MnZn ferrite material of high initial permeability and low loss and preparation method thereof

A magnetic permeability and low loss technology, applied in the field of oxide magnetic materials, can solve the problems of not having low loss and high initial magnetic permeability at the same time, and achieve low cost, low loss characteristics, and high initial magnetic permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

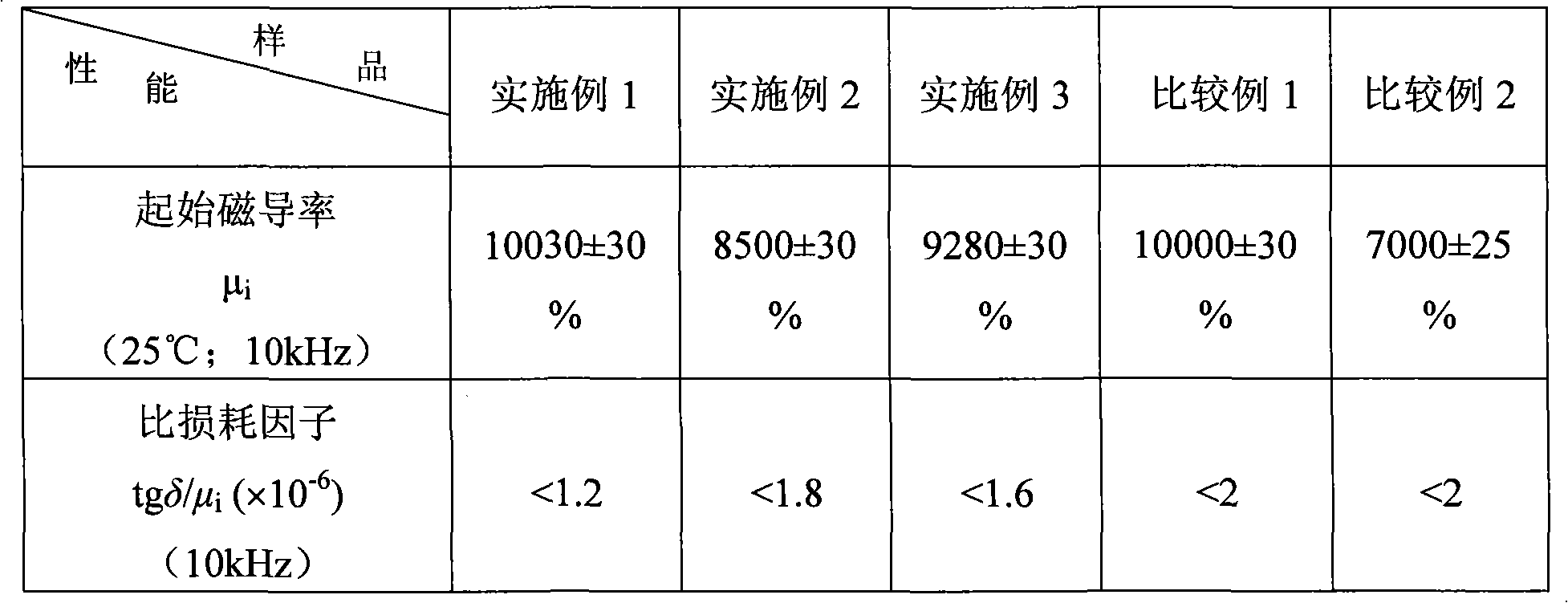

Examples

Embodiment 1

[0029] (1) Ingredients: ingredients are made according to the main components and content. Weigh the Fe with a purity of 99.5wt% 2 o 3 , Mn with a purity of 99% 3 o 4 , ZnO with a purity of 99.7%, and the mass ratio of the three is 60:29:11;

[0030] (2) Primary ball milling: put the powder into a ball mill jar according to the mass ratio of ball:material:ethanol=2:1:1, and then wet mill in a ball mill. The ball milling time is 30 minutes, and the rotation speed is 400r / min;

[0031] (3) Pre-burning: put the ball-milled powder into a resistance furnace for pre-burning, the pre-burning temperature is 900°C, and the holding time is 4 hours;

[0032] (4) Secondary ball milling and doping: Weigh the pre-fired powder and auxiliary components, chemically pure SnO 2 : 0.01wt%, TiO 2 : 0.03wt%, Er 2 o 3 : 0.03wt%, Bi 2 o 3 : 0.06wt%, PbO: 0.08wt% is put into the ball mill jar, then according to the mass ratio is ball: material: the ratio of ethanol=2: 1: 1, add pellet respe...

Embodiment 2

[0037] (1) Ingredients: ingredients are made according to the main components and content. Weigh the Fe with a purity of 98.5wt% 2 o 3 , MnO with a purity of 98%, ZnO with a purity of 99.7%, the molar ratio of the three is 69:15.5:15.5;

[0038] (2) Primary ball milling: put the powder into a ball mill jar according to the mass ratio of ball:material:ethanol=2:1:1, and then wet mill in a ball mill. The ball milling time is 30 minutes, and the rotation speed is 500r / min;

[0039] (3) Pre-burning: put the ball-milled powder into a resistance furnace for pre-burning, the pre-burning temperature is 800°C, and the holding time is 3h;

[0040] (4) Secondary ball milling and doping: Weigh the pre-fired powder and auxiliary components, chemically pure SnO 2 : 0.03wt%, TiO 2 : 0.01wt%, Er 2 o 3 : 0.05wt%, Bi 2 o 3 : 0.05wt%, PbO: 0.03wt% is put into the ball mill jar, then according to the mass ratio is ball: material: the ratio of ethanol=2: 1: 1, add pellet respectively, the...

Embodiment 3

[0045] (1) Ingredients: ingredients are made according to the main components and content. Weigh the Fe with a purity of 98.5wt% 2 o 3 , MnO with a purity of 98%, ZnO with a purity of 99.7%, the molar ratio of the three is 73:12:15;

[0046] (2) Primary ball milling: put the powder into a ball mill jar according to the mass ratio of ball:material:ethanol=2:1:1, and then wet mill in a ball mill. The ball milling time is 40 minutes, and the rotation speed is 600r / min;

[0047] (3) Pre-burning: put the ball-milled powder into a resistance furnace for pre-burning, the pre-burning temperature is 900°C, and the holding time is 1h;

[0048] (4) Secondary ball milling and doping: Weigh the pre-fired powder and auxiliary components, chemically pure SnO 2 : 0.04wt%, TiO 2 : 0.02wt%, Er 2 o 3 : 0.03wt%, Bi 2 o 3 : 0.05wt%, PbO: 0.06wt% is put into the ball mill jar, then according to the mass ratio is ball: material: the ratio of ethanol=2: 1: 1, add pellet respectively, then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com