Composite shielding material and preparation method thereof

A composite shielding and electromagnetic shielding technology, applied in the field of composite shielding materials and its preparation, can solve the problems of hard texture, complex construction, high density, etc., and achieve the effects of smooth surface, high degree of automation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

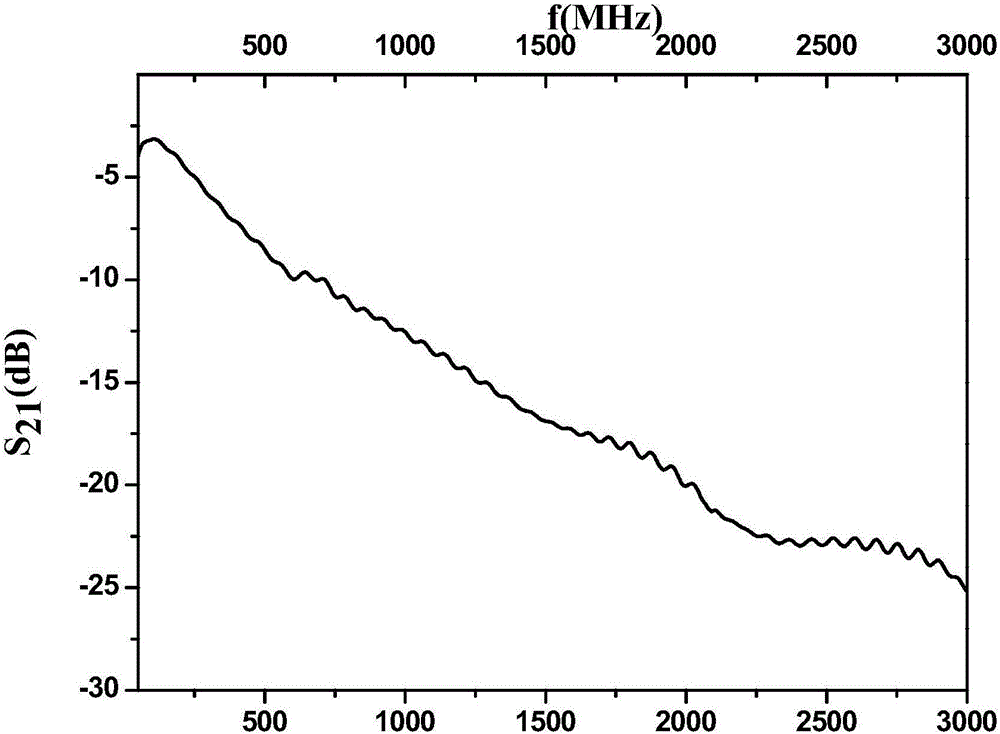

Embodiment 1

[0032] A composite shielding material, comprising by weight:

[0033]

[0034] The thickness of the expanded graphite is 0.5 μm, and the length is 50 μm.

[0035] The flake magnetic powder is Fe-Si-Al, the content of Fe in the magnetic powder is 78%, the content of Si is 12%, the content of Al is 10%, the thickness of the flake magnetic powder is 0.3 μm, and the length is 10 μm.

[0036] The dispersant in this embodiment is glyceryl trioleate; the rubber is nitrile rubber; the vulcanizing agent is dicumyl peroxide.

[0037] The mixture of expanded graphite and flake magnetic powder in this embodiment is a binary mixture, the mass ratio of binary mixture to rubber is 2:1; the mass ratio of flake magnetic powder to expanded graphite is 1:1.

[0038] The preparation method of above-mentioned composite shielding material, comprises the following steps:

[0039] 1) Preparation of expanded graphite: take 100 parts by weight of expandable graphite, place it in a muffle furnace a...

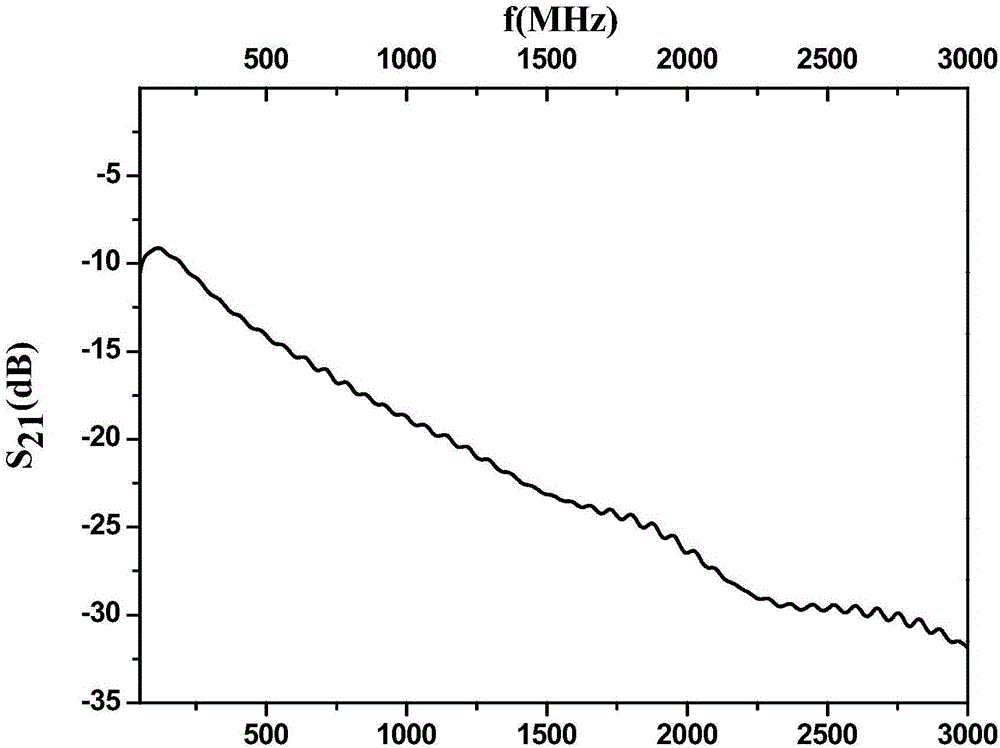

Embodiment 2

[0046] A composite shielding material, comprising by weight:

[0047]

[0048]The thickness of the expanded graphite in the present embodiment is 15 μm, and the length is 200 μm; The flaky magnetic powder is Fe-Si-Al, and the Fe content is 90% in the magnetic powder, and the Si content is 5%, and the Al content is 5%, and the flaky magnetic powder The thickness is 5 μm and the length is 100 μm.

[0049] The dispersant in this embodiment is benzenesulfonic acid; the rubber is ethylene-propylene rubber; and the vulcanizing agent is dibenzoyl peroxide.

[0050] The mixture of expanded graphite and flake magnetic powder in this embodiment is a binary mixture, the mass ratio of binary mixture to rubber is 10:1; the mass ratio of flake magnetic powder to expanded graphite is 9:1.

[0051] The preparation method of above-mentioned composite shielding material, comprises the following steps:

[0052] 1) Preparation of expanded graphite: Take 100 parts by weight of expandable grap...

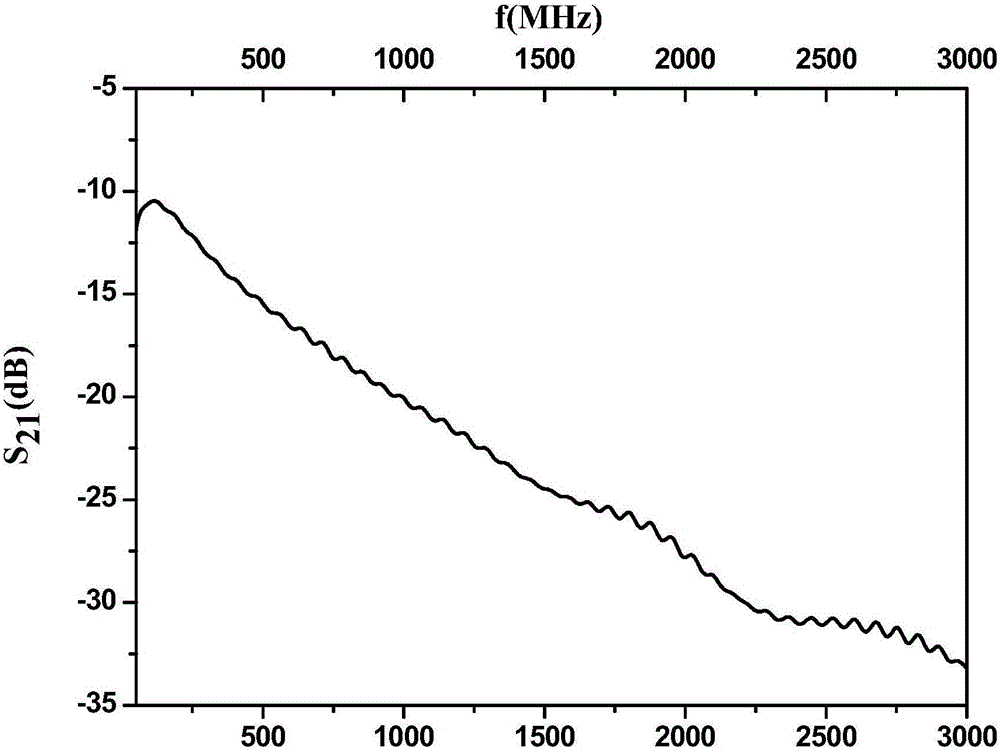

Embodiment 3

[0059] Take 3000 parts of expandable graphite (referred to as Kp) and place it in a muffle furnace at 700°C, take it out after 1 minute to obtain expanded graphite, and record it as EG. Add flaky FeSiAl magnetic powder (900 parts) and expanded graphite (100 parts) (mass ratio: 9:1) into a homogeneous mixer, and add an appropriate amount of ethanol and 2 parts of triolein as a dispersant, and stir for 2 hours. Mix the mixture well, then dry the mixture. Fluorine rubber, flaky FeSiAl magnetic powder and dicumyl peroxide (DCP) were selected as the matrix, absorbent and vulcanizing agent respectively.

[0060] Put 100 parts of fluororubber, 1000 parts of flaky FeSiAl magnetic powder and expanded graphite mixture into a banbury mixer, the banburying temperature is 90°C, after 30 minutes of banburying, add 4 parts of vulcanizing agent dicumyl peroxide (DCP ), then banburying for 30 minutes. After taking out the mixture, put it into an open mill for kneading. After kneading for 5 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com