High-strength wear-resisting and compression-resistant shielded cable

A shielded cable, high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor anti-electromagnetic wave performance, affect the promotion and use of cables, and weak cable anti-compression performance, so as to improve the anti-compression performance and good electromagnetic wave performance. Shielding performance, effect of eliminating harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

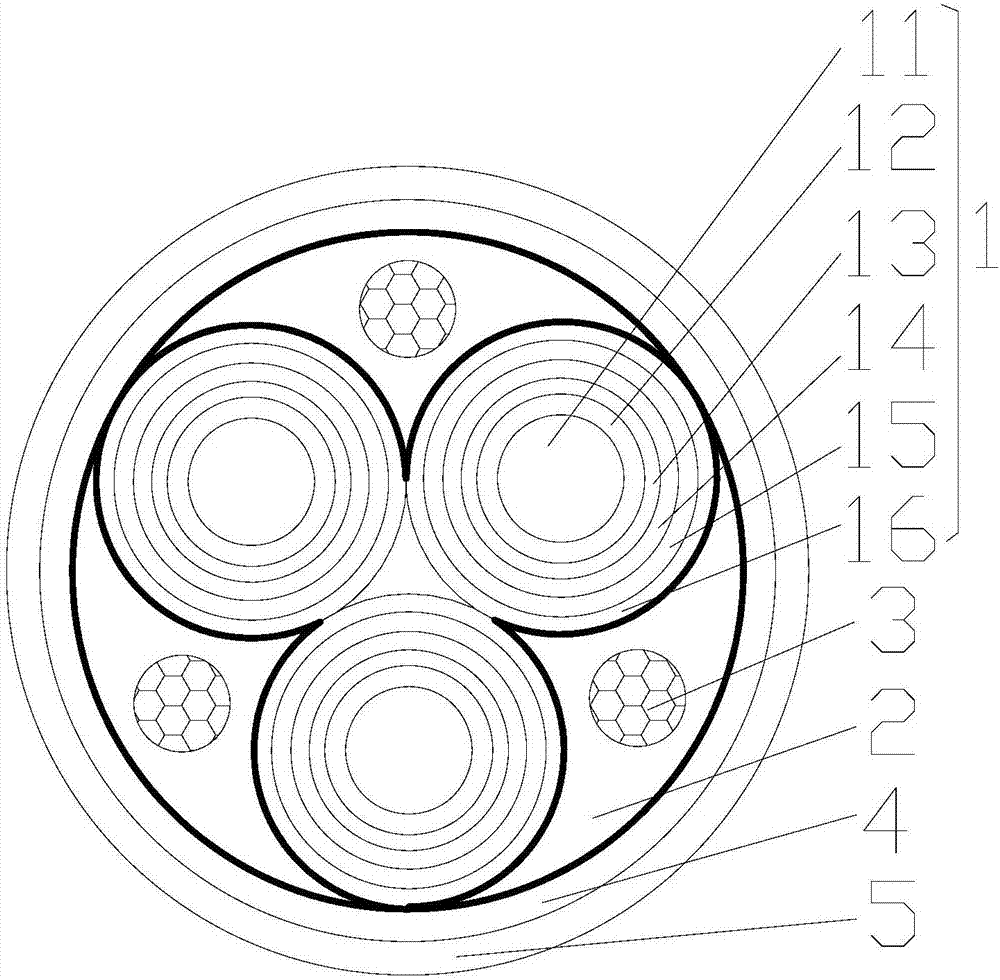

[0007] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a high-strength wear-resistant and pressure-resistant shielded cable proposed by the present invention.

[0008] refer to figure 1 , a high-strength wear-resistant and anti-compression shielded cable proposed by the present invention, comprising: a cable core, an aluminum-plastic composite tape 4 and an outer sheath 5; the cable core includes three wire cores 1, three elastic anti-compression cores 2 and a binding core 3 , the three wire cores 1 are placed vertically in parallel and lean against each other. On any cross section, the connecting lines between the centers of the three wire cores 1 are equilateral triangles. Conductive conductor shielding layer 12, insulating layer 13, copper tape shielding layer 14, elastic buffer layer 15 and wrapping layer 16, specifically, the conductor 11 is formed by twisting a plurality of copper wires, and the elastic compression core 2 is located at two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com