Antireflective double layer P/N heterojunction graded composite material with monocrystalline silicon as carrier, and application thereof

A composite material and monocrystalline silicon technology, which is applied in organic compound/hydride/coordination complex catalysts, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low photoelectric conversion efficiency, difficulty in recycling, and easy agglomeration and other problems, to achieve the effect of low reaction equipment requirements, reduced recombination, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

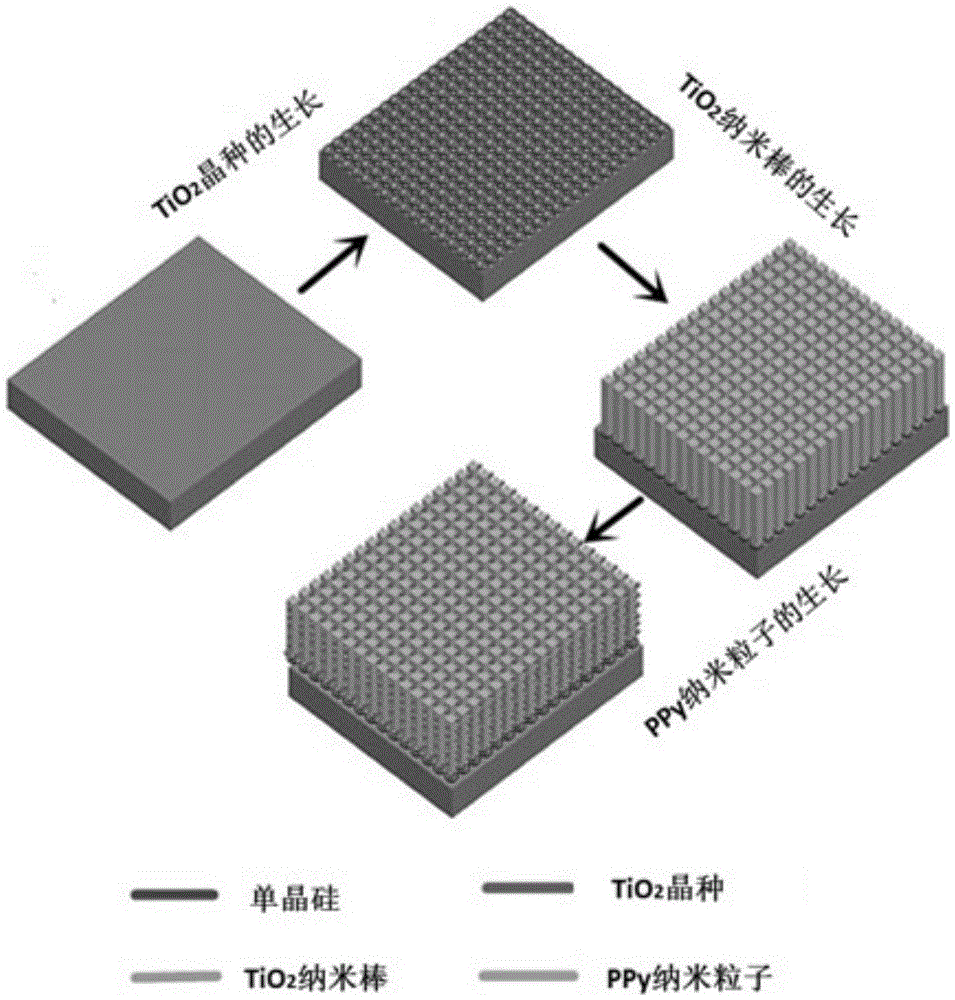

[0024] Step 1: Growth of TiO on the surface of single crystal silicon 2 seed crystal

[0025] Place the wafer in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 80°C, and the heating time is 30min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.075mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 20 times. Finally, the above sample is placed in a 450°C muffle Calcined in the furnace for about 30min.

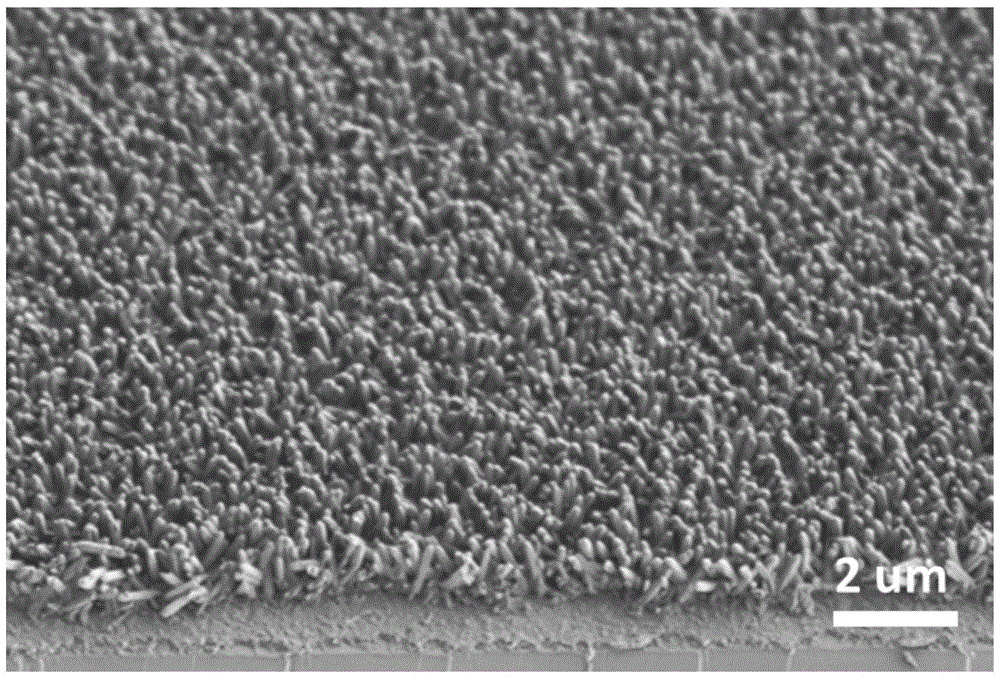

[0026] Step 2: TiO 2 Seed induced TiO 2 Preparation of nanorods

[0027] Attach TiO to the surface obtained in step 2 2 The seeded silicon wafers were placed under hydrothermal conditions to grow TiO 2 Nano stave. The hydrothermal synthesis condition is at a temperature of 130°C, and treated in a reaction kettle filled with 10mL deionized water, 10mL concentrated hydrochloric acid (37% by mass fraction) and 0.5mL tetrabutyl titanate for 8h, and th...

Embodiment 2

[0032] Step 1: Growth of TiO on the surface of single crystal silicon 2 seed crystal

[0033] Place the wafer in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 80°C, and the heating time is 40min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.05mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 15 times. Finally, the above sample is placed in a 450°C muffle Calcined in the furnace for about 1h.

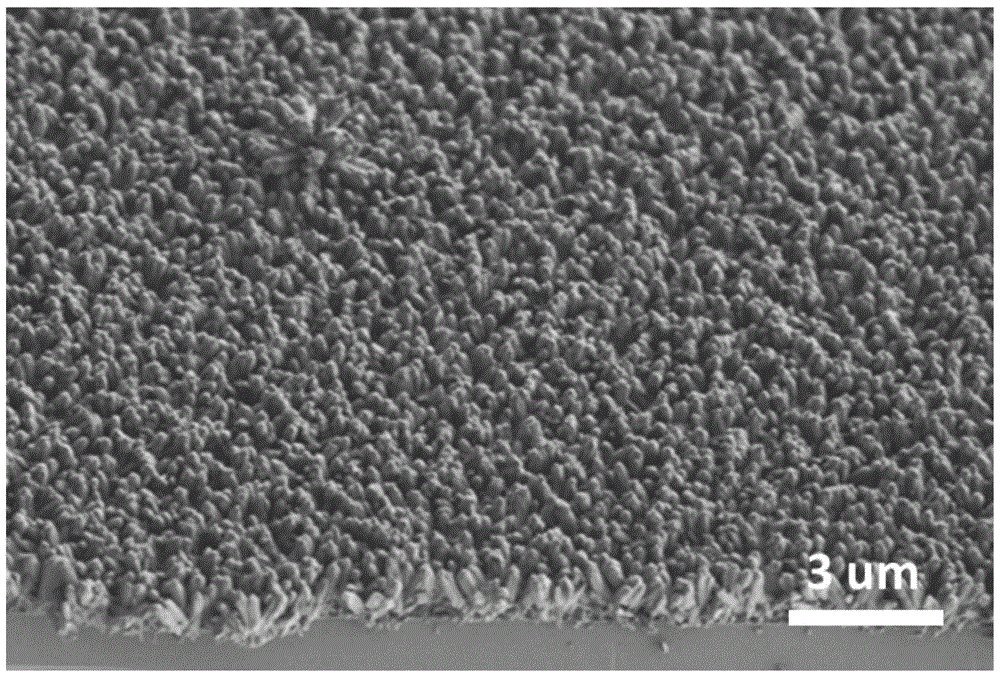

[0034] Step 2: TiO 2 Seed induced TiO 2 Preparation of nanorods

[0035] The surface obtained in step 1 is attached with TiO 2 The seeded silicon wafers were placed under hydrothermal conditions to grow TiO 2 Nano stave. The hydrothermal synthesis condition is at a temperature of 130°C, and treated in a reactor filled with 10mL deionized water, 10mL concentrated hydrochloric acid (37% mass fraction) and 0.5mL tetrabutyl titanate for 8h, and then the s...

Embodiment 3

[0040] Step 1: Growth of TiO on the surface of single crystal silicon 2 seed crystal

[0041] Place the wafer in NH 3 h 2 O, H 2 o 2 and H 2 In the mixed solution of O, the volume ratio is 1:1:5, the temperature is 90°C, and the heating time is 30min. Then, immerse in the isopropanol solution of tetrabutyl titanate with a concentration of 0.1mol / L for pulling. The pulling speed is 2mm / s, and the pulling is repeated 10 times. Finally, the above sample is placed in a 500°C muffle Calcined in the furnace for about 30min.

[0042] Step 2: TiO 2 Seed induced TiO 2 Preparation of nanorods

[0043] The surface obtained in step 1 is attached with TiO 2 The seeded silicon wafers were placed under hydrothermal conditions to grow TiO 2 Nano stave. The hydrothermal synthesis condition is at a temperature of 120°C, and treated in a reactor filled with 10mL of deionized water, 10mL of concentrated hydrochloric acid (37% by mass) and 0.5mL of tetrabutyl titanate for 8h, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com