Retardation plate and circularly polarizing plate

一种相位差板、圆偏光板的技术,应用在相位差板和圆偏光板领域,能够解决生产效率差、相位差板厚度厚、波长区域宽度不够等问题,达到生产效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0534] Hereinafter, the present invention will be described by way of synthesis examples, examples, and comparative examples, but the present invention is not limited thereto at all. In addition, unless otherwise specified, "part" and "%" are mass standards. In addition, below, the phase difference plate which laminated|stacked at least two phase difference plates of the phase difference plate 1 and the phase difference plate 2 of this invention is referred to as a laminated phase difference plate.

[0535] [Adjustment of polymerizable liquid crystal composition]

[0536] [Preparation of polymerizable liquid crystal composition (1)]

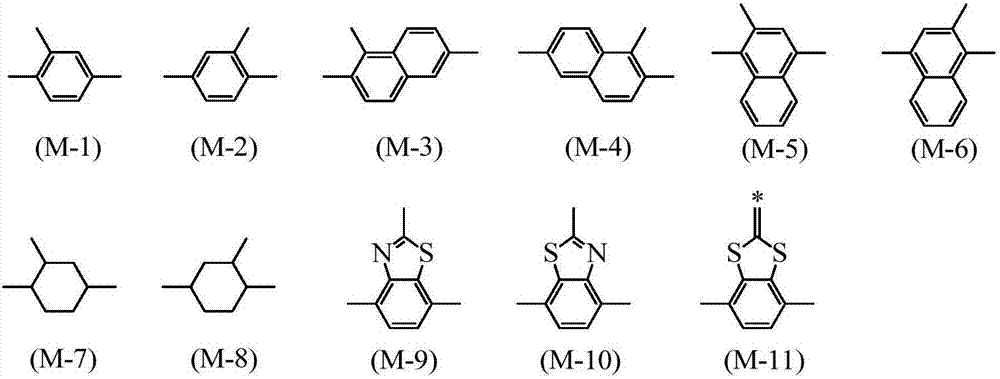

[0537] Using a stirring device with a stirring blade, under the condition that the stirring speed is 500rpm and the solution temperature is 60°C, 55 parts of the compound represented by the formula (1-a-5), the compound represented by the formula (1-a-6) 25 parts of compound, 10 parts of compound represented by formula (2-a-1) and n=6, 10 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV radiation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com