Optical filter

A technology of optical filter and shielding layer, applied in the field of optical filter and its manufacturing, can solve the problems such as the adverse effect of display image tone, and achieve the effect of easy manufacturing and handling, and excellent ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

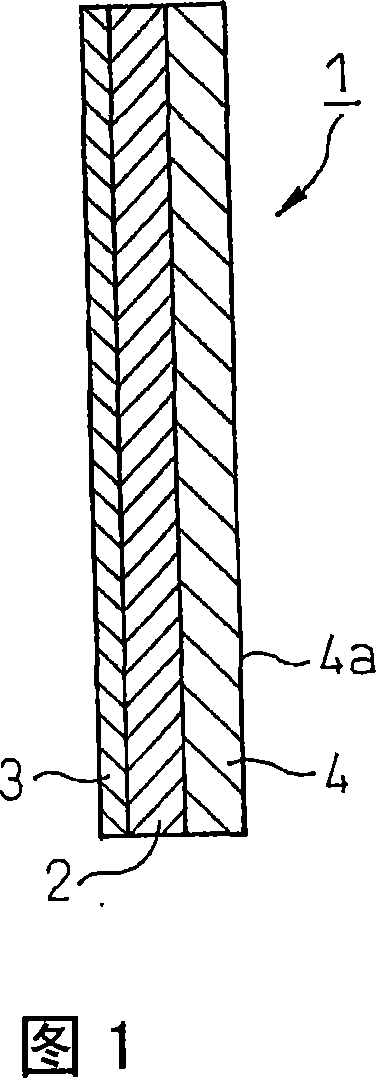

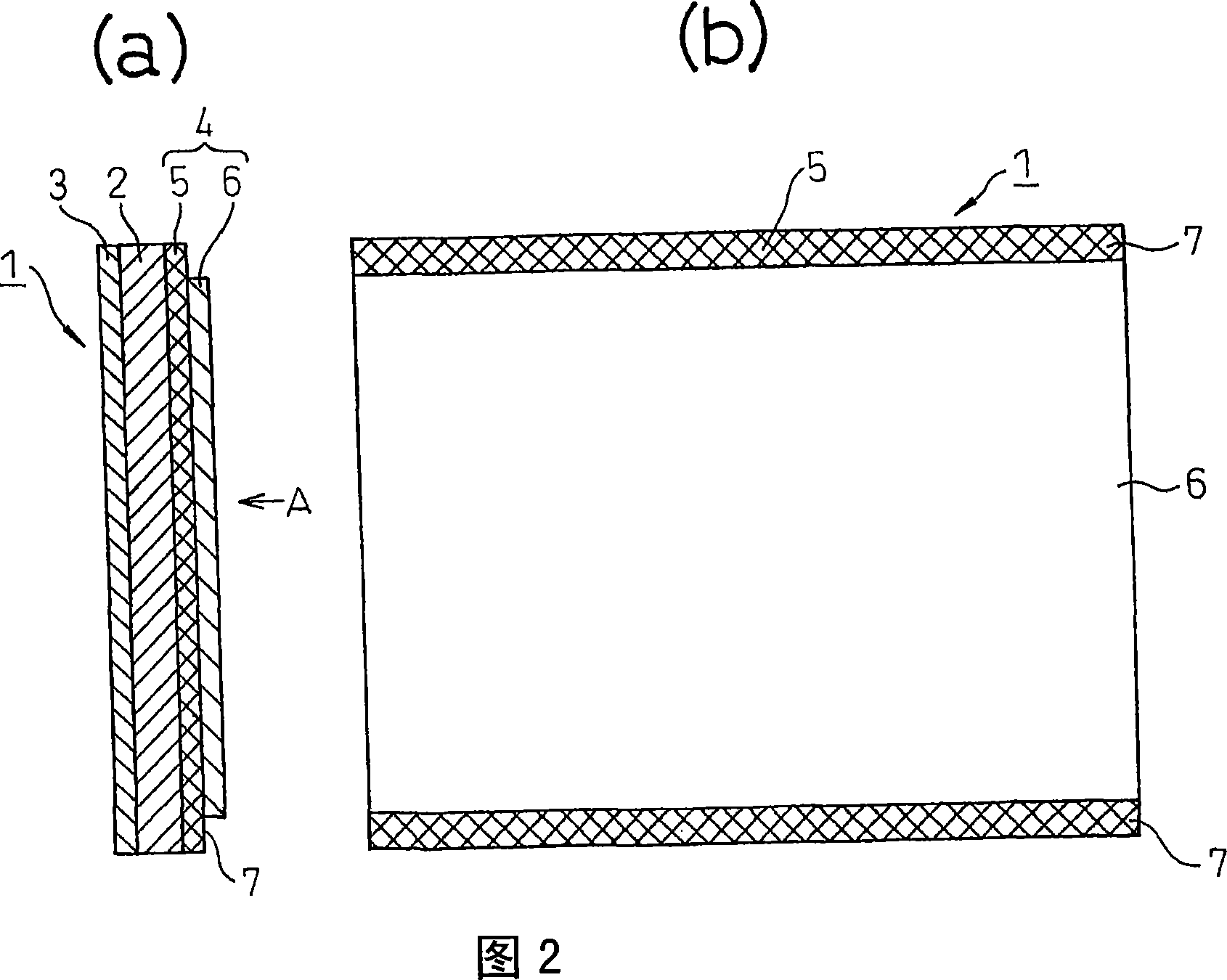

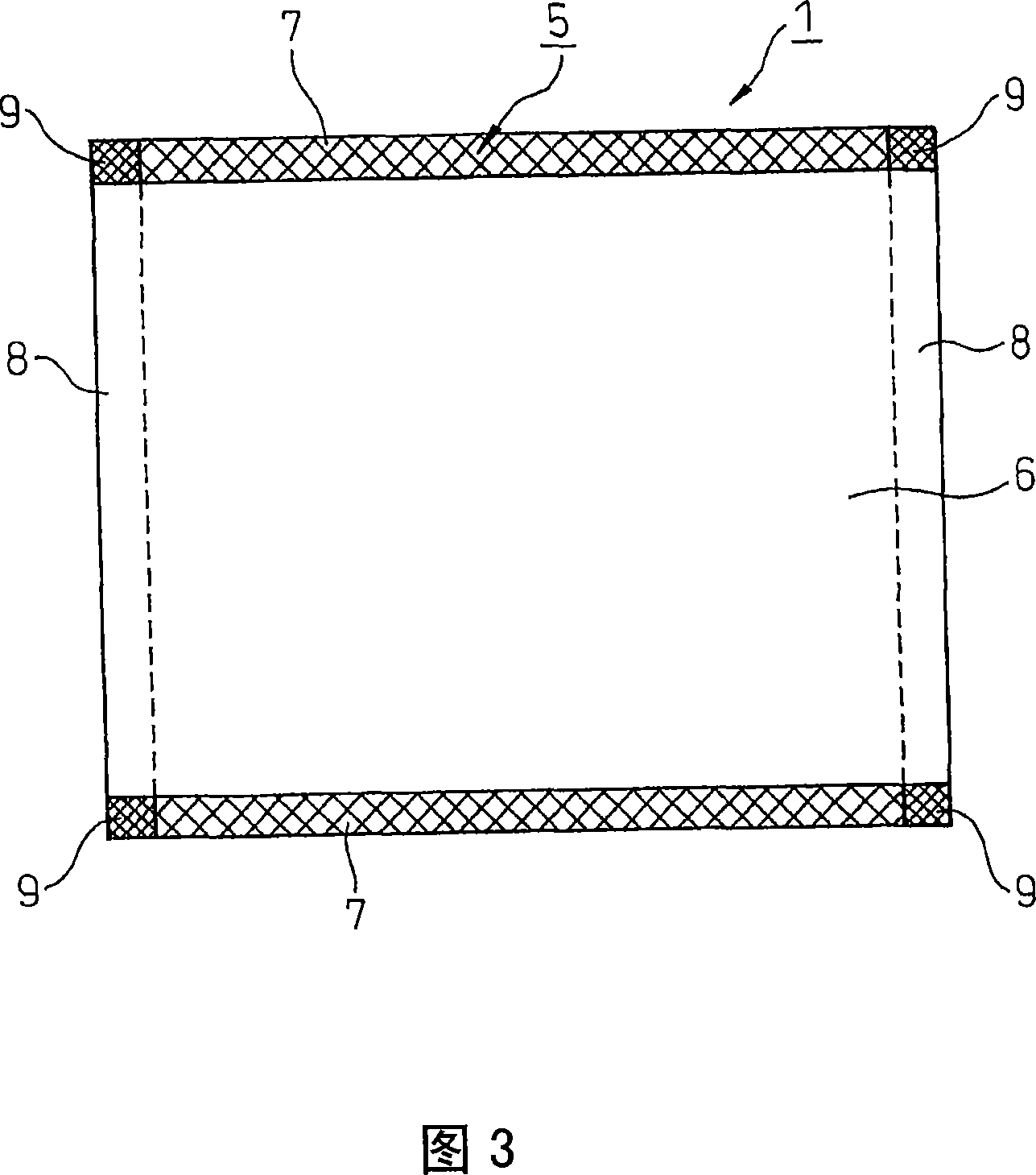

[0159] A 100-μm-thick PET film containing a UV absorber is used as a transparent substrate, and a UV-curable resin layer containing 50% by weight of a silica filler is formed on one side of the film to a thickness of about 1 μm to form a hard coat layer. On it, a conductive medium refractive index layer consisting of a silicon oxide layer containing 85% by weight of antimony-containing tin oxide and having a thickness of about 140 nm is formed, and a silicon oxide layer containing 65% by weight of titanium oxide is formed thereon and A high-refractive-index layer with a thickness of about 110 nm was formed on which a low-refractive-index layer consisting only of silicon oxide and having a thickness of about 90 nm was formed to form an antireflection layer, and a protective film made of PET was laminated on its surface. Then, on the opposite side of the PET film, a paste containing palladium colloid was printed using a screen with a grid-like (mesh) pattern of L / S=30 / 270 (μm), a...

Embodiment 2

[0167] A PET film containing an ultraviolet absorber with a thickness of 100 μm was used as a transparent substrate, and a hard coat layer, a conductive middle refractive index layer, a high refractive index layer, and a low refractive index layer were formed on one side thereof in the same manner as in Example 1. The anti-reflective layer is laminated with a PET protective film on the surface. Then, on the opposite side of the PET film, a paste containing palladium colloid was printed using a screen with a grid-like (mesh) pattern of L / S=30 / 270 (μm), and it was impregnated in electroless copper In the plating solution, electroless copper plating was performed, followed by electrolytic copper plating, and then Ni-Sn alloy electroplating was performed to form a mesh-shaped electromagnetic wave shielding layer. Then, on the surface of the electromagnetic wave shielding layer, utilize the screen printing method to print the following ink, which contains the following chemical for...

Embodiment 3

[0174] As a transparent base material, a PET film with a thickness of 100 μm containing an ultraviolet absorber was used, and a hard coat layer, a conductive middle refractive index layer, a high refractive index layer, and a low refractive index layer were formed on one side thereof in the same manner as in Example 1. The anti-reflection layer is composed of a protective film made of PET laminated on the surface. Then, on the opposite side of the PET film, a paste containing palladium colloid was printed using a screen with a grid-like (mesh) pattern of L / S=30 / 270 (μm), and it was impregnated in electroless copper In the plating solution, electroless copper plating is carried out, followed by electrolytic copper plating, and then Ni-Sn alloy electroplating is carried out to form a mesh electromagnetic wave shielding layer. Then, on the surface of the electromagnetic wave shielding layer, utilize the screen printing method to print the following ink, which contains the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com