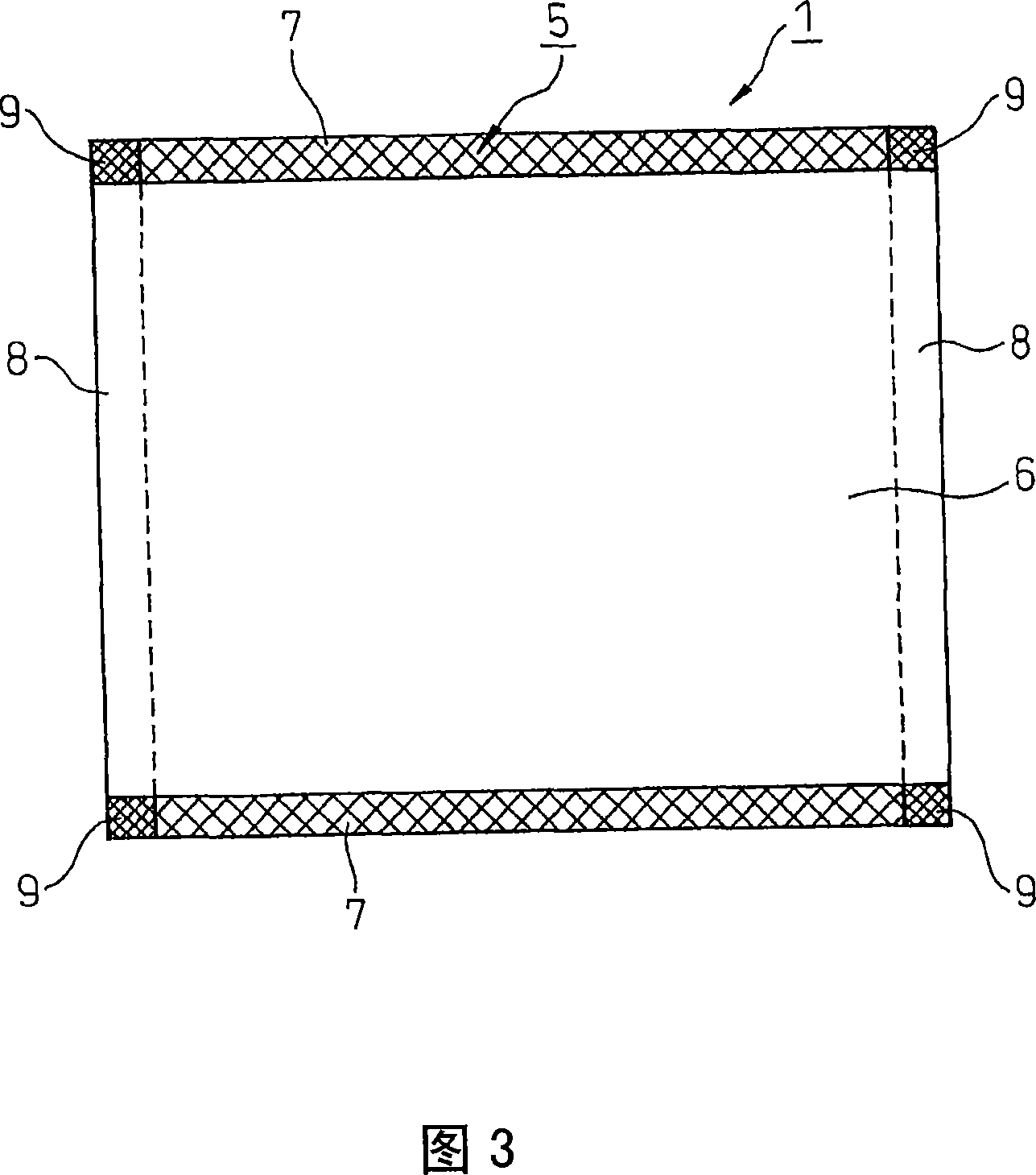

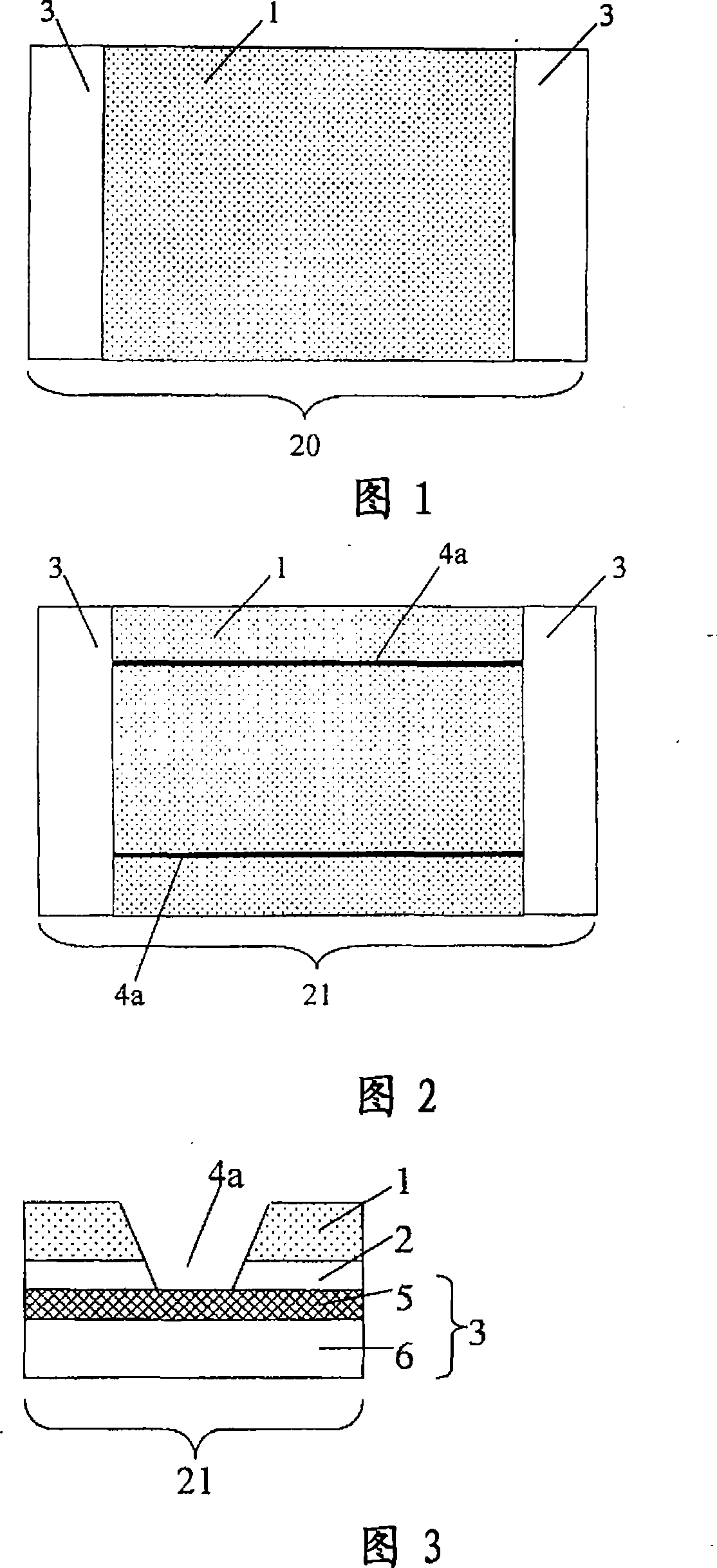

Optical filter

InactiveCN101061399AGood anti-reflection performanceExcellent electromagnetic wave shieldingMagnetic/electric field screeningOptical filtersVisibilityElectromagnetic shielding

Disclosed is an integrated film-like optical filter wherein an antireflective layer is formed on one side of a transparent base (such as a PET film), a composite layer including an electromagnetic shielding layer and a near-infrared blocking layer is bonded to the other side of the transparent base, and the exposed surface of the composite layer has adhesive properties. This optical filter is light in weight and is easy to produce and handle. In addition, the optical filter is excellent in in-use durability and visibility of visible images, and is useful as an optical filter for display surfaces of plasma displays or the like.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Method for preparing photoelectric functional compound fabric through fractional in-situ deposition

The invention relates to a method for preparing a photoelectric functional compound fabric through fractional in-situ deposition. The method comprises the following steps of: (1) dropwise adding a zinc acetate / alcoholic solution and a sodium hydroxide / alcoholic solution under violent stirring, and mixing to obtain nanometer zinc oxide sol; (2) putting the fabric into the nanometer zinc oxide sol,carrying out soaking and rolling twice, and baking after airing; (3) soaking the fabric obtained in the step (2) into a mixed aqueous solution containing zinc nitrate and a homogeneous precipitation agent, and baking after washing; and (4) soaking the fabric obtained in the step (3) into a mixed aqueous solution containing aniline and protonic acid, airing and then soaking the fabric into a mixedaqueous solution containing ammonium persulfate and protonic acid, extruding and finally continuing to react to obtain the finished product. The preparation method disclosed by the invention is simple and feasible, safe and environment-friendly and has low requirements on equipment performance. The photoelectric multifunctional compound fabric prepared by utilizing the method disclosed by the invention has the advantages of favorable electrical conductivity, flame retardance, antibiotic property, photocatalysis property, antistatic property, electromagnetic wave shielding property and other properties, and wide application prospect.

Owner:DONGHUA UNIV

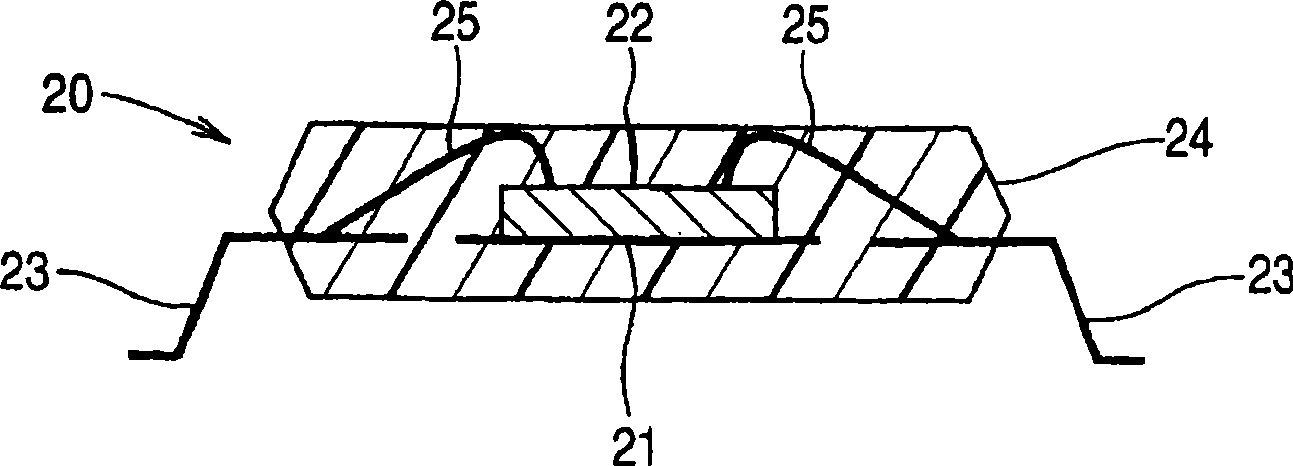

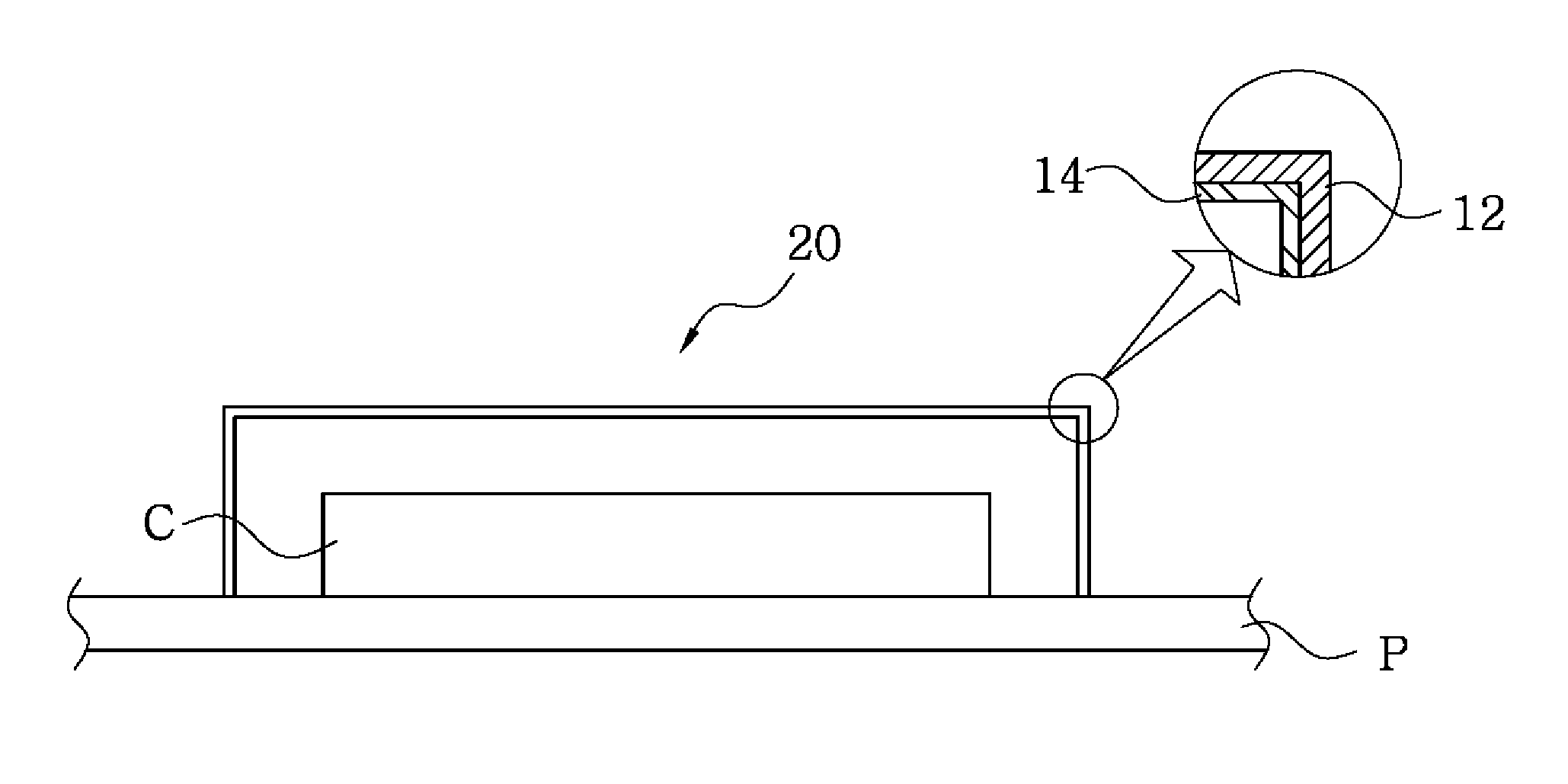

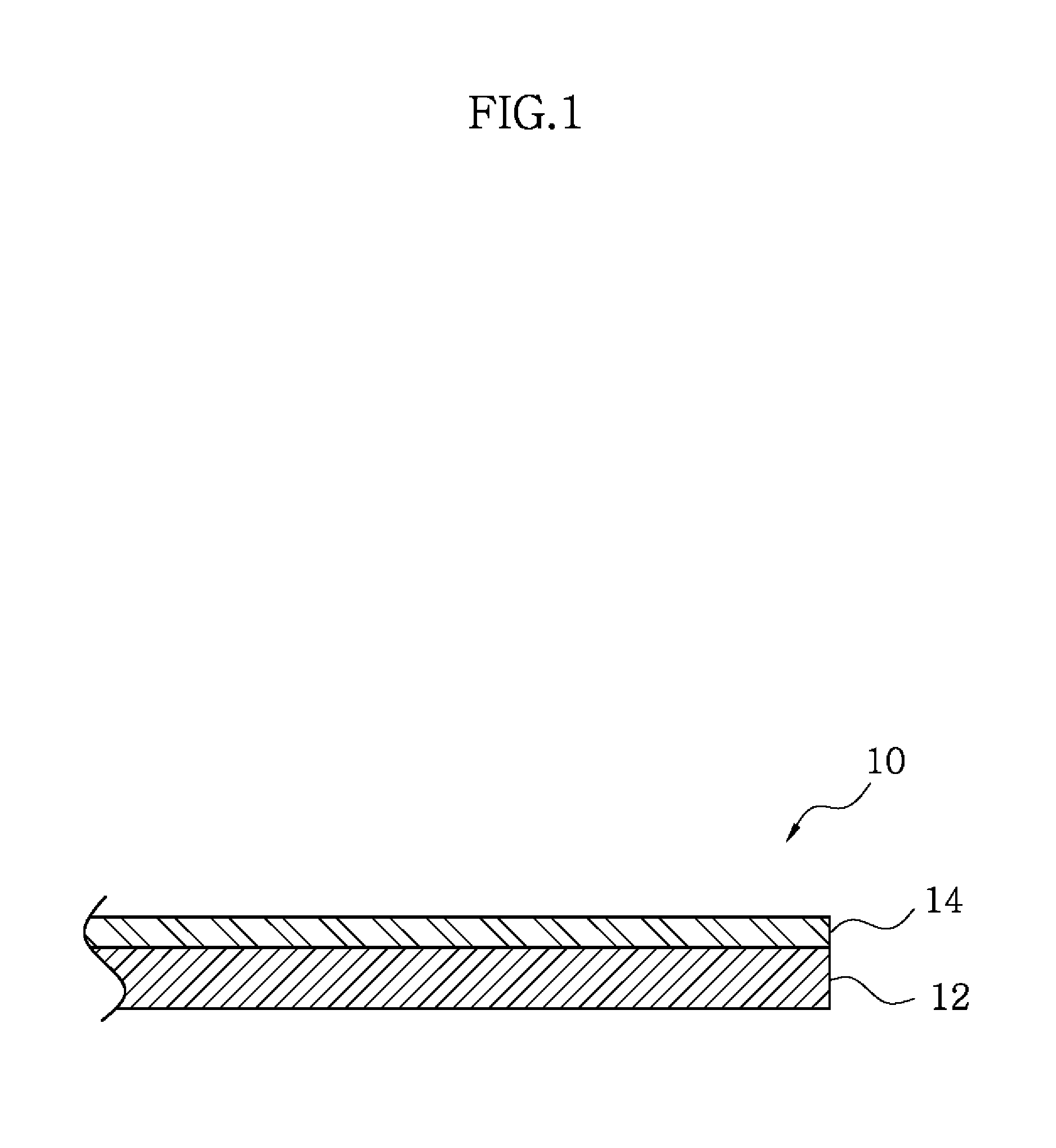

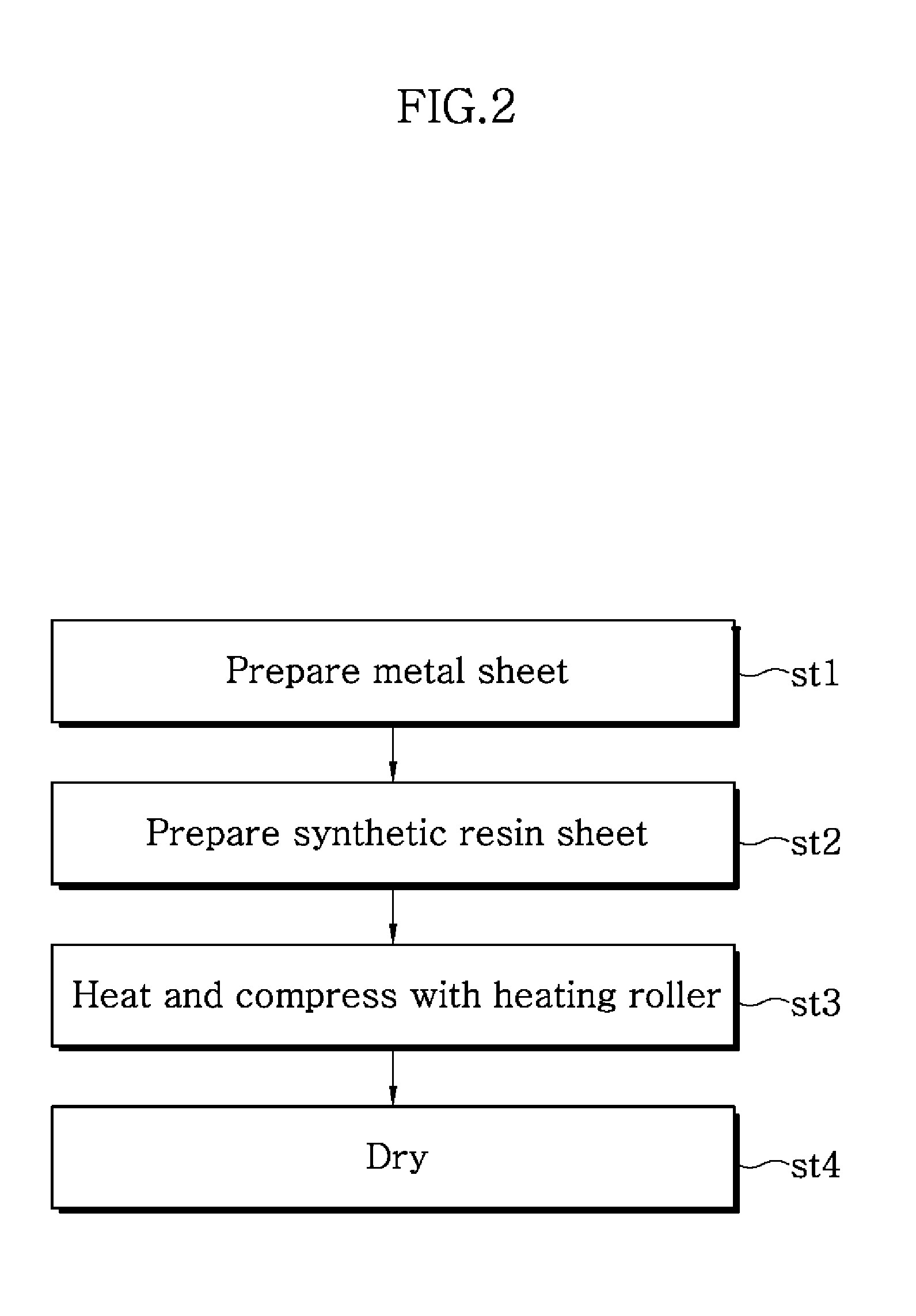

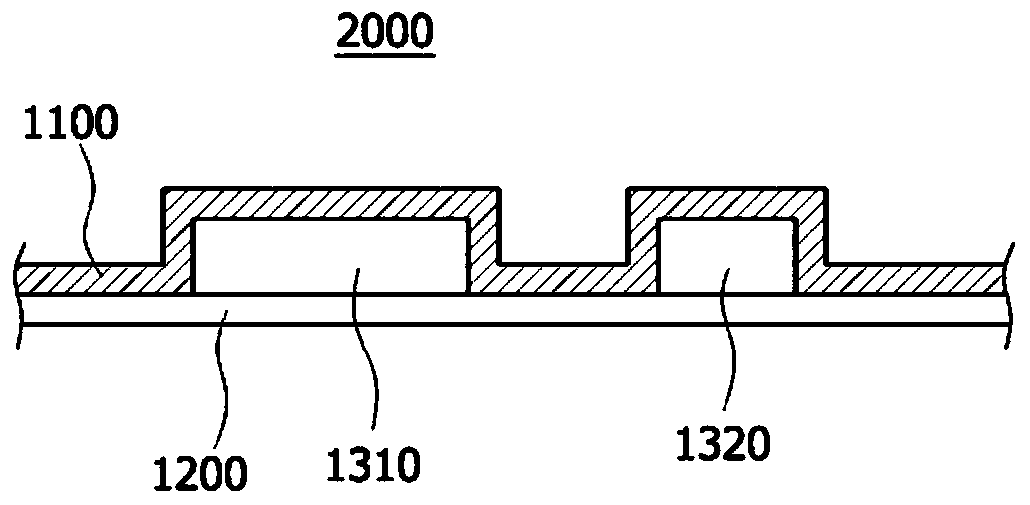

Plate for a shield can for an SMD process, manufacturing method thereof, and shield can using the plate

InactiveUS20140027171A1Effective shieldingImprove conductivitySynthetic resin layered productsLaminationSilanesCoupling

The shield can plate for a SMD process in accordance with the present invention, includes: a metal conductive layer which is made of one selected from a group consisting of copper (Cu), zinc (Zn), nickel (Ni), silver (Ag), iron (Fe) and chromium (Cr) or an alloy thereof, or clad metal, performs an electromagnetic shielding function and maintains a physical structure when a shield can is constructed; an insulating layer which is made of one or more of polyethylene terephthalate (PET) and polyethylene naphthalate (PEN), which are crystalline polymers, wherein the insulating layer is laminated on one side of the metal conductive layer; and a silane-based coupling layer interposed between the metal conductive layer and the insulating layer.

Owner:SONG MIN HWA

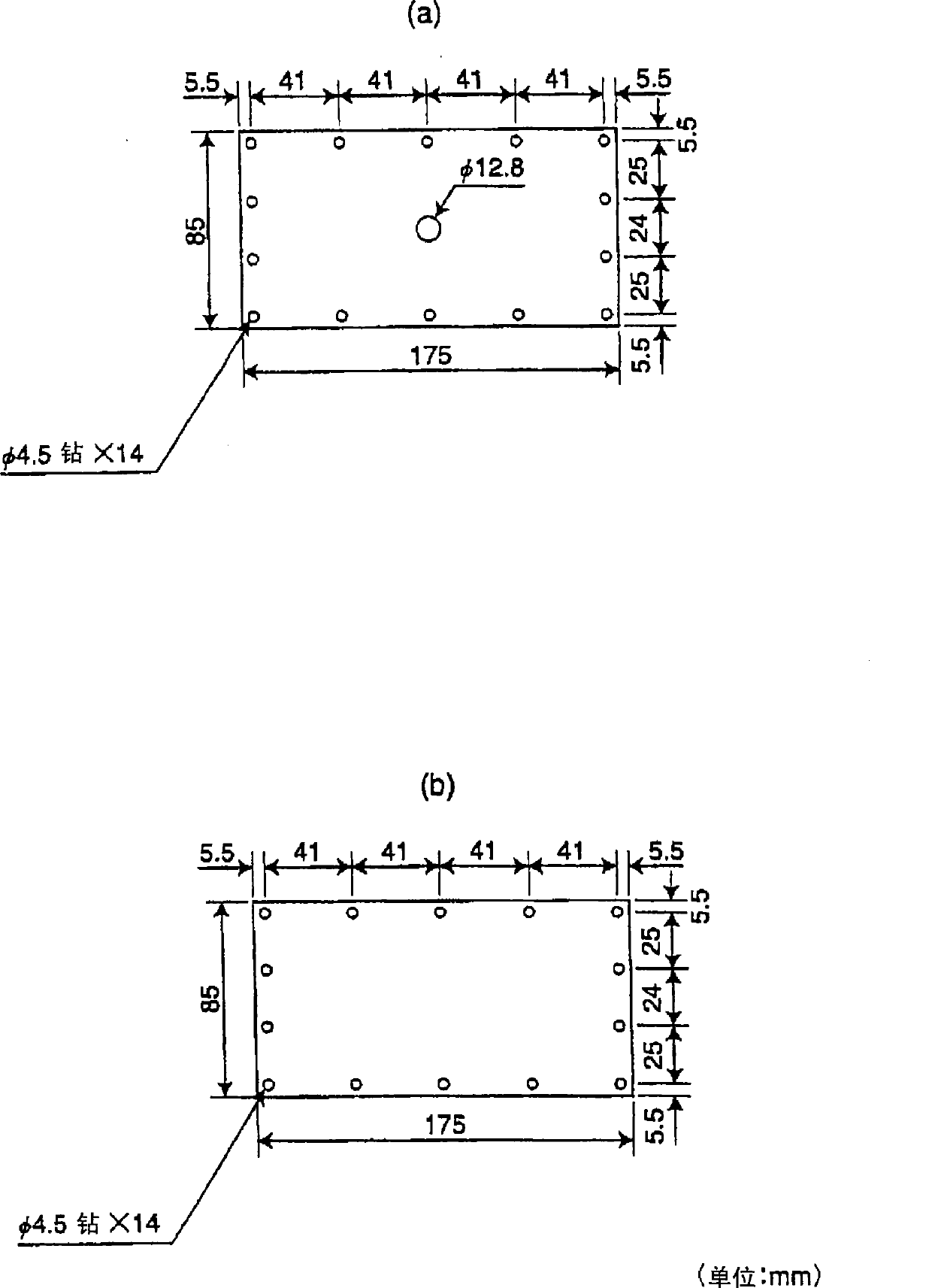

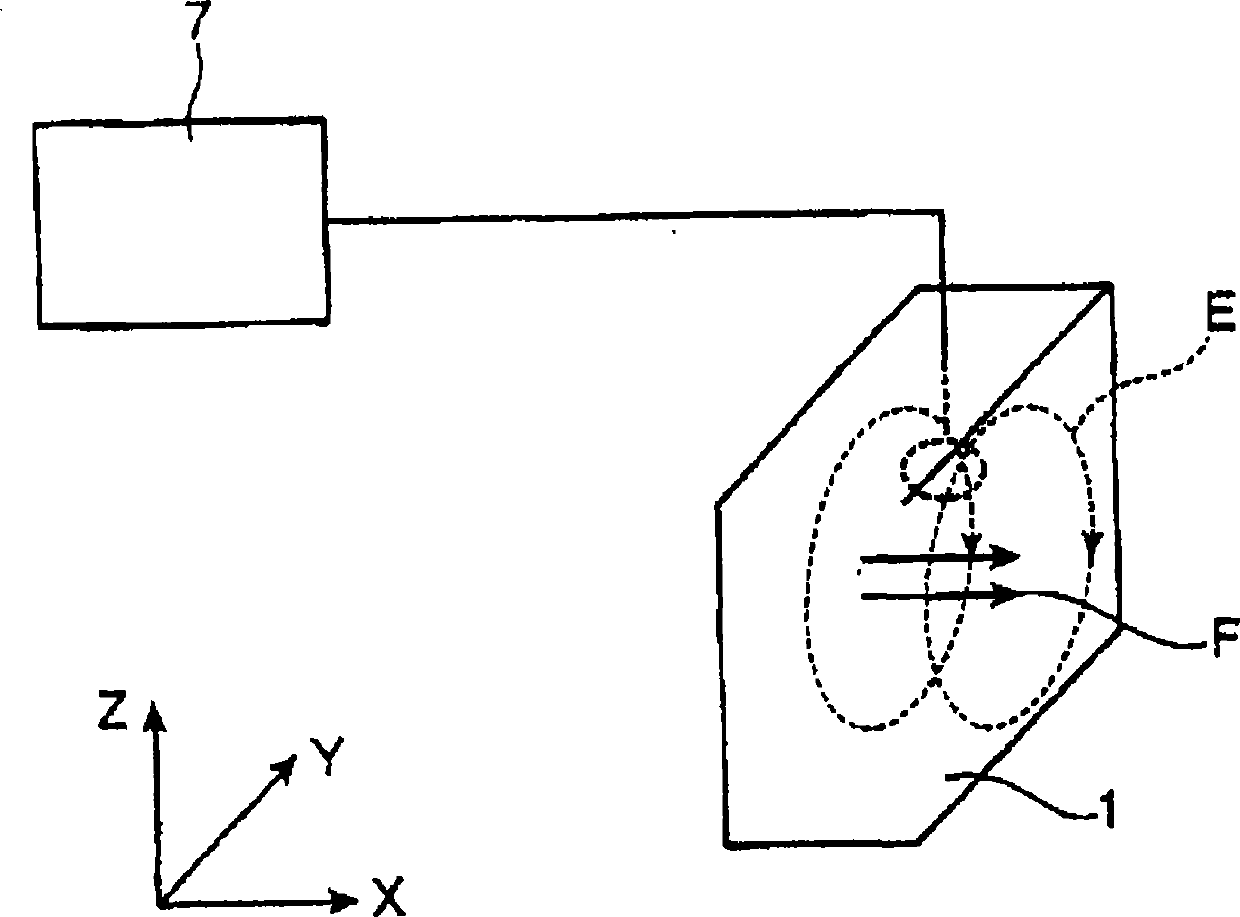

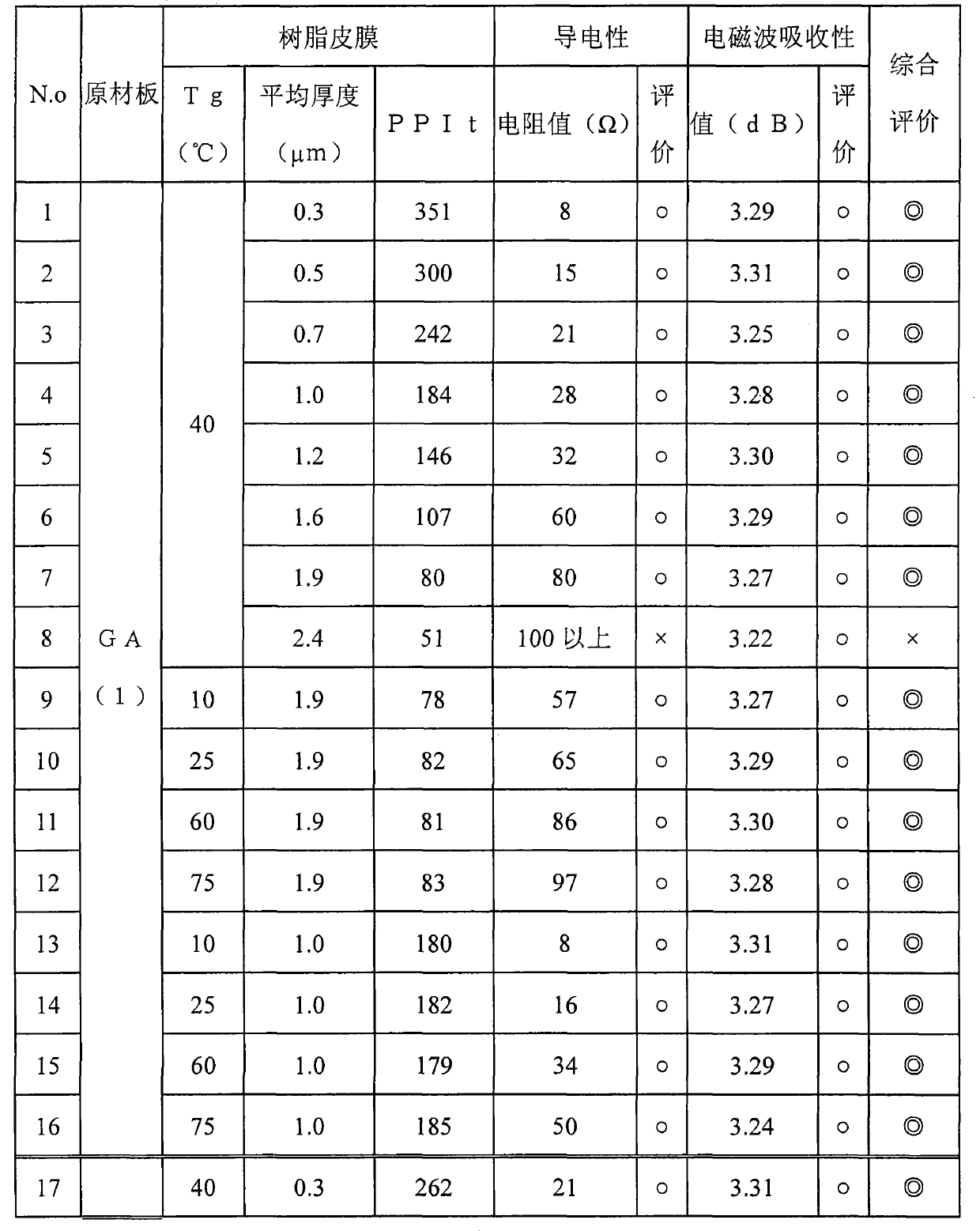

Resin coated metal sheet with excellent electromagnetic wave shielding performance

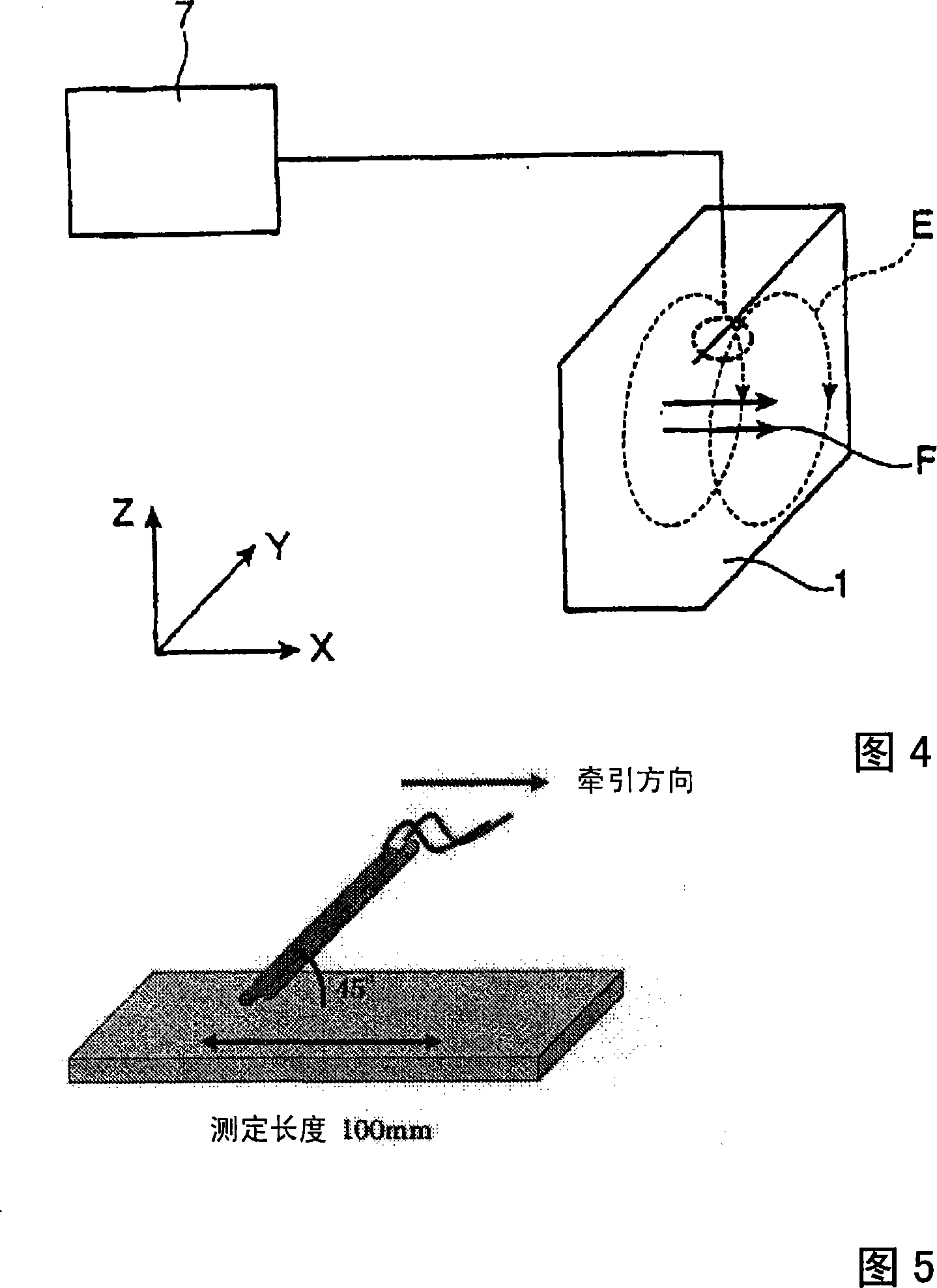

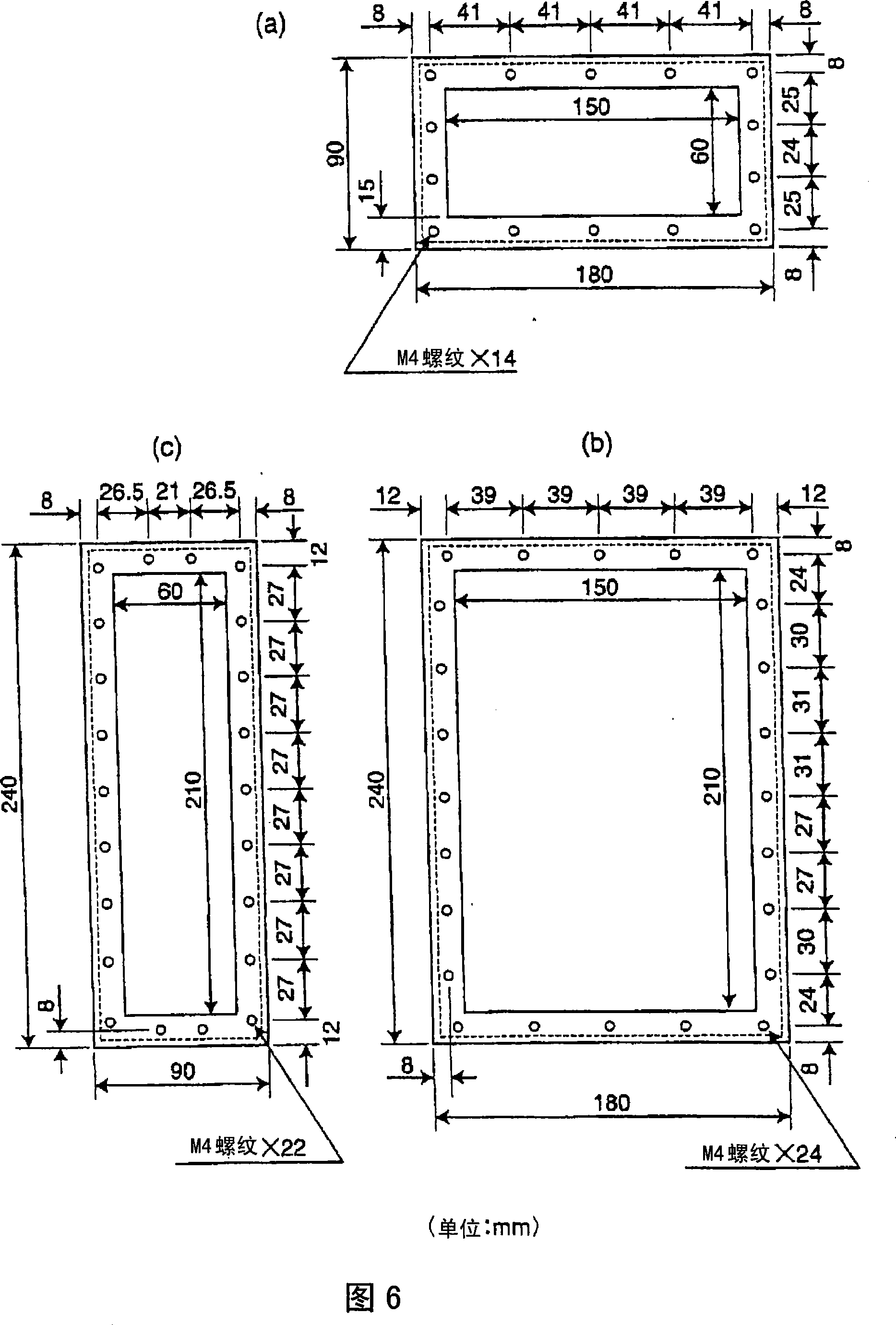

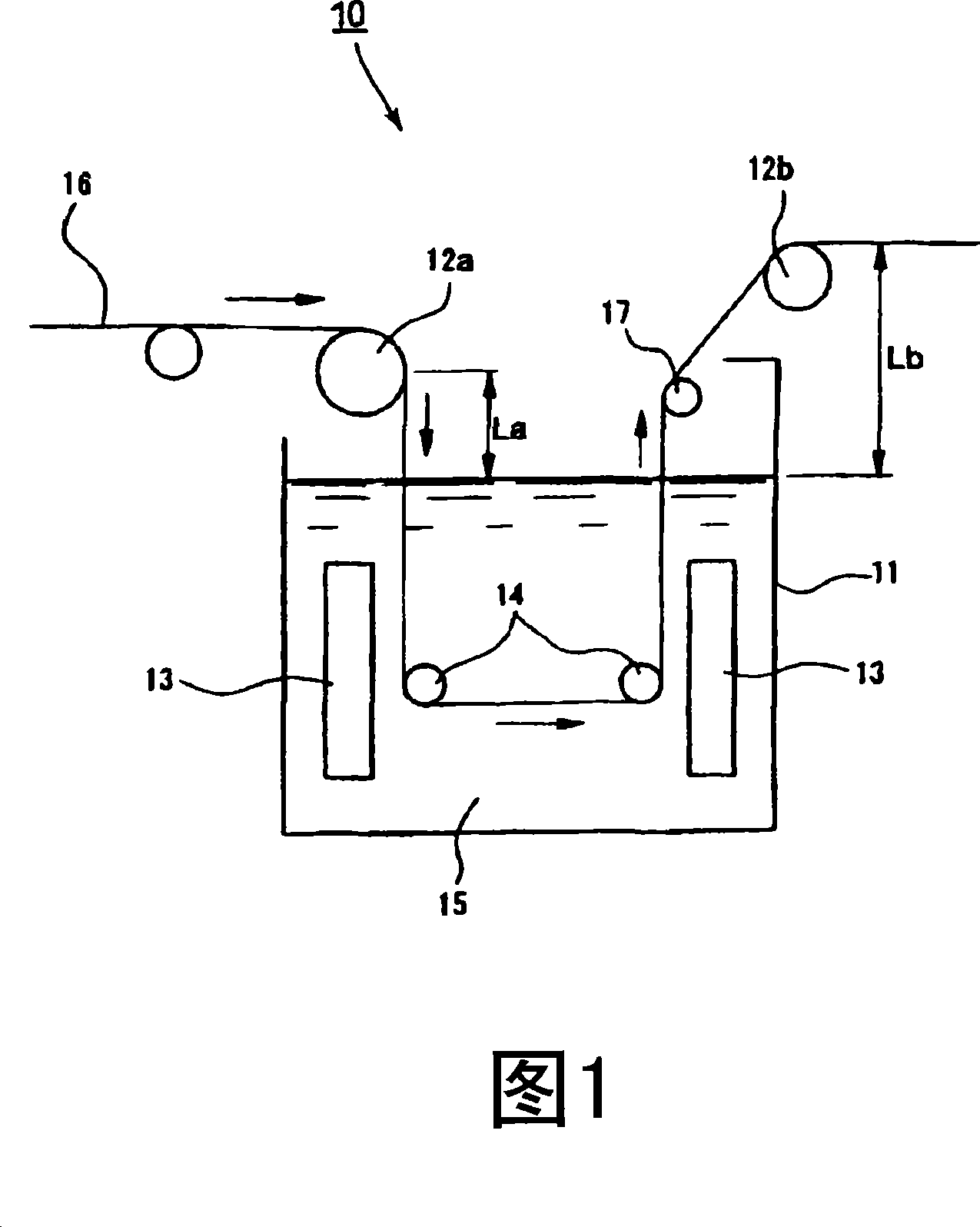

InactiveCN101090005AImprove conductivityExcellent electromagnetic wave shieldingHot-dipping/immersion processesMagnetic/electric field screeningMetal sheetPolyresin

The present invention is a resin-coated metal plate whose surface is covered with a resin film. By improving the electrical conductivity of the resin-coated metal plate, it can exhibit excellent electromagnetic wave shielding properties and preferably can exhibit good characteristics even under light contact. The resin film satisfies the necessary conditions of the following formula (1), that is, PPIt≥70...(1). PPIt represents the number of peak-to-bottom counts when 1 / 2 of the peak count level (2H) is taken as the thickness t (μm) of the resin film in PPI (Peaks PerInch) described in SAE J911-1986.

Owner:KOBE STEEL LTD

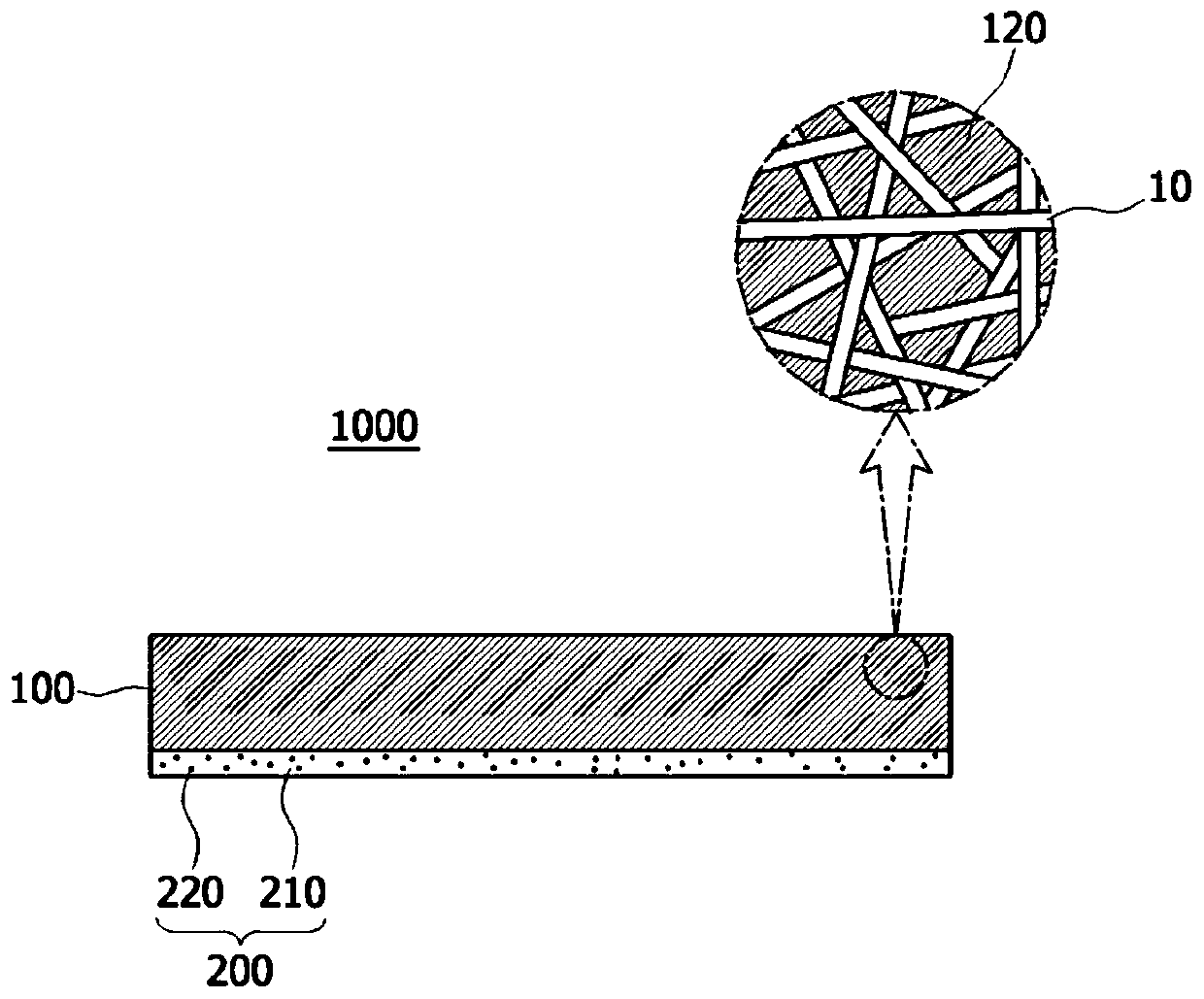

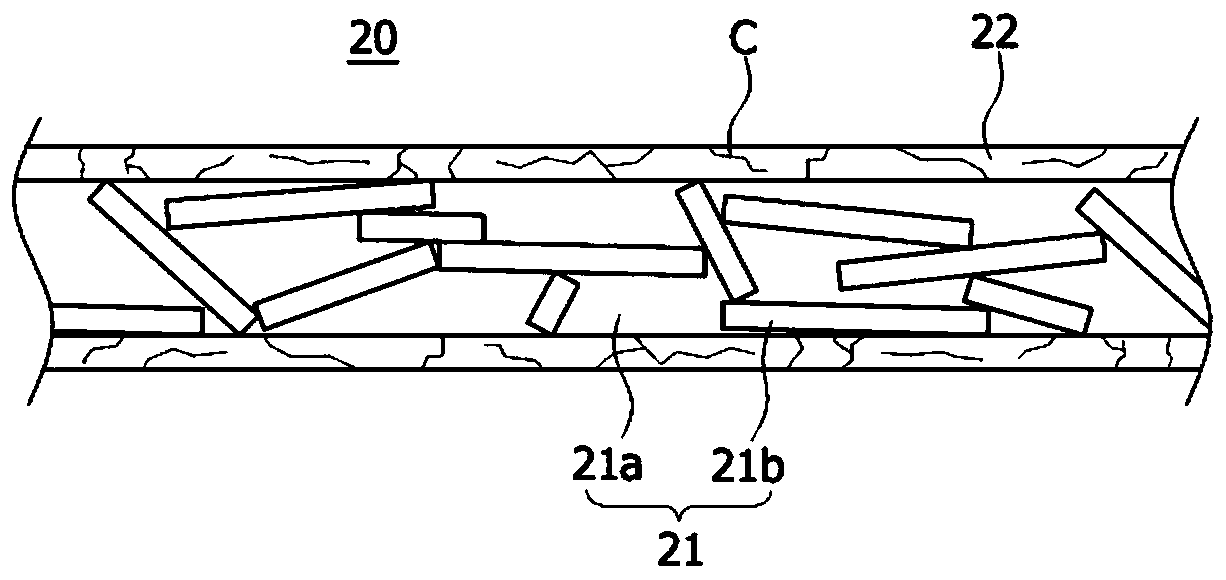

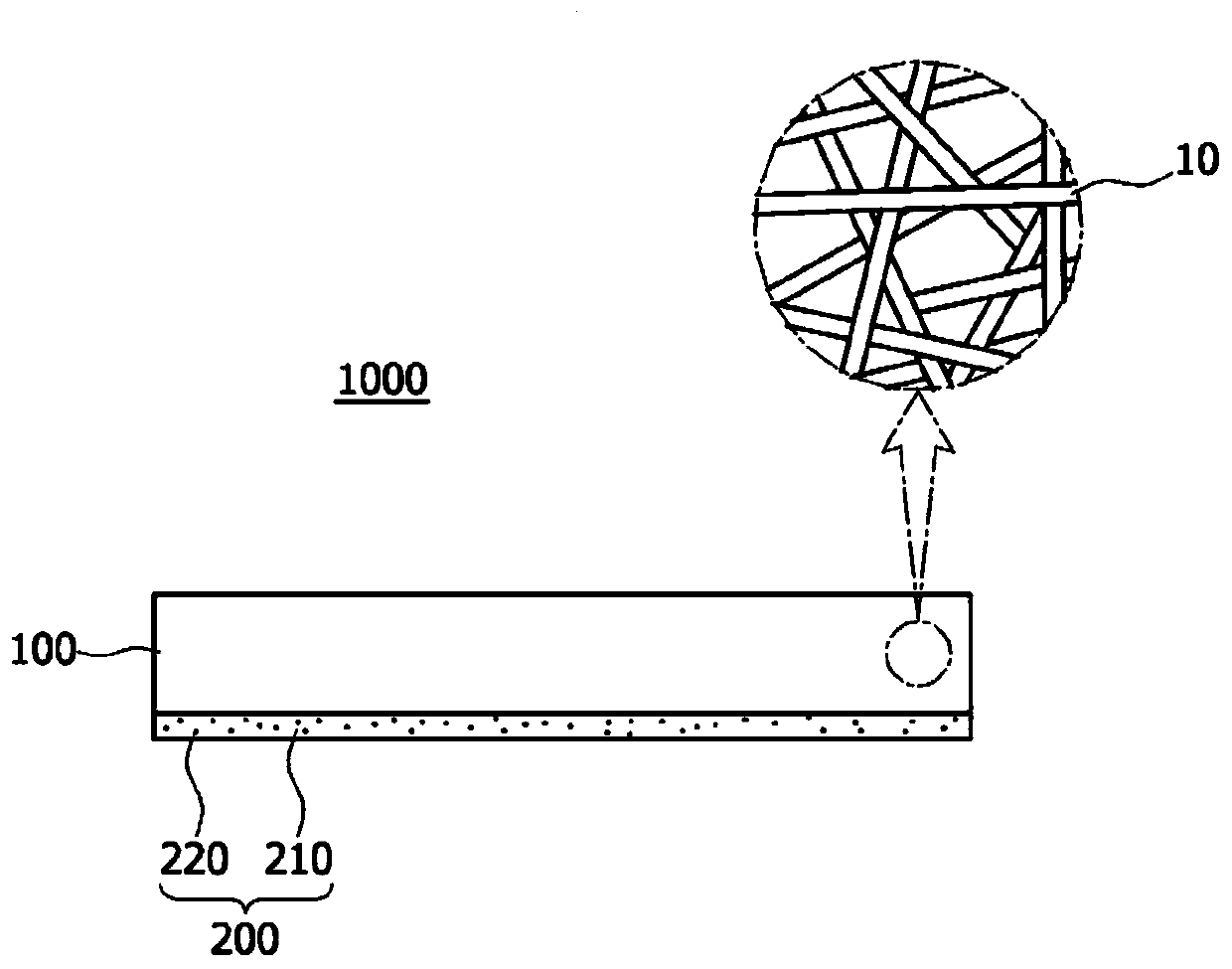

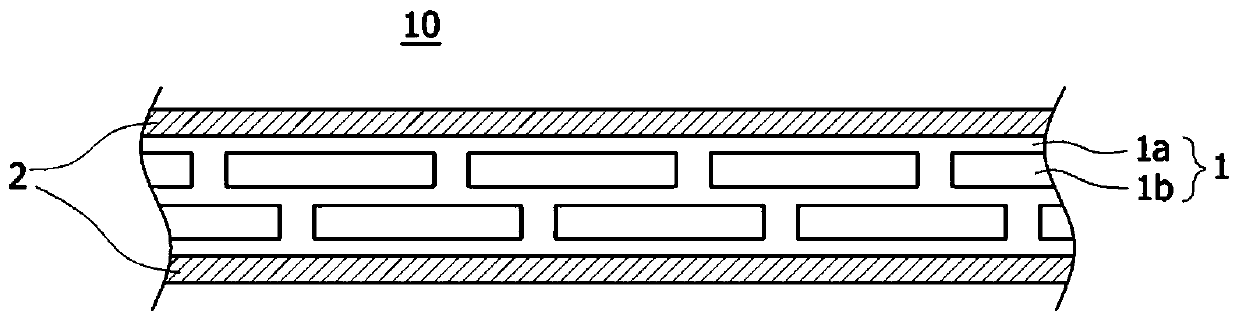

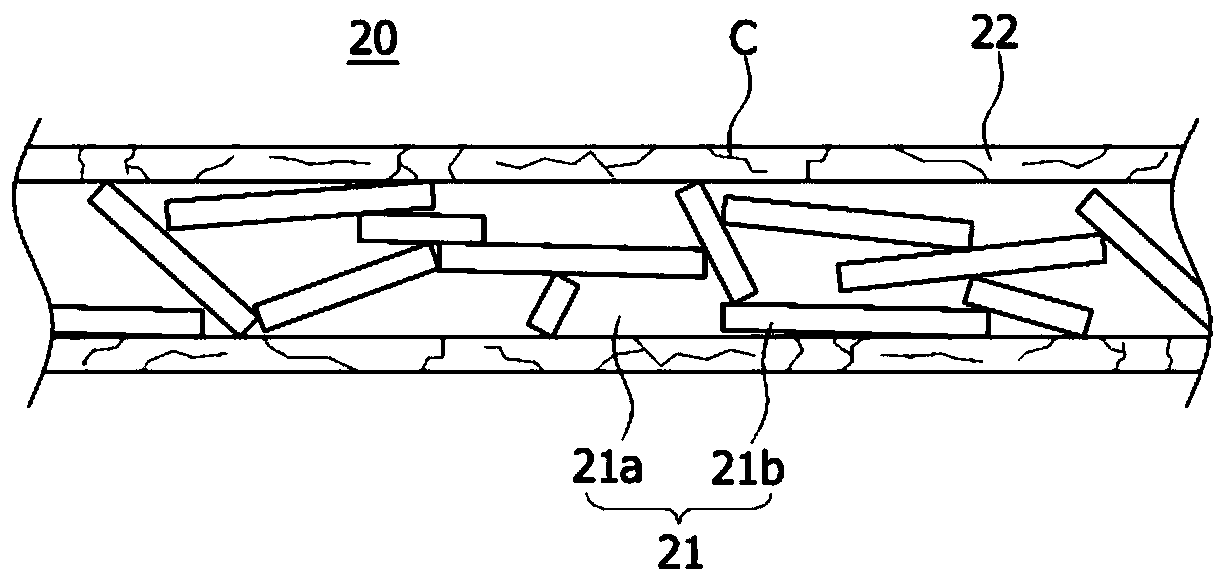

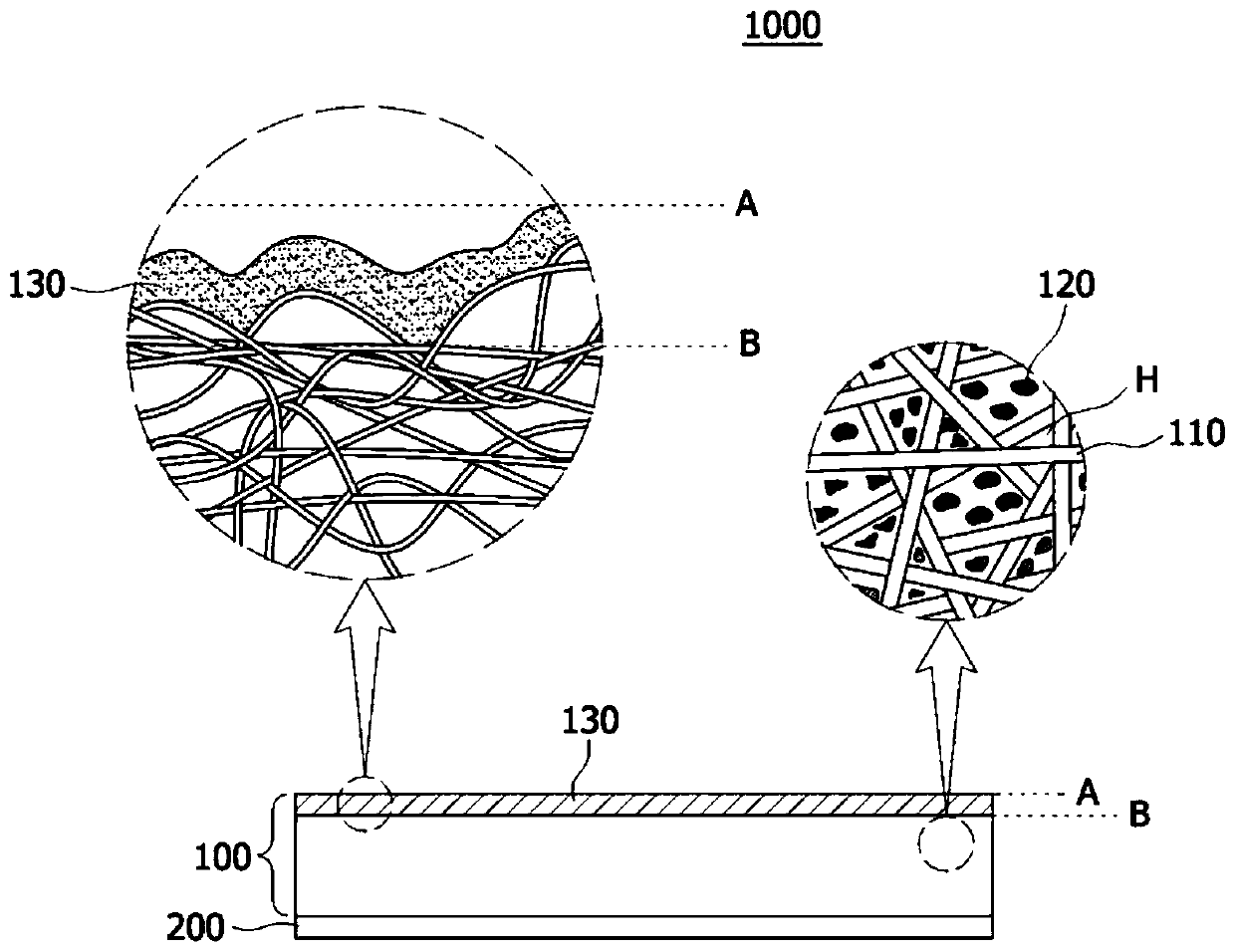

Flexible electromagnetic wave shielding material, electromagnetic wave shielding type circuit module comprising same and electronic device furnished with same

ActiveCN110089208AGood flexibilityImprove flexibilityShielding materialsModifications by conduction heat transferFiberHigh density

Provided is a flexible electromagnetic wave shielding material. An electromagnetic wave shielding material, according to one embodiment of the present invention, comprises: a conductive fiber web comprising a plurality of pores; and a heat dissipation part provided in at least some of the pores. Due to these features, as the electromagnetic wave shielding material according to the present invention has excellent flexibility, elasticity, and creasing / recovery, it is possible to freely modify the shape thereof as desired and to attach the electromagnetic wave shielding material to be completelyadhered to a surface even if the surface where the material is to be disposed has a curved shape such as uneven or stepped surfaces, and thus it is possible to exhibit excellent electromagnetic wave shielding performance. Also, degradation of the electromagnetic wave shielding performance can be prevented even with various shape changes. Further, since heat dissipation performance is excellent, heat generated in an electromagnetic wave generating source can be rapidly conducted and radiated. In addition, even when parts are mounted with a high density in a narrow area, the electromagnetic waveshielding material can be provided to completely adhere to the mounted parts while overcoming the tight spacing intervals and steps between the parts, such that the flexible electromagnetic wave shielding material can easily be adopted in a compact or flexible electronic device.

Owner:AMOGREENTECH CO LTD

Flexible electromagnetic wave shielding material, electromagnetic wave shielding type circuit module comprising same and electronic device furnished with same

ActiveCN110073732AGood flexibilityImprove flexibilityElectroconductive/antistatic filament manufactureShielding materialsFiberShape change

Owner:AMOGREENTECH CO LTD

Light-transmitting electromagnetic shielding film, optical filter and plasma television

InactiveCN101142868AIncreased durabilityImprove conductivityMagnetic/electric field screeningSynthetic resin layered productsInfraredEmulsion

Disclosed is a light-transmitting electromagnetic shielding film which has both high electromagnetic shielding properties and high infrared blocking properties. Specifically disclosed is a light-transmitting electromagnetic shielding film wherein a metal silver portion and a light-transmitting portion are formed by exposing and developing an emulsion layer which is arranged on a supporting body and contains a silver salt emulsion. This light-transmitting electromagnetic shielding film is characterized by having infrared blocking properties.

Owner:FUJIFILM CORP

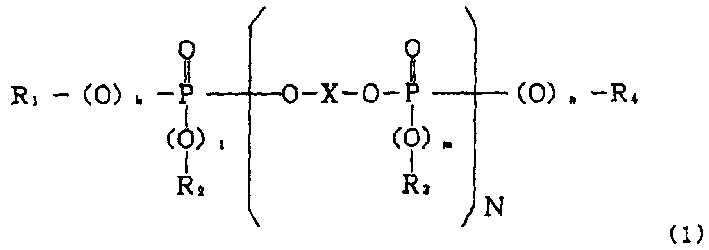

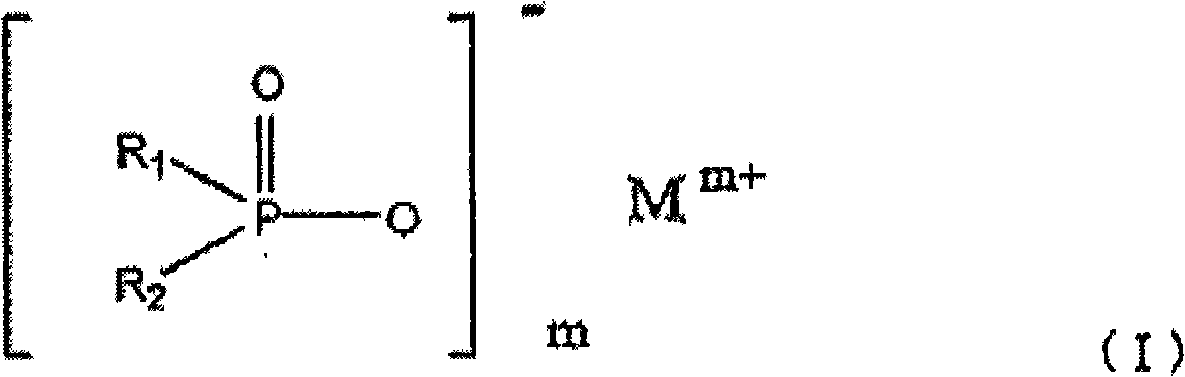

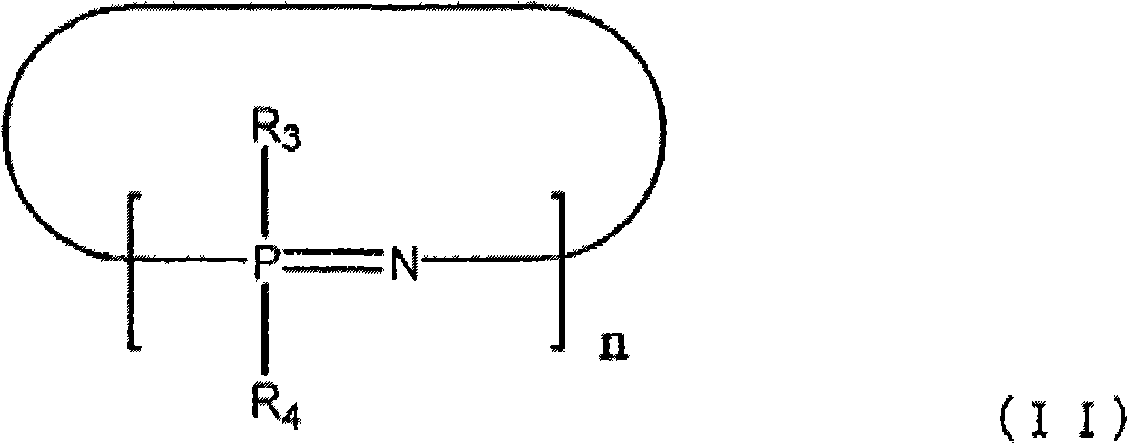

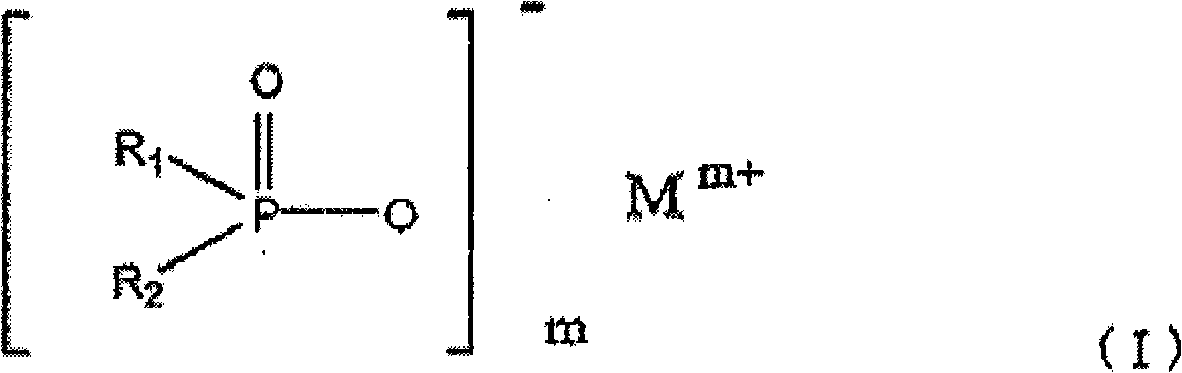

Flame-retardant and electromagnetic interference attenuating thermoplastic resin compsn

InactiveCN1481422AImprove flame retardant performanceExcellent electromagnetic wave shieldingFiberMetal coating

A flame-retardant and electromagnetic interference attenuating thermoplastic resin composition excellent in flame retardance, surface appearance and processability in molding, which comprises 100 parts by weight of a thermoplastic resin (A), 0.5 to 30 parts by weight of a halogen-free phosphate flame retardant (B) represented by the general formula (1), 5 to 35 parts by weight of a metal-coated fiber (C), and 3 to 30 parts by weight of a flaky or needle-like filler (D):(1) wherein R1, R2, R3 and R4 are each independently hydrogen or a monovalent organic group, with the proviso that at least one of R1, R2, R3 and R4 is a monovalent organic group; X is a divalent organic group; k, l, m and n are each independently 0 or 1; and N is an integer of 0 to 10.

Owner:NIPPON A & L INC

Preparation method of polyaniline/carbon nano tube compound electromagnetic shielding material

InactiveCN102153862BGood dispersionLarge electromagnetic wave reflection cross sectionFiberPolymer science

The invention discloses a preparation method of a polyaniline / carbon nano tube compound electromagnetic shielding material. The preparation method comprises the following steps: (a) carboxylation of carbon nano tubes: adding concentrated H2SO4 into a mixture of carbon nano tubes and NaNO3 at low temperature, evenly stirring, raising the temperature, adding KMnO4, finally adding an H2O2 solution, and carrying out post-processing so as to obtain the carboxylated carbon nano tubes; and (b) preparation of the polyaniline / carbon nano tube compound shielding material. The surface of the polyaniline / carbon nano tube compound electromagnetic shielding material prepared by the method is composed of burr-shaped polyaniline nano fibers with rough surfaces. The polyaniline / carbon nano tube compound material has a large electromagnetic wave reflection section, thus the electromagnetic wave shielding property can be effectively improved; and the material has good electromagnetic shielding property in a microwave frequency band of 8-12 GHz, and can be used as a good electromagnetic shielding material.

Owner:ANHUI UNIVERSITY

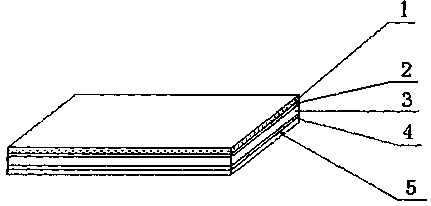

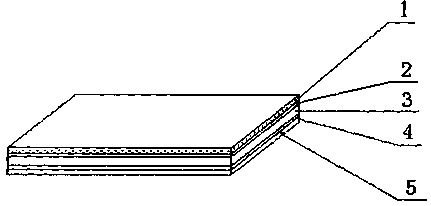

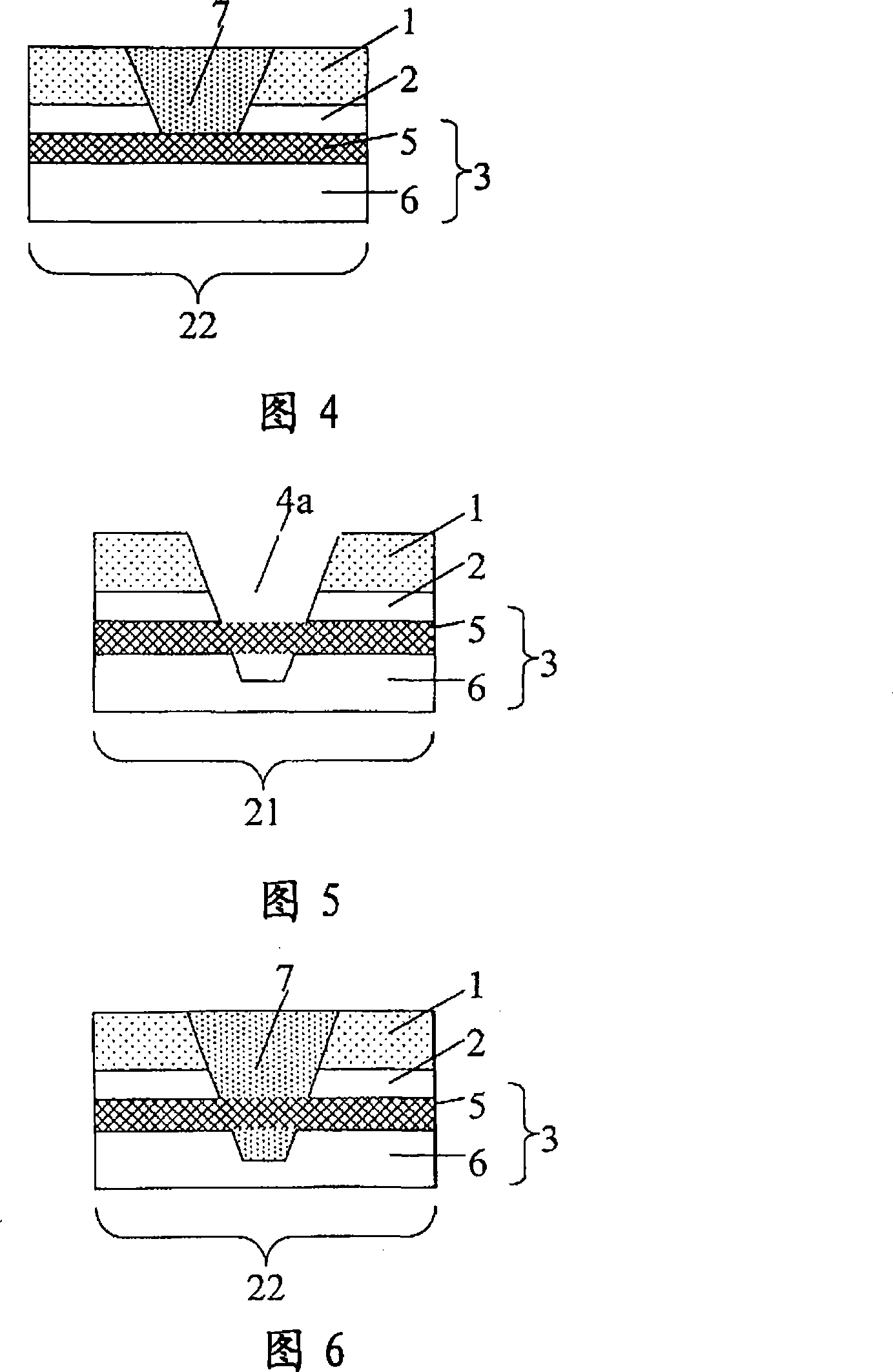

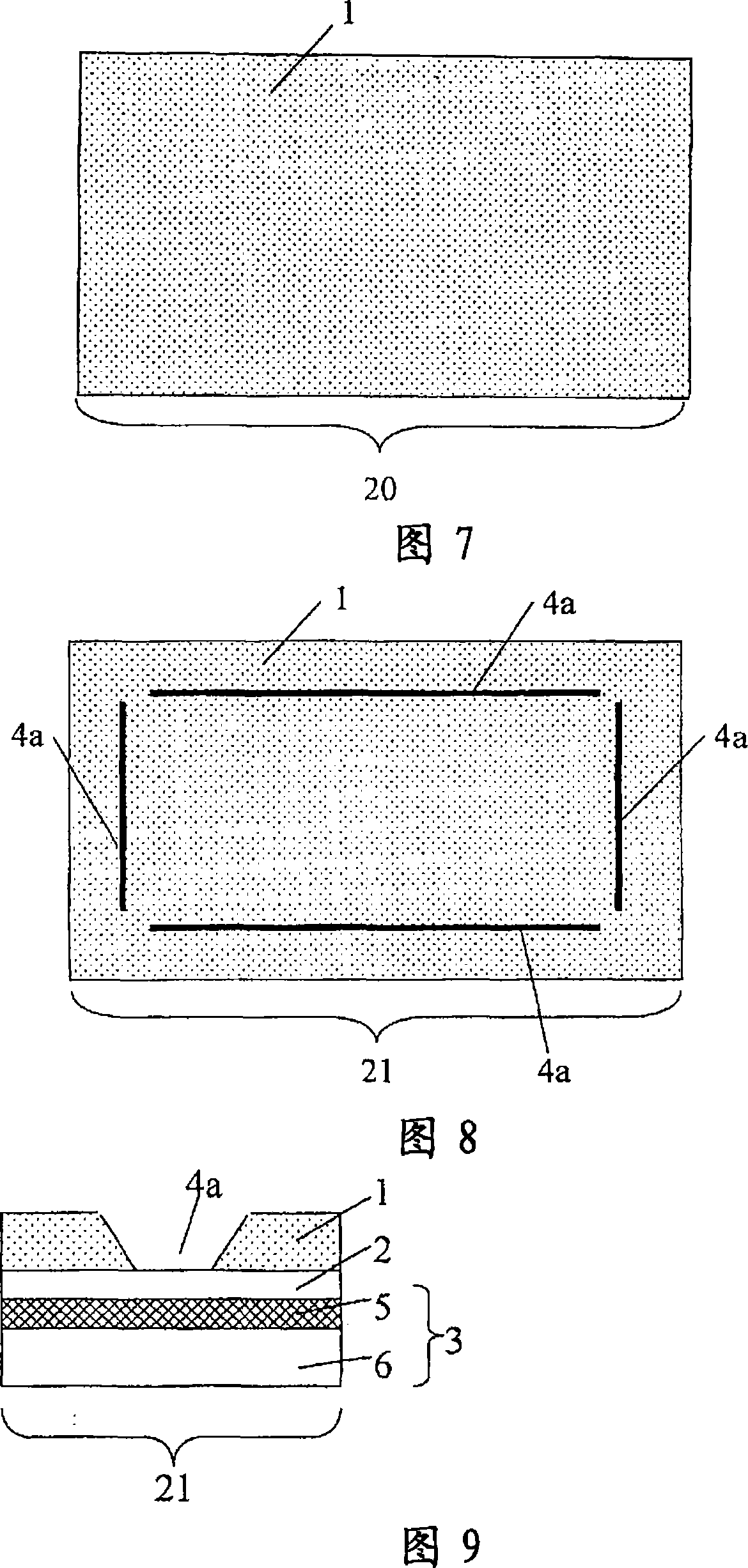

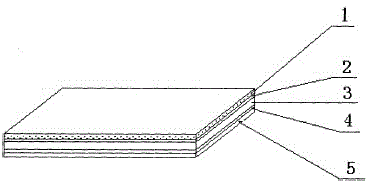

Magnesium-plastic composite board

InactiveCN109955562ALight weightHigh strengthSynthetic resin layered productsConstructions elementsPolymer adhesiveElectromagnetic shielding

A magnesium-plastic composite board is disclosed and used for architectural decoration. The magnesium-plastic composite board is formed by continuous hot pressing of a magnesium alloy panel (1) with the outer surface coated with an organic coating, a back aluminum alloy bottom plate (5), polymer adhesive films (2) (4) and a middle plastic core material (3). The magnesium-plastic composite board integrates decoration and functions, and is a decorative and functional material integrates characteristics of light weight, high specific strength and rigidity, corrosion resistance, impact resistance,sag resistance, vibration resistance, noise reduction and electromagnetic shielding functions. The magnesium-plastic composite board is suitable for the fields of manufacture of partition walls for aircrafts and ships, manufacture of light train cases, electromagnetic shielding engineering and architectural decoration.

Owner:段竹琴

Flat display member and method for manufacturing same, and flat display and method for manufacturing same

InactiveCN101248715AImprove production efficiencyExcellent electromagnetic wave shieldingMagnetic/electric field screeningCoatingsDisplay deviceOptoelectronics

Disclosed is a flat display member comprising at least an antireflection layer, a conductive layer and a transparent resin layer, wherein the antireflection layer is arranged on a first surface of the conductive layer and the transparent resin layer is arranged on a second surface of the conductive layer which is opposite to the first surface. This flat display member has an electrode ranging from the outermost surface on the first surface side to the conductive layer or the transparent resin layer in the peripheral portion. This flat display member can be manufactured efficiently, and is excellent in electromagnetic shielding properties and visibility. Also disclosed is a method for manufacturing such a flat display member.

Owner:TORAY ADVANCED FILM CO LTD

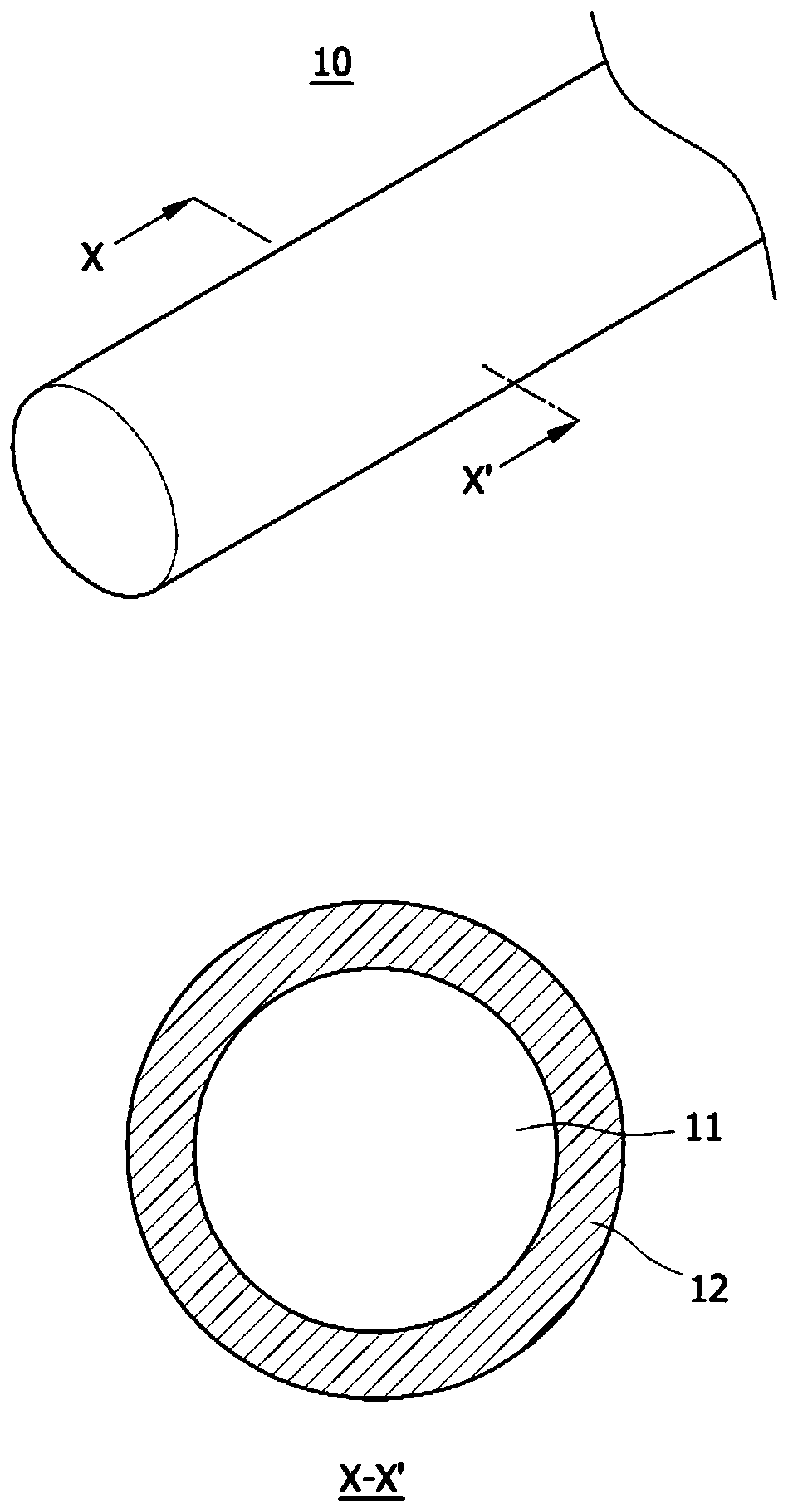

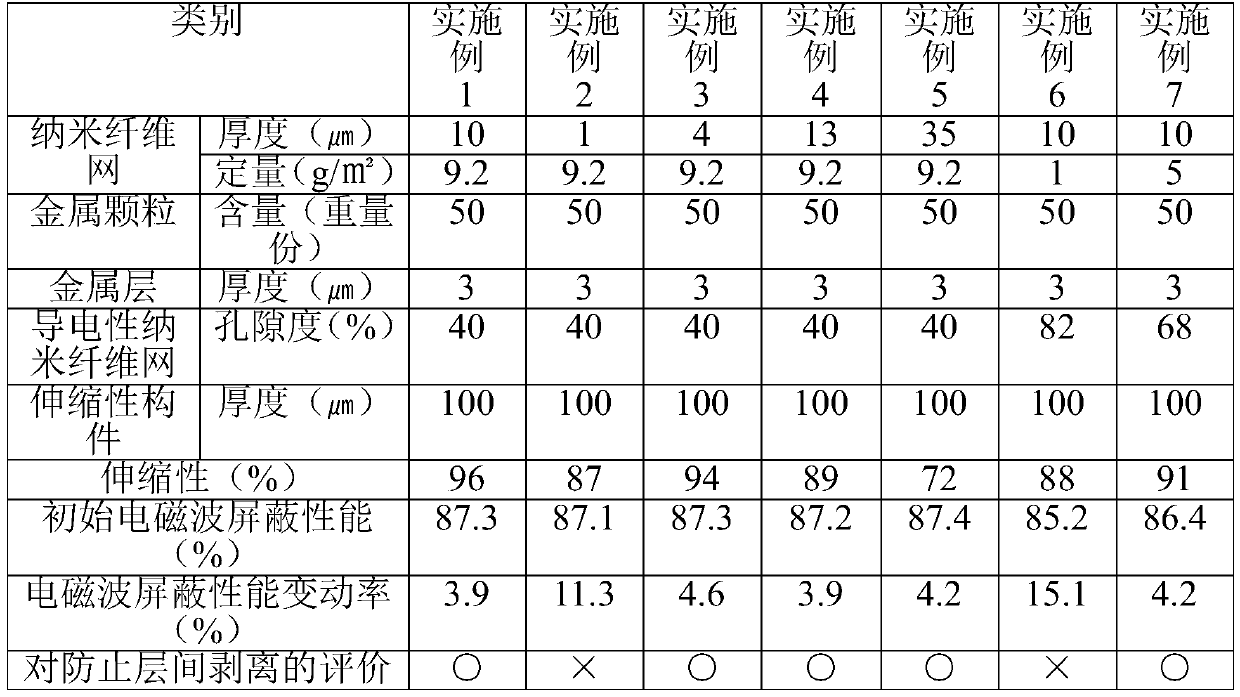

Flexible electromagnetic wave shielding material and manufacturing method therefor

ActiveCN110073733AImprove flexibilityOvercome denseShielding materialsFilament/thread formingShape changeHigh density

A flexible electromagnetic wave shielding material is provided. The electromagnetic wave shielding material according to one embodiment of the present invention comprises: a conductive nanofiber web having a nanofiber web formed of nanofibers and including a plurality of pores and a metal layer covering a part of the nanofibers disposed on a surface portion of the nanofiber web, in which metal particles are provided on at least a part of the pores; and an elastic member bonded to one surface of the metal layer of the conductive nanofiber web. Due to these features, as the electromagnetic waveshielding material has excellent elasticity, it is possible to freely modify the shape thereof as desired and to attach the electromagnetic wave shielding material to be completely adhered to a surface even if the surface where it is disposed has a curved shape such as uneven or stepped surfaces, and thus it is possible to exhibit excellent electromagnetic wave shielding performance. Further, degradation of the electromagnetic wave shielding performance can be prevented even with various shape changes. Furthermore, even when components are mounted with a high density in a narrow area, the electromagnetic wave shielding material can be provided to completely adhere to the mounted components by overcoming tight spacing and steps between the components, such that the electromagnetic wave shielding material can be easily adopted in compact or flexible electronic devices.

Owner:AMOGREENTECH CO LTD

Metal-coated fabric

InactiveCN101687387AExcellent electromagnetic wave shieldingImprove flame retardant performanceShielding materialsScreening gaskets/sealsPolymer scienceFire retardant

Owner:SEIREN CO LTD

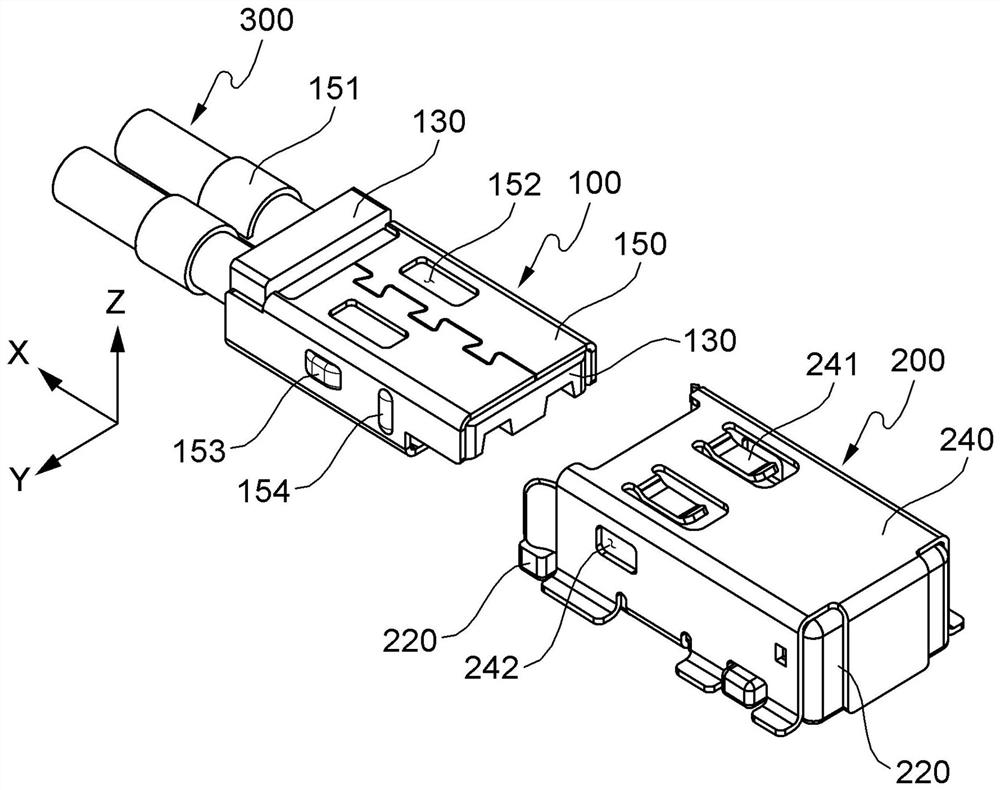

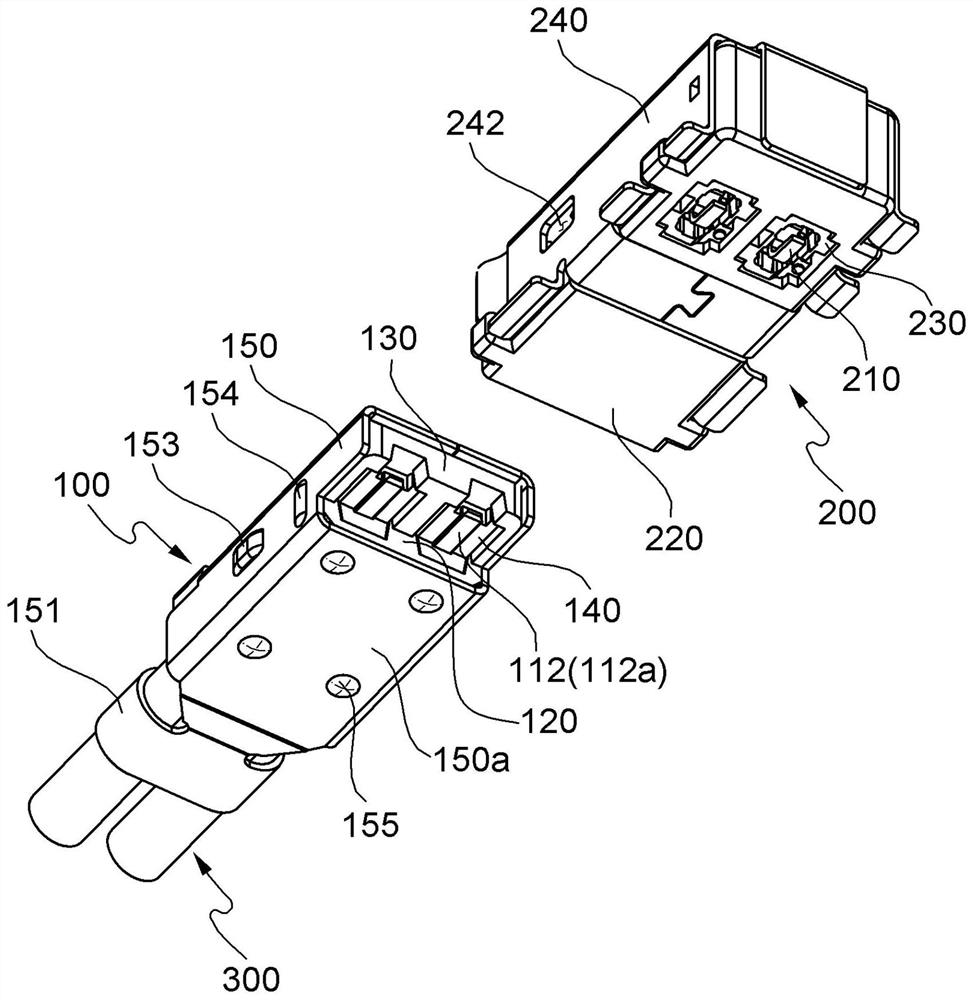

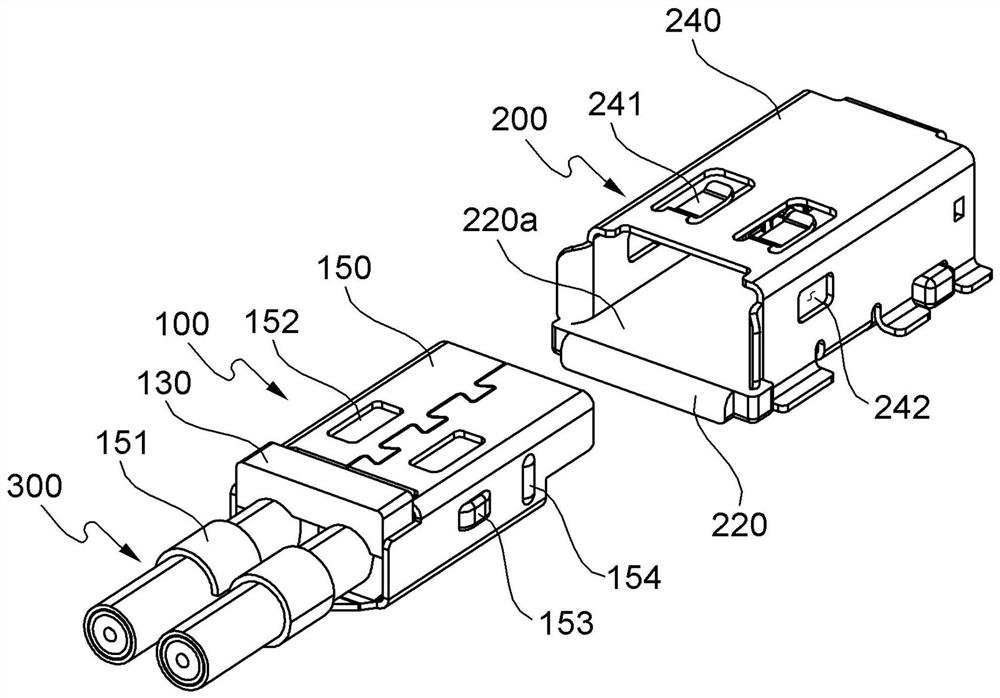

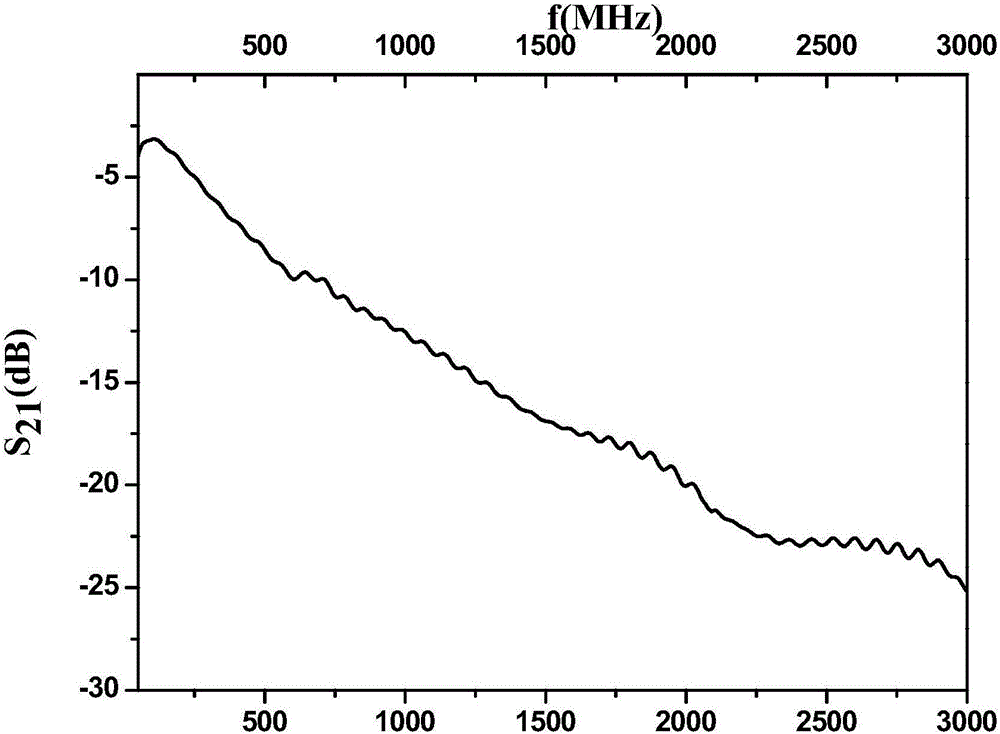

Connector assembly including receptacle connector and plug connector

PendingCN113725642AExcellent electromagnetic wave shieldingTwo pole connectionsCoupling device detailsStructural engineeringMechanical engineering

A connector assembly according to the present invention includes a receptacle connector; and a plug connector to be slidably inserted into the receptacle connector, wherein the plug connector includes a signal pin having one side in electrical contact with a signal line of a cable, a shield can formed to enclose the signal pin so that a lower surface of the other side of the signal pin is exposed and to be electrically spaced apart from the signal pin, a first insulating member coupled to the signal pin to insulate between the signal pin and the shield can, and a plug shell enclosing the shield can so as to expose the lower surface of the other side of the signal pin.

Owner:センサービューカンパニーリミテッド

Black coloring process of stainless steel precision screen mesh

InactiveCN103205790BExcellent electromagnetic wave shieldingHigh transparencyAnodisationWire gauzePotential difference

The invention discloses a black coloring process of a stainless steel precision screen mesh, and the black coloring process comprises the following step of: sequentially carrying out cleaning, activating and blackening processing on the weaved stainless steel precision screen mesh in the presence of a sealed container, wherein the blackening processing is as follows: spraying a vaporous blackening agent to a tensioning stainless steel precision screen mesh, applying voltage on the tensioning stainless steel precision screen mesh, so that the potential difference of the tensioning stainless steel precision screen mesh and the sprayed vaporous blackening agent is formed and arc discharge is generated, reacting the stainless steel wire of the stainless steel precision screen mesh with the blackening agent, and forming an ultrathin blackening layer on the surface of the stainless steel wire.The blackening layer obtained on the surface of the stainless steel precision screen mesh has the advantages of uniformity, densification and good adhesive force and cannot generate interference on the aperture of the stainless steel precision screen mesh by being extremely thin; and the black coloring process disclosed by the invention has the advantages of simplicity and fast deposition of the blackening layer, meets the requirement for environmental protection as the blackening agent does not contain the elements, such as selenium, phosphorus, chromium, and the like which pollute the environment, is nontoxic and can be directly discharged, and is lower in preparation cost.

Owner:安平县千鼎丝网有限公司

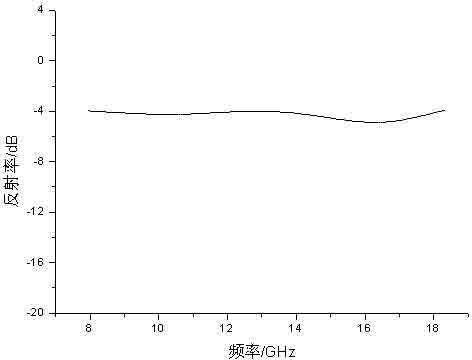

Composite shielding material and preparation method thereof

InactiveCN106009111AImprove electromagnetic performanceImprove shielding performanceFrequency bandMagnetic powder

The invention discloses a composite shielding material. The composite shielding material is prepared from the following components in parts by weight: 100 parts of expanded graphite, 100-900 parts of sheet magnetic powder, 0.6-2 parts of a dispersing agent, 100 parts of rubber, and 0.3-2 parts of a vulcanizing agent. The invention further discloses a preparation method of the composite shielding material. The prepared composite shielding material has the characteristics of high electromagnetic property, high shielding property and the like, and can have good wave absorbing property in a GHz frequency band.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Conductive adhesive film for FPC electroplating and production process thereof

ActiveCN111073530AShort processEasy to operatePolyureas/polyurethane adhesivesCyclodextrin adhesivesPhotoinitiatorBenzene

The invention discloses a conductive adhesive film for FPC electroplating. The conductive adhesive film is characterized in that the conductive adhesive film comprises a base film and a conductive adhesive layer compounded on the base film, wherein the conductive adhesive layer is prepared from the following raw materials in parts by weight: 40-60 parts of 2, 3-difluorofumaric acid / hydroxyl-terminated polyurethane polycondensate, 2-4 parts of diethyl aminovinylmalonate modified epoxy cyclodextrin, 1-3 parts of methacryloyloxypropyltriethoxysilane, 5-10 parts of aminoferrocene modified 4, 4',4'' [ benzene-1, 3, 5-triyl tri (acetylene-2, 1-diyl) ] triphenylformaldehyde, 10-15 parts of superconducting carbon black, 5-10 parts of conductive micro powder and 0.8-1.3 parts of a photoinitiator. The invention also discloses a production process of the conductive adhesive film for FPC electroplating. The conductive adhesive film for FPC electroplating disclosed by the invention has the advantages of good electrical conductivity, aging resistance, high peeling strength, good impact resistance, good damp-heat resistance, excellent electromagnetic wave shielding performance, high bending resistance and difficulty in moisture absorption.

Owner:苏州市新广益电子股份有限公司

Tungsten alloy shielding plate and electronic information card provided with tungsten alloy shielding plate

ActiveCN106756379BExcellent electromagnetic wave shieldingThe overall thickness is thinRecord carriers used with machinesRare earthCopper

The invention discloses an electronic information card provided with a tungsten alloy shield plate. The electronic information card comprises an electronic information card substrate and the tungsten alloy shield plate arranged in the electronic information card substrate; the electronic information card substrate comprises a chip and / or a magnetic strip; the tungsten alloy shield plate comprises the following components in mass percentage: 30%-98% of tungsten, 1.23%-40% of nickel, 0.53%-27% of copper, 0.24%-3% of cobalt and 0.1%-1.0% of rare earth. The invention further discloses the tungsten alloy shield plate. According to the tungsten alloy shield plate and the electronic information card provided with the same, the tungsten alloy shield plate with an excellent radiation-proof property is arranged in the electronic information card, so that information in the electronic information card can be prevented from being read or interfered.

Owner:GUANGDONG HUASITE ALLOY PROD CO LTD

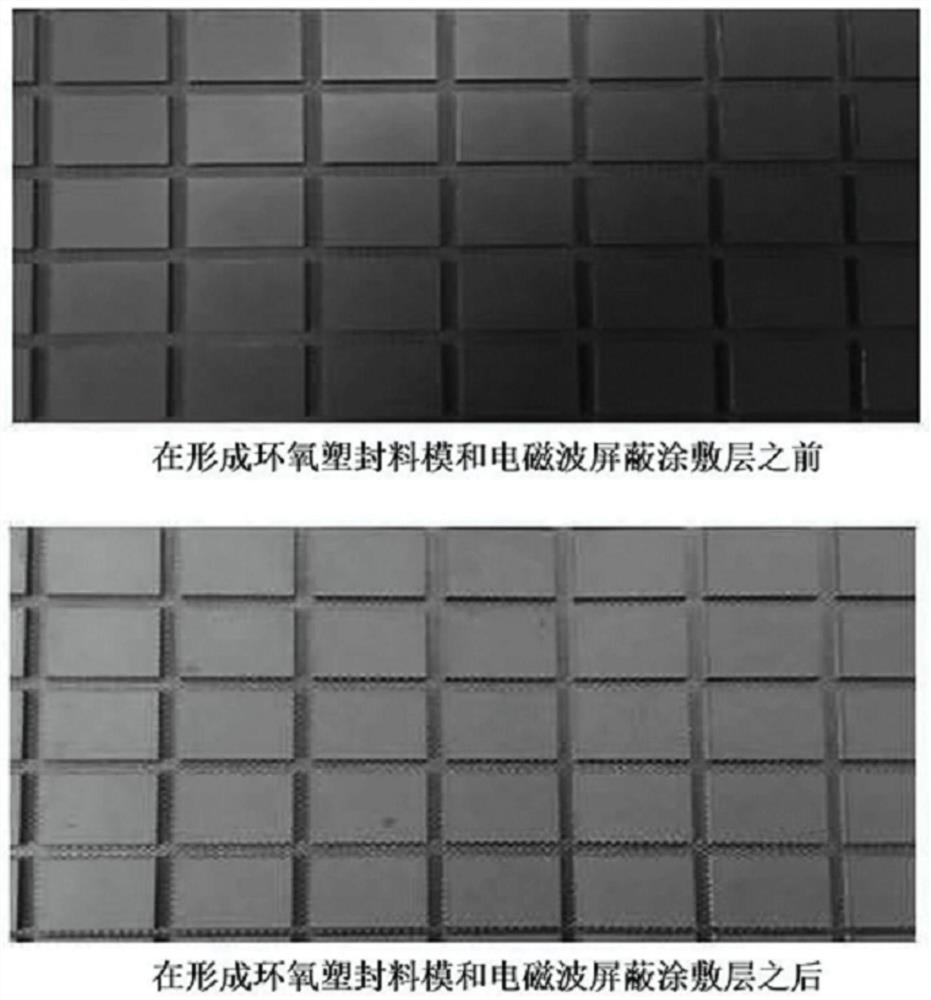

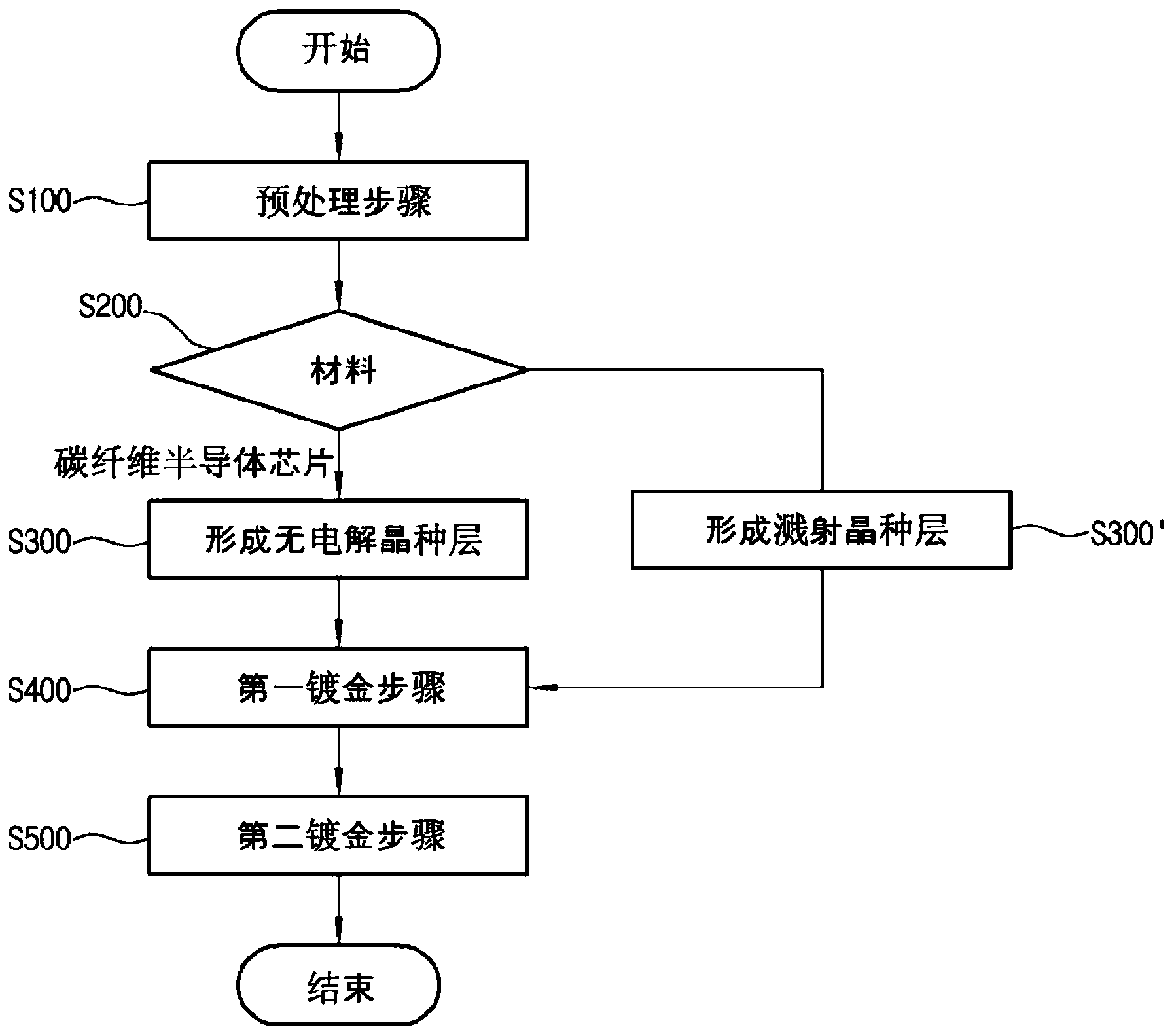

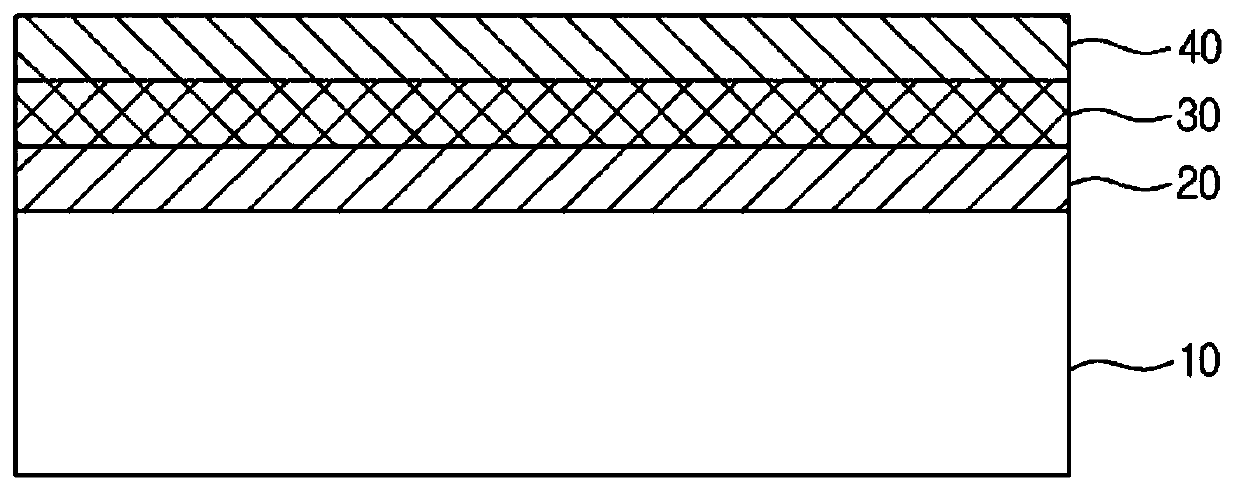

Electromagnetic shielding coating method

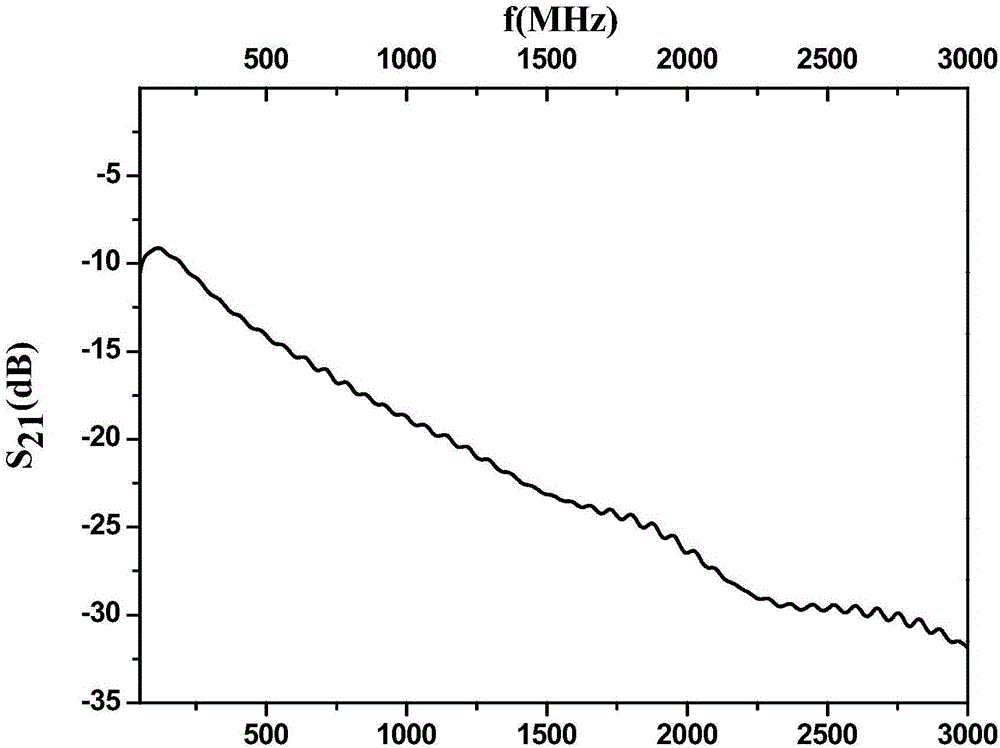

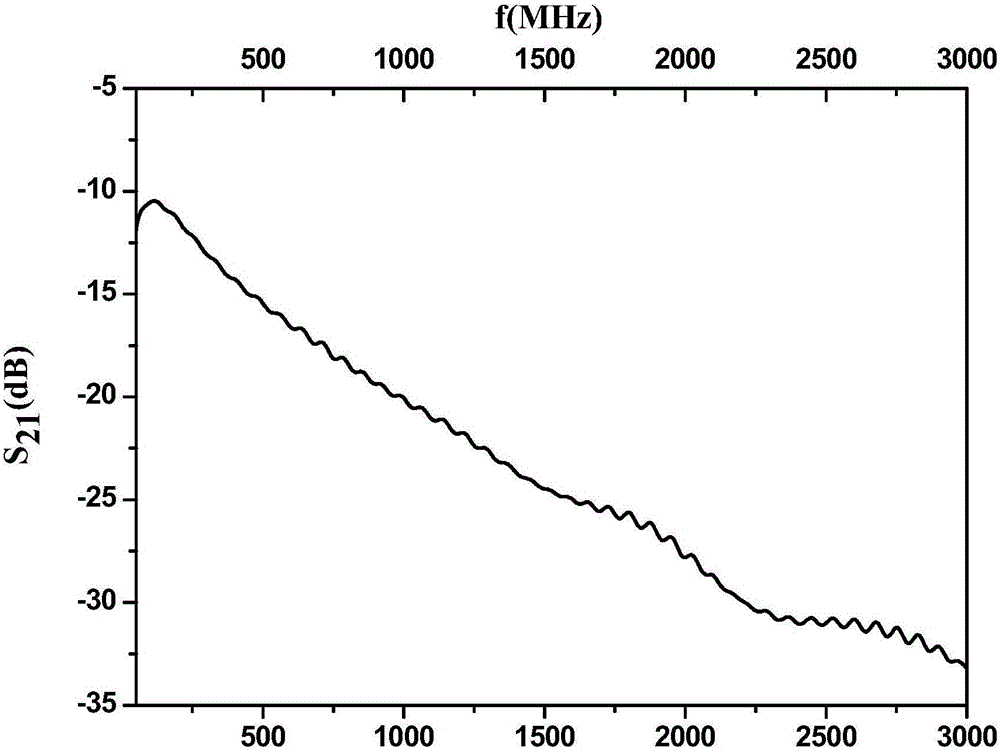

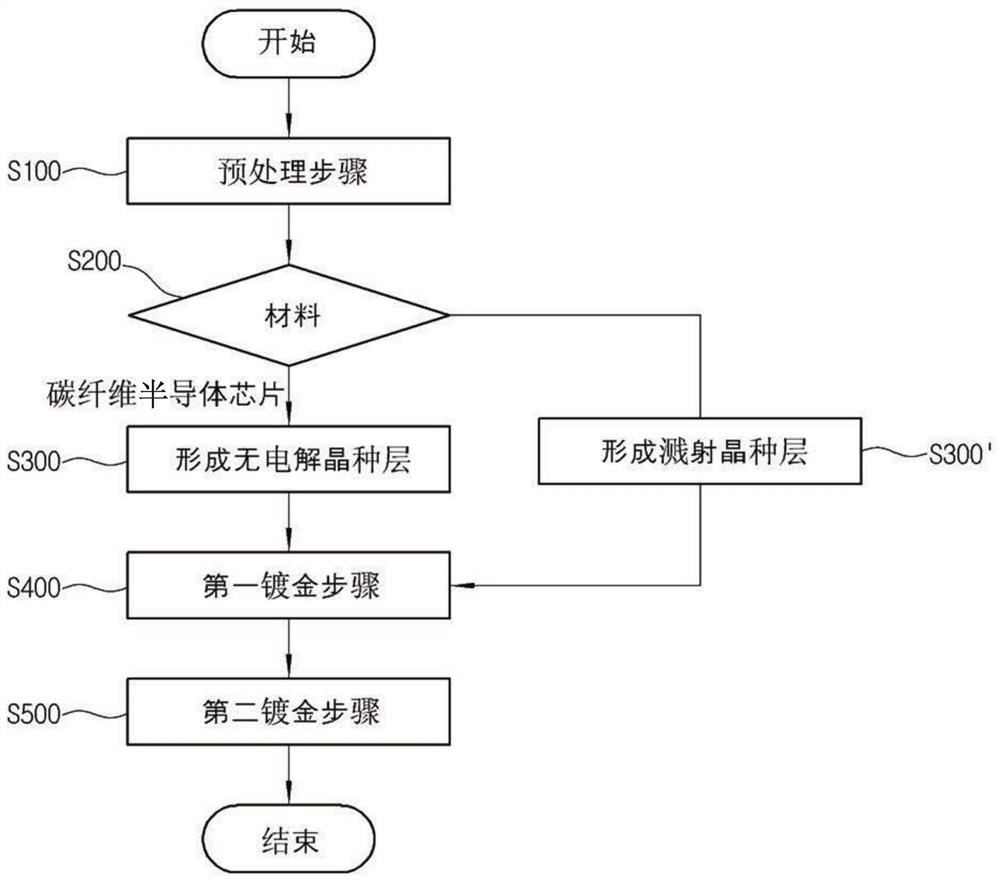

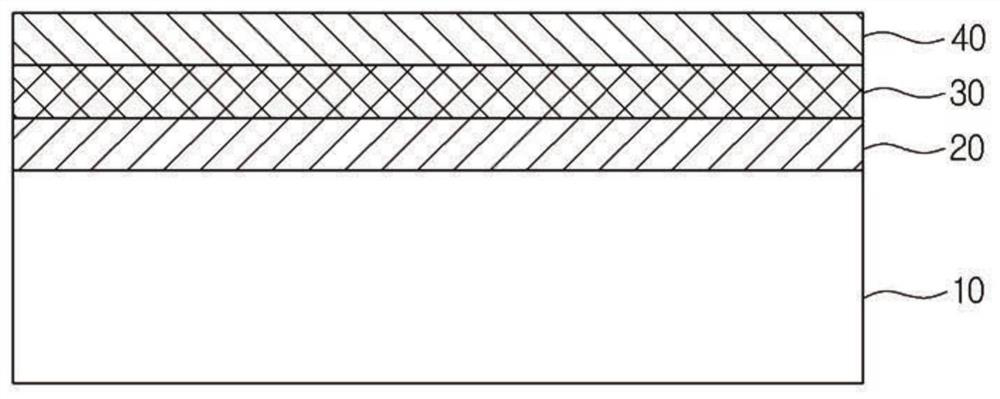

ActiveCN110791752BExcellent electromagnetic wave shieldingExcellent adhesionMagnetic/electric field screeningLiquid/solution decomposition chemical coatingCopperMobile device

The invention relates to an electromagnetic wave shielding coating method, as a method for electromagnetic wave shielding coating on the surface of metal or non-metallic materials, which includes: a pretreatment step, cleaning the surface of the material, and performing a dry method before coating surface etching; a surface seed crystal replacement molding step, forming a metal seed layer on the pretreated surface; a first gold plating step, using the first metal to perform electroless gold plating on the surface of the seed layer to realize the basic shielding function; and the second The second gold plating step is to use the second metal to carry out electroless gold plating on the surface of the first metal gold-plated layer to realize the final shielding function. The above-mentioned first metal is copper, and the above-mentioned second metal is tungsten. The electromagnetic wave shielding coating method provided by the present invention It can be applied to the surface of components of smart cars, mobile devices, and wearable devices. It has excellent electromagnetic wave shielding effect, coating durability, shortens production time, and is excellent in terms of cost efficiency.

Owner:维洲TNC株式会社

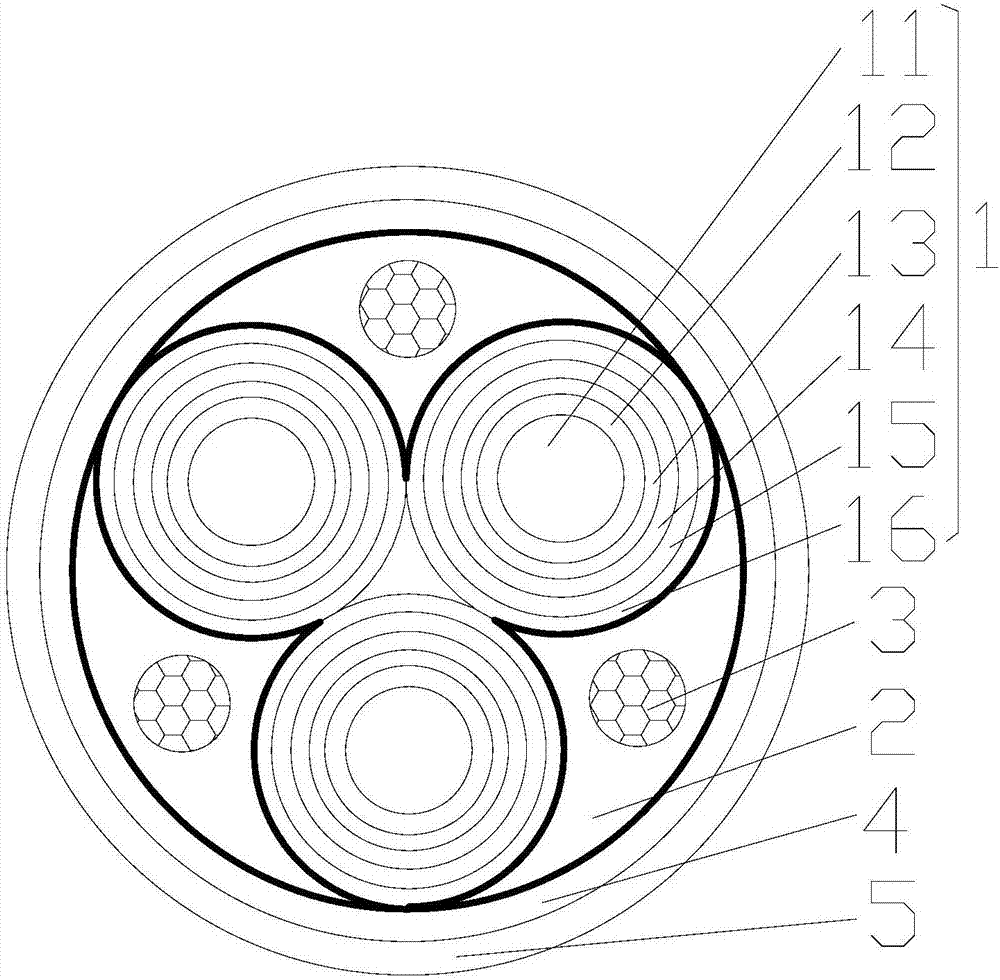

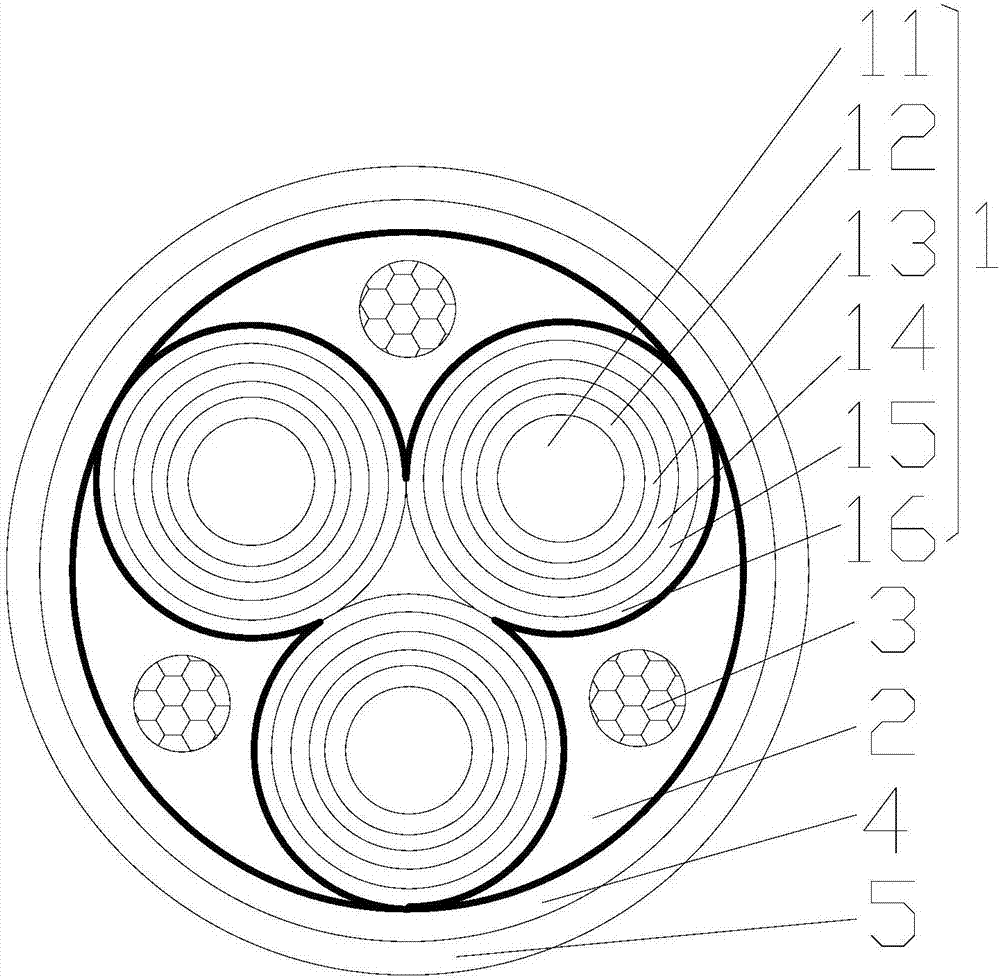

High-strength wear-resisting and compression-resistant shielded cable

InactiveCN107331457AImprove stress resistanceCompact structureInsulated cablesInsulated conductorsShielded cableElectrical conductor

The high-strength wear-resistant and compression-resistant shielded cable proposed by the present invention includes a cable core, an aluminum-plastic composite tape and an outer sheath; the cable core includes three wire cores, three elastic compression-resistant cores and a bundled core, and the three wire cores are arranged in parallel and longitudinally. Abutting against each other, on any cross section, the central connection line of the three cores is an equilateral triangle, and the three cores include a conductor in the middle, a semiconducting shielding layer, an insulating layer, a copper tape shielding layer, an elastic The buffer layer and the wrapping layer, the elastic compressive core is located between two adjacent wire cores, which has an inner arc surface that is opposed to the wire cores, and the elastic compressive cores cooperate with each other so that the cable cores have a circular cross-section and are bundled The core is located in the elastic compression core, which is formed by twisting a plurality of steel wires, the aluminum-plastic composite tape is wrapped around the outer periphery of the cable core, and the outer sheath is extruded and wrapped around the outer periphery of the aluminum-plastic composite tape. The high-strength wear-resistant and pressure-resistant shielded cable proposed by the invention has a compact structure, is wear-resistant, pressure-resistant and tensile, and has good electromagnetic wave shielding performance.

Owner:代卫东

Electromagnetic shielding coating method

ActiveCN110791752AExcellent electromagnetic wave shieldingExcellent adhesionMagnetic/electric field screeningLiquid/solution decomposition chemical coatingEngineeringElectromagnetic shielding

Provided is a method for performing an electromagnetic interference shielding coating operation on the surface of a metal or a nonmetal material, comprising: a pre-process step of cleaning the surfaceof the material and performing a dry surface etching operation before coating; a surface seed replacement forming step of forming a metal seed layer on the pre-processed surface; a first plating stepof performing an electroless plating operation on a surface of the seed layer by a first metal having a basic shielding function; and a second plating step of performing an electroless plating operation on a surface of the first metal plating layer by a second metal having a finishing shielding function, wherein the first metal is copper (Cu) and the second metal is tungsten (W). The present invention provides the electromagnetic interference shielding coating method which can be applied to the surface of components of a smart car, a mobile device and a wearable device, and has excellence inan electromagnetic interference shielding effect, coating durability, manufacturing time and economic feasibility for costs.

Owner:维洲TNC株式会社

Resin coated metal sheet with excellent electromagnetic wave shielding performance

InactiveCN101090005BImprove conductivityExcellent electromagnetic wave shieldingHot-dipping/immersion processesMagnetic/electric field screeningPolymer scienceResin coating

The invention resin coating metal plate with resin involucra on the surface of the metal plate, which can raise the conductivity of the resin coating metal plate, and has excellent electromagnetic interference shielding capacity, preferably under gently contacting. The said resin involucra satisfies the necessary condition of the following formula (1): PPIt>=70 ellipsis (1). The PPIt denotes thenumber of peak-valley when 1 / 2 of the peak count level (2H) is used as the thickness t(mu m) of resin involucra in PPI(Peaks Per Inch) recorded in SAE J911-1986.

Owner:KOBE STEEL LTD

Magnesium plastic composite board

InactiveCN105729940AExcellent electromagnetic wave shieldingGood dent resistanceMetal layered productsElectromagnetic shieldingComposite plate

A magnesium plastic composite board is used for architectural ornament and decoration. The magnesium plastic composite board is prepared from a magnesium alloy panel (1) coated by an organic coating on an outer surface and a back aluminum alloy base plate (5) by continuous hot pressing compounding through polymer bonding films (2), (4) and an intermediate plastic core member (3). The composite board combines decoration and function, and has the advantages of light weight, high specific strength and stiffness, corrosion resistance, impact resistance, recess resistance, seismic resistance, noise reduction and electromagnetic shielding function. The composite board is applicable to the fields of partition wall material of airplanes and ships, manufacturing of light train cabinet, electromagnetic shielding engineering and architectural decoration.

Owner:刘彦珍

High-strength and pressure-resistant shielding cable

InactiveCN107316680AImprove stress resistanceExcellent electromagnetic wave shieldingPower cables with screens/conductive layersInsulated cablesShielded cableElectrical conductor

The high-strength compression-resistant and shielded cable proposed by the present invention includes a cable core, an aluminum-plastic composite tape and an outer sheath; the cable core includes three wire cores, three elastic compression-resistant cores and a bundled core, and the three wire cores are longitudinally arranged in parallel and abut against each other. Rely, on any cross-section, the central connection line of the three cores is an equilateral triangle, and the three cores include a conductor located in the middle, a semiconducting shielding layer, an insulating layer, a copper tape shielding layer, and an elastic buffer layer that are sequentially wrapped around the outside of the conductor. And the wrapping layer, the elastic compression core is located between two adjacent wire cores, it has an inner arc surface that is against the wire cores, and the elastic compression cores cooperate with each other so that the cable cores have a circular cross-section, and the bundled core is located in the In the elastic compression core, it is formed by twisting a plurality of steel wires, the aluminum-plastic composite tape is wrapped around the outer periphery of the cable core, and the outer sheath is extruded and wrapped around the outer periphery of the aluminum-plastic composite tape. The high-strength compression-resistant shielding cable proposed by the invention has a compact structure, is compression-resistant and tensile-resistant, and has good electromagnetic wave shielding performance.

Owner:代卫东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com