Patents

Literature

73results about How to "Industrial simplicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

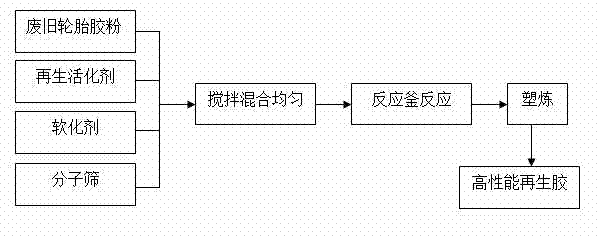

High-performance regenerated rubber and preparation method thereof

The invention relates to a high-performance regenerated rubber and a preparation method thereof. The regenerated rubber is prepared by performing desulfuration on waste rubber powder. The high-performance regenerated rubber is prepared from the following components in parts by weight: 100 parts of the rubber powder of the waste rubber, 2-8 parts of regeneration activators, 4-12 parts of softening agents and 4-10 parts of molecular sieves. The prepared regenerated rubber has excellent performance, is high in tensile intensity and breakage elongation index, can partially replace natural rubber and synthetic rubber and is used for producing various types of rubber products. In addition, the preparation method is simple and feasible as well as high in efficiency, ensures the product to be excellent in performance, and causes no adverse influence on an environment.

Owner:HUBEI UNIV OF TECH

Carbon fiber shielding paper preparing process

InactiveCN101265676AImprove shielding effectGuaranteed lightweightDefoamers additionPaper/cardboardCarbon fibersPlant fibre

A process for preparing carbon fiber screening paper is provided. The invention includes the following steps: mixing chopped carbon fiber and plant carbon fiber in a certain proportion, adding certain amounts of a dispersant and a defoaming agent, dispersing on a fluffer, and papermaking in a paper former. While the light weight of material is guaranteed, the paper is endowed with good screening performance and easy process, which make full use of the advantages of large scale production in the papermaking industry. Furthermore, the paper electric conductive screening performance can be controlled by adjusting and quantifying the amount of the carbon fiber. The carbon fiber screening paper, which is an electric conductive material with high performance, replaces the conventional electric conductive screening material and covers the shortages thereof. The prepared screening paper has good screening performance of electromagnetic waves, the screening effectiveness at 100KHz-1500MHz is more than 30dB and the maximum is 50dB, thereby being generally applicable to radiation protection and anti-interference of common commercial or electronic products.

Owner:SHAANXI UNIV OF SCI & TECH

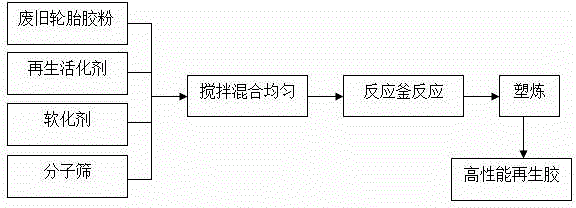

Green method for recycling lithium in cathode materials

ActiveCN106340692AImprove conversion efficiencyWeak base selectivityWaste accumulators reclaimingBattery recyclingLithium carbonateCarbon dioxide

The invention provides a green method for recycling lithium in cathode materials, and the method comprises the following steps of 1, using cathode materials containing lithium and mixture of weak base and water as the reaction raw materials, carrying out reaction at the temperature of 5 DEG C-90 DEG C and at the pressure of 0.2 MPa-1.0 MPa, proceeding liquid-solid separation on the materials remaining after the reaction and then obtaining lithium and residue; 2, carrying out postprocessing on the extraction solution of lithium to obtain lithium carbonate. The green method for recycling lithium in cathode materials has simple procedures and green reaction process, during which, the leaching efficiency of lithium is larger than 95 WT%, the purity of lithium carbonate is larger than 98.5 WT%, and the impurity content satisfies national standard GB / T11075 2013.

Owner:北京中科百特科技有限公司

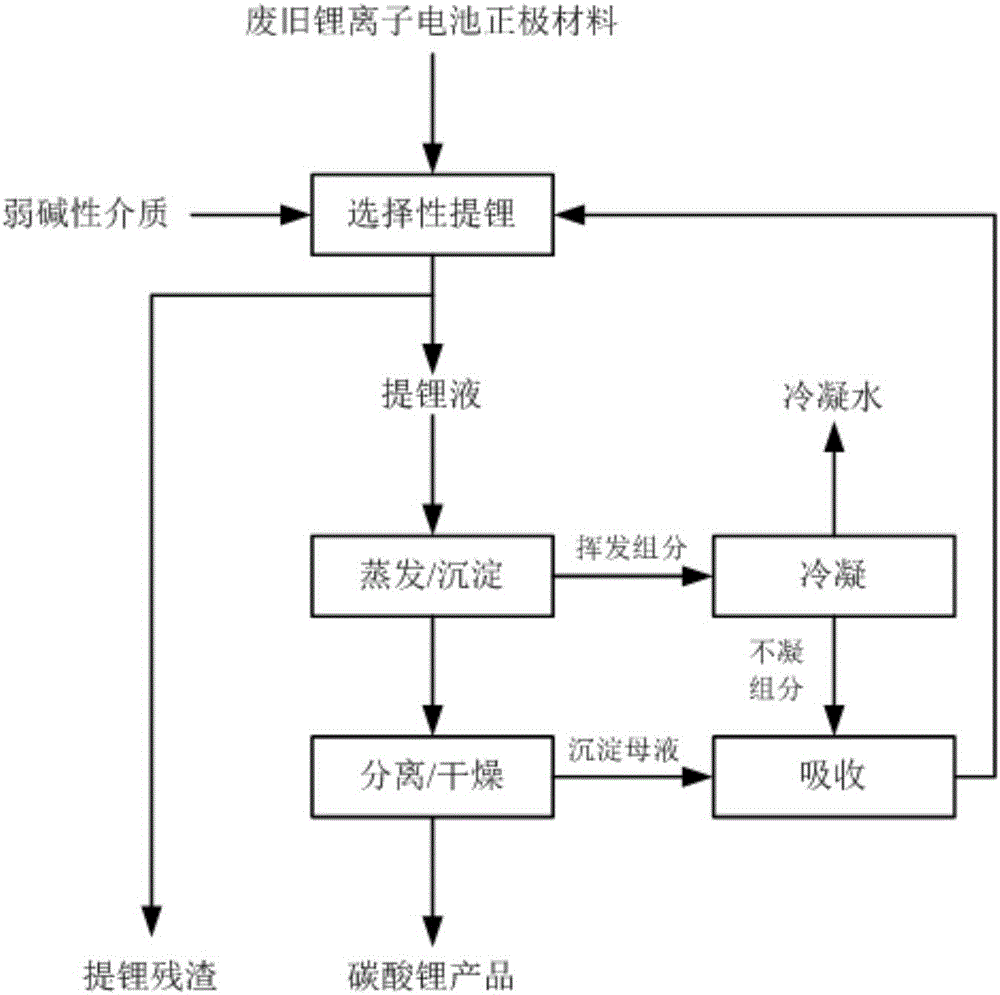

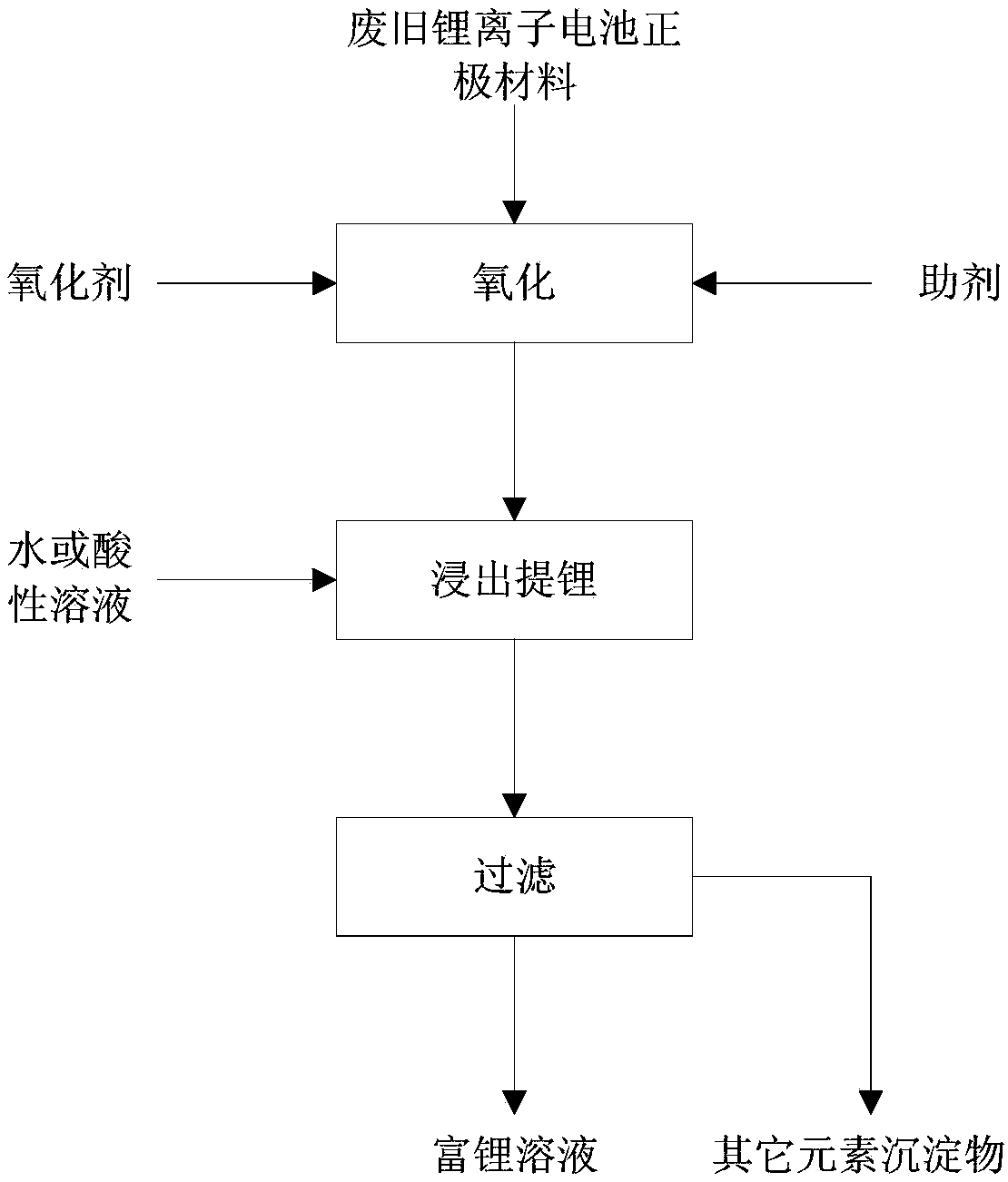

Method for selectively recycling lithium in waste lithium ion battery positive electrode material

InactiveCN108390120ASimple processShort processWaste accumulators reclaimingBattery recyclingWater solubleLithium electrode

The invention provides a method for selectively recycling lithium in a waste lithium ion battery positive electrode material. The method comprises the following steps: (1) adding an oxidant into the waste lithium ion battery positive electrode material and carrying out oxidization reaction; converting lithium into water-soluble lithium salt through an auxiliary agent; (2) leaching the water-soluble lithium salt obtained by step (1) in water or an acidic solution and filtering to obtain a lithium-enriched solution and leached residues. The method provided by the invention has a simple flow anda clean process and the recycling rate of the lithium can reach 95 percent or above.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

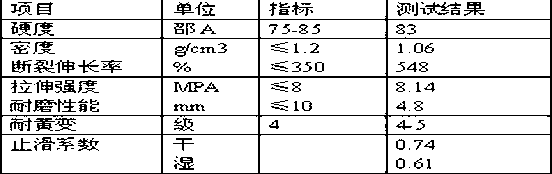

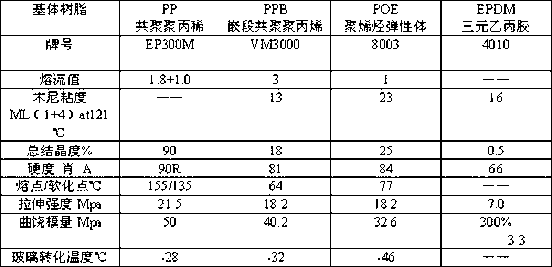

Ultrahigh-wear-resistant sole material and manufacturing method thereof

InactiveCN103183873AImprove wear resistanceIncrease elasticitySolesChemical recyclingAntioxidantWear resistant

The invention relates to an ultrahigh-wear-resistant sole material and a manufacturing method thereof. The material is composed of 65-70 parts of ethylene propylene diene monomer, 25-30 parts of melting plastic, 30-40 parts of white carbon black, 5-10 parts of softening oil, 1.5-2 parts of stearic acid, 3-4 parts of polyethylene glycol, 0.5 parts of an antioxidant, 15-20 parts of carbon masterbatch, 4-6 parts of a high-performance wear-resisting agent, 4-5 parts of zinc oxide powder, 1.5-2 parts of dicumyl peroxide, and 5-7 parts of an assistant crosslinking agent. The melting plastic is composed of 10 parts of homopolymer polypropylene 300M, 40 parts of copolymer polypropylene, and 50 parts of ethylene-octene copolymer. The high-performance wear-resisting agent is composed of 28 parts of white carbon black, 72 parts of a silane coupling agent, and 50 parts of silica gel. The material provided by the invention has the advantages of high wear resistance, high elasticity, and light weight. Also, the invention provides a manufacturing method of the high-wear-resistant material. The industrial process is simple, and cost is low.

Owner:FUJIAN ZHENGYI IND

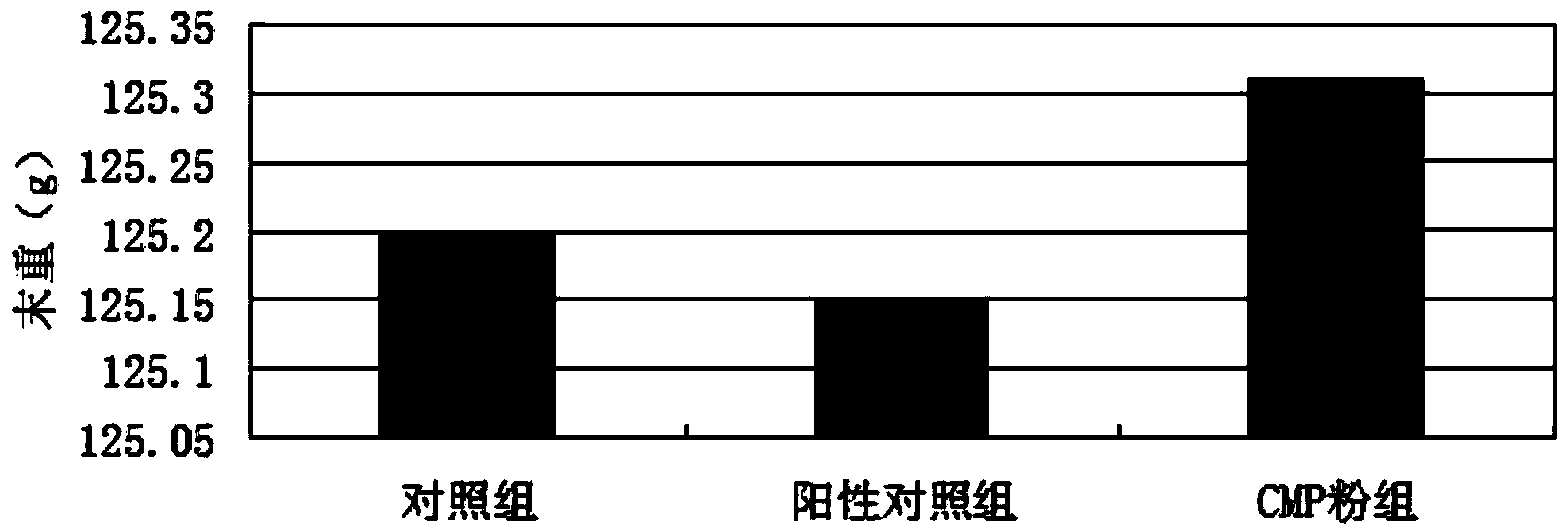

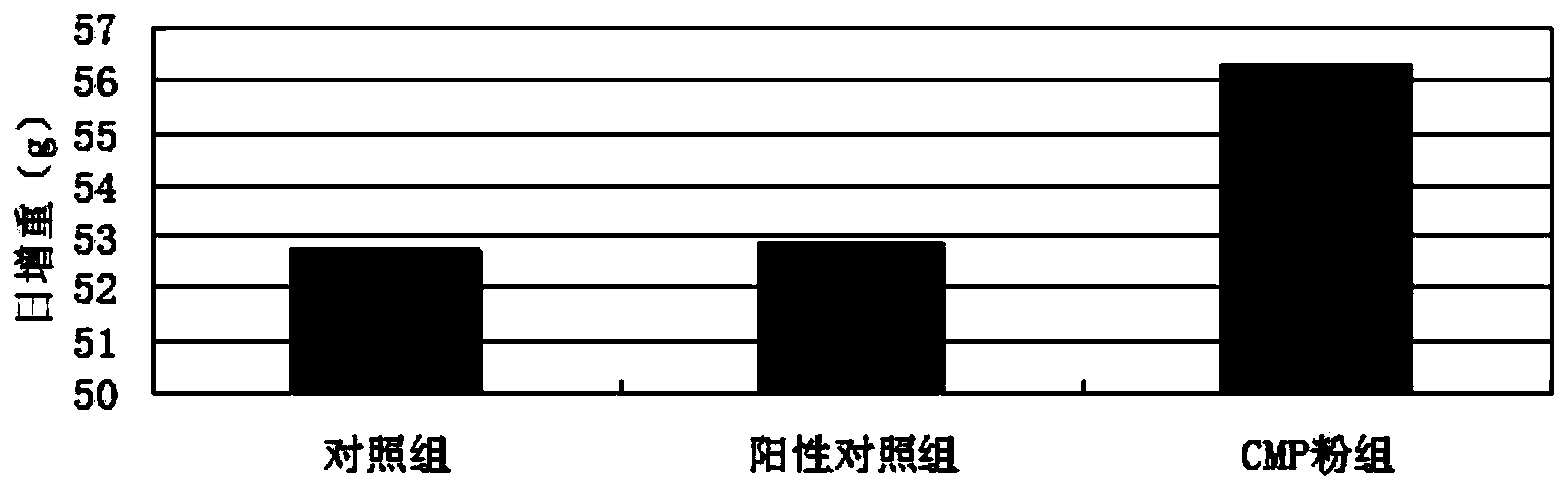

Preparation method of carboxymethyl pachyman and novel application of carboxymethyl pachyman

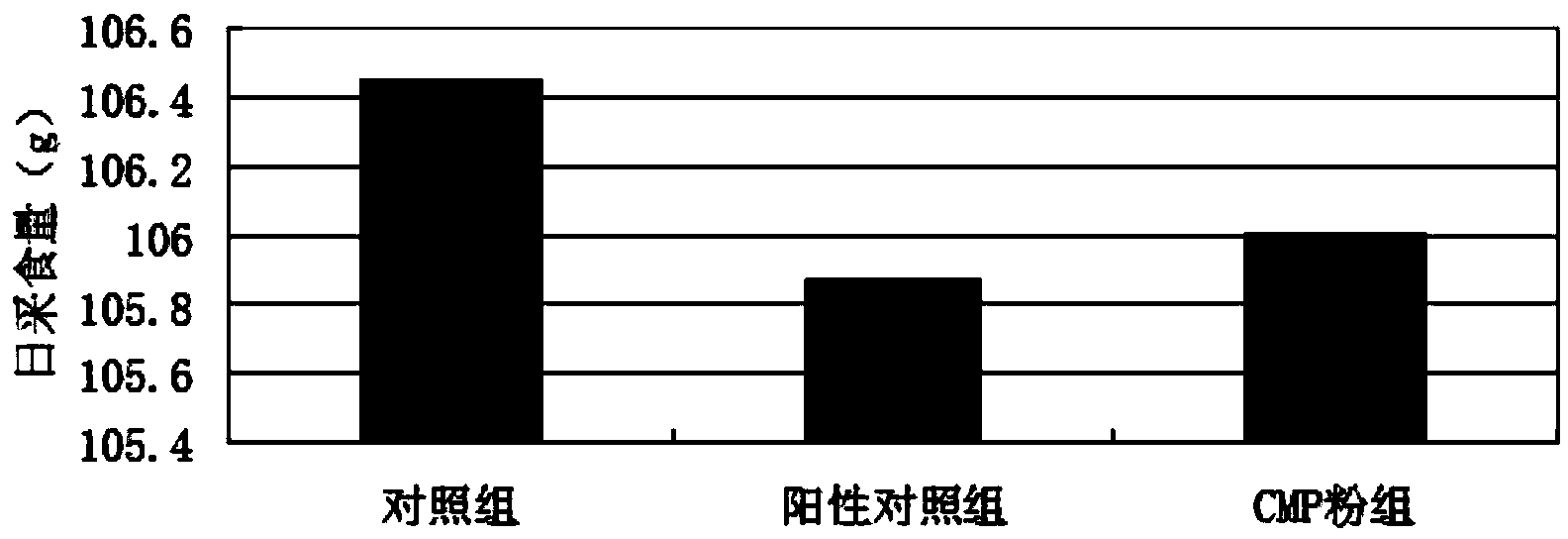

ActiveCN104387482AImprove carboxymethylation efficiencyHigh degree of substitutionOrganic active ingredientsAnimal feeding stuffReaction temperatureFeed additive

The invention provides a preparation method of carboxymethyl pachyman and a novel application of the carboxymethyl pachyman. According to the method, in the process of carrying out carboxymethylation modification on pachymaran, components and ratios of a reaction medium are changed, the reaction temperature is regulated and a catalyst process is adopted, so that the carboxymethylation efficiency of the pachymaran is remarkably improved, the utilization rate of the raw and auxiliary materials is increased, and the cost is saved. Meanwhile, by virtue of the novel application of the carboxymethyl pachyman prepared by the method to preparation of immunopotentiators of livestock and poultry, the immunity to pathogenic microorganisms of the livestock and the poultry can be remarkably enhanced, and the immune efficacy of vaccines can be improved; by virtue of the novel application of the arboxymethyl pachyman prepared by the method to feed additives, the meat performance of the livestock and the poultry can be effectively improved.

Owner:RINGPU TIANJIN BIOLOGICAL PHARMA

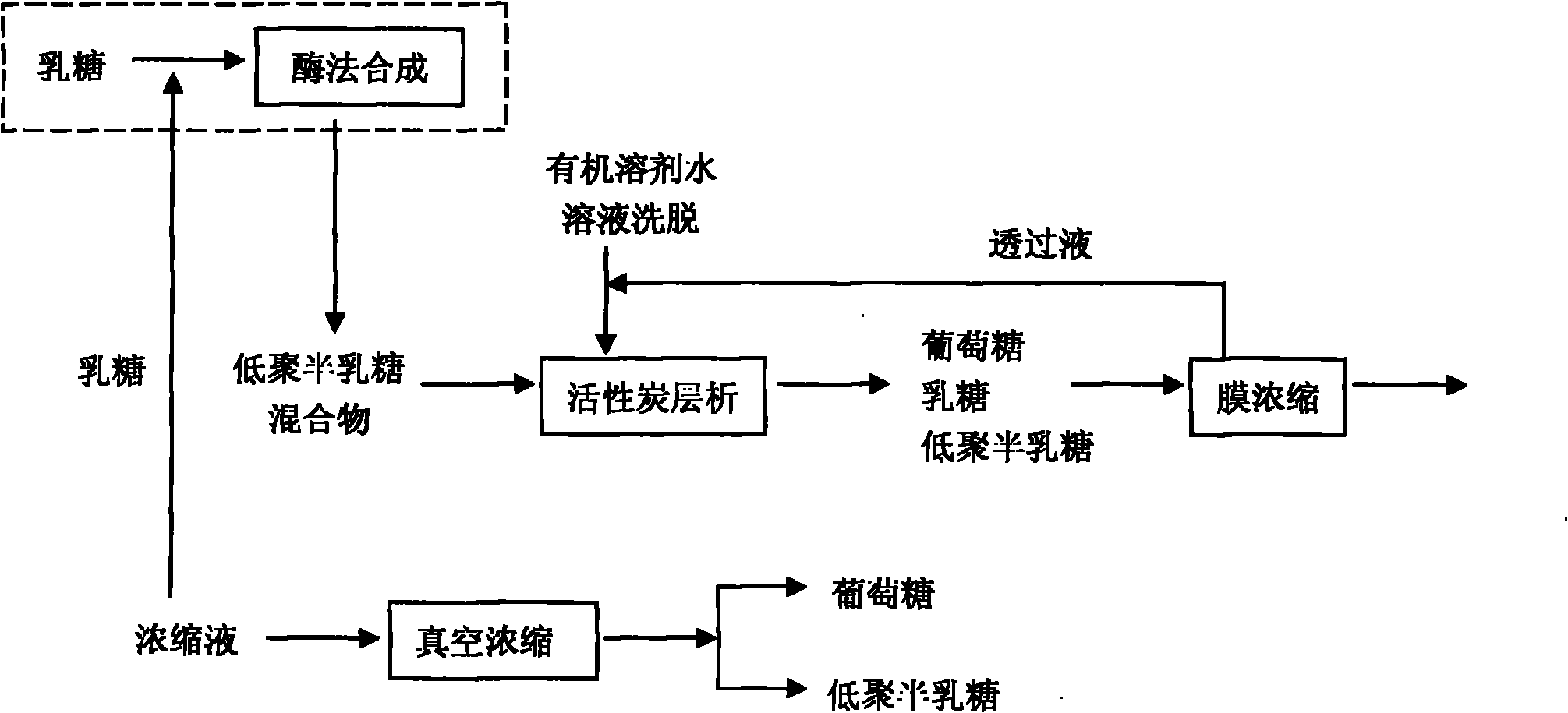

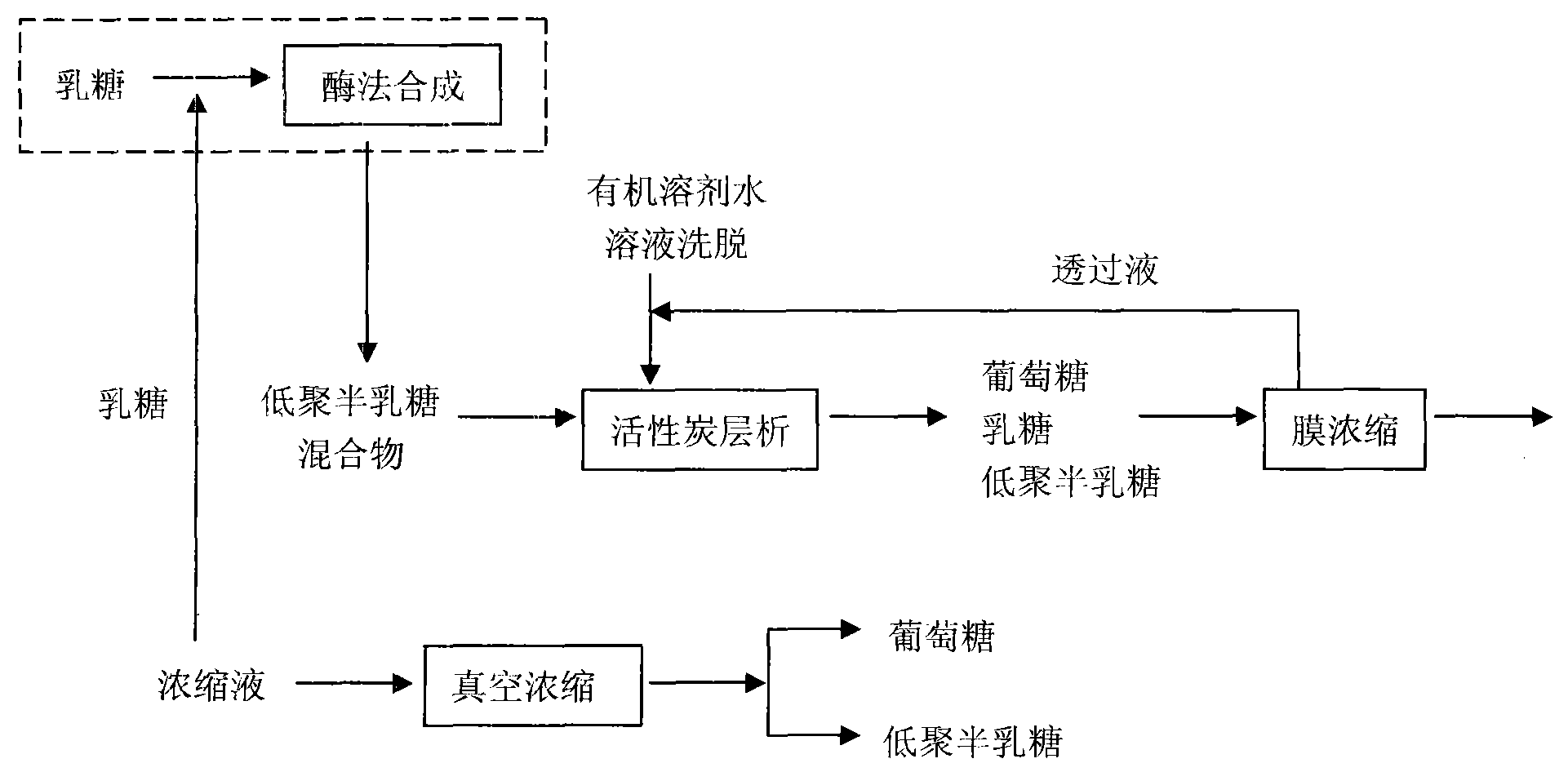

Galactooligosaccharides economic purification method

InactiveCN101781371ALow costIndustrial simplicitySugar derivativesOligosaccharidesEnzymatic synthesisPurification methods

The invention relates to a galactooligosaccharides economic purification method, in particular to high purity galactooligosaccharides product separated from galactooligosaccharides mixture prepared by enzymatic synthesis by adopting low-cost active carbon as chromatography purification medium. The invention is characterized in that: galactooligosaccharides mixture solution prepared by enzymatic synthesis is added into active carbon chromatography column, organic solvent aqueous solution in different concentrations are used for elution, elution fractions in different stages are collected, firstly membrane method is adopted to concentrate and recycle organic solvent aqueous solution, the organic solvent aqueous solution is returned to chromatography system to be repeatedly used as eluant, lactose concentrated solution is returned to enzymatic synthesis working stage to be recycled as raw material, galactooligosaccharides and glucose concentrated solution is further concentrated by adopting vacuum concentration method, and the concentrated solution is subject to spray drying, thus obtaining high purity galactooligosaccharides product and glucose byproduct.

Owner:YANTAI UNIV

Method for preparing 2,3 - dichloro - 5 - trichloro methylpyridine

ActiveCN101092392ALow priceIncrease production capacityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReaction temperaturePyridine

This invention discloses a method for preparing 2, 3-dichloro-5-trichloromethyl pyridine. The method comprises: utilizing inexpensive commercialized 2-chloro-5-trichloromethyl pyridine as the raw material, and chlorinating at 100-250 deg.C in the presence of catalyst and Cl2 to synthesize 2, 3-dichloro-5-trichloromethyl pyridine. The catalyst is commercialized, and is inexpensive. The method has such advantages as simple process and high yield, and can synthesize 2, 3-dichloro-5-trichloromethyl pyridine in one step.

Owner:LANZHOU CHEMSPECWEIER CHEM CO LTD

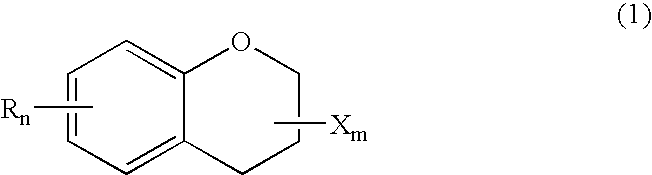

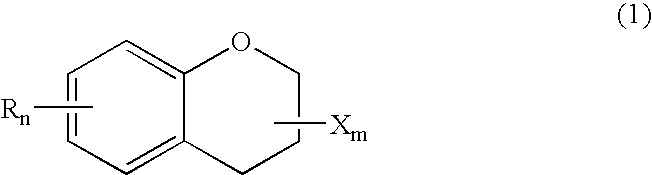

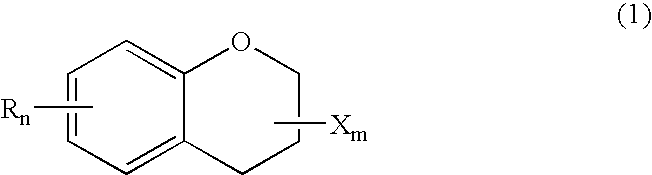

Method for producing optically active chroman-carboxylate

InactiveUS20060141591A1Facilitates separation and recoveryHigh purityOrganic chemistryFermentationAlcoholEnantiomer

In the method for producing an optically active chromancarboxylate of the present invention, one of the enantiomers of racemic chromancarboxylic acid is esterified in a solvent containing an alcohol in the presence of a biocatalyst. After the esterification, the other enantiomer, i.e., the non-reacted chromancarboxylic acid is separated out of the reaction mixture to obtain the aimed optically active ester. The optically active chromancarboxylate is useful as the material for medicines, agricultural chemicals, etc. The invention provides an efficient production method thereof which is industrially applicable.

Owner:MITSUBISHI GAS CHEM CO INC

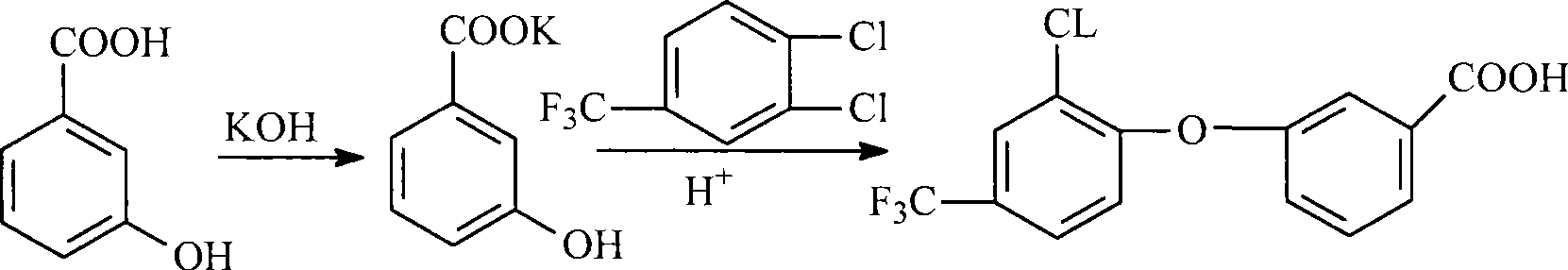

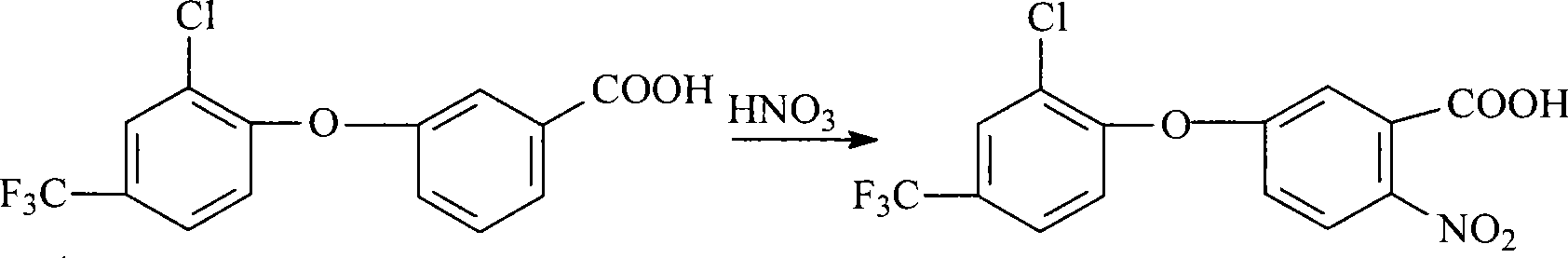

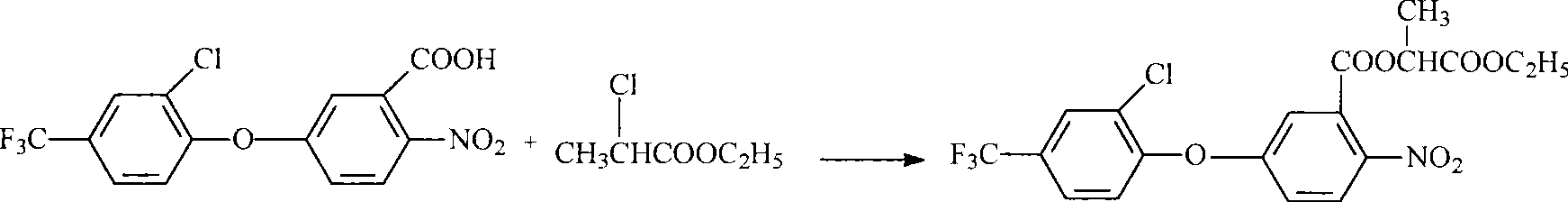

Loctofen preparation method

ActiveCN101362698AHigh content of original drugHigh yieldOrganic chemistryOrganic compound preparationDiphenyl etherBenzene

The invention relates to a preparation method of Lactofen technical product of pesticides, belonging to the technical field of fluorine-containing diphenyl ether pesticide. 3,4-dichloro (trifluoromethyl) benzene and m-hydroxybenzoic acid are used as starting materials. After salification, condensation, acidification and nitrification processes, acifluorfen-sodium that is the intermediate product is produced. Acifluorfen-sodium and ethyl 2-chloropropionate are condensed into Lactofen technical product of pesticides under the action of catalyzer. The invention is characterized in that the catalyzer is quaternary ammonium salt and the dosage is within the range 5 permil to 10 permil. The method of the invention has the advantages of high yield, high content of technical product of pesticides, cheap and available raw material and easy realization in industry.

Owner:QINGDAO HANSEN BIOLOGIC SCI

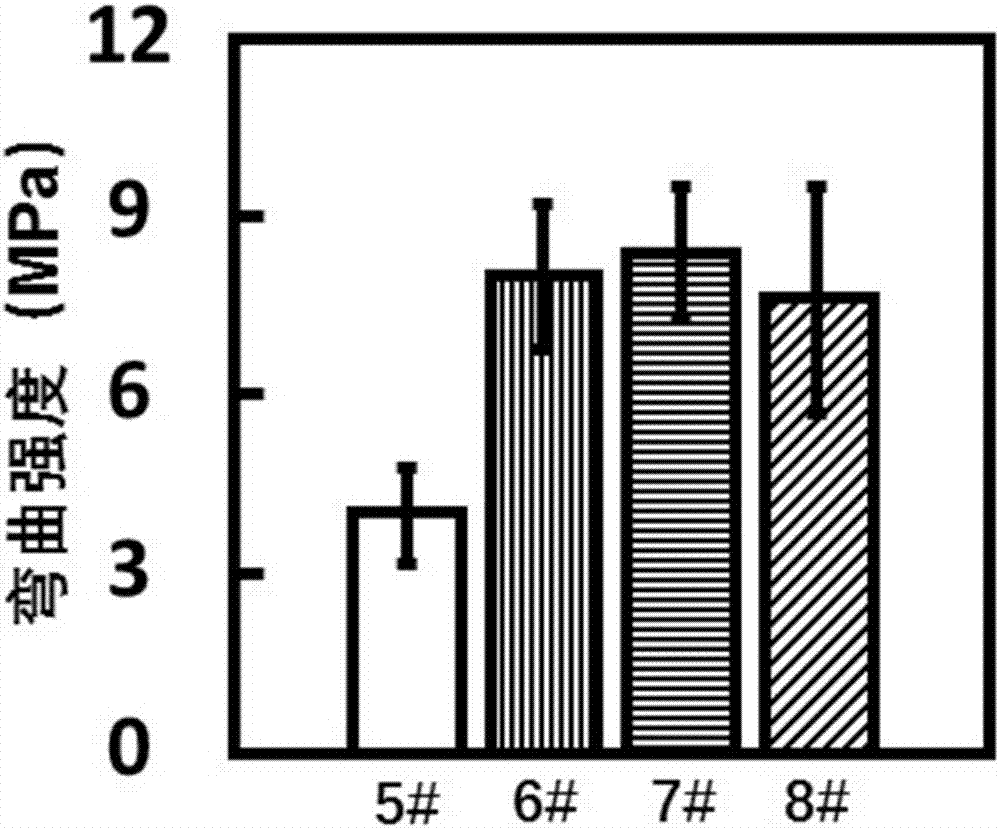

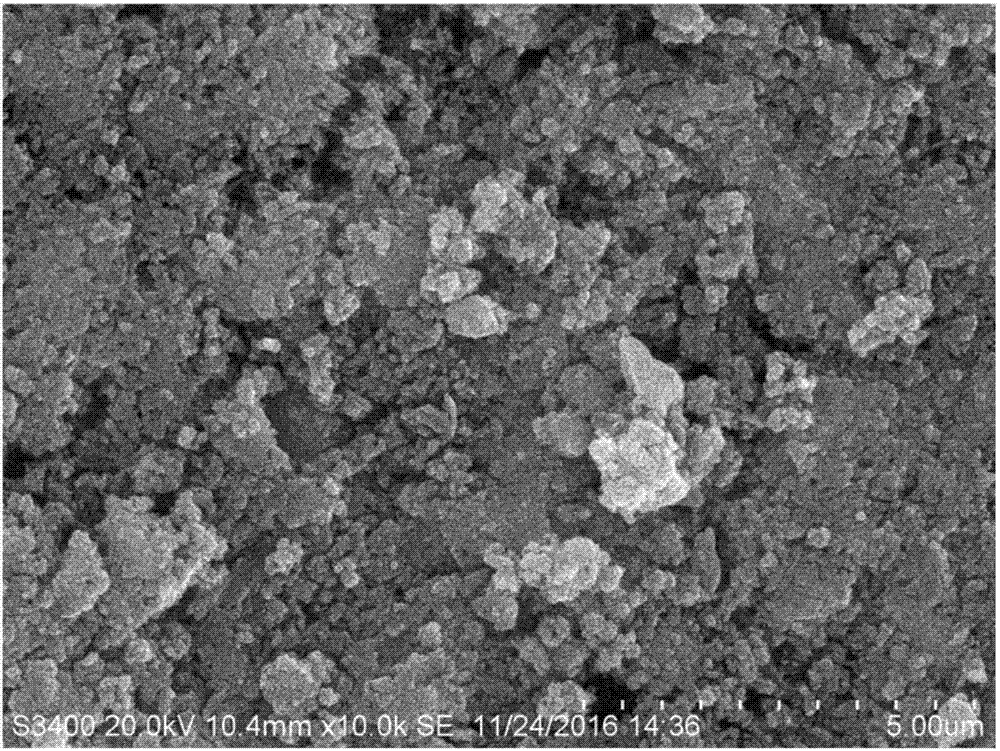

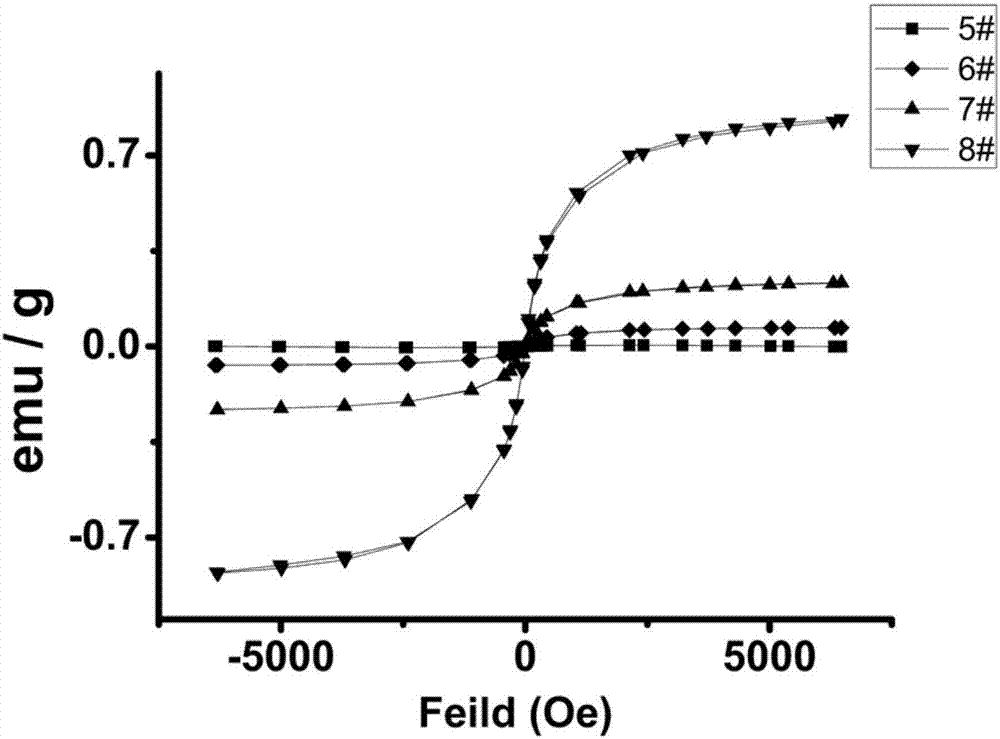

Nano calcium phosphate bone cement and preparation method thereof

ActiveCN107137771AImprove mechanical propertiesEnhance osteogenic activityPharmaceutical delivery mechanismTissue regenerationCalcium biphosphateBiocompatibility Testing

The invention relates to nano calcium phosphate bone cement and a preparation method thereof. The nano calcium phosphate bone cement is prepared by the steps of adding a water soluble nanomaterial into calcium phosphate bone cement; and uniformly mixing the mixture and self-curing the mixture to obtain the nano calcium phosphate bone cement. The nano bone cement is prepared by mixing a metal nanomaterial which is good in biocompatibility with bone cement matrix powder. The material not only has a good mechanical property, but also has the enhanced osteogenic activity. The performance of the nano bone cement can be adjusted by adjusting the type and quantity of the nanomaterial, for example, the bone cement is endowed with a magnetic property by adding a magnetic nanomaterial, and the strength of the bone cement is enhanced by increasing the additive amount of the nanomaterial in a certain range. The preparation method of the nano bone cement provided by the invention is simple in process and high in operability, can better meet the clinical use demand and has promotional value.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

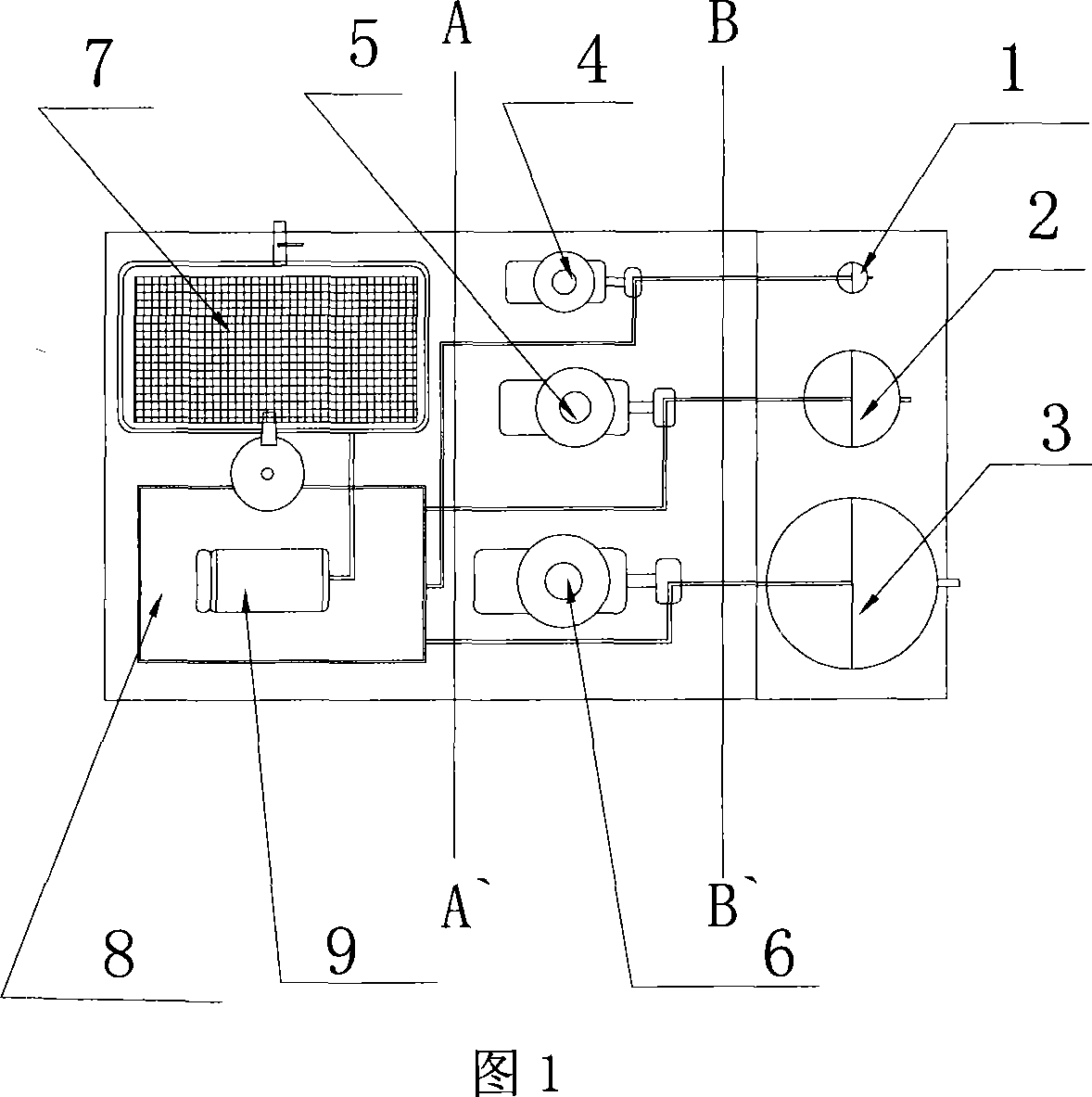

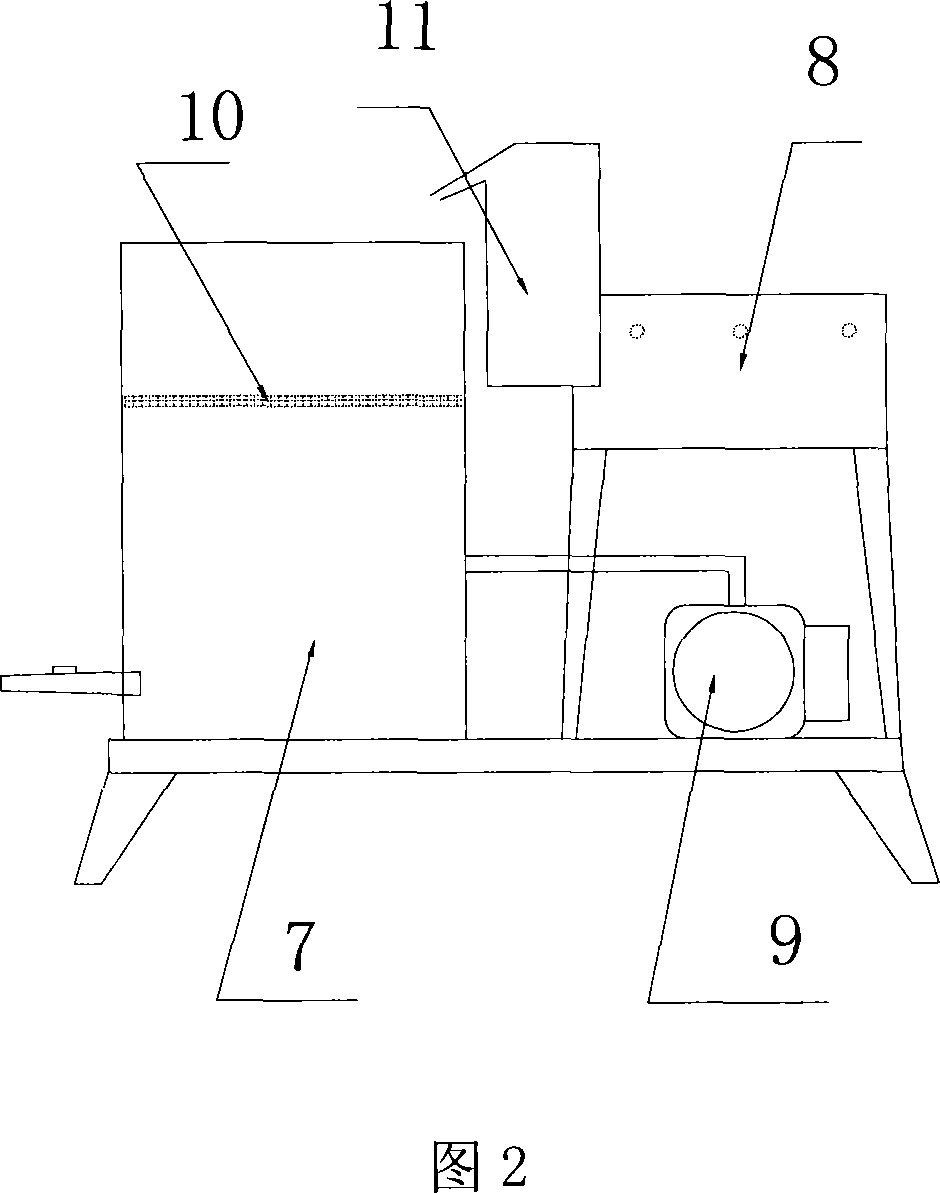

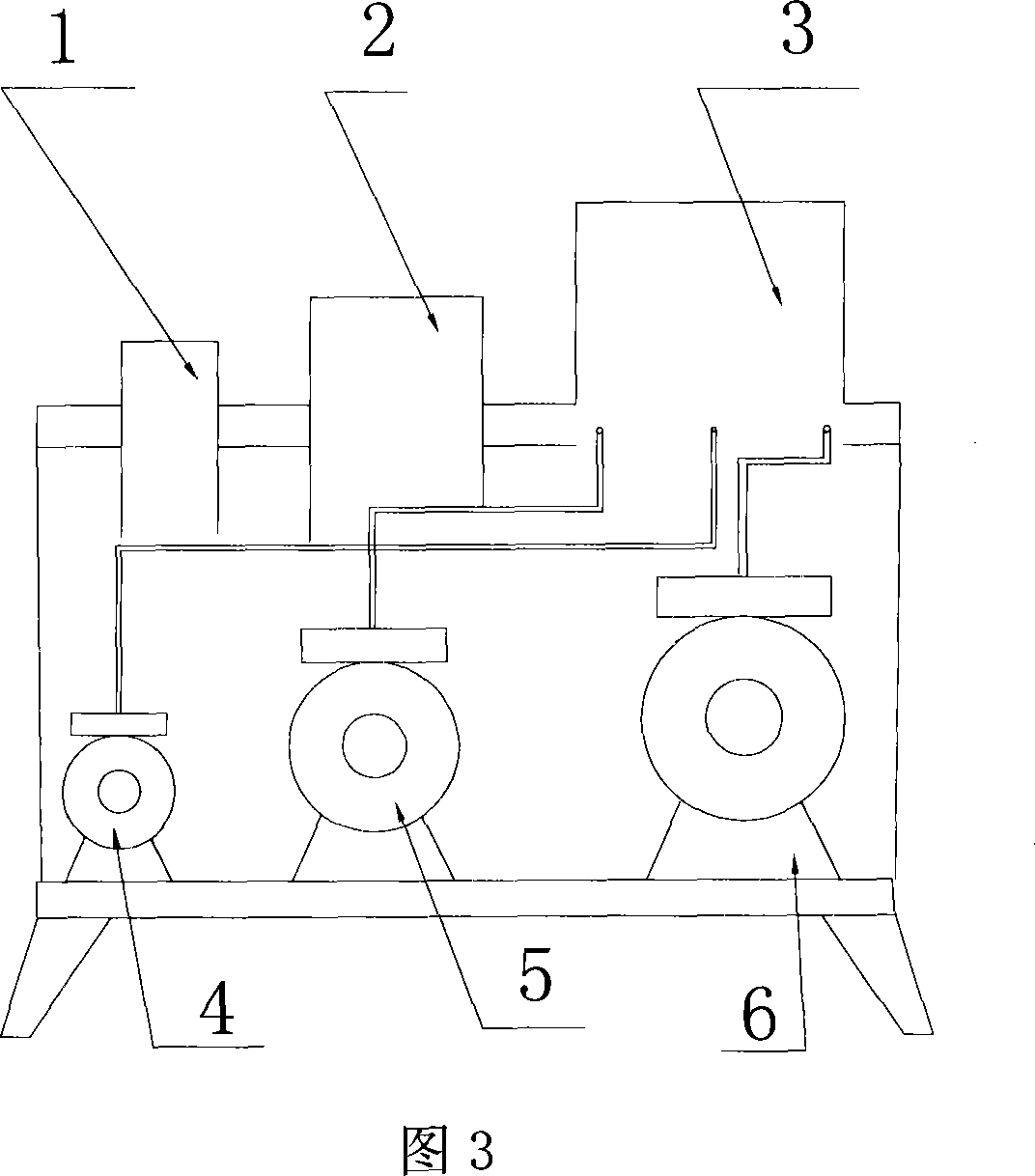

Treatment method and device for alkaline straw pulp paper making black liquor

InactiveCN101033588AImprove efficiencyMaximize resource utilizationPulp liquor regenerationAcidulantChemistry

Owner:济南大陆机电股份有限公司

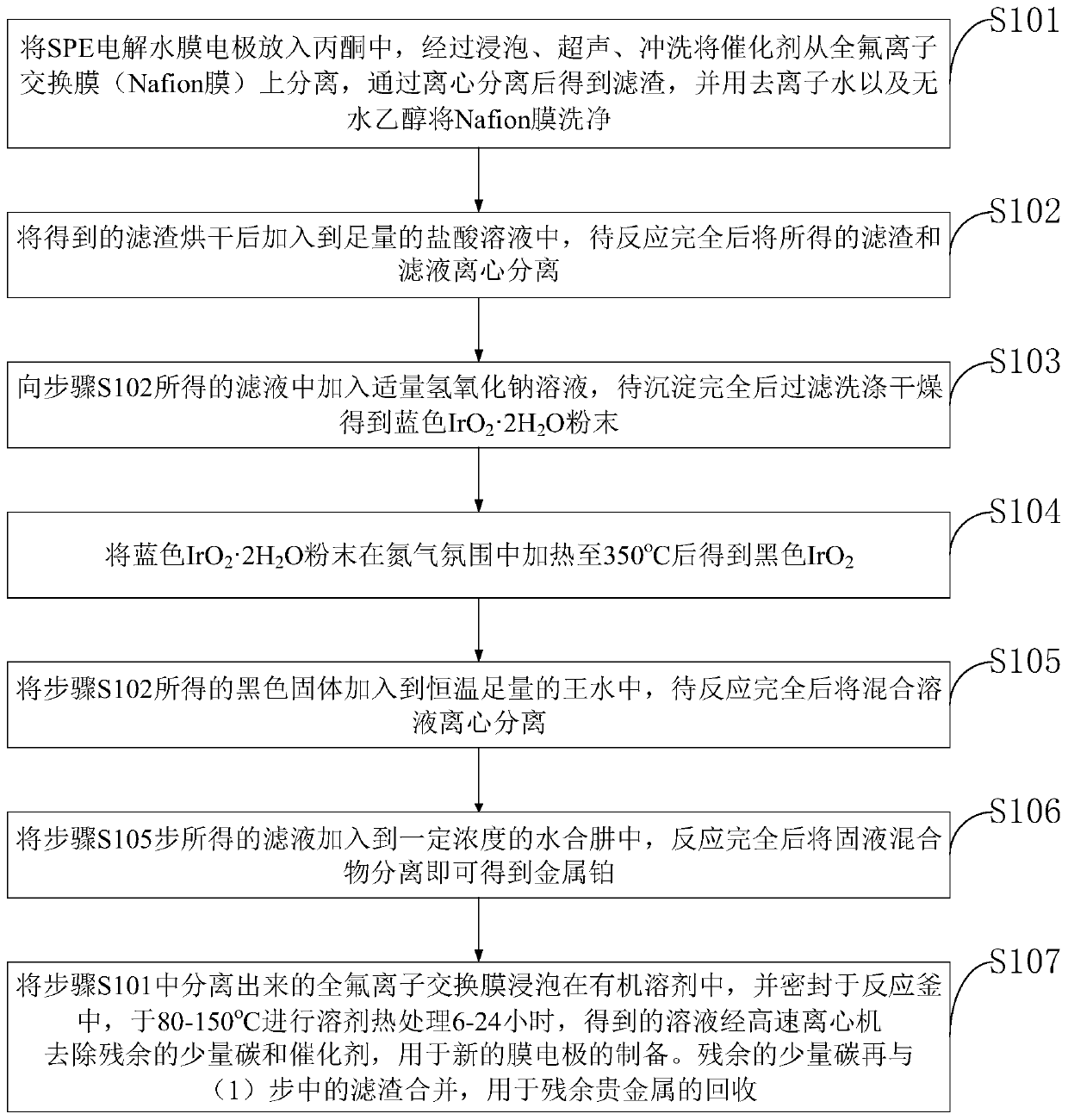

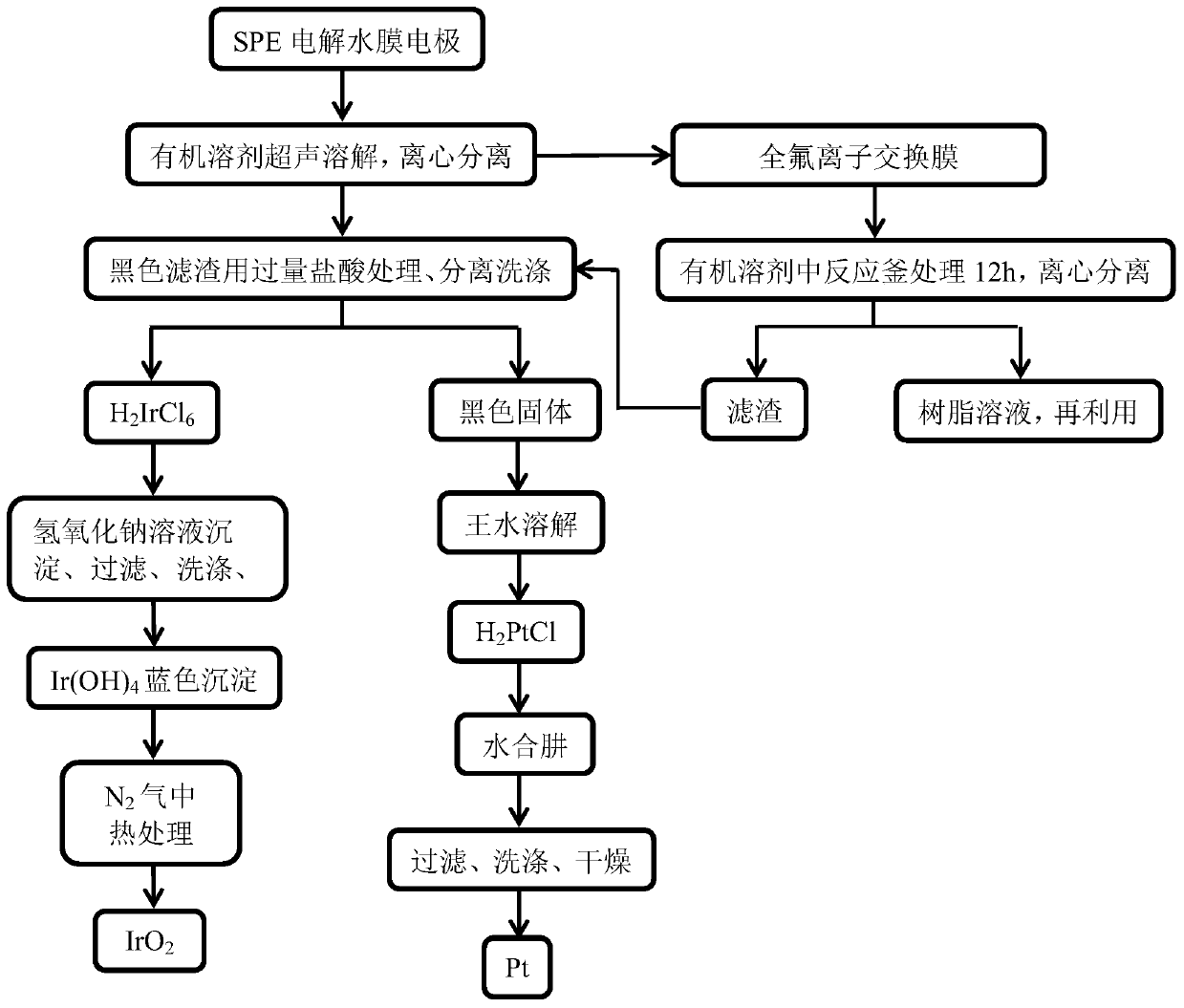

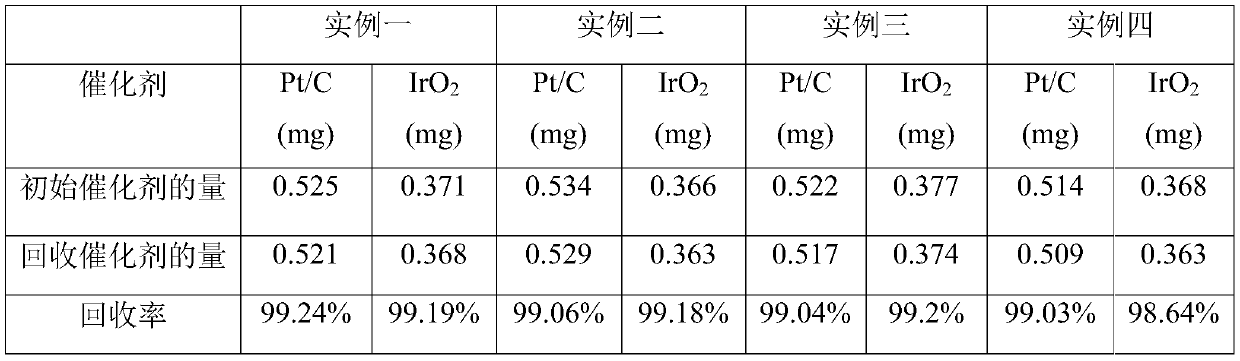

Comprehensive recycling method of solid polymer electrolyte water-electrolysis membrane electrode

InactiveCN110643817ASimple processHigh recovery rateFuel cells disposal/recyclingProcess efficiency improvementPolymer electrolytesPtru catalyst

The invention belongs to the technical field of comprehensive recycling of SPE water-electrolysis membrane electrodes, and discloses a comprehensive recycling method of a solid polymer electrolyte water-electrolysis membrane electrode. The SPE water-electrolysis membrane electrode is soaked and subjected to ultrasound treatment and flushing to separate a catalyst from a perfluor ion exchange membrane; obtained filter residues are dried and added into a plenty of a hydrochloric acid solution, and after the reaction is thorough, the obtained filter residues and a filtrate are subjected to centrifugal separation; a sodium hydroxide solution is added into the obtained filtrate to obtain blue powder; the blue powder is heated to obtain a black solid; the black solid is added into aqua regia, and then centrifugal separation is conducted; an obtained filtrate is added into hydrazine hydrate to obtain metal platinum; the perfluor ion exchange membrane which is separated out is soaked and subjected to heat treatment, and obtained carbon and a catalyst are combined with the filter residues. The comprehensive recycling method has the advantages that the technological process is simple, the cost is low, the pollution is small, and the recovery rate is high and reaches 99% or above; the pressure that precious metal resources are scarce is greatly relieved.

Owner:SHANGHAI UNIV

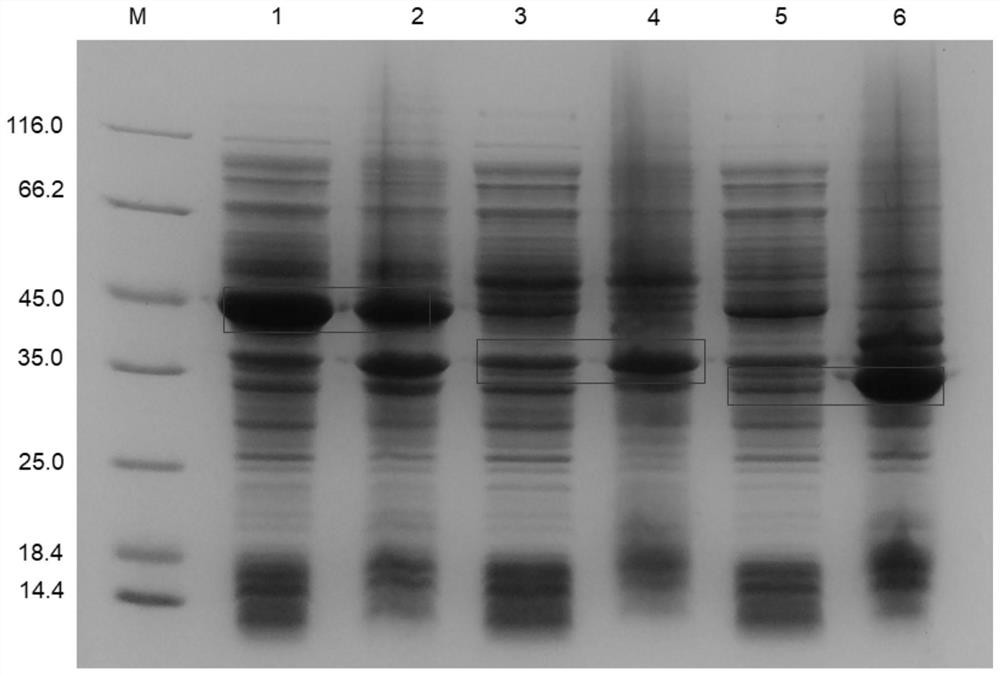

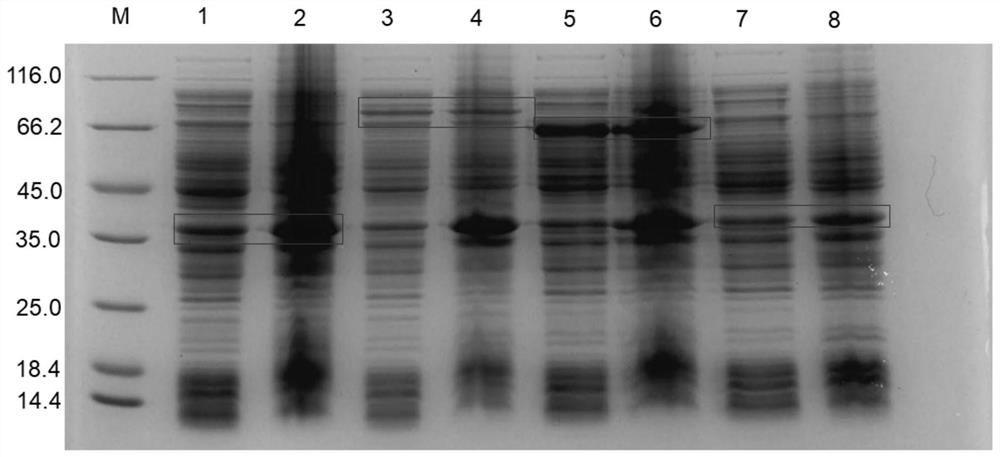

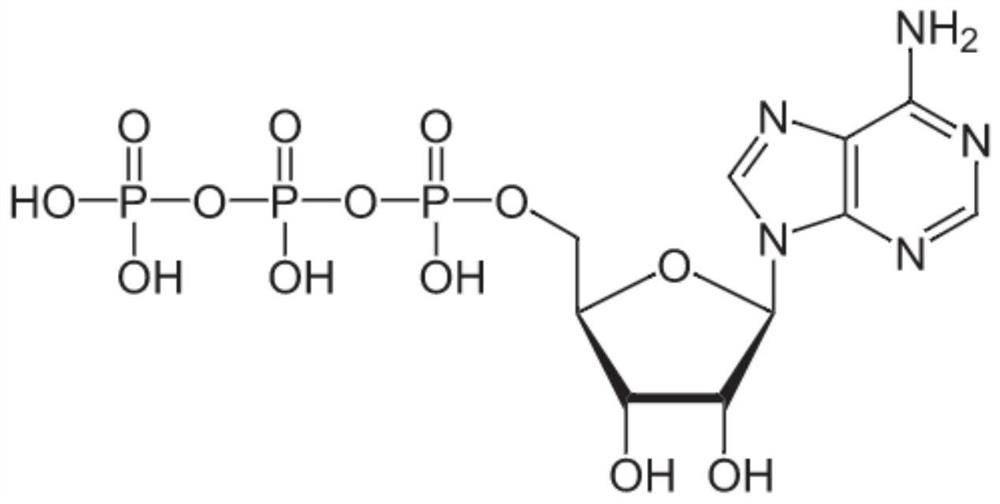

Method for preparing cyclic adenosine monophosphate by adenylate cyclase

PendingCN112063670AImprove stabilityExtended half-lifePhosphorus-oxygen lyasesFermentationCyclaseAdenosine

The invention discloses a method for preparing cyclic adenosine monophosphate by adenylate cyclase. The method comprises the following steps that the adenylate cyclase serves as a catalyst, adenosinetriphosphate serves as a substrate, and in the presence of Mg <2+>, a reaction solution containing the cyclic adenosine monophosphate is obtained. According to the adenylate cyclase, an amino acid sequence as shown in SEQ ID NO.14 is provided, the stability is good, the half-life period is long at medium and low temperatures, ATP can be efficiently catalyzed to generate cAMP in one step at mediumtemperature, a substrate conversion rate reaches 90 % or above, the advantages of simple industry, mild conditions, short period, few by-products and the like are achieved, the clean and pollution-free effects are achieved, and the energy conservation, consumption reduction and emission reduction in the cAMP production process can be realized.

Owner:杭州美亚药业股份有限公司

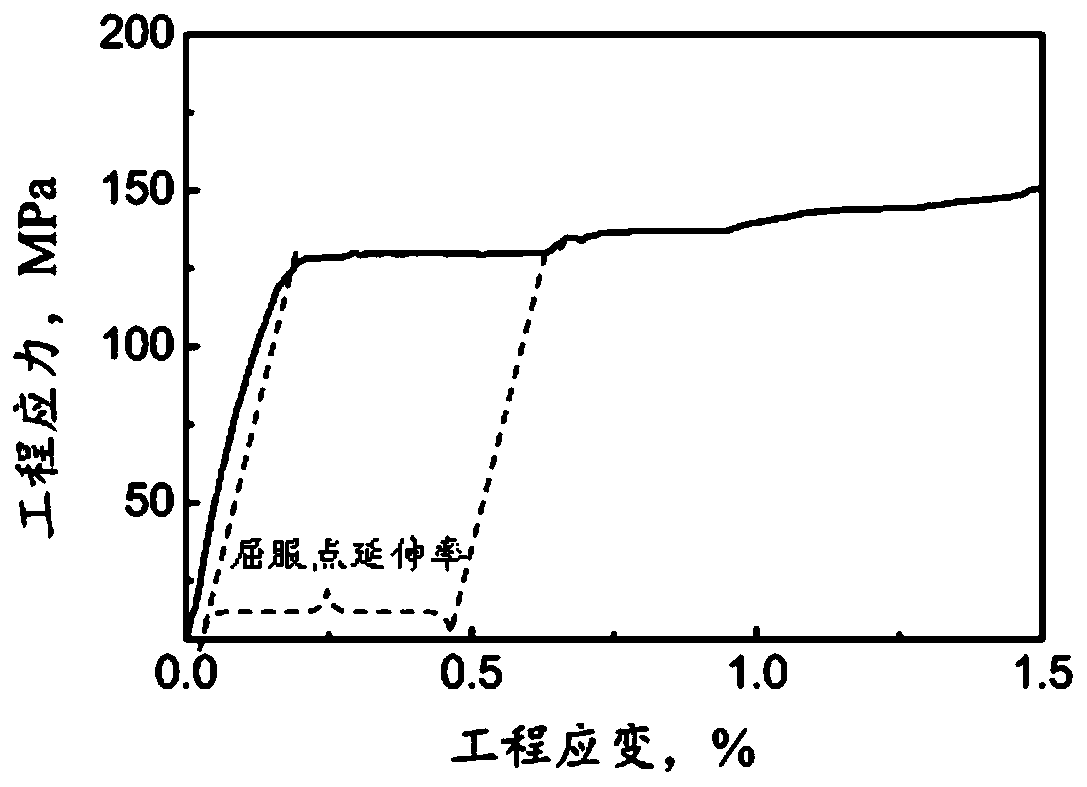

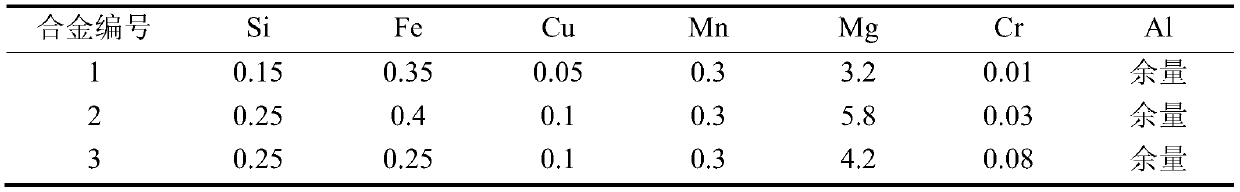

Alloy plate for automobile body and preparation method thereof

The invention provides an alloy plate for an automobile body and a preparation method of the alloy plate. An alloy comprises, by mass percentage, not larger than 0.4% of Si, not larger than 0.4% of Fe, 0.2-0.5% of Mn, 3.0-6.0% of Mg, not larger than 0.03% of Cr, not larger than 0.15% of Cu and the balance Al and impurities. According to the alloy plate and the preparation method, by controlling the content of the trace element Cr and the final annealing process and the straightening amount, on one hand, the YPE of the plate is reduced, and on the other hand, the plate still has excellent mechanical and forming properties of the material. The preparation method comprises the following steps that final annealing is carried out on a continuous annealing line, wherein the temperature rise speed is larger than 20 DEG C / s, and after heat preservation at 480-520 DEG C is carried out for 15 s and 5 min, water quenching is carried out, and the cooling speed is larger than 10 DEG C / s; the finalgrain size should be controlled at 20-40 micrometers, and the YPE is smaller than or equal to 0.2%; and the final annealing plate is subjected to straightening treatment, and the straightening amountis 0.5-1%. The plate prepared by the method is suitable for an automobile body structural member and an automobile body covering panel inner plate.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

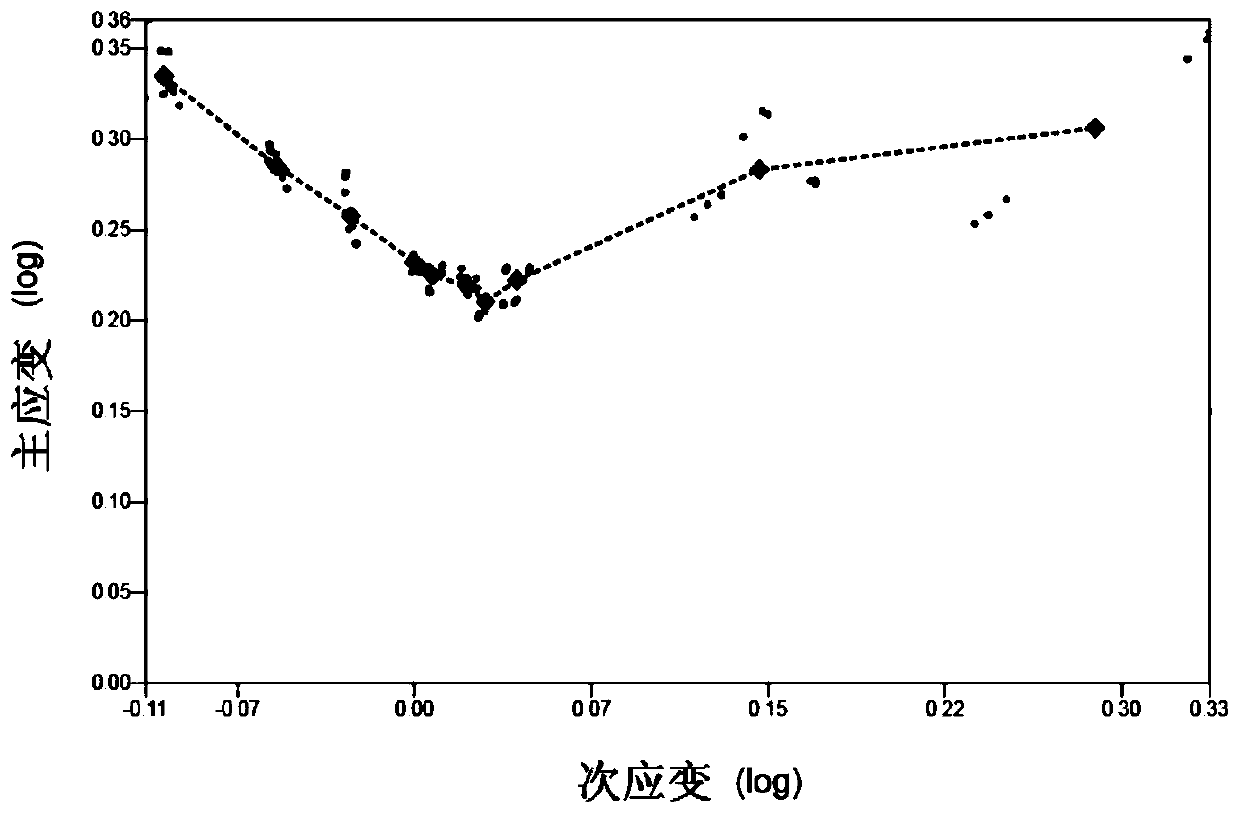

Cold rolling method of 5-series aluminum plate free of discoloration defect after anodizing

The invention provides a cold rolling method of a 5-series aluminum plate free of discoloration defect after anodizing. The 5-series aluminum plate is subjected to semicontinuous casting and homogenization treatment, then a hot-rolled plate with the thickness being 4-8 mm is obtained through hot rolling, a plate with the thickness being 0.3-4.0 mm is prepared through 2-10 passes of cold rolling machining, and recrystallization annealing treatment is conducted in the cold rolling process once. After an aluminum material obtained through the cold rolling method is subjected to anodizing and coloring treatment, the surface of the aluminum material is uniform in color and free of defects such as color difference, pits and the like, the requirements of electric equipment product outer parts forthe anodized aluminum material can be met, the product market competitiveness is obvious, and the economic benefits are remarkable.

Owner:CHINALCO RUIMIN +1

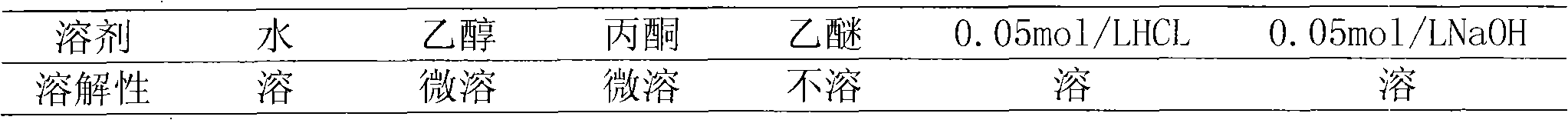

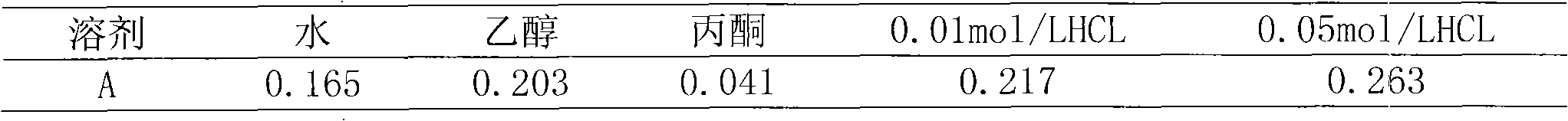

Method for extracting black pigment from black waxy corn complete cobs

InactiveCN102352121AIndustrial simplicityEasy to manufactureOrganic chemistryNatural dyesVomit blackDistilled water

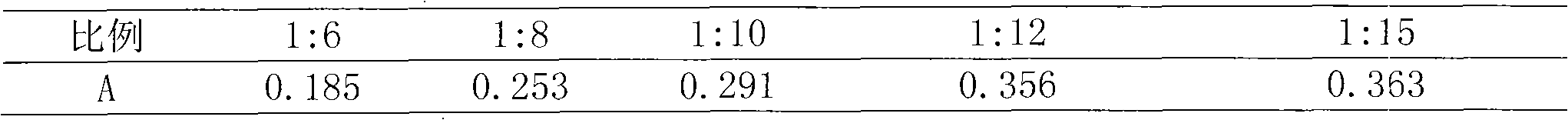

The invention belongs to an extraction method of black pigment, and particularly relates to a method for extracting black pigment from black waxy corn, which comprises the following steps: by using dry black waxy corn complete cobs as the raw material, degreasing with a weakly polar solvent, and leaching with a 0.05mol / HCl solution for 12 hours, wherein the ratio of sample to leaching agent is 1:12; after carrying out secondary leaching at 60 DEG C, slightly concentrating under reduced pressure (the vacuum degree is 0.9 MPa) at 60 DEG C, and dissolving by adding water; and after purifying with macroporous resin, eluting with distilled water until the solution becomes colorless, eluting with a 50-70% ethanol solution (eluting agent), concentrating the ethanol eluate under reduced pressure to obtain an extract, and drying to obtain the finished black pigment product. The purity of the black pigment is obviously higher than that of the unpurified black pigment, and the extraction rate is up to 9.62%. The invention can be used for obtaining high-purity black pigment; the preparation method is scientific and reasonable, is simple and easy to implement, changes wastes into valuable substances, solves the problem in treatment of corn cob waste, and provides a new application of corn cobs.

Owner:安徽大诚明农业科技股份有限公司

Preparation method of microcrystalline wear-resistant alumina ceramic by utilizing rare earth compounds

The invention discloses a preparation method of microcrystalline wear-resistant alumina ceramic by utilizing rare earth compounds. The preparation method comprises following steps: (1) mixing following raw materials in percentage by weight: 70 to 99.7% of Al2O3, 0.1 to 10% of rare earth dysprosium compound, 0.05 to 10% of calcium compound or calcium mineral, 0.05 to 10% of magnesium compound or magnesium mineral and 0.1 to 15% of silicon compound or silicon mineral; (2) mixing the mixture with water, subjecting the solution to a wet milling treatment with a stirring mill, or a ball mill, or a tube mill, controlling the milling time in the range of 5 and 96 hours to evenly mix the materials, grinding until the average particle size of the powder is in the range of 0.2 to 2 [mu]m, and controlling the mass ratio of water to raw materials in the range of 1:3 to 3:1; (3) drying the obtained raw materials, preparing the raw materials into green bodies through the isostatic pressing, or roller forming, or axial extruding; (4) sintering the green bodies in the present of air or in the present of reducing atmosphere (CO, H2 or N2), controlling the temperature of 1050 to 1650 DEG C, keeping the temperature for 30 to 300 minutes, and finally cooling to the room temperature so as to obtain the ceramic material. The preparation method has the advantages of wide raw material resources, simple industrial production, and low ware rate of the prepared alumina ceramic.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

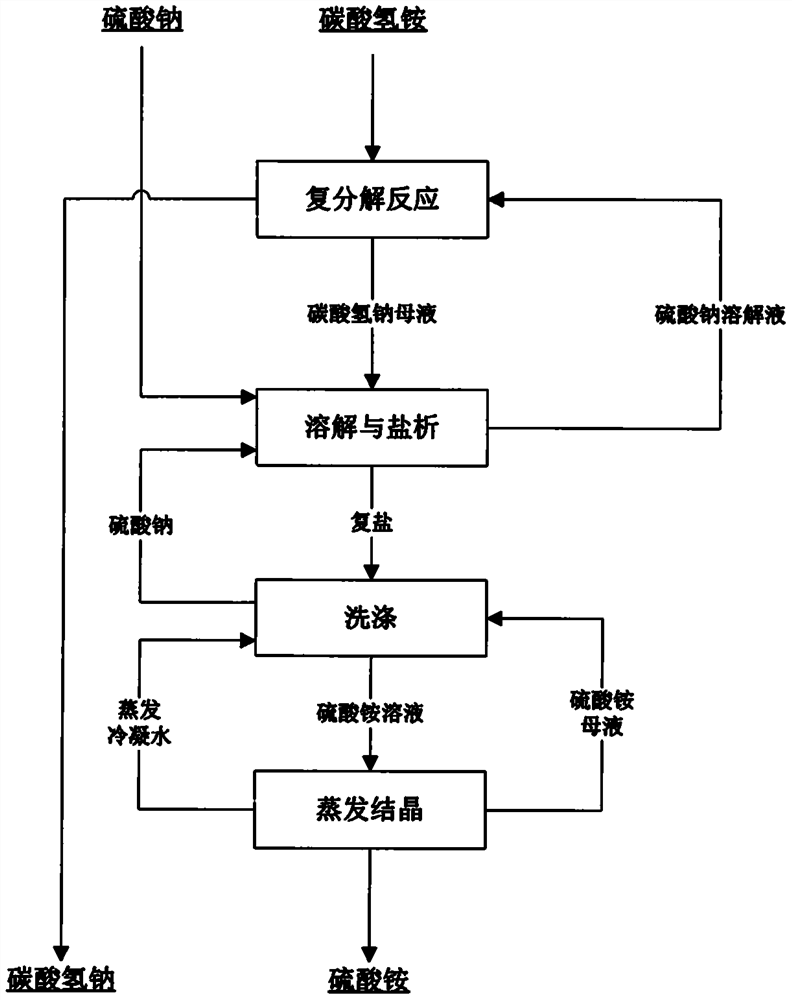

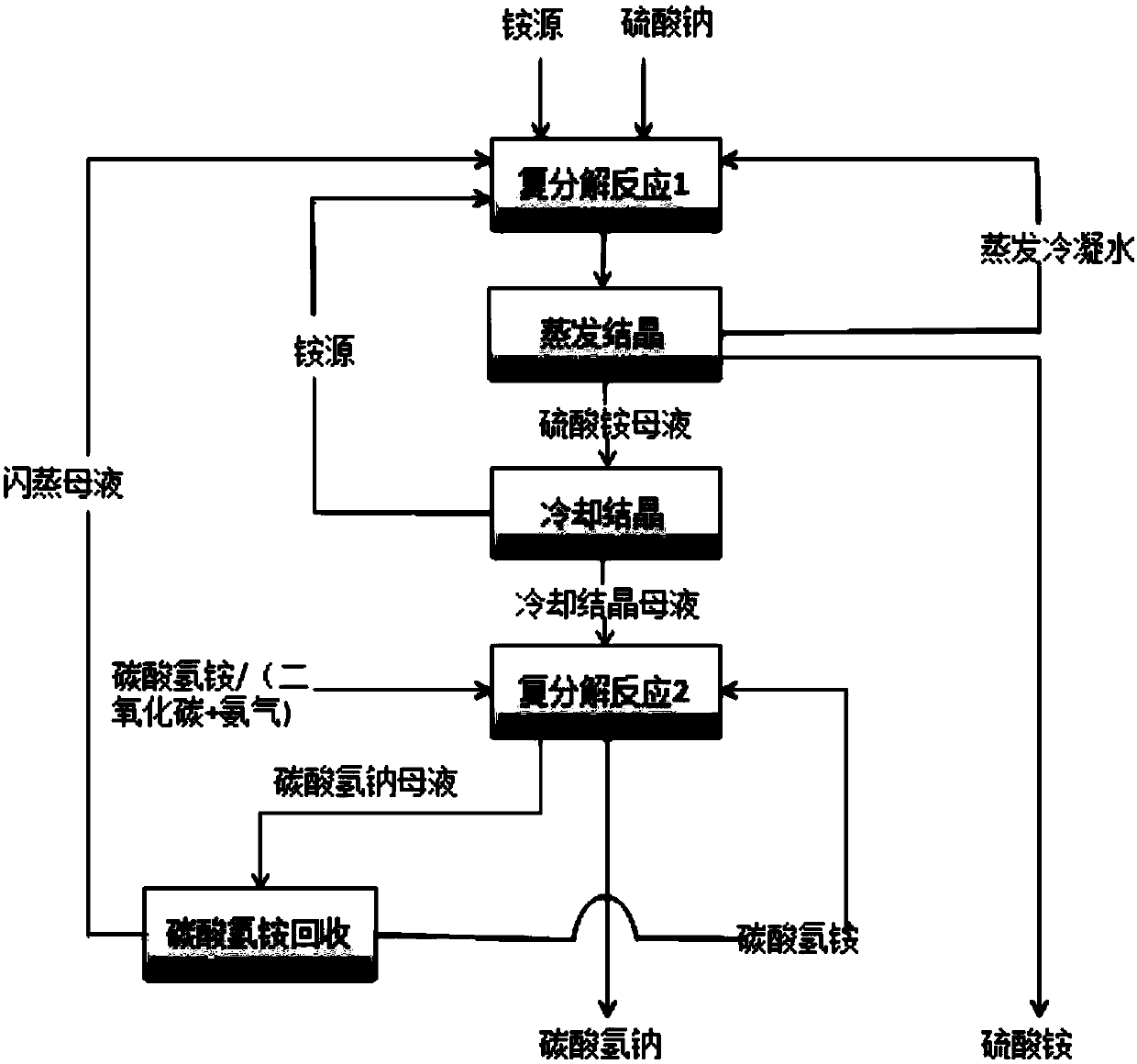

Novel method for preparing sodium bicarbonate and co-producing ammonium sulfate from sodium sulfate

ActiveCN113493214AHigh purityMeet the requirements of GB535Ammonium sulfatesCarbonate preparationSodium hydrogencarbonateSodium sulfate

The invention provides a novel method for preparing sodium bicarbonate and co-producing ammonium sulfate from sodium sulfate. The method comprises the following steps of: (1) reacting a sodium sulfate solution (salting-out mother liquor obtained in the subsequent process) with ammonium bicarbonate to prepare sodium bicarbonate solid and sodium bicarbonate mother liquor; (2) adding sodium sulfate (comprising externally added sodium sulfate and sodium sulfate obtained in the step (3)) into the sodium bicarbonate mother liquor, reacting under certain conditions, and performing liquid-solid separation to respectively obtain double salt and salting-out mother liquor; (3) washing the double salt with ammonium sulfate mother liquor and evaporation condensate water in the subsequent process to obtain an ammonium sulfate solution and sodium sulfate; and (4) evaporating the ammonium sulfate solution to obtain an ammonium sulfate product, and returning evaporation mother liquor and the evaporation condensate water to the step (3). The method is simple in process and low in cost, the utilization rate of sodium sulfate is larger than 95%, the purity of the sodium bicarbonate is larger than 96%, and the purity of the ammonium sulfate product meets the requirement of GB535.

Owner:北京镜澄科技有限公司

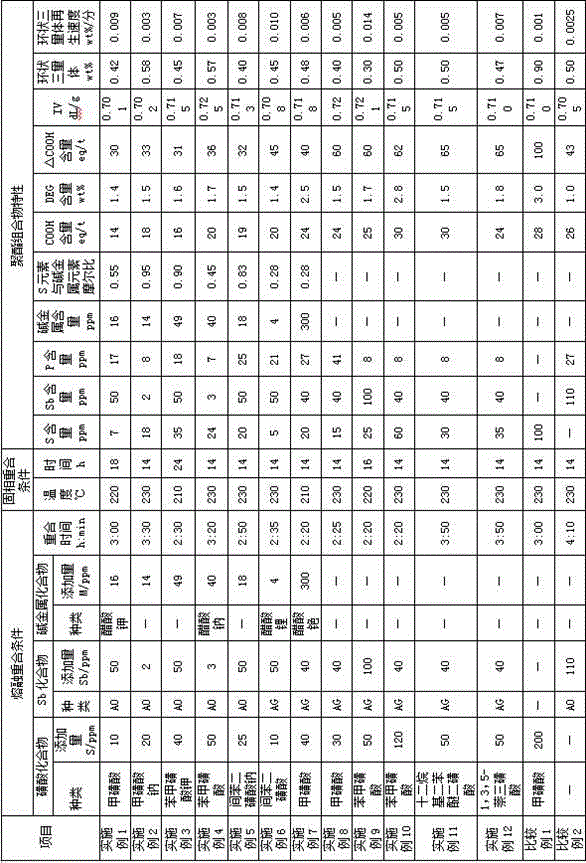

Polyester composition, and preparation method and use thereof

The invention discloses a polyester composition with low content of annular trimer, and a preparation method thereof. The polyester composition contains 1-100ppm of sulfur element and 1-100ppm of antimony element. The content of the annular trimer in the obtained polyester composition is 0.2-0.8wt%, the regeneration speed of the annular trimer in the polyester composition is very low, and the generation speed of the annular trimer in the process of melting at 300DEG C in nitrogen atmosphere is 0.001-0.015wt% / min, so the polyester composition can be used to films and other polyester products.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

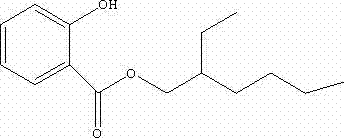

Preparation method of isooctyl salicylate

ActiveCN102775311AHigh recovery rateHigh purityPreparation by ester-hydroxy reactionMethyl salicylateSalicylic acid

The invention discloses a preparation method of isooctyl salicylate, which comprises the following steps: 1. adding an isooctyl alcohol solution into a methyl salicylate solution, and stirring for 1-3 hours to form a raw material solution; 2. adding an inorganic alkali catalyst into the raw material solution to form a reaction solution; 3. heating the reaction solution to 100-200 DEG C, stirring to react for 4-10 hours, cooling the reaction solution to 20-80 DEG C, washing the reaction solution with 50-100 DEG C hot water, separating, and extracting an organic phase; and 4. adding anhydrous Na2SO4 into the organic phase to dry the organic phase, standing, removing the Na2SO4 in the organic phase, adding the organic phase into a flask, carrying out vacuum distillation with an oil pump, and collecting the 174-178 DEG C / 1.0kPa fraction which is the isooctyl salicylate. The isooctyl salicylate prepared by the preparation method disclosed by the invention has the advantages of high recovery rate, high purity and low preparation cost.

Owner:江苏普源化工有限公司 +1

Preparation method of zinc manganese silicate fluorescent powder with short afterglow

InactiveCN104212443AHigh luminous intensityShort afterglow timeLuminescent compositionsManganese(II) carbonateLuminous intensity

The invention discloses a preparation method of zinc manganese silicate fluorescent powder with short afterglow. The fluorescent powder is prepared by a high temperature solid state method, wherein the source of Mn is ZnMn2O4 instead of conventional manganese oxide or manganese carbonate or other compounds. The zinc manganese silicate green fluorescent powder prepared by the method is high in luminous intensity and short in afterglow time, thus completely meeting the requirement on 3D plasma display. The preparation method does not change existing technology of preparing the zinc manganese silicate fluorescent powder by the high temperature solid state method, thus being easy to implement industrially, and very applicable to scale production.

Owner:SOUTHEAST UNIV

High-elasticity polyolefin foamed sheet and manufacturing method thereof

The invention discloses a multi-high-polymer smelting combination of a high-elasticity polyolefin foamed sheet and a manufacturing method thereof. The invention aims to solve the problem that the rebound rate of the existing foamed profile is only 40-45%. The formula disclosed by the invention comprises 50 parts of ethylene-1-octylene copolymer (DOWENGAGE8150), 40 parts of ethylene-hexene-octadecene terpolymer (JPE-KS340) and 10 parts of propylene-ethylene copolymer (EXXONMOBILVitmaxx 6102) (which form the smelting composition), 17.5 parts of talcum powder, 2.5 parts of activating agent, 0.8 part of crosslinking agent, 0.17 part of aid and 3.5 parts of chemical foaming agent, totaling PHR 125. The manufacturing method comprises the following steps: mixing, banburying, mixing, and carrying out secondary thinning to obtain a sheet; and carrying out mold pressure, cross-linking, and foaming at 165 DEG C under the pressure of 200kg / cm<2> for 1.2 minutes per millimeter, thereby manufacturing the polyolefin foamed material of which the elasticity is up to 75-80%.

Owner:FUJIAN ZHENGYI IND

Method for preparing ammonium sulfate and sodium bicarbonate from sodium sulfate

ActiveCN111039304AIncrease profitThe method flow is simpleCarbonate preparationAmmonia compoundsHydrogen phosphateDiammonium phosphate

The invention provides a method for preparing ammonium sulfate and sodium bicarbonate from sodium sulfate, which adopts an ammonium source as a conversion medium for preparing ammonium sulfate and sodium bicarbonate from sodium sulfate. The ammonium source comprises any one or a mixture of at least two of diammonium hydrogen phosphate, ammonium formate or ammonium nitrate. The method is simple inprocess and low in cost, the utilization rate of sodium sulfate is larger than 85%, the purity of sodium bicarbonate is larger than or equal to 90%, and the purity of the ammonium sulfate product meets the requirements of GB535-1995.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method of treating waste residue in production of neopentyl glycol

InactiveCN103483178AHigh puritySimple processHydroxy compound separation/purificationCarboxylic compound separation/purificationSeparation technologyNanofiltration

The invention provides a method of treating waste residue in production of neopentyl glycol. The method comprises the following steps: (1) dissolving waste residue in production of neopentyl glycol, with water to obtain a rough sodium formate solution; (2) filtering the rough sodium formate solution through a precise filter and an ultrafilter so as to remove particle impurities; and (3) carrying out nanofiltration and separation on the particle impurity-removed solution through a nanofiltration system, wherein high-purity sodium formate and neopentyl glycol in the obtained nanofiltration permeate and nanofiltration concentrate can be recovered. The purity of the sodium formate is high and can achieve more than 95%. The process water can be recycled, thus the resource waste and retreatment problems cannot be caused. Useful solutes in the waste residue can be entirely recovered, and impurities can serve as fuels for generating heat. The method is simple in technique by adopting a membrane separation technology, and easily realized industrially.

Owner:YANTAI UNIV

Treatment method of sulfur-containing waste salt and solution thereof

InactiveCN112551554ASimple processImprove efficiencyAmmonium sulfatesAlkali metal sulfites/sulfatesPhysical chemistrySodium sulfate

The invention provides a treatment method of sulfur-containing waste salt and a solution thereof. The treatment method comprises the steps of (1) preparing a saturated solution of the sulfur-containing waste salt; (2) mixing the sulfur-containing waste salt with the saturated solution obtained in the step (1), carrying out high-temperature salting-out, and carrying out solid-liquid separation to obtain salting-out mother liquor and sodium sulfate; (3) carrying out cooling crystallization on the salting-out mother liquor obtained in the step (2), and carrying out solid-liquid separation to obtain ammonium sulfate mother liquor and mixed salt; the mixed salt being reused in the step (2); and (4) evaporating and concentrating the ammonium sulfate mother liquor obtained in the step (3), and carrying out solid-liquid separation to obtain evaporated mother liquor and ammonium sulfate; the evaporation mother liquor being reused in the step (3). The treatment method is suitable for the sulfur-containing waste salt and a solution of the sulfur-containing waste salt, efficient separation of sodium sulfate and ammonium sulfate is achieved, meanwhile, the operation process is simplified, the production cost is reduced, and no three wastes are generated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

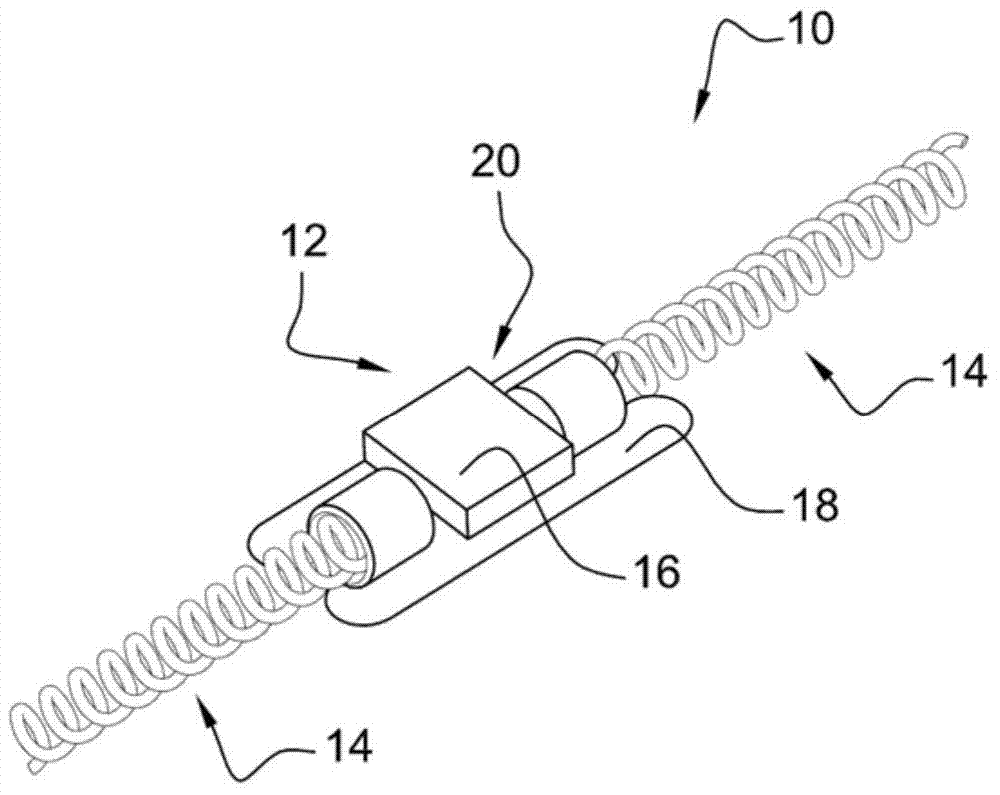

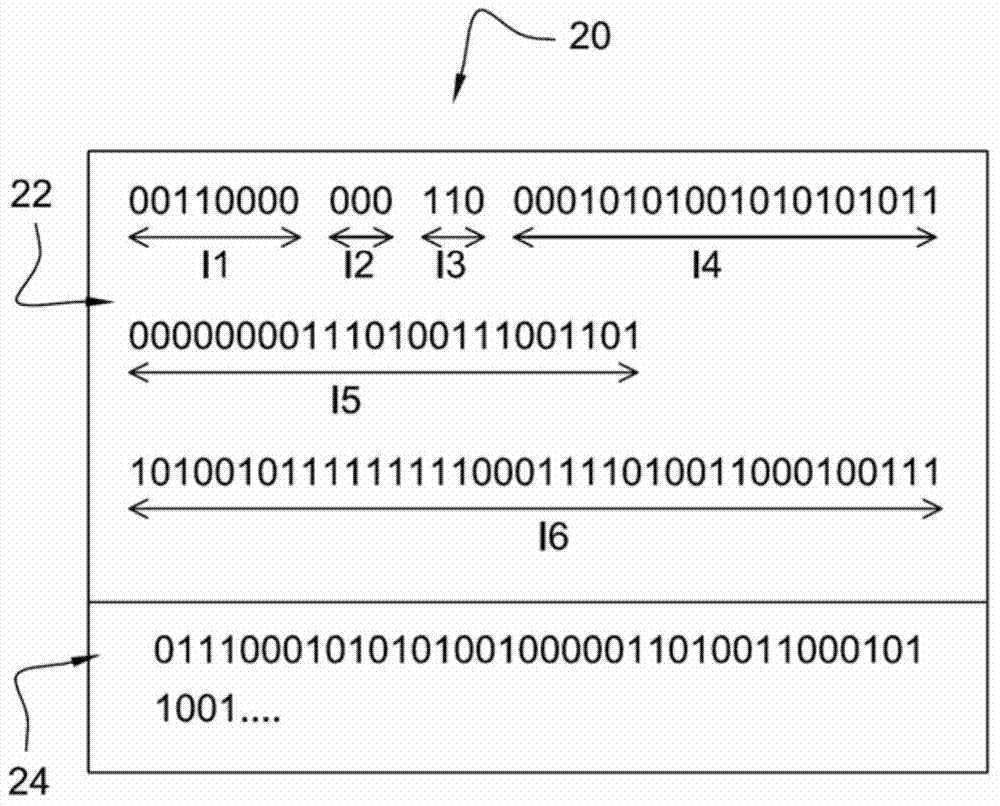

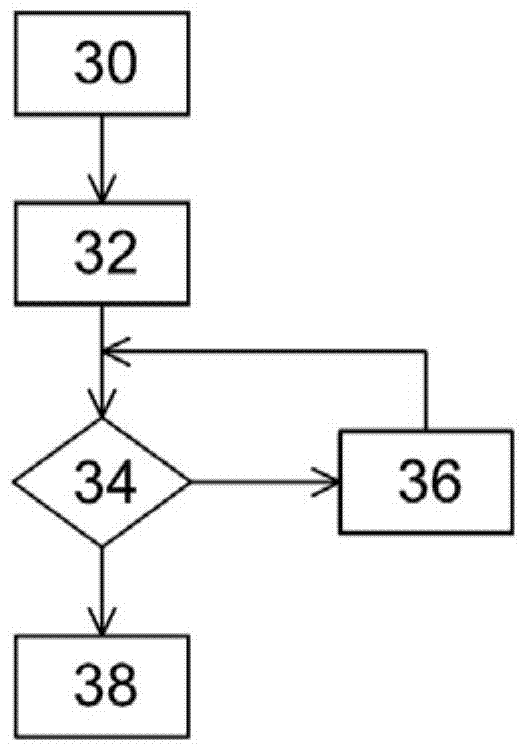

Method for reading data stored in an electronic device for a tyre

ActiveCN104284788AIndustrial simplicityShorten write timeSensing record carriersTyre measurementsData storingData store

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

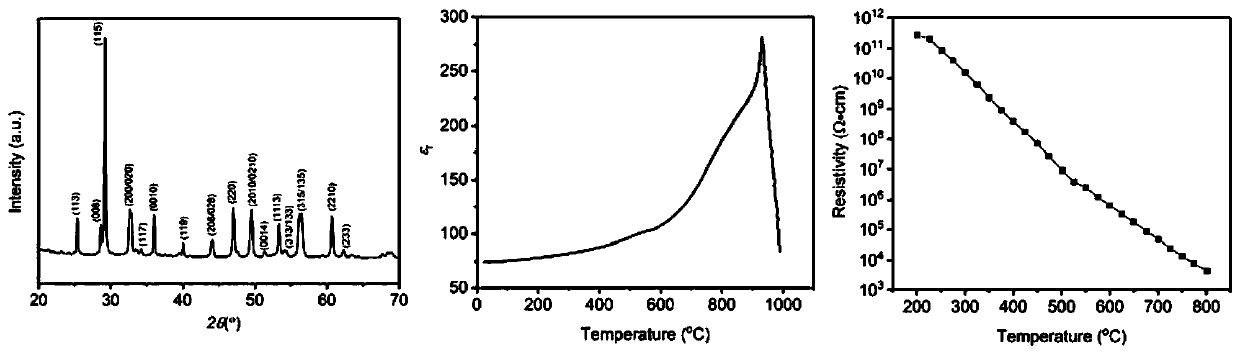

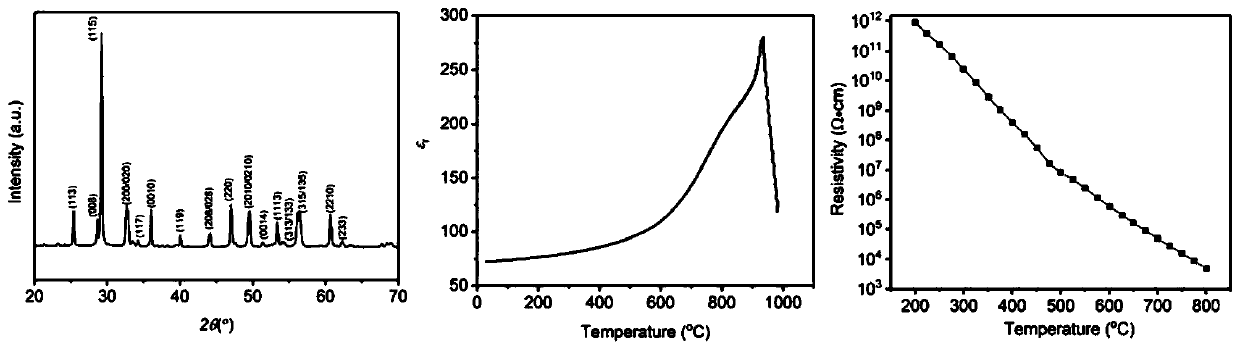

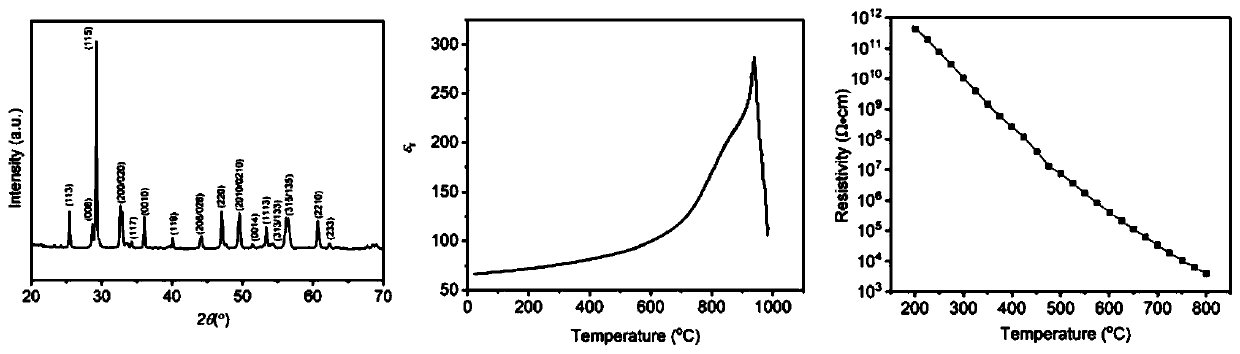

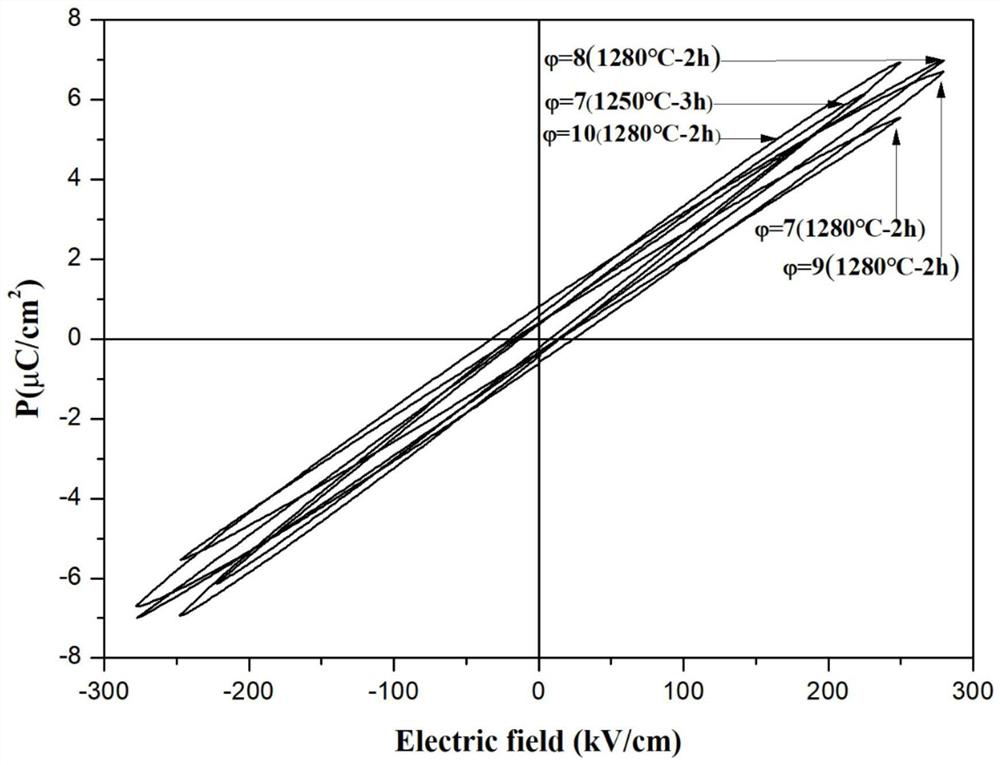

Nb-position Cr/Mo codoped bismuth-calcium niobate high-temperature piezoelectric ceramic material and preparation method therefor

ActiveCN109704761AImprove piezoelectric performanceExcellent piezoelectric propertiesElectricityAviation

The invention discloses a Nb-position Cr / Mo codoped bismuth-calcium niobate high-temperature piezoelectric ceramic material and a preparation method therefor. The piezoelectric ceramic material has ageneral formula of CaBi2Nb2-x (Mo2 / 3Cr1 / 3)xO9, wherein x is not smaller than 0.03 and not greater than 0.075. The invention further discloses the preparation method for the piezoelectric ceramic material. The method comprises the steps of adopting a piezoelectric material of a system CaBi2Nb2O9 as a base, doping certain proportions of Cr and Mo to the Nb position according to a mole ratio of 1: 2,and adopting the traditional solid-phase synthesis method, thereby preparing the novel bismuth-layered-structure piezoelectric ceramic material. Compared with the prior art, the piezoelectric ceramicmaterial obtained by the method has the advantages that main performance parameters are as follows: d33 is equal to 15pC / N, TC is equal to 939 DEG C, and rho is equal to 3.3*10<5>omega.cm when the temperature is 600 DEG C; and furthermore, the preparation process is stable and reliable, the production cost is low, industrial production is easy to achieve, and the piezoelectric ceramic material has a good application prospect in the field of high temperatures. Various piezoelectric sensors are assembled from ceramic components made from the material and can be applied to special hot environments of aerospace & aviation, petrochemical industry and the like.

Owner:HANGZHOU DIANZI UNIV

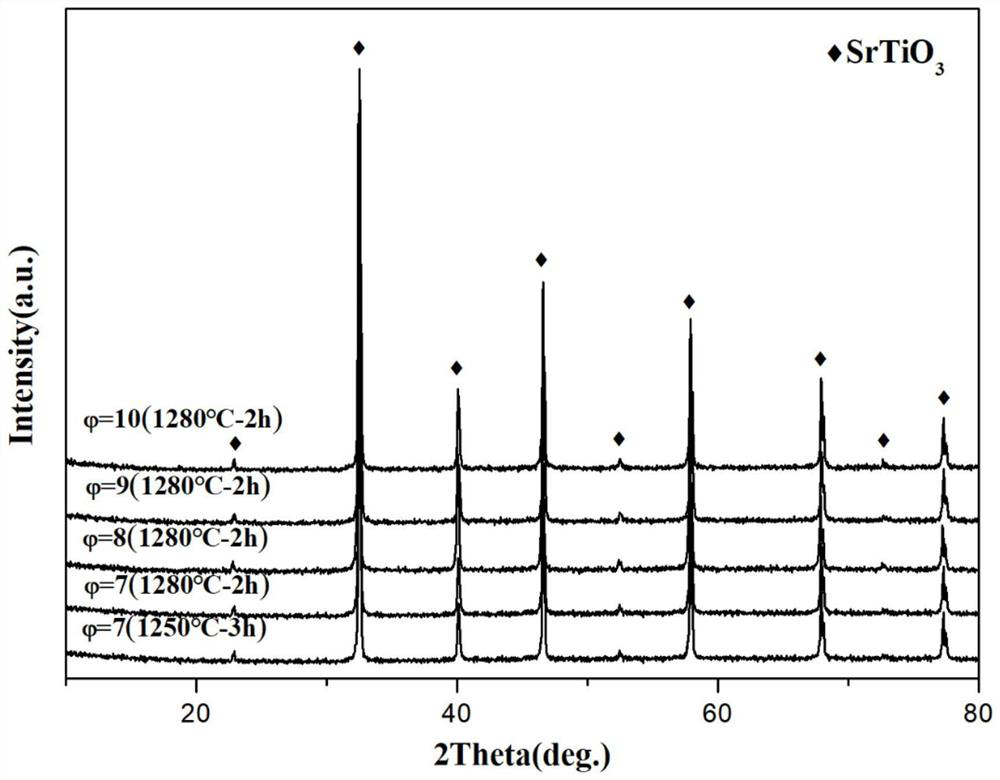

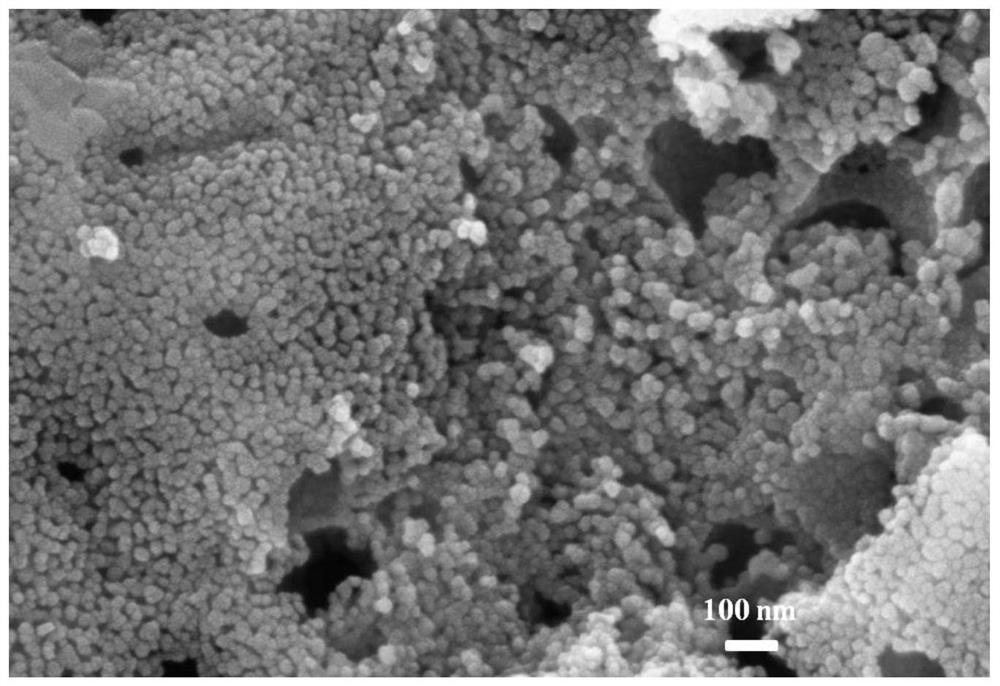

Preparation method of strontium titanate energy storage dielectric ceramic material with high breakdown and high energy storage density

ActiveCN112279639AFine and uniform particlesLower sintering temperatureStrontium titanateCompression molding

The invention discloses a preparation method of a strontium titanate energy storage dielectric ceramic material with high breakdown and high energy storage density. The preparation method is characterized by comprising the following steps: 1. dripping butyl titanate into deionized water to form Ti (OH) 4 precipitate, dripping nitric acid into the precipitate drop by drop, and dissolving the precipitate with the least nitric acid to form a TiO (NO3) 2 clear solution; 2, adding glycine and strontium nitrate into the TiO (NO3) 2 solution, uniformly mixing to form a precursor solution, and heating, evaporating and concentrating the precursor solution until the precursor solution is foamed and combusted to obtain carbon-containing nano SrTiO3 ceramic primary powder; and 3, carrying out carbon removal, granulation, compression molding, rubber discharging and sintering on the obtained nano SrTiO3 ceramic primary powder to obtain the SrTiO3 ceramic dielectric material with fine and uniform crystal grains. The preparation method is simple, rapid and low in energy consumption, and the prepared SrTiO3 ceramic is fine and uniform in crystal grain, high in density, high in breakdown strength and large in releasable energy storage density. The process for preparing the strontium titanate energy storage dielectric ceramic material is simple, rapid and convenient, and easy for industrial production.

Owner:SOUTHWEAT UNIV OF SCI & TECH

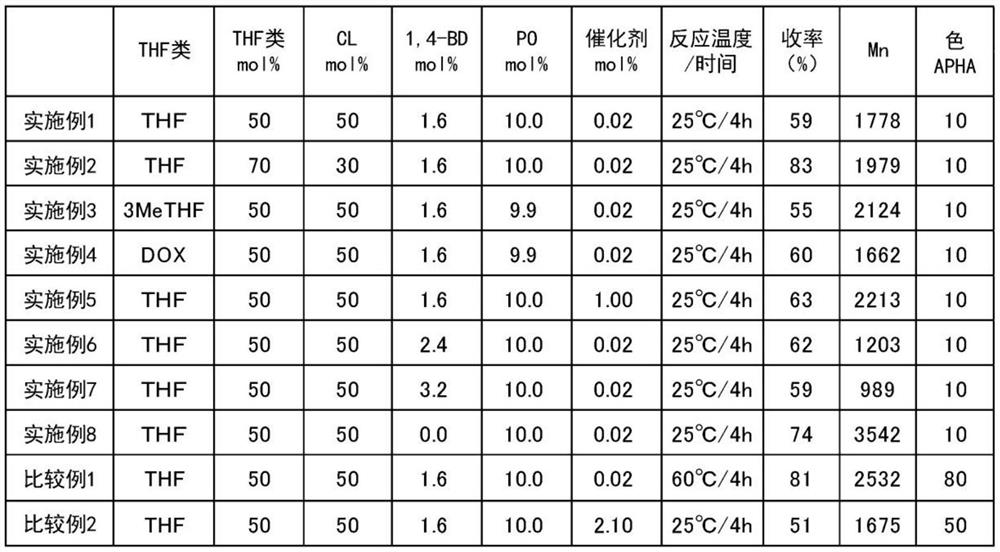

Copolymer and method for producing polyurethane

The invention relates to a copolymer and a preparation method of polyurethane. Provided is a method for industrially producing a high-quality polyether in a very simple and waste-free manner, according to the method, the molecular weight of a lactone polymer can be easily controlled, waste acid as a residual catalyst can be easily and completely removed, and coloring and impurity generation are reduced. The present invention relates to a method for producing a copolymer of a five-membered cyclic ether (A) and a lactone (B). The method is characterized in that a copolymerization reaction is performed at a temperature in the range of 10-50 DEG C, a heteropolyacid is used as a catalyst, an active hydrogen atom-containing compound containing a hydroxyl group, an amino group, and a mercapto group is used as a reaction initiator (C), and a three-membered to four-membered cyclic ether (D) is used.

Owner:HODOGAYA KAGAKU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com