Loctofen preparation method

A technology for the preparation of lactoferin and lactoferin, which is applied in the field of the preparation of lactoferin-ethyl raw medicine, to achieve the effects of high content of the original medicine, reduction of by-product formation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

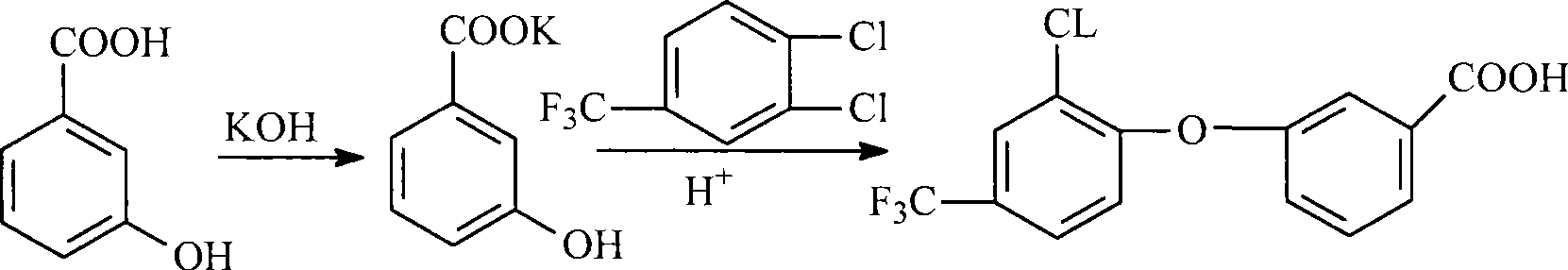

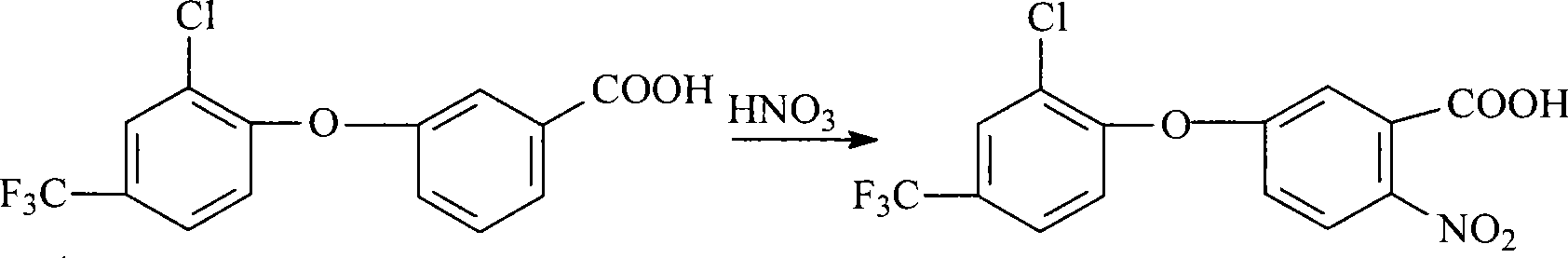

[0037] 1) Preparation of 3-[2-chloro-4-(trifluoromethyl)phenoxy]benzoic acid

[0038] In a 100L reactor, add 38.60Kg dimethyl sulfoxide (99%, 490mol) and put it into the reactor after metering, and add 10.10Kg potassium hydroxide (93%, 168mol) and 10.45Kg m-hydroxybenzene while stirring Formic acid (98%, 74.2 mol) was heated to 110° C. for a salt-forming reaction for 3 hours, and the water and part of the solvent generated by the reaction were removed under reduced pressure. Then add 3.45Kg anhydrous potassium carbonate (98%, 24.5mol) and 15.28Kg 3.4-dichlorobenzotrifluoride (98.5%, 70mol) in still, continue to heat up to 152-158 ℃, carry out condensation reaction, condensation reaction 20 -22 hours, the solvent dimethyl sulfoxide was removed. Add water to dissolve the remaining solids in the kettle, add concentrated hydrochloric acid dropwise to the solution for acidification to make PH=1-2, after the acidification is completed, carry out centrifugation, dry the wet product ...

Embodiment 2

[0045] 1) Preparation of 3-[2-chloro-4-(trifluoromethyl)phenoxy]benzoic acid

[0046] In a 100L reactor, add 38.60Kg dimethyl sulfoxide (99%, 490mol) and put it into the reactor after metering, and add 10.10Kg potassium hydroxide (93%, 168mol) and 10.45Kg m-hydroxybenzene while stirring Formic acid (98%, 74.2 mol) was heated to 110° C. for a salt-forming reaction for 3 hours, and the water and part of the solvent generated by the reaction were removed under reduced pressure. Then add 3.45Kg anhydrous potassium carbonate (98%, 24.5mol) and 15.28Kg 3.4-dichlorobenzotrifluoride (98.5%, 70mol) in still, continue to heat up to 152-158 ℃, carry out condensation reaction, condensation reaction 20 -22 hours, the solvent dimethyl sulfoxide was removed. Add water to dissolve the remaining solids in the tank, add concentrated hydrochloric acid dropwise to the solution for acidification to make PH = 1-2, after the acidification is completed, perform centrifugation, and dry the cake to ob...

Embodiment 3

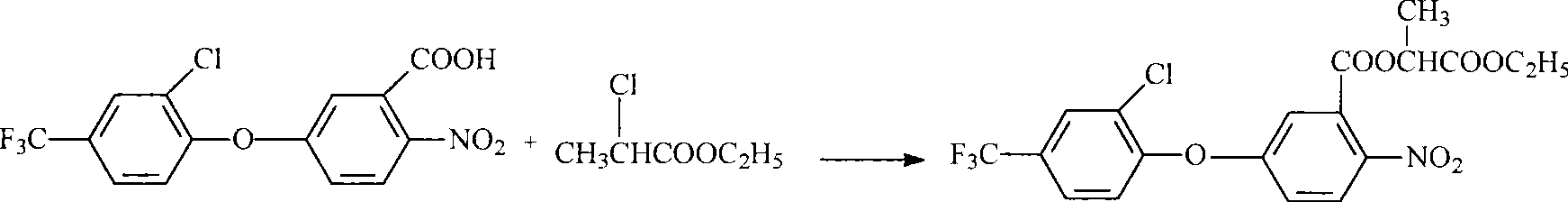

[0053] Repeat the same steps as described in Example 1, but from step 3): the preparation of lactofen: in a 100L reactor, add 73.25Kg ethyl 2-chloropropionate (99%, 530mol), 19.86Kg 5-[2-chloro-4-(trifluoromethyl)phenoxy]-2-nitrobenzoic acid (91.0%, 50mol) was added under stirring, and the temperature was raised to 80-85°C to obtain solution A. In a 150L reactor, add 43.95Kg ethyl 2-chloropropionate (99%, 320mol) and 9.15Kg potassium carbonate (99%, 65mol), stir and heat up at 80-85°C to obtain solution B, and at 80-85°C, dissolve A Add the solution dropwise into solution B. After the dropwise addition, heat up to 90-95°C and add 0.2Kg tetrabutylammonium bromide, then keep it warm at 90-95°C for 6-8 hours, measure the reaction end point by HPLC, filter, and add water to the filtrate Wash with water until neutral, remove the water layer, remove excess ethyl 2-chloropropionate from the oil layer to obtain 24.4Kg of lactofen-alifop, with a content of 87.3%, and a yield of 92.3%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com