Antireflection film and process for producing the antireflection film

An anti-reflection film, anodizing technology, applied in other home appliances, applications, coatings, etc., can solve the problems of insufficient transmission performance and insufficient anti-reflection performance, and achieve the effect of excellent transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

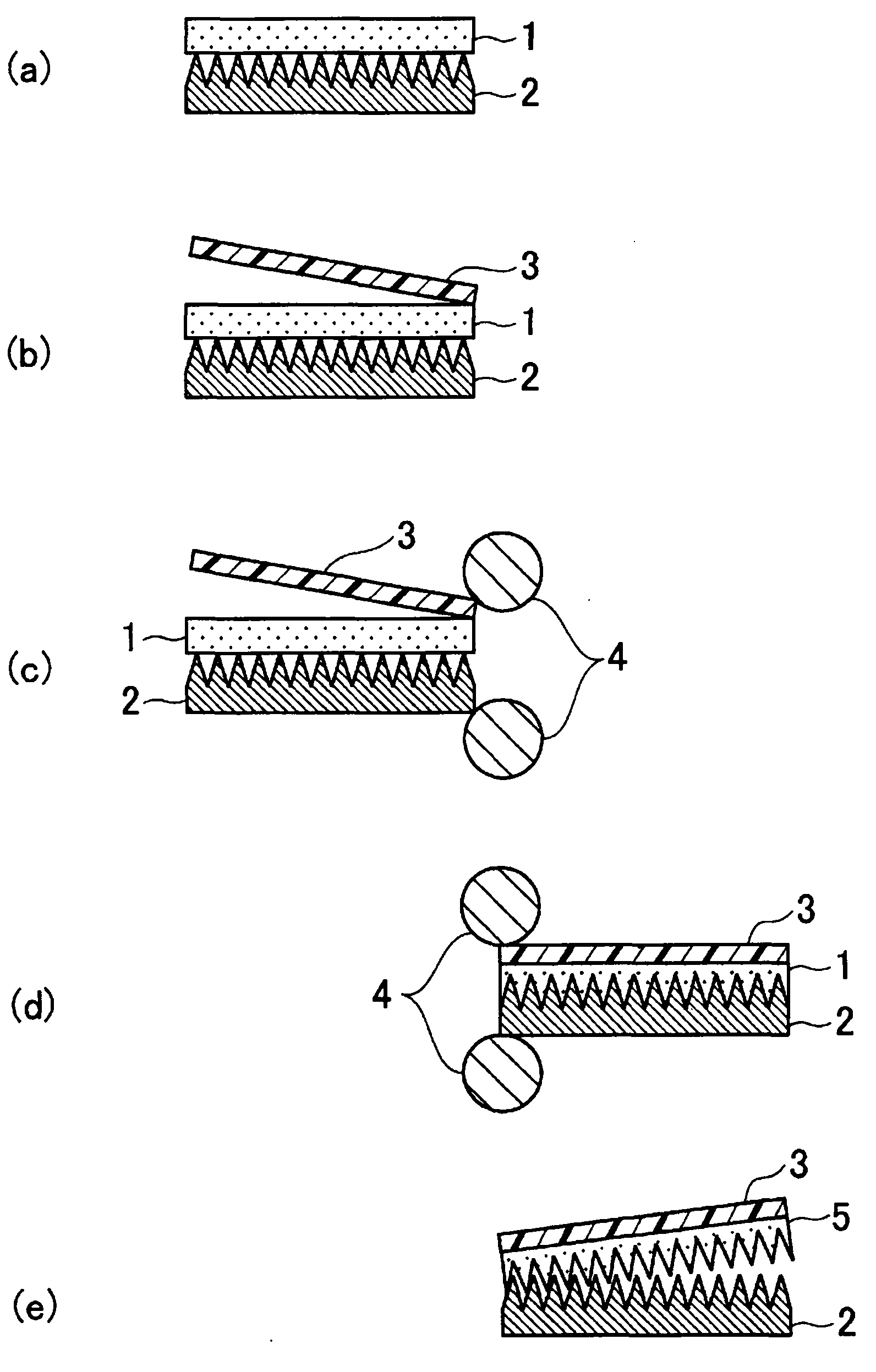

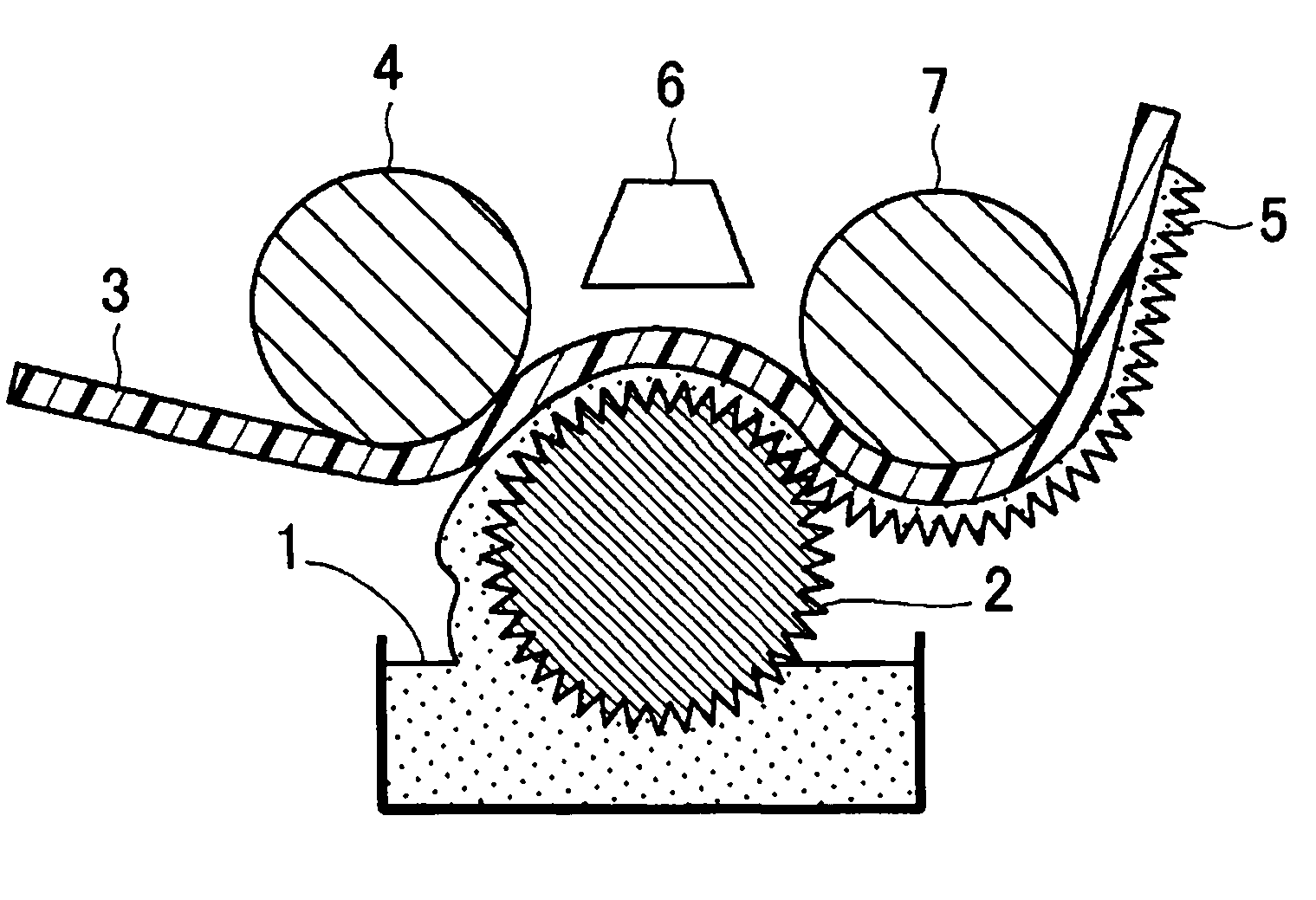

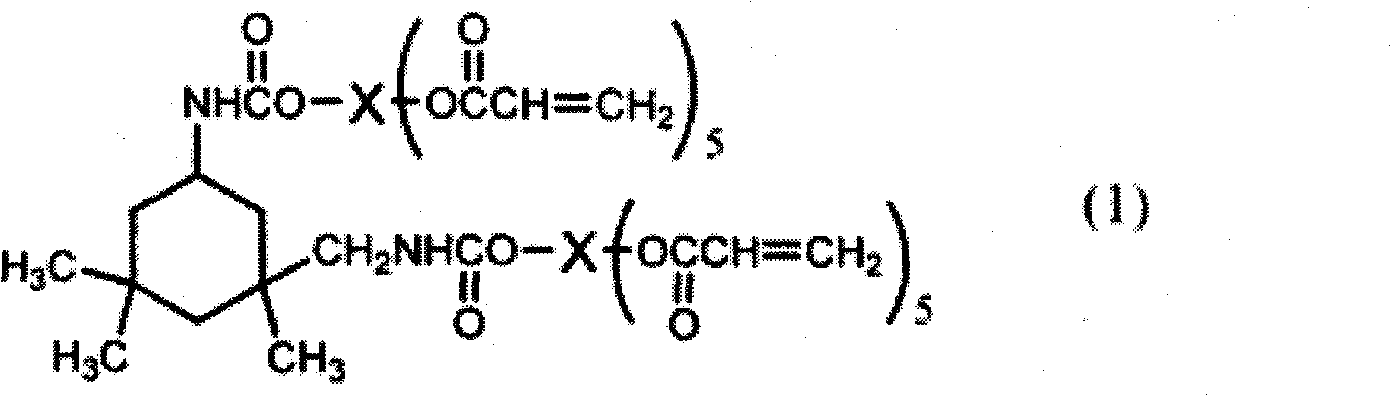

Method used

Image

Examples

Embodiment 1

[0125]

[0126] A 99.85% aluminum rolled plate (2 mm thick) as an aluminum material was ground for 10 minutes with a single-sided flat polishing disc (manufactured by Speedfam) using an alumina-based abrasive (manufactured by FUJIMI INCORPORATED) to obtain a mirror surface. After scrubbing the abrasive surface, perform a non-aggressive degreasing treatment.

[0127] Then, a mold having tapered pores was produced by a combination of the anodization conditions shown below and the etching (pore diameter expansion) treatment conditions shown below for the formed anodized film.

[0128]

[0129] Use solution: 0.05M oxalic acid

[0130] Voltage: 80V DC voltage

[0131] Temperature: 5°C

[0132] Time: 50 seconds

[0133]

[0134] Liquid used: 2% by weight phosphoric acid

[0135] Temperature: 50°C

[0136] Time: 5 minutes

[0137] Anodic oxidation and etching (pore diameter expansion) were alternately repeated 5 times to obtain an anodized coating surface having tapered p...

Embodiment 2

[0149] As in Example 1, wherein instead of using an alumina-based grinding material for grinding, use a ball polishing wheel to grind using a grinding material based on silica gel (manufactured by FUJIMI INCORPORATED), except that it is the same as in Example 1 Get an anti-reflection film.

Embodiment 3

[0151] As in Example 1, wherein instead of using an alumina-based abrasive for grinding, use a bias cut cloth polishing wheel (manufactured by Koyo-Sha Co., Ltd.) using a silicic anhydride-based grease abrasive (manufactured by ICHIGUCHI Corporation) Except polishing, it carried out similarly to Example 1, and obtained the antireflection film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com