Process of producing aluminum phosphide from yellow phosphorus and recovering byproducts simultaneously

A process method, aluminum phosphide technology, applied in the direction of chemical instruments and methods, phosphides, phosphorus compounds, etc., can solve the problems of low utilization rate of raw materials, environmental pollution, low labor productivity, etc., to reduce the scale of equipment and investment, The effect of reducing production costs and solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

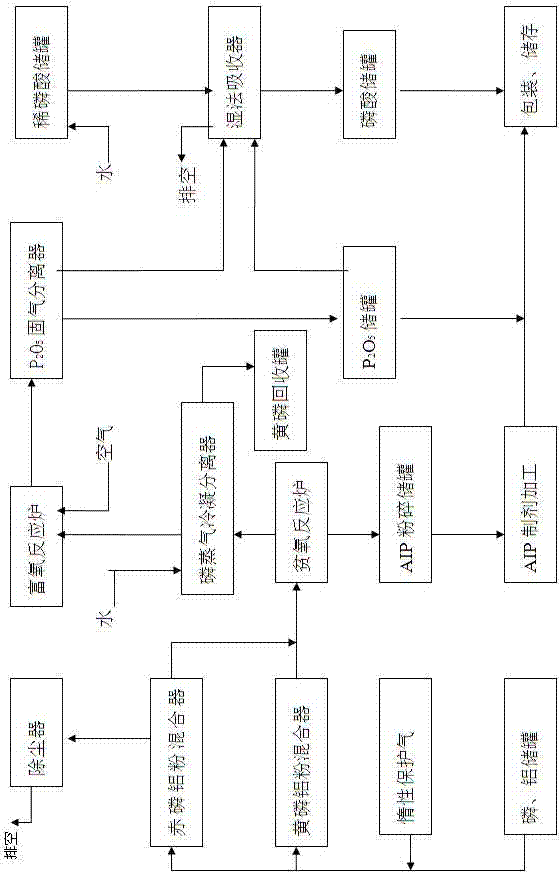

[0022] according to figure 1 The present invention is described in detail. The present invention is a process for producing aluminum phosphide by using yellow phosphorus while recovering by-products (yellow phosphorus, phosphorus pentoxide, phosphoric acid). The specific process steps are as follows:

[0023] The first step is to fill the agitating mixer with inert gas, replace the air in the agitating mixer, control the agitating mixer to continuously fill inert gas, and keep the temperature >44.4℃~﹤287℃, the optimum temperature is 50℃~60℃ . Wherein the inert gas is carbon dioxide, nitrogen, argon, etc., preferably nitrogen.

[0024] In the second step, the yellow phosphorus is heated to above 44.4°C, the optimum temperature is 50°C-60°C, and then the aluminum powder and yellow phosphorus are added to the stirring mixer under the conditions described in the first step at a weight ratio of 1:>1.05. Stirring and mixing time > 20 minutes, until the stirring is uniform. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com