Resin coated metal sheet with excellent electromagnetic wave shielding performance

A metal plate, resin technology, applied in the fields of magnetic/electric field shielding, shielding, metal layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

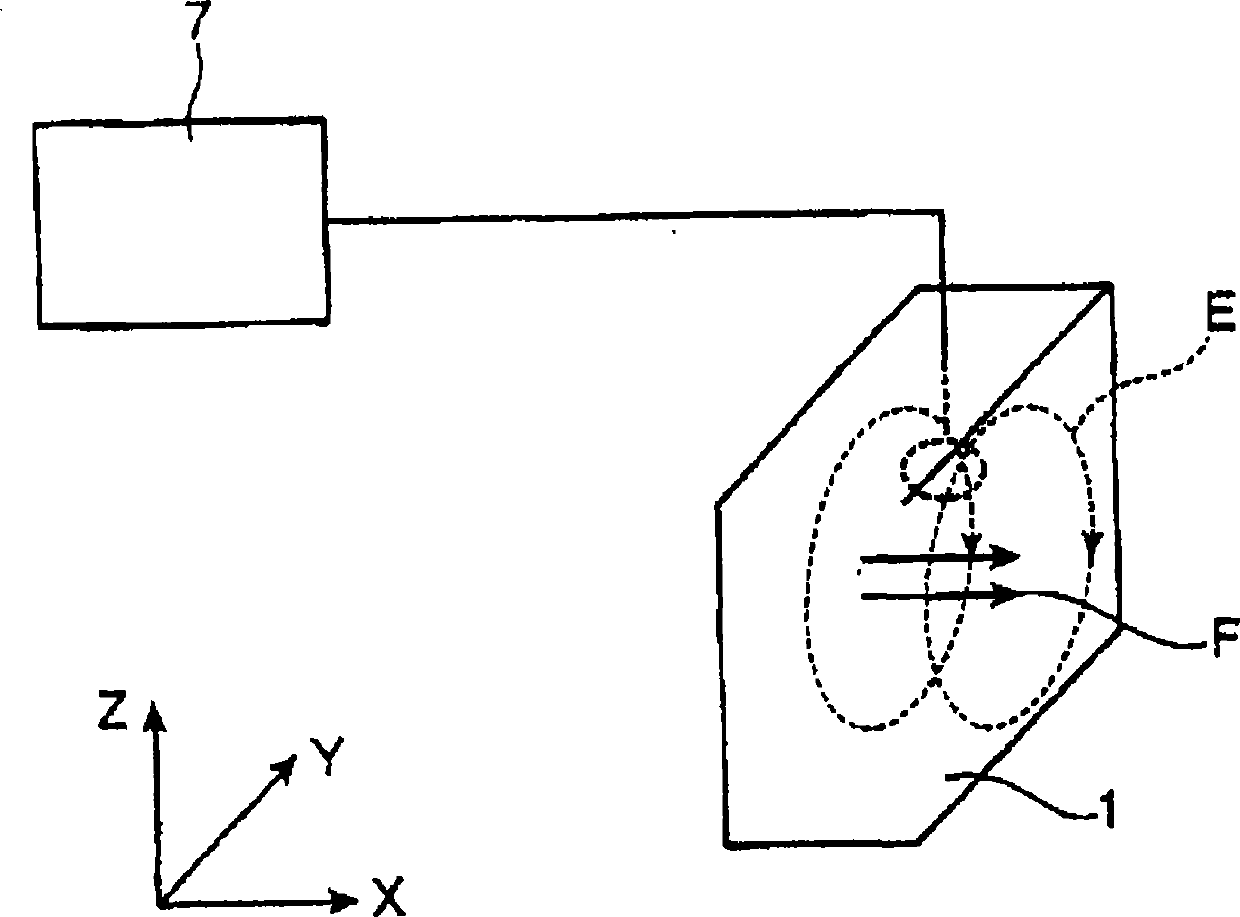

Method used

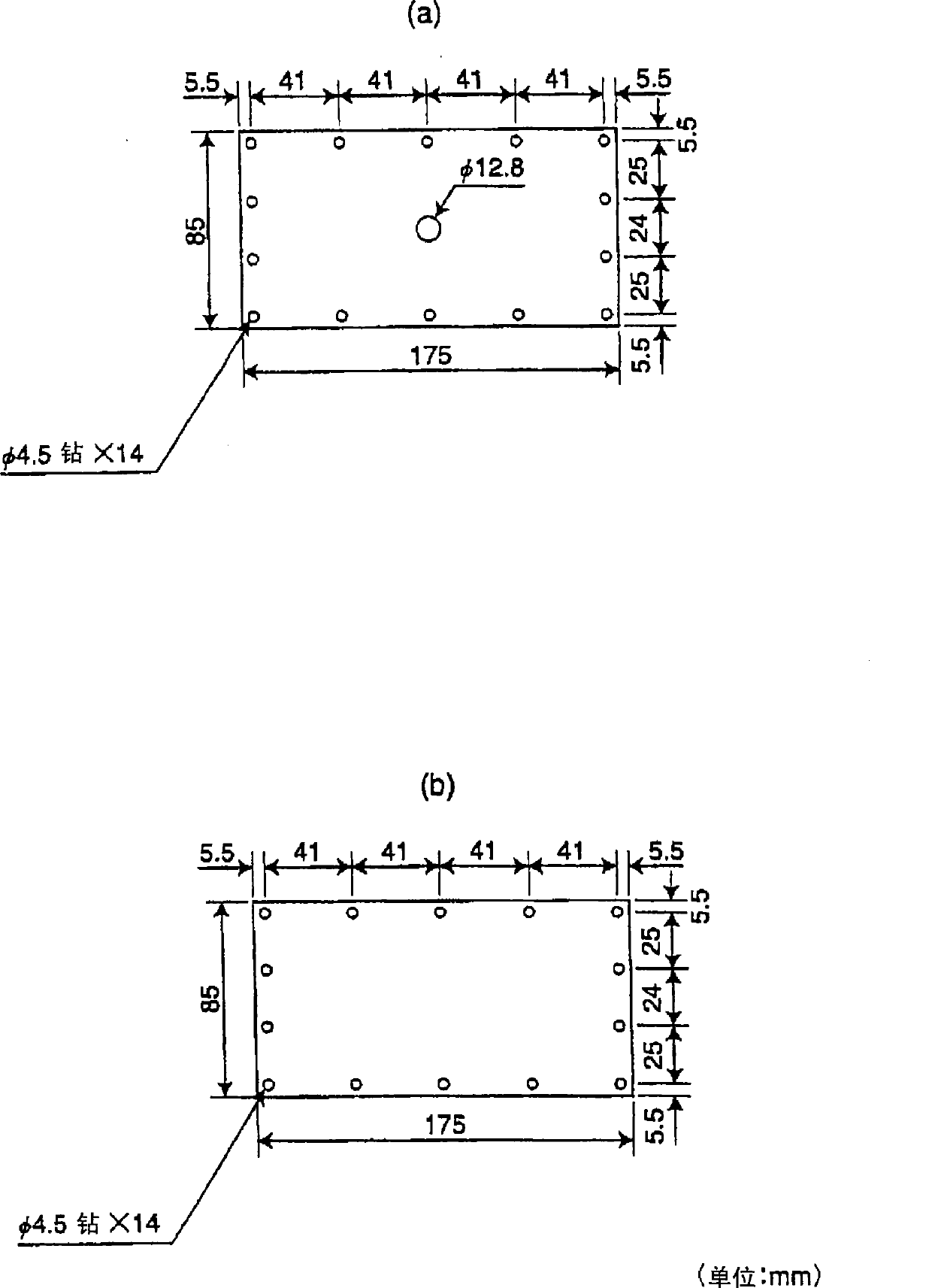

Image

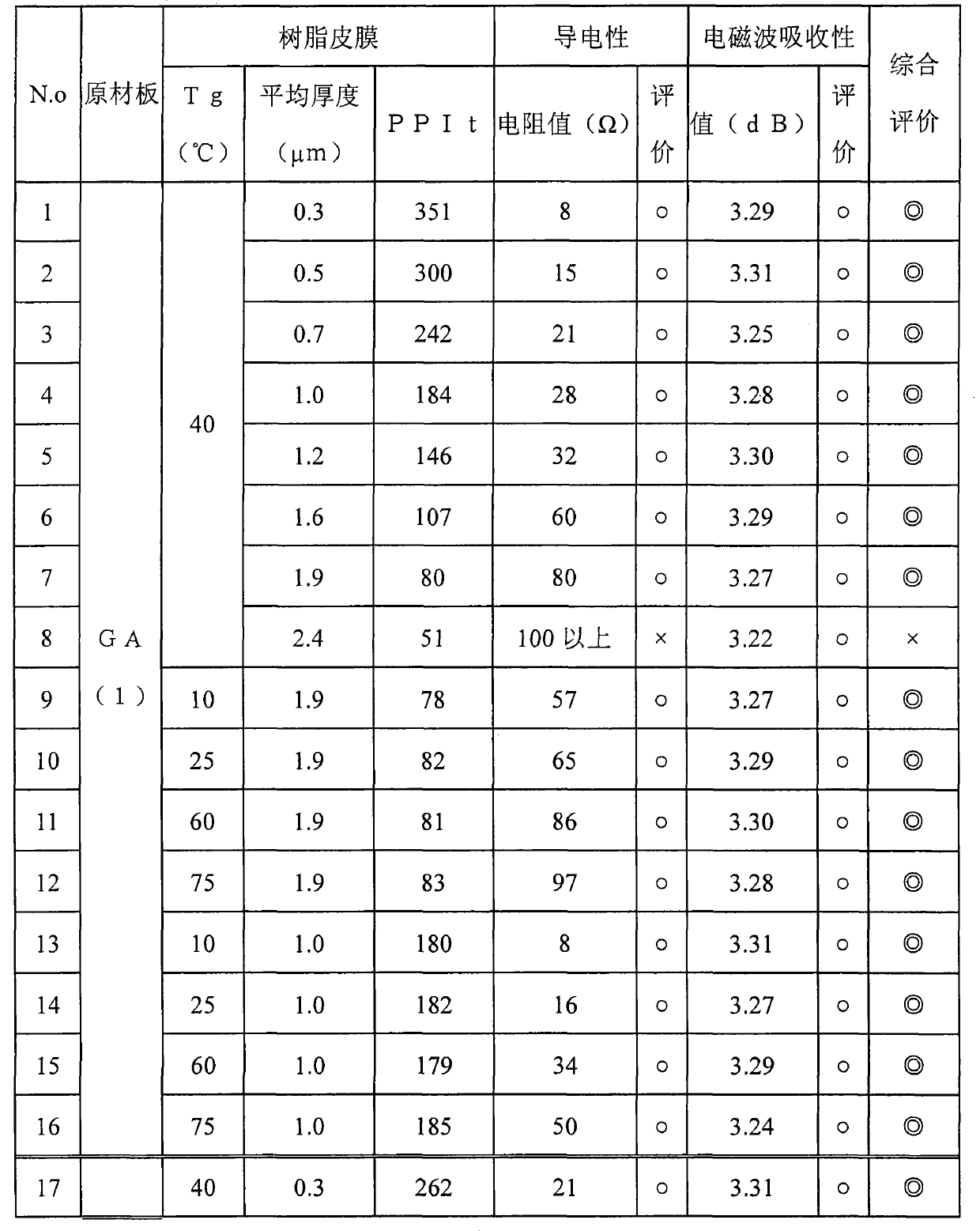

Examples

Embodiment 1

[0109] EG(1): Galvanized steel sheet

[0110] (Single-sided plating adhesion 20g / m 2 , Ra: 0.76μm)

[0111] EG(2): Galvanized steel sheet

[0112] (Single-sided plating adhesion 15g / m 2 , Ra: 0.78μm)

[0113] EG(3): Galvanized steel sheet

[0114] (Single-sided plating adhesion 12g / m 2 , Ra: 0.75μm)

[0115] EG(4): Galvanized steel sheet

[0116] (Single side plating adhesion 9g / m 2 , Ra: 0.80μm)

[0117] EG(5): Galvanized steel sheet

[0118] (Single-sided plating adhesion 6g / m 2 , Ra: 0.76μm)

[0119] EG(6): Galvanized steel sheet

[0120] (Single-sided plating adhesion 3g / m 2 , Ra: 0.77μm)

[0121] GI: hot-dip galvanized steel sheet

[0122] (Single-sided plating adhesion 60g / m 2 , Ra: 0.56μm)

[0123] CR: cold-rolled steel plate (Ra: 0.86μm)

[0124] GA(1): alloyed hot-dip galvanized steel sheet

[0125] (Single side plating adhesion 40g / m 2 , Fe: 10%, Ra: 1.34μm)

[0126] GA(2): alloyed hot-dip galvanized steel sheet

[0127] (Single side plating adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com