Electromagnetic shielding coating method

An electromagnetic wave and metal technology, applied in the direction of magnetic/electric field shielding, coating, electrical components, etc., can solve the problems of inability to separate the coating layer, cannot be formed normally, low reuse rate, etc., and achieve excellent electromagnetic wave shielding performance, tightness Excellent adhesion and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

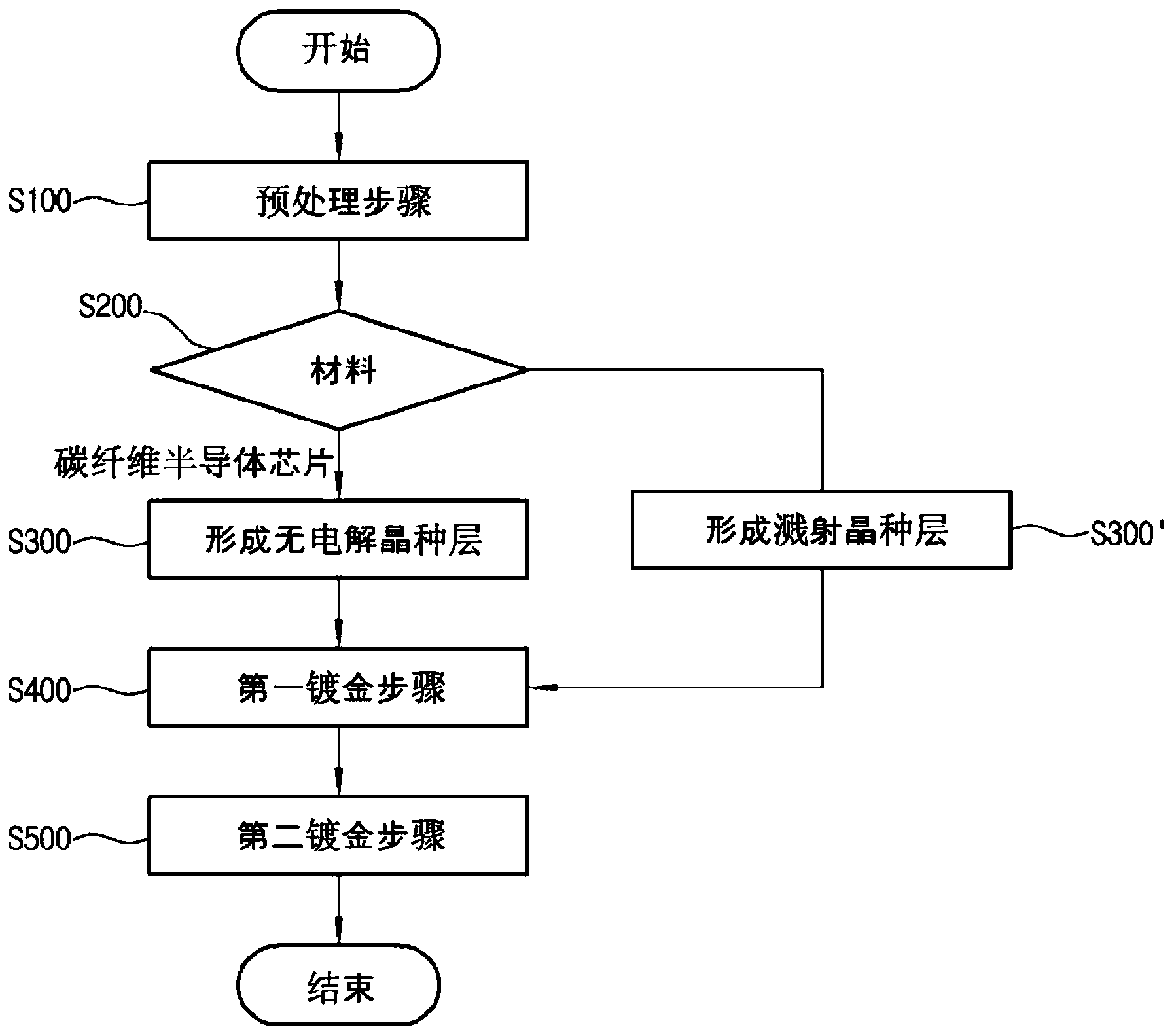

Method used

Image

Examples

Embodiment 1

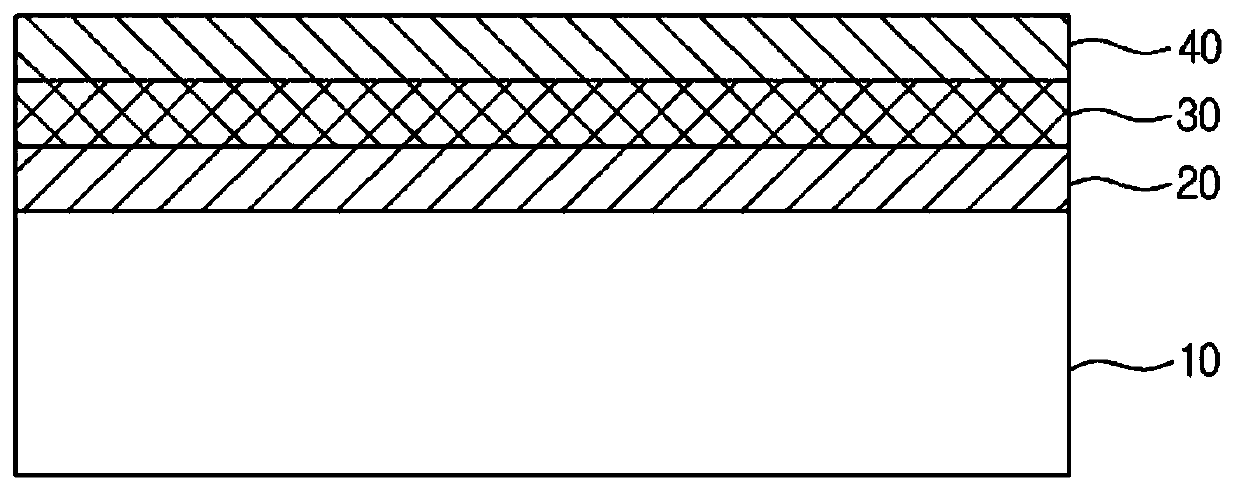

[0078] At a temperature of about 180°C, maintain 10 -5 mmHg to 10 -3 The surface of the semiconductor chip is irradiated with surface plasma with 99% oxygen at a vacuum degree of mmHg, and after that, carbon tetrafluoride (CF 4 ) gas etches the surface of the material.

[0079] Put the surface of the semiconductor chip through the above steps into an aqueous solution of palladium sulfate at a temperature of 55° C. and a concentration of 7 g / L. After adding an aqueous solution of sodium hypophosphite so that the concentration becomes 3 g / L, immerse it for 8 minutes. A seed layer is formed.

[0080] Take out the semiconductor chip and place it in an aqueous copper chloride solution with a temperature of 30°C and a concentration of 80g / L, add sodium hypophosphite solution, and immerse it for 5 minutes. The ammonium acid hydrate aqueous solution was immersed for 30 minutes to form an electromagnetic wave shielding coating layer.

Embodiment 2

[0082] Except in the 10×10cm woven carbon fiber 2 An electromagnetic wave shielding coating layer was formed in the same manner as in Example 1 except that the surface of the carbon fiber fabric was subjected to the electromagnetic wave shielding coating method of the present invention instead of the semiconductor chip. A semiconductor package was prepared by allowing the carbon fiber fabric formed with the coating layer to completely surround the semiconductor surface.

Embodiment 3

[0084] At a temperature of about 180°C, maintain 10 -5 mmHg to 10 -3 Surface plasma irradiation is performed on the surface of the semiconductor chip for smart cars with 99% oxygen at a vacuum degree of mmHg.

[0085] On the surface of the plasma-treated material, with nickel and iron as target substances, at a temperature of 195°C and 10 - 5 mmHg to 10 -3 Under the condition of vacuum degree of mmHg, the plasma sputtering process was performed on nickel and iron as the target substances at a power of 1.5 kW. Put the above-mentioned semiconductor chip for smart cars into an aqueous copper chloride solution with a temperature of 30°C and a concentration of 80g / L, and add a sodium hypophosphite solution and then immerse it for 5 minutes. Then, at a temperature of 75°C and a concentration of A 40 g / L ammonium tungstate hydrate aqueous solution was immersed for 30 minutes to form an electromagnetic wave shielding coating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com