Patents

Literature

57 results about "Aluminium phosphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium phosphide (aluminum phosphide) is a highly toxic inorganic compound with the chemical formula AlP used as a wide band gap semiconductor and a fumigant. This colorless solid is generally sold as a grey-green-yellow powder due to the presence of impurities arising from hydrolysis and oxidation.

Vermins-proof mildew-proof fumigation product using allyl isosulfocyanate as the active composition and uses thereof

The present invention relates to an insecticidal mildeco-proofing fumigant product using allyl isosulfocyanate as active component. Its composition includes (by wt%) 1-80% of allyl isosulfocyanate, 0.1-5% of antioxidation agent and the rest is adjuvant. Said invention can be made into oil miscible liquid, emulsifiable concentrate, emulsion in water or tablet, etc. and can be extensively used in grain depot, tobacco storage and textiles storage and can be used for making sterilization treatment of soil.

Owner:北京中德恒星科技有限公司

Aluminium phosphide residue non-poisonous innocuous finishing agent and treating method thereof

A treating agent for treating the residual dregs of aluminium phosphide without poison and harm is prepared from copper sulfate as catalyst, acid (nitric acid, hydrochloric acid, or sulfuric acid), and perchloric acid as oxidant. Its treating method includes such steps as adding the treating agent to said residual dregs while stirring, heating to 25-100 beg.C and keeping the temp for 0.5-4 hr.

Owner:UNIV OF SCI & TECH BEIJING

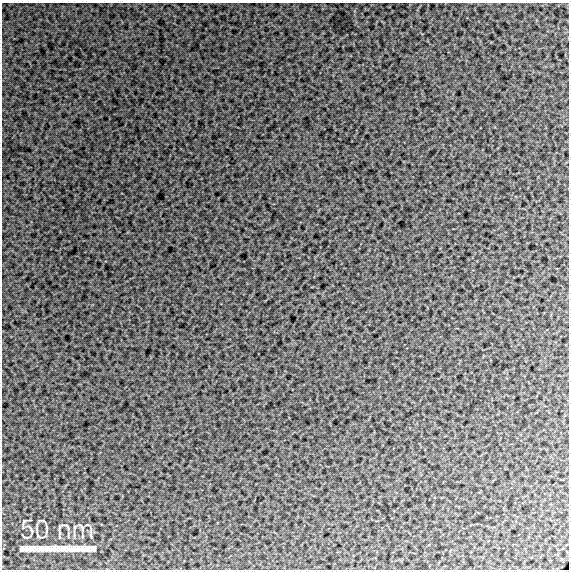

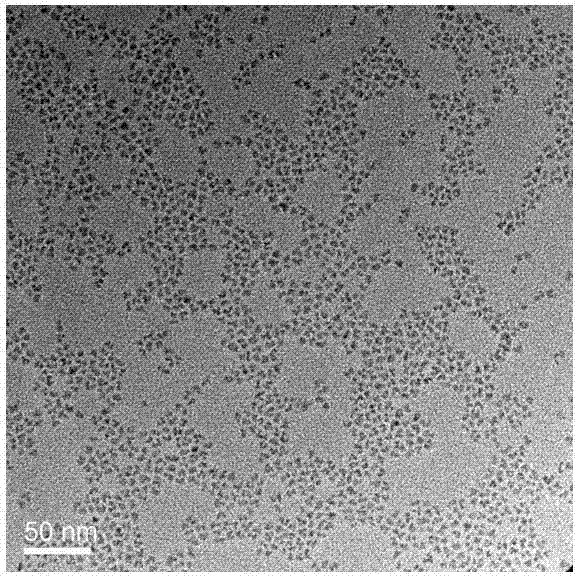

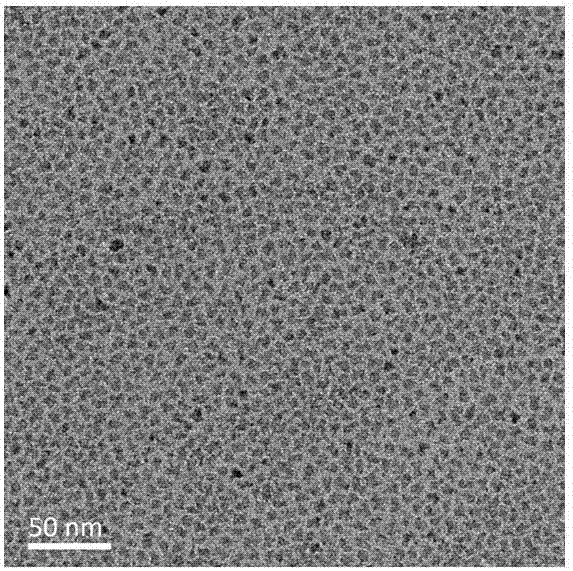

Method for preparing tetrahedral light-emitting indium phosphide/zinc sulfide core-casing quantum dots

ActiveCN107312534ALow priceStable chemical structureLuminescent compositionsChemical structureQuantum yield

The invention discloses a method for preparing tetrahedral light-emitting indium phosphide / zinc sulfide core-casing quantum dots. The method comprises the following steps: preparing high-boiling point tris(dialiphatic amido) phosphine, preparing InP quantum dot cores, preparing InP / ZnS core-casing quantum dots and separating the InP / ZnS core-casing quantum dots. Through the use of the high-boiling point tris(dialiphatic amido) phosphine as a phosphorus source, the price is low, the chemical structure is stable, the reaction is mild and safe, and gas is not produced. All reaction precursors are common chemical reagents and low in toxin and safe to store and use. The luminescent color of the InP / ZnS core-casing quantum dots can be precisely controlled simultaneously by the reaction temperature, the ratio of indium halide to the tris(dialiphatic amido) phosphine, the type of the halide and the reaction time, and high fluorescence quantum yield can be ensured.

Owner:南京紫同纳米科技有限公司

Storage, sterilization and pest preventing freshness-keeping film for broad bean, and preparation method thereof

The present invention discloses a storage, sterilization and pest preventing freshness-keeping film for broad bean, and a preparation method thereof, and belongs to a protective measure for broad bean pest damage. The freshness-keeping film comprises, by weight, 0.2-0.5% of chloropicrin, 0.3-0.5% of aluminium phosphide, 3-4% of a mixture comprising flatspine pricklyash oil, cinnamon oil and porous starch, 1-2% of polyethylene wax, 0.5-1% of glycerol monostearate, 0.5-0.7% of oleamide, 2-3% of calcium carbonate, and 62.3-72% of a low density polyethylene resin. According to the present invention, the storage, sterilization and pest preventing freshness-keeping film for the broad bean is prepared by adopting commonly used sterilization and pest preventing components, the production process is simple, the existing equipment can be adequately adopted to process and produce the film according to the ratio of various components of the freshness-keeping film, the freshness-keeping film can further be used for provision of storage and pest preventing for other grains, and the application range is broad.

Owner:XIHUA UNIV

Aluminium-phosphorus intermediate alloy and its preparation method

An Al-P intermediate alloy used for fining the crystallized silicon in Al-Si alloy is prepared from the industrial pure aluminium, Cu-P alloy, crystallized silicon, red phosphorus and aluminium phosphite through proportioning, smelting pure aluminium, sequentially adding others, stirring, until full reaction, and casting into ingot or extruding into wire material. Its advantages are no pollution,high smelting speed, and long and stable modifying effect.

Owner:SHANDONG UNIV

Low-temperature rice storage method

InactiveCN102047953ALong retention periodGuaranteed qualitySeed preservation by freezing/coolingFlavorGram

The invention relates to a low-temperature rice storage method which comprises the following steps: (1) packing the processed rice into bags with plastic film, stacking in a low-temperature storehouse, and adjusting the temperature of the low-temperature storehouse to below 15 DEG C; (2) sucking air from each packing bag, filling carbon dioxide into the packing bags according to the ratio of 8-12 kilograms of carbon dioxide to 10,000 kilograms of rice, and sealing the packing bags; and (3) putting aluminium phosphide sheets on the top end of the stack of rice packing bags according to the addition of 2 grams of aluminium phosphide per each cubic meter of stack. The low-temperature rice storage method provided by the invention organically combines various storage methods, makes full use of the advantages of various storage methods, can effectively prolong the rice preservation time and at least doubles the rice storage time while ensuring the rice quality and keeping the original flavor of rice.

Owner:肖振东

Pillow filled with rapeseed, seat-cushion back-cushion and floor-mat, and making method therefor

InactiveCN101002651APromote healthy developmentEliminate poisonous fireBed-coversConvulsionCurative effect

A health-care pillow, or mattress, or seat cushion, or floor cushion for detoxicating, preventing sore and furuncle, and treating infantile convulsion, hemicrania and cervicodynia is composed of the case of pillow or mattress or cushion and the core made of rapeseeds. Its preparing process includes such steps as choosing high-quality round rapeseeds, sieving, washing, drying in the air, fumigating by aluminum phosphide tablet in a sealed room, and filling them in case.

Owner:陈德光

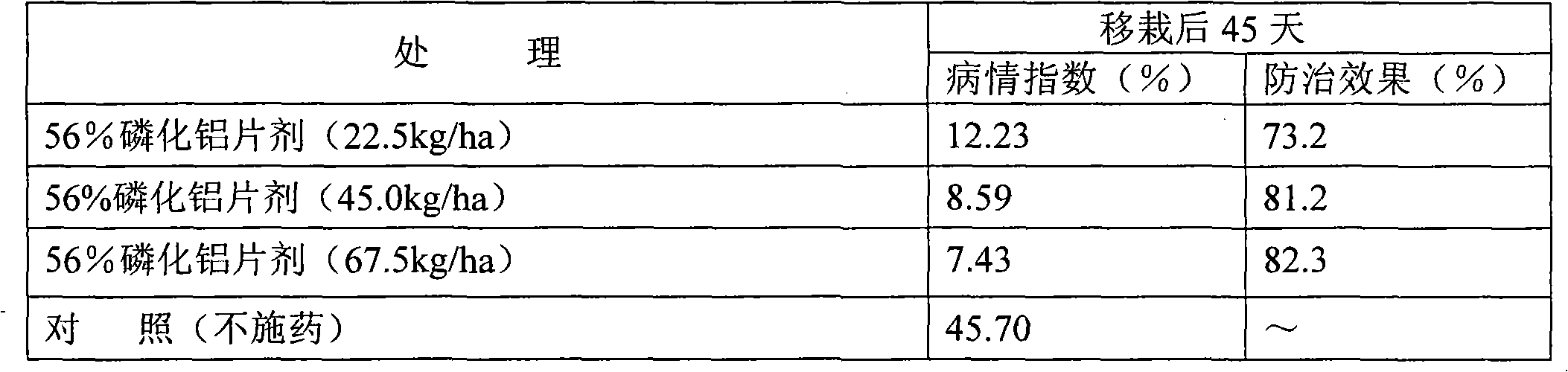

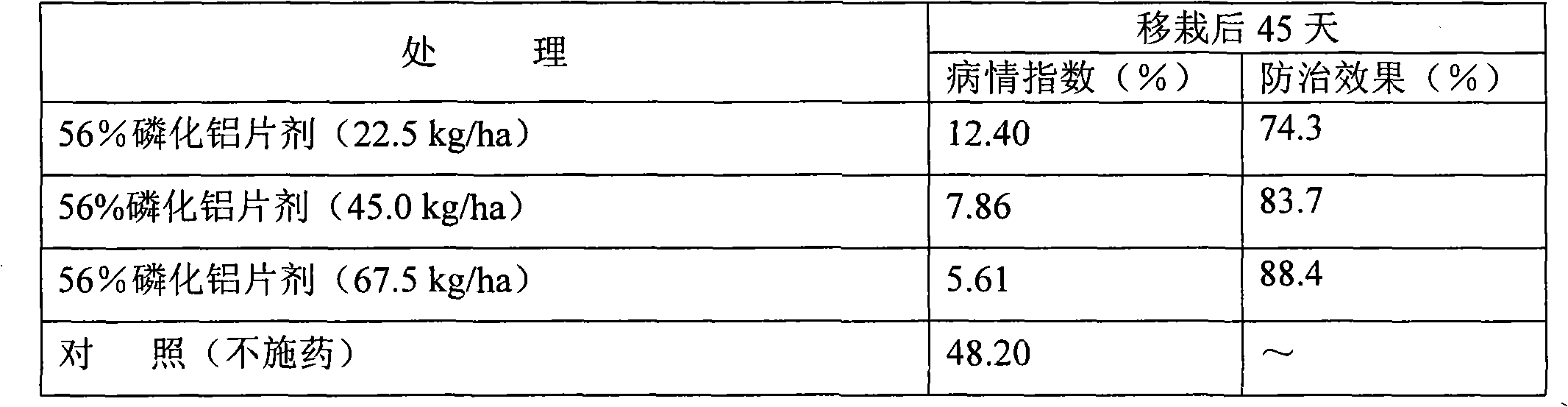

Method for preventing and controlling vegetable root knot nematode disease by fumigating soil with aluminium phosphide

The invention relates to a method for preventing and controlling a vegetable root knot nematode disease by fumigating soil with aluminium phosphide. In the method, 56 percent of aluminium phosphide tablets are fertilized into soil with the depth about 30 centimeters, a soil surface is covered by a plastic film, nematodes can be fast killed by a phosphine (PH3) gas released by the aluminium phosphide, and fumigating processing is carried out for 5-7 days so as to efficiently prevent and control the root knot nematode disease of a plant. The invention is not only used for protected-land vegetables but also widely used for preventing and controlling the nematodes on peanuts, vegetables, tobacco and multiple crops which are grown on openground and has high application value and very obvious economic and social benefits.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

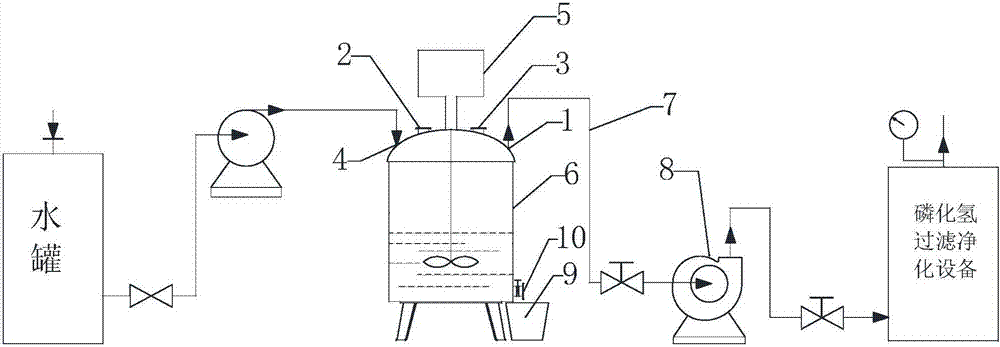

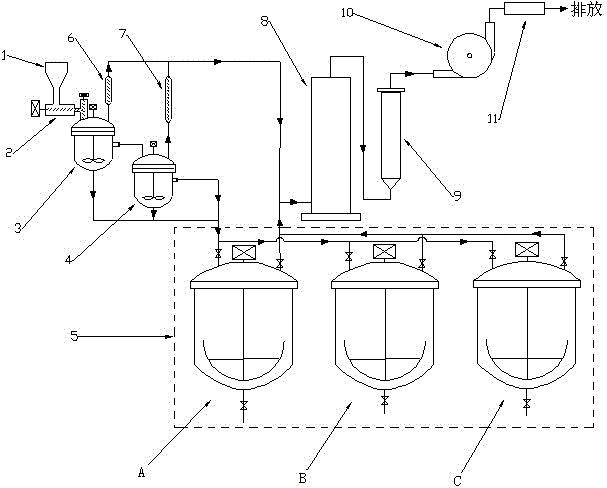

Method and device for treating residues of aluminum phosphide tablet fumigation agent

InactiveCN104085867APrevent spontaneous combustionEasy to handlePhosphatesAluminium chloridesHydrogen phosphideAluminium phosphide

The invention discloses a method and a device for treating residues of an aluminum phosphide tablet fumigation agent. A gas conveying tube on a polymerization reactor is utilized to feed generated hydrogen phosphide gas into an absorbing tower; the absorbing tower adopts counter-current operation; an absorbing liquid is sprayed from the top of the tower, the hydrogen phosphide gas enters from the bottom of the tower; a 25-75wt% sodium chlorite absorbing liquid is stored in a storage slot; the absorbing liquid is fed into the absorbing tower so as to be circulated and absorbed by a pump; a pollution-free phosphate liquor is formed after the absorbing liquid is statured, and can be used as an agricultural fertilizer; after being hydrolyzed in the polymerization reactor, the aluminum phosphide residues are polymerized at 65-75 DEG C under normal pressure and enter a separator, so that auxiliary materials are separated out, the pH of the filtrate is regulated to obtain a polymerized aluminum chloride water treating agent which can be directly sold as a product; the separated waste residues are harmless talcum powder or magnesium stearate which can directly enter soil. The method and the device disclosed by the invention have the advantage that the residues of the aluminum phosphide tablet fumigation agent are completely treated in a harmless manner.

Owner:中国人民解放军防化学院

Aluminum phosphide residue harmless treatment method and treatment device system

The invention discloses an aluminum phosphide residue harmless treatment method and a treatment device system. The aluminum phosphide residue harmless treatment method comprises the following steps: 1) adding aluminum phosphide residues into a residue treatment container, and adding an alkaline chemical agent and water to carry out a reaction so as to obtain hydrogen phosphide gas and first residue slurry, wherein the alkaline chemical agent is an alkaline chemical agent dissolved into water to be reacted with aluminum hydroxide; 2) adding an oxidizing agent into the first residue slurry until no hydrogen phosphide escapes so as to obtain second residue slurry, wherein the oxidizing agent is an oxidizing agent reacted with the hydrogen phosphide; 3) adding an acid into the second residue slurry for performing pre-curing treatment so as to obtain third residue slurry, wherein the acid is an acid reacted with aluminum hydroxide; and 4) adding a curing agent into the third residue slurry for curing, thereby obtaining the massive condensate. According to the treatment method, aluminum phosphide residues can be safely, rapidly and completely treated in a fumigation warehouse on site, and the treated residues do not contain any aluminum phosphide residue.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

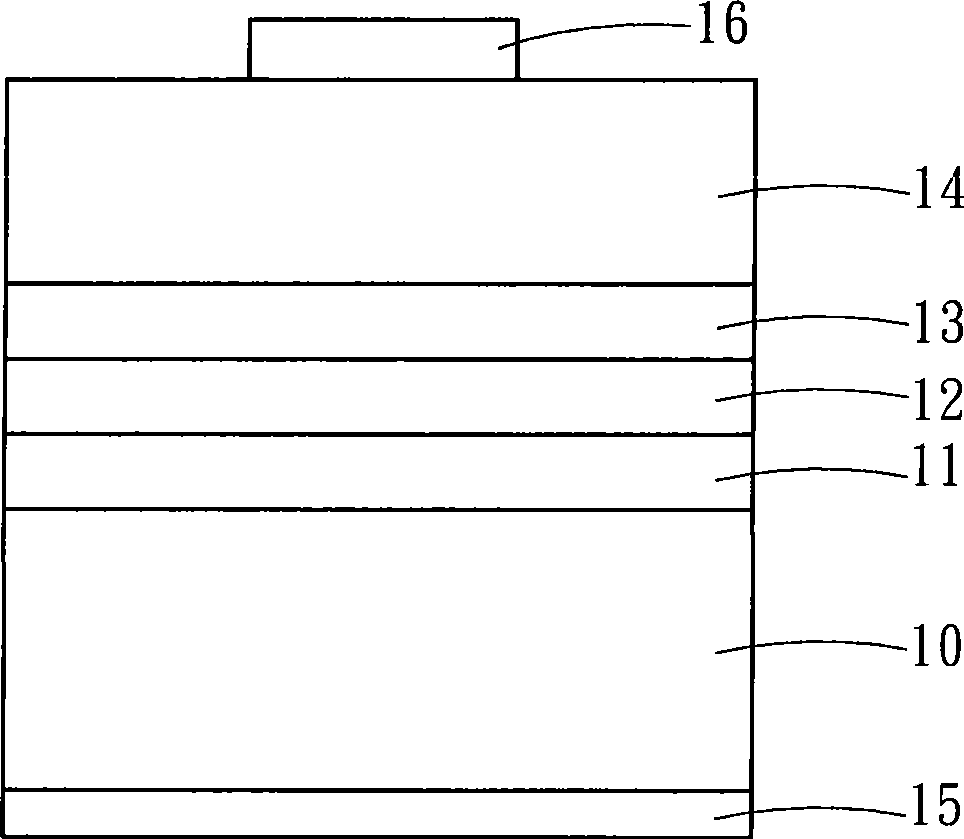

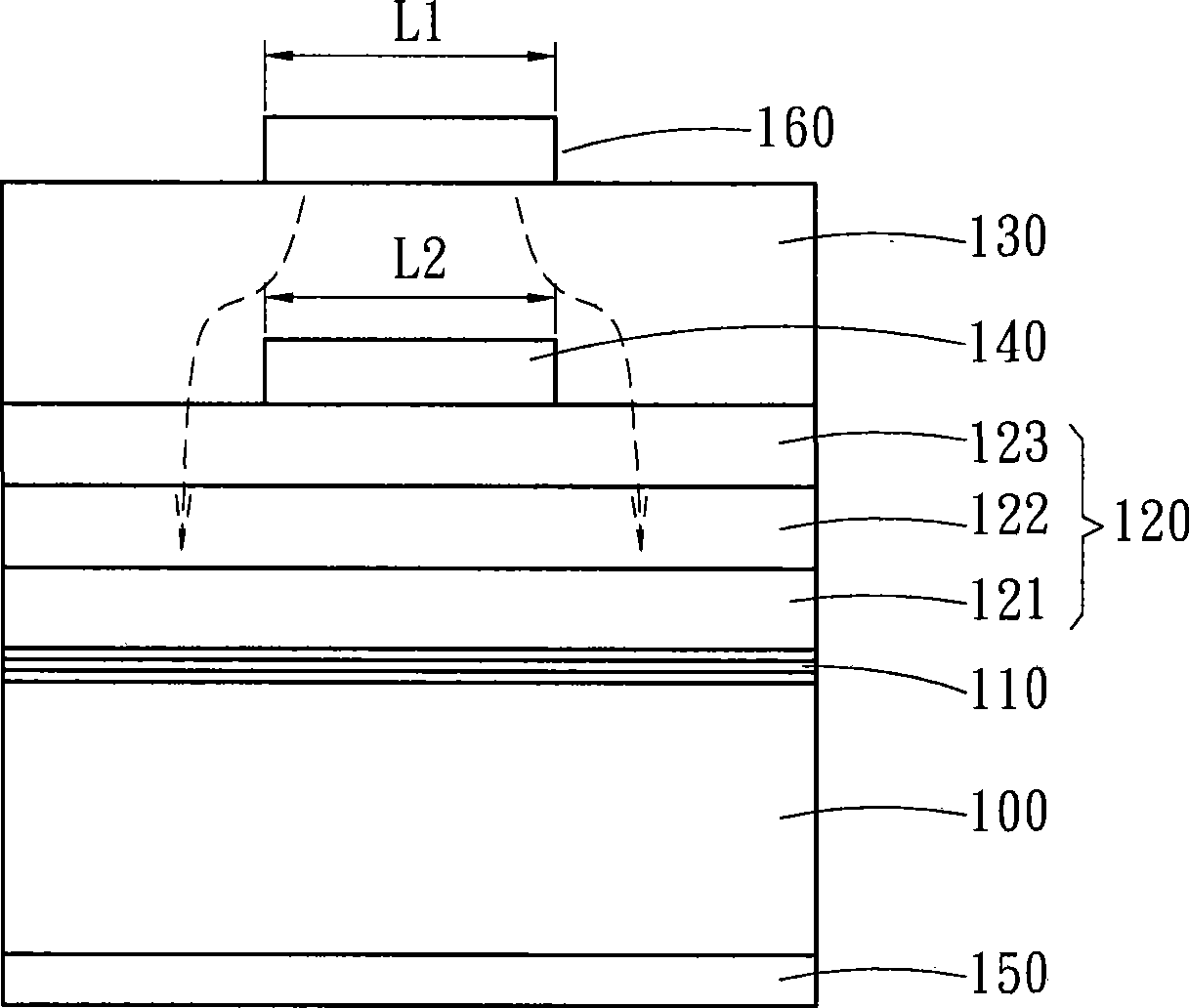

High-brightness LED construction

The invention relates to a high-brightness LED structure. A highly doped island structure layer formed by n-type aluminium phosphide indium (AlInP) is utilized to be formed on partial surface of a semiconductor laminated structure of aluminium phosphide gallium indium (AlGaInP) so as to form a current barrier. As the island structure layer is coated with a p-type window layer and is positioned below an ohm p electrode, strengthened input current flows to the semiconductor laminated structure of the AlGaInP, which is masked with a non-light-emitting surface electrode, so as to enable current distribution to reach an optimum state and then improve the light emitting efficiency of an LED.

Owner:TEKCORE CO LTD

Aluminum phosphide sustained-release coating treatment method

InactiveCN104430329AEase cast speedGood killing effectBiocideEdible seed preservationHydrogen phosphideMaterials science

The invention relates to an aluminum phosphide sustained-release coating treatment method. In the production process of aluminum phosphide, after an aluminum phosphide tablet is formed, the aluminum phosphide tablet is put in liquid paraffin for soaking for 20-60 seconds, and the soaked aluminum phosphide tablet is dried and then packaged after being taken out. The quality of liquid paraffin is different, stored grains can be damaged after poor liquid paraffin is used, and thus colorless and tasteless liquid paraffin with high quality needs to be adopted, and residues harm to the health of people cannot be generated after the stored grains are fumigated. By utilizing macromolecular coating treatment, the leakage of hydrogen phosphide molecules is caused, so that the discharging speed of aluminum phosphide in unit time is greatly reduced, the duration time of pesticide effect is prolonged, the killing effect of pests is improved, the safety of workers in a production packaging process is improved, and the intoxicating phenomenon of workers in a aluminium phosphide packaging process is completely eradicated. Through verification of an applicant for many years, the aluminum phosphide sustained-release coating treatment method disclosed by the invention is safe, reliable, good in using effect and free of harmful residues for grains.

Owner:赵华林

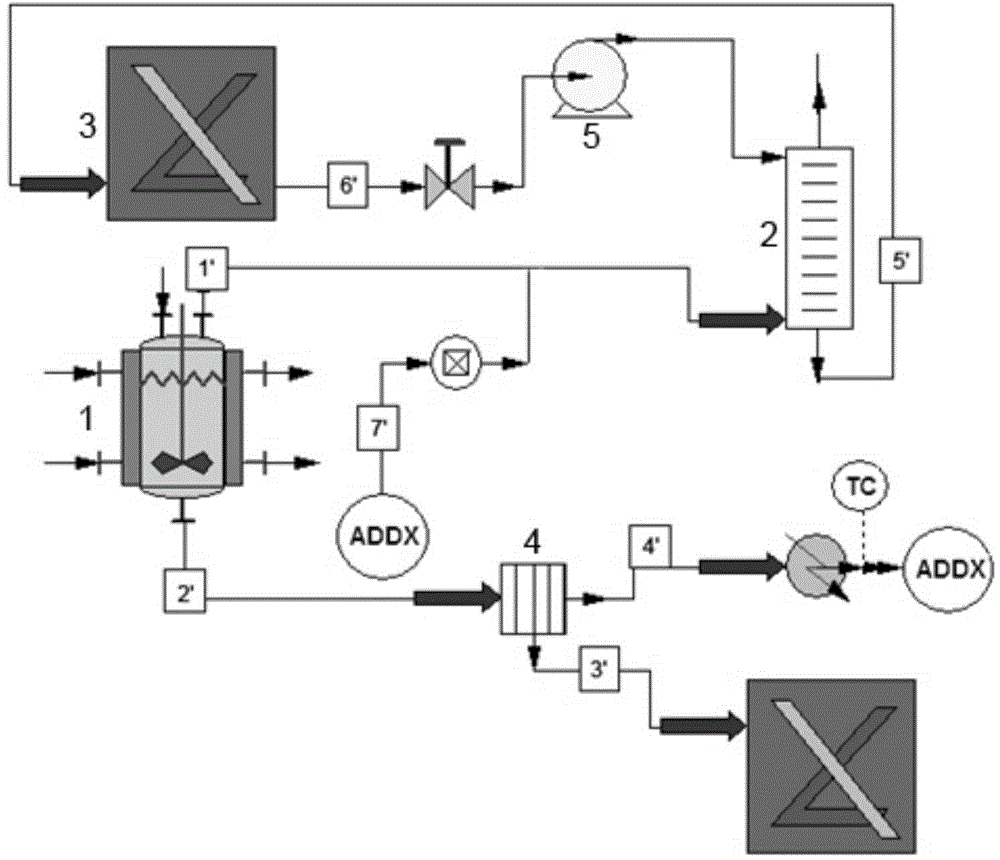

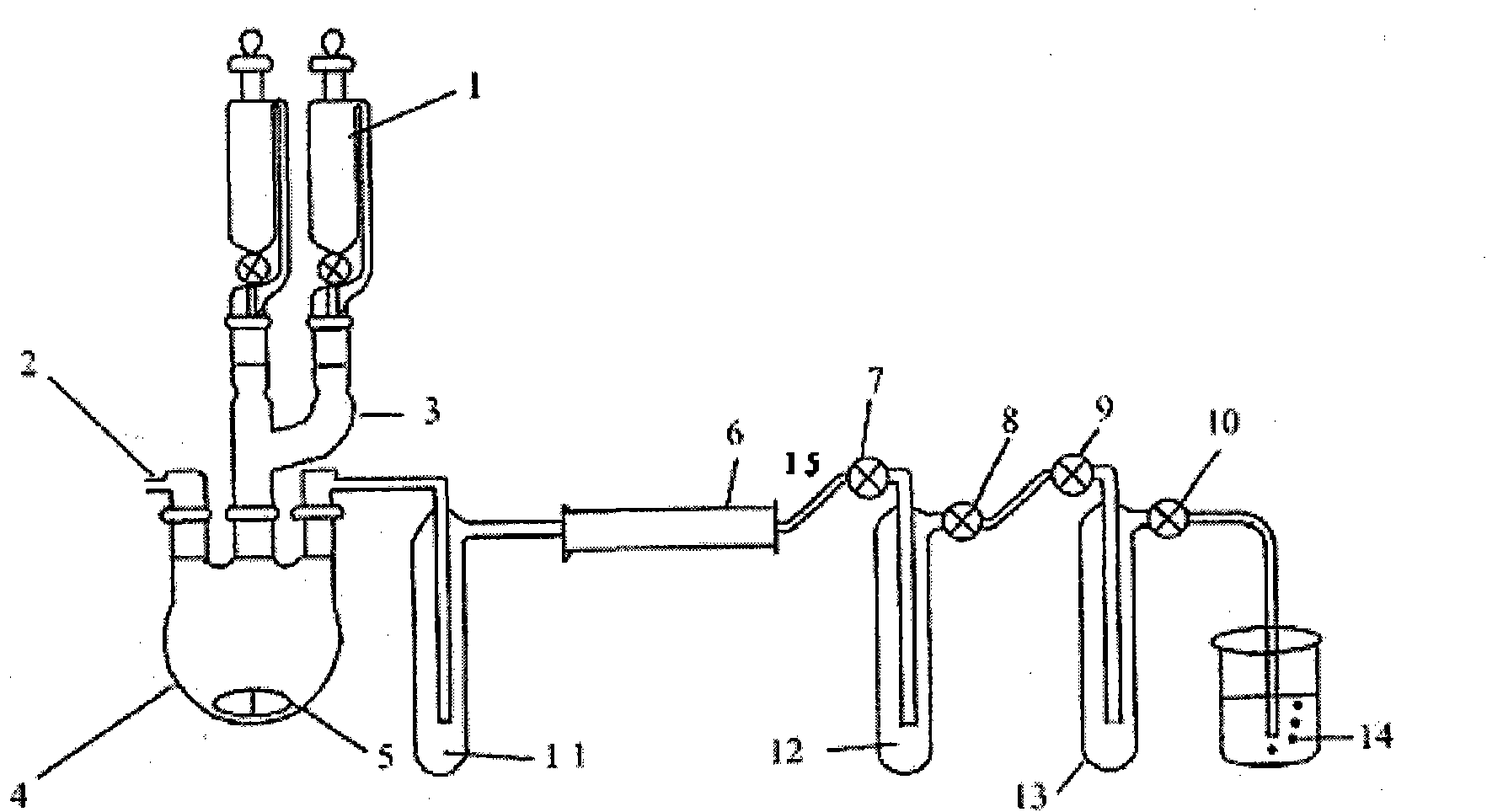

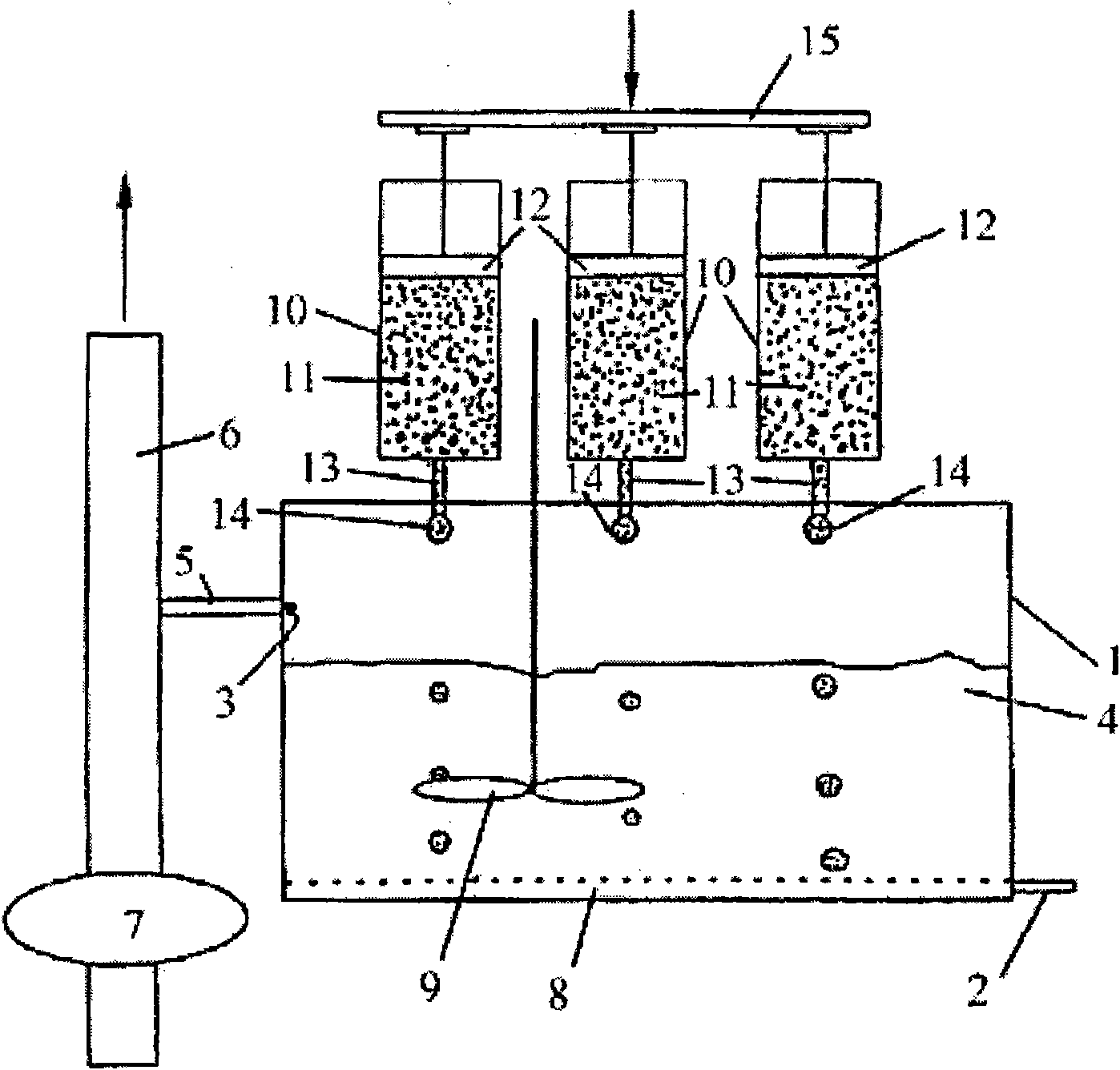

Technology for preparing phosphine by reacting aluminium phosphide with sulfuric acid

InactiveCN101955170AIdeal preparation technologyReasonable designHydrogen phosphidesPhospholanNitrogen

The invention discloses technology for preparing phosphine by reacting aluminium phosphide with sulfuric acid. In the technology, the upper end of an integrated flask is connected and provided with a constant-pressure charging hopper through a connection pipe and also connected and provided with a nitrogen inlet pipe; an electromagnetic heating stirrer is arranged on inner bottom of the flask; and a KOH drying pipe, a piston 1, a piston 2, a piston3, a piston 4, a catcher 1, a catcher 2 and a catcher 3 are sequentially connected through a connection pipe. The technology has the advantages of reasonable design and convenient use and is ideal technology for preparing phosphine.

Owner:TIANJIN TAIYUAN INDAL GAS

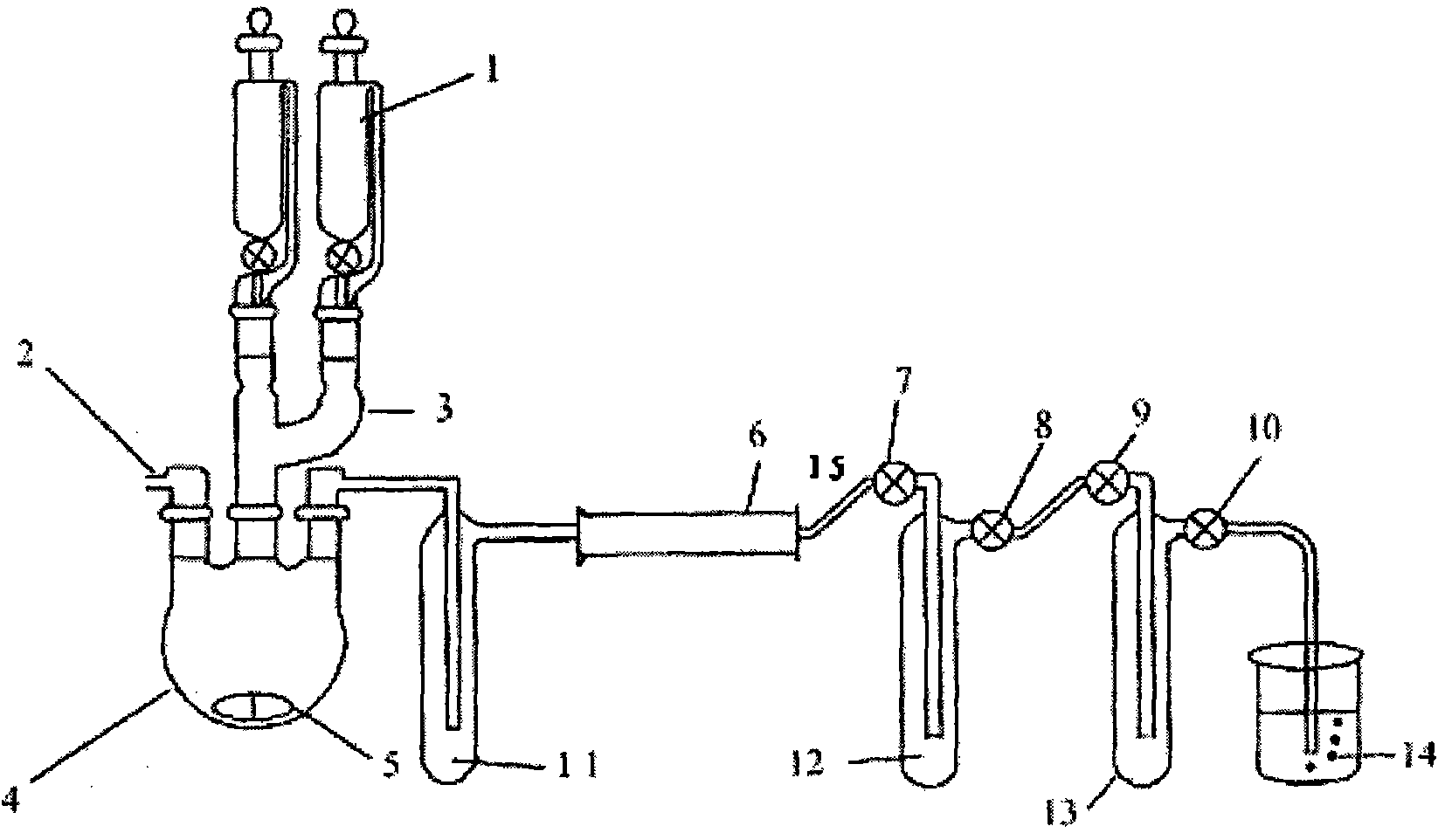

Technique for preparing phosphine by performing hydrolysis reaction on aluminium phosphide

InactiveCN101955171AIdeal preparation technologyReasonable designHydrogen phosphidesEngineeringHydrolysis

The invention discloses a technique for preparing phosphine by performing a hydrolysis reaction on aluminium phosphide. Particularly, the technique adopts the following technical scheme that: a gas inlet pipe is connected with and installed at the lower end of an integrated reaction chamber; the reaction chamber is connected with a conduit through one end of a gas outlet pipe; the conduit is connected with a fumigant transfer pipe; a fan is connected with and installed on the lower part of the fumigant transfer pipe; the fan is connected with the reaction chamber through the other end of the gas outlet pipe; the upper part of the reaction chamber is connected with a cartridge case through a slim tube; a piston is connected to and installed in the cartridge case; a driving plate is connected with and installed at the upper end of the piston; and a gas distributing plate and a stirrer are connected to and installed in the reaction chamber. The technique has reasonable design, is convenient for use and is an ideal process technique for preparing the phosphine.

Owner:TIANJIN TAIYUAN INDAL GAS

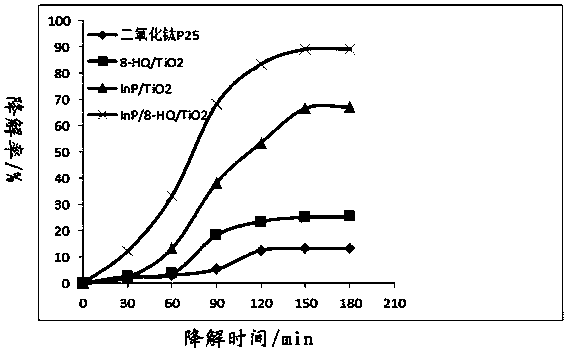

Method for catalytically degrading antibiotic wastewater with photocatalytic material containing indium phosphide doping-modified TiO2

ActiveCN108187706ACatalyzed Oxidative DegradationImprove degradation rateWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationChemical oxygen demand

The invention belongs to the technical field of prevention and control of organic wastewater, and particularly relates to a method for catalytically degrading antibiotic wastewater with a photocatalytic material containing indium phosphide doping-modified TiO2. The invention provides a photocatalytic material containing indium phosphide doping-modified TiO2. With tetrabutyl titanate as a precursorof TiO2 and indium phosphide and 8-hydroxyquinoline as modifiers, the invention adopts a sol-gel method to prepare the dual-modified TiO2 photocatalytic material. The photocatalytic material preparedby the invention can catalytically and oxidatively degrade sulfadiazine under ultraviolet light and / or sunlight, and moreover, the catalytic material can be recycled, and can be used in high-concentration COD (chemical oxygen demand) wastewater.

Owner:海门市知舟工业设计有限公司

Safe production technique for manufacturing high-purity phosphine on large scale

InactiveCN104058375AAvoid pollutionAvoid corrosionChemical industryHydrogen phosphidesEthylic acidEngineering

The invention discloses a safe production technique for manufacturing high-purity phosphine on large scale. Aluminum phosphide and deionized water or zinc phosphide and acetic acid used as raw materials are subjected to sealed solid feeding, negative-pressure three-stage cascade reactor reaction, low-temperature low-pressure trapping purification, tail gas oxidation trivalent phosphorus removal, and absorption of phosphorus pentoxide by alkali liquor and activated charcoal under closed reaction conditions. The technique can simultaneously satisfy the four requirements of capability of large-scale industrial manufacturing from laboratories to industrialization, control on the virulent phosphine in air in the production workshop and surrounding environment to be lower than allowable concentration, no intricate corrosion problem in equipment, and high product purity, and provides a safe and reliable production technique for industrial production.

Owner:李达刚 +3

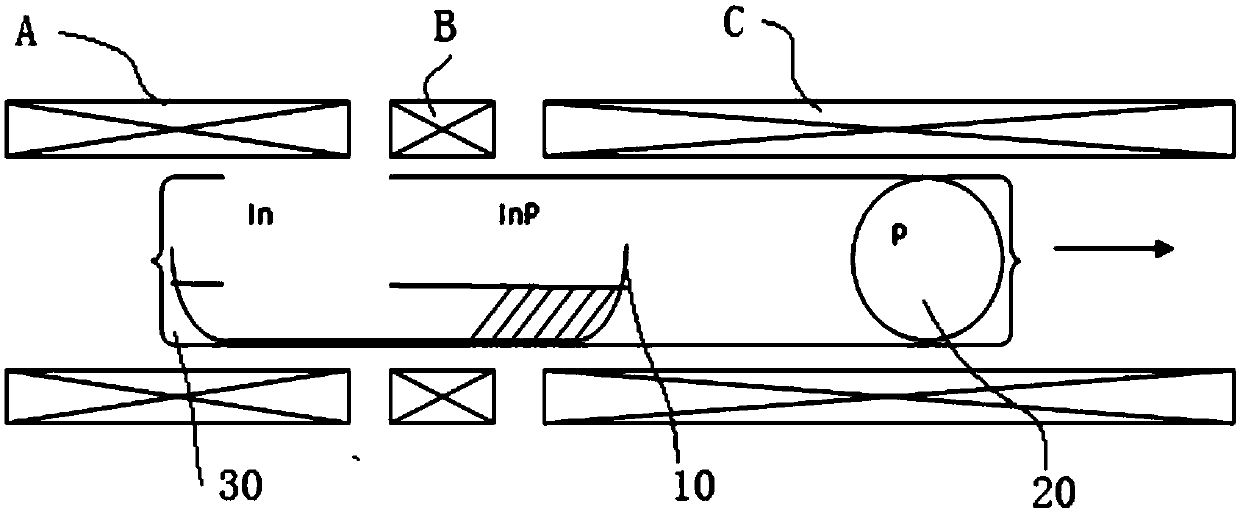

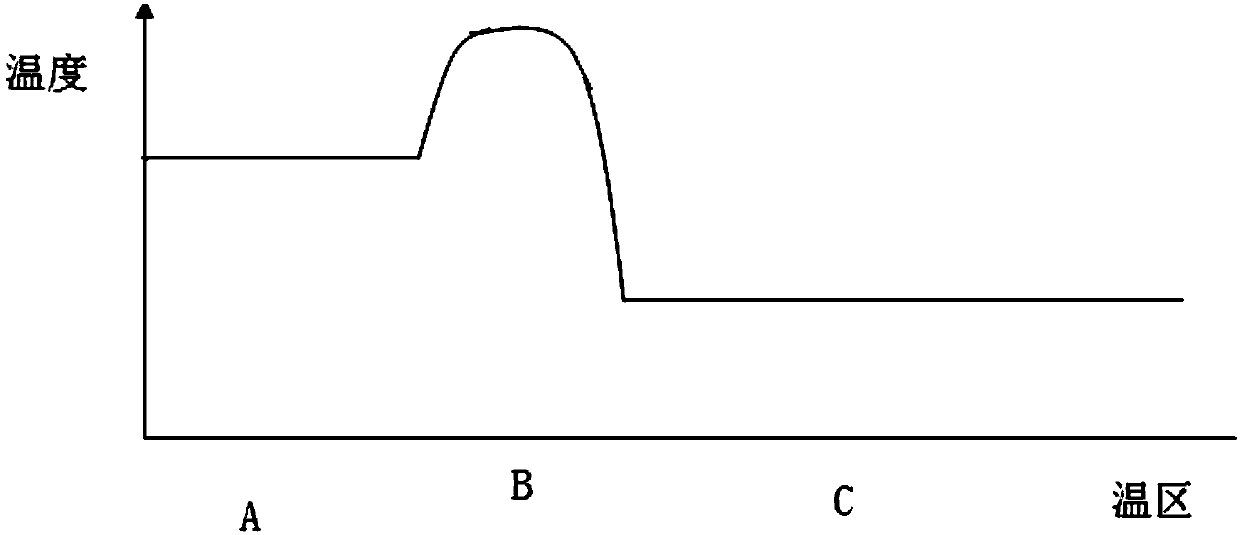

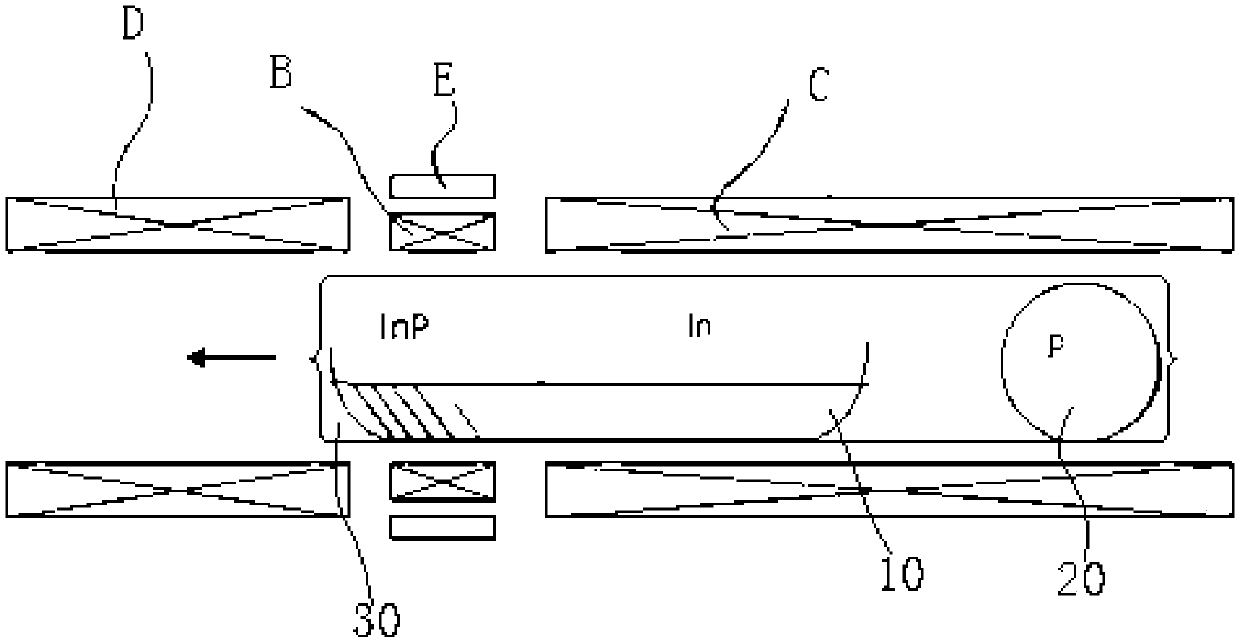

Synthesis method of indium phosphide and synthesis device thereof

InactiveCN107937984ASolve the real problemLow costPolycrystalline material growthSingle crystal growth detailsIndiumSynthesis methods

The invention relates to a synthesis method of indium phosphide and a synthesis device thereof. A first container for storing indium and a second container for storing phosphorus in a sealed pipe areboth placed in a phosphorus pressure control area initially, the temperature of the phosphorus pressure control area is greater than or equal to the vaporization temperature of phosphorus and is lowerthan the melting point of indium phosphide, the temperature of the phosphorous pressure control area is utilized to melt and preheat indium and vaporize phosphorus, and in the moving direction of thesealed pipe, the first container is located in front of the second container; the sealed pipe moves from the phosphorous pressure control area to a reaction area, the temperature of the reaction areais greater than or equal to the melting point of indium phosphide, in the reaction area, phosphorus steam is melted into an indium melt to form an indium phosphide melt; the sealed pipe moves from the reaction area to a polycrystal cooling area, the temperature of the polycrystal cooling area is lower than the reaction area, and the indium phosphide melt cools into an indium phosphide polycrystalin the polycrystal cooling area. According to the invention, the phosphorous pressure control area is utilized to store liquid indium to effectively avoid the Si pollution problem caused by reactionof high temperature indium with a quartz crucible wall, and the InP polycrystal product has higher purity.

Owner:珠海鼎泰芯源晶体有限公司

Method for improving yield of greenhouse pepper

InactiveCN104472130AReduce diseaseReduce usageBioloigcal waste fertilisersCultivating equipmentsGreenhouseTemperature difference

The invention discloses a method for improving the yield of greenhouse pepper. The method improves the yield of pepper by inputting ozone into furrows under mulching film, performing fumigation disinfection on soil through aluminum phosphide, adding organic matrix into the soil in greenhouses where pepper is cultivated to improve the structure of the soil, regulating the content of carbon dioxide inside the greenhouses, controlling diurnal internal and external temperature differences to regulate the growth of the pepper and the like.

Owner:覃慧璇

Non-irritant fumigating pesticides used for greenhouse

The invention discloses a non-irritant fumigating pesticides used for greenhouse, which comprises the following components according to weight: 100 parts of argy worwood dry powder, 20-40 parts of aluminium phosphide and 2-10 parts of malathion. The provided non-irritant fumigating pesticides used for greenhouse employs argy worwood dry powder which is good to human body as a main component, and is mixed with aluminium phosphide and malathion, insect pest can be effectively controlled, the fumigant with characteristics of no stimulation and no toxicity can be realized, and a new approach can be provided for fumigating insecticide.

Owner:LIUZHOU TIANZI HORTICULTURE

Insect-and-ant prevention polyethylene water supply tubular product and preparation method thereof

InactiveCN104098822AImprove mechanical propertiesImprove anti-agingRigid pipesLow-density polyethyleneSlag

The invention discloses an insect-and-ant prevention polyethylene water supply tubular product and a preparation method thereof. The insect-and-ant prevention polyethylene water supply tubular product is prepared from the following raw materials in parts by weight: 40-60 parts of high density polyethylene, 20-40 parts of linear low density polyethylene, 15-25 parts of polyethylene naphthalate, 5-10 parts of nano aluminium phosphide, 10-15 parts of bis(2-ethylhexyl) terephthalate, 7-14 parts of naphthenic acid butyl ester, 2-3 parts of propyl gallate, 10-15 parts of steel slag micro powder, 8-16 parts of germanium powder, 15-20 parts of filling master batch, 3-6 parts of polyethylene wax, 2-4 parts of coconut monoethanol amide, 3-4 parts of polyamide wax micro powder, 2.5-4.5 parts of eucalyptus oil, 1.5-2.5 parts of 2-ethylhexyl diphenyl phosphate, 2-3 parts of dibasic lead stearate, 1-2 parts of di(beta-butoxy carbonyl-ethyl) tin bis(isooctyl mercaptoacetate), 1-2 parts of dichlorodiphenyltrichloroethane and 2-3 parts of benzyl benzoate. According to the invention, insect-and-ant prevention elements such as nano aluminium phosphide, eucalyptus oil and dichlorodiphenyltrichloroethane are added in the PE (polyethylene) water supply tubular product, so that the polyethylene water supply tubular product can be effectively prevented from being bitten by insects and ants; in addition, the prepared tubular product has excellent mechanical property, ageing resistance, heat resistance and processability, and is long in service life and wide in application prospect.

Owner:ANHUI DINGYUAN ZHENYUN PLASTIC

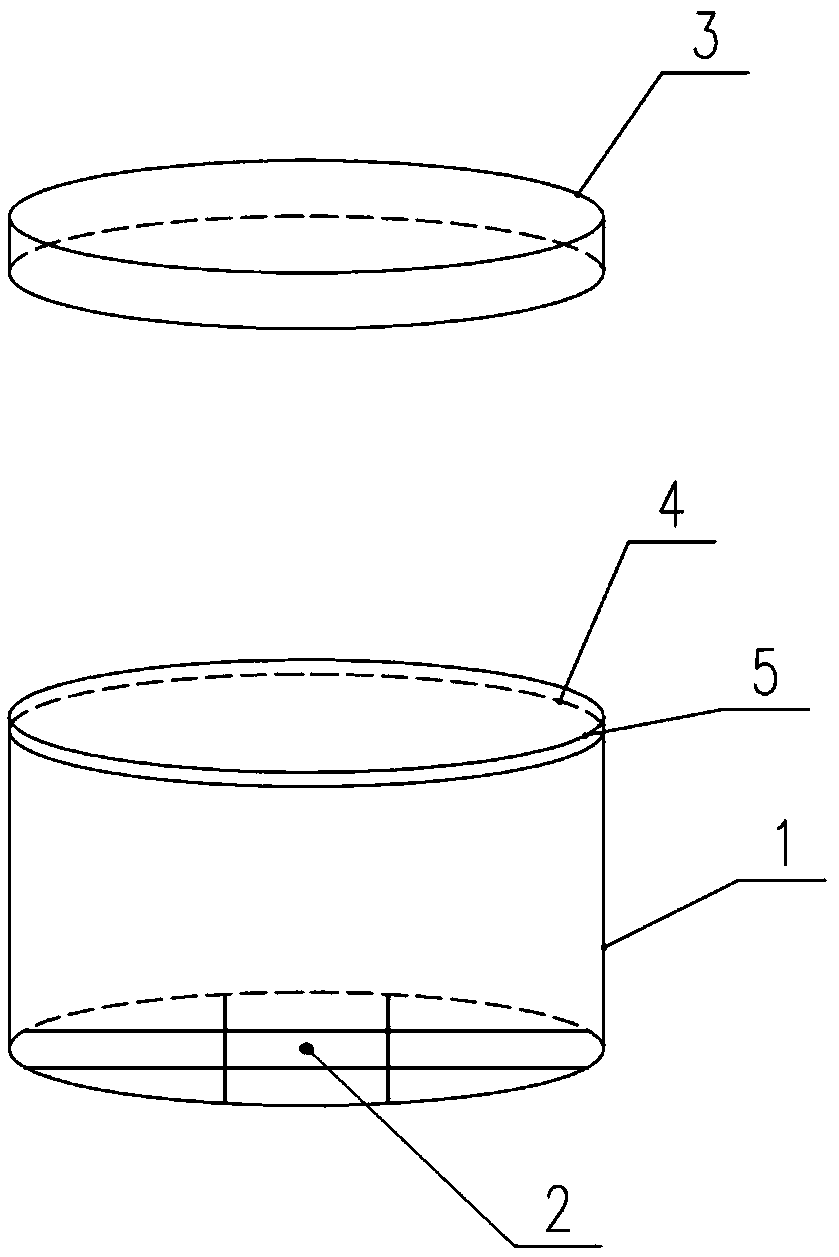

Aluminium phosphide safe administration box and application method thereof in prevention and control of stored grain insects

InactiveCN108669057AAvoid contactProtect physical and mental healthFumigatorsGrain storageEngineering

The invention discloses an aluminium phosphide safe administration box, and relates to the field of grain storage safety production. The box comprises a pesticide box, a drying agent bag, a box cover,a polymeric membrane and protective film. The aluminium phosphide safe administration box has the advantages that the structure is simpler, the operation is convenient, the use is safe, and not onlyare safety of aluminium phosphide during transportation and storage and physical and psychological health of administration personnel during the use of the aluminium phosphide guaranteed, but also theuse effect of the aluminium phosphide is guaranteed.

Owner:广州岭南穗粮谷物股份有限公司

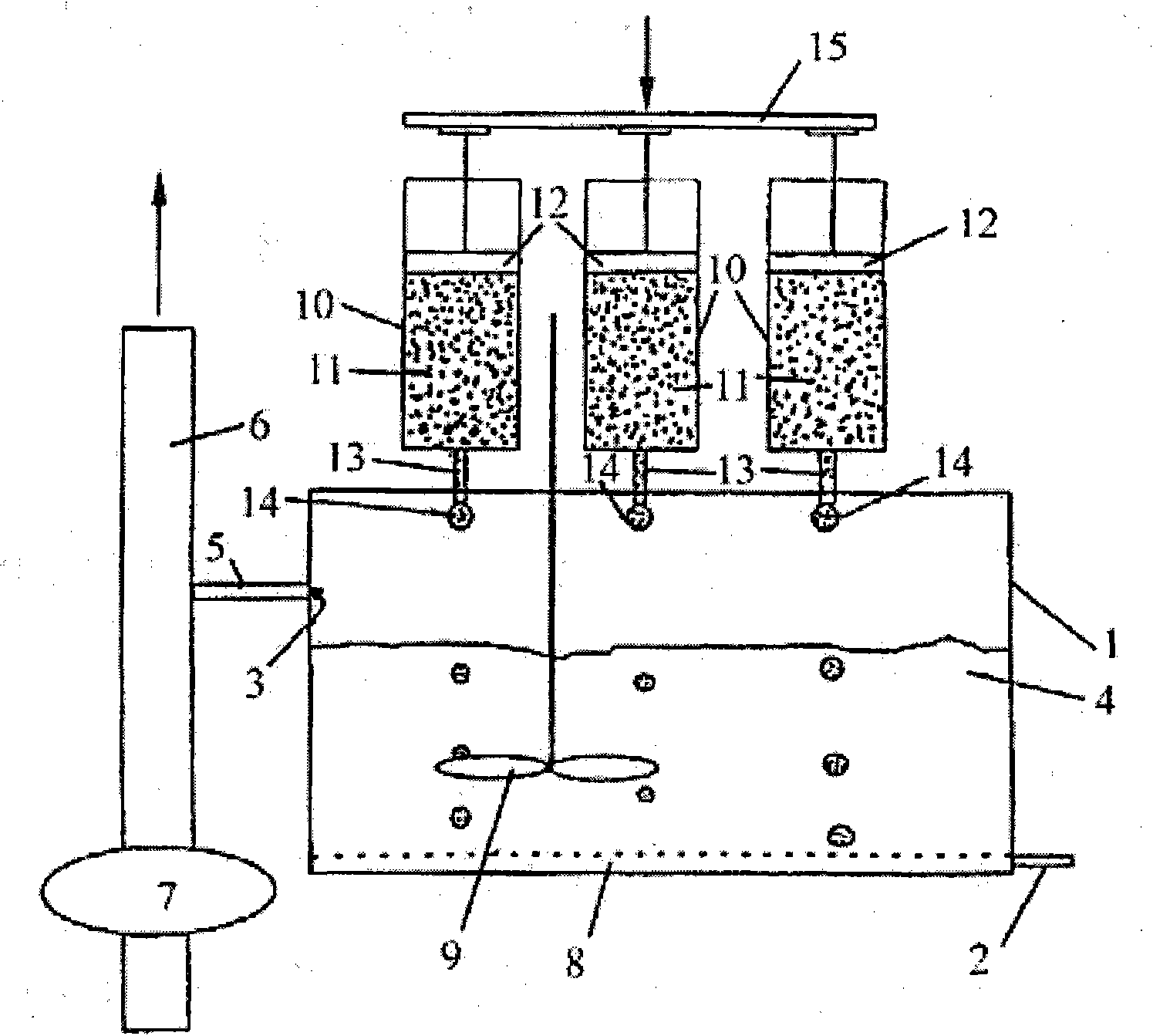

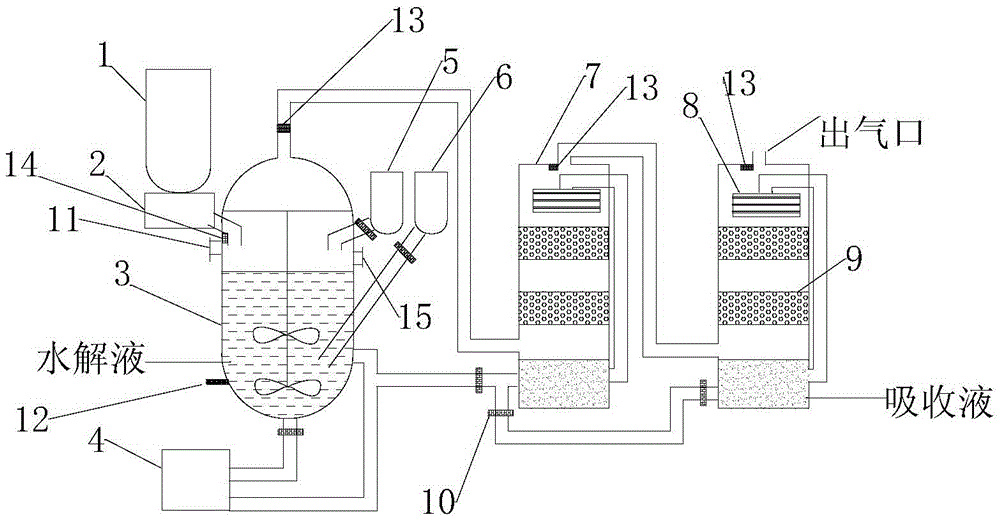

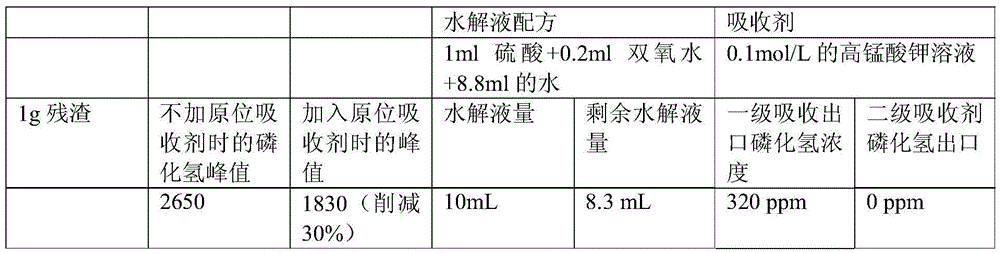

Device and process for safely treating aluminum phosphide fumigating residues

The invention discloses a device and process for safely treating aluminum phosphide fumigating residues. The process comprises the steps that firstly, inert gas is introduced into a hydrolyzing and absorbing tank, air in the hydrolyzing and absorbing tank is discharged, then water is injected into the hydrolyzing and absorbing tank, then a hydrolyzing agent, the aluminum phosphide fumigating residues and a site absorption agent are sequentially added to the hydrolyzing and absorbing tank, and absorption liquid is sprayed for absorption in an exhaust absorption device; and secondly, reaction liquid generated after a hydrolyzing reaction is conducted is discharged and filtered, filter residues are neutralized and buried safely, filter liquid returns to the hydrolyzing and absorbing tank to replace the water added to the hydrolyzing and absorbing tank in the first step, residual liquid is absorbed by exhaust to complement the insufficient part, and raw materials are added for a next reaction. According to the device and process, the hydrolyzing reaction is performed in the hydrolyzing and absorbing tank, exhaust absorption comprises site absorption in the hydrolyzing and absorbing tank and further absorption in a two-stage exhaust absorption tower, and the residual liquid absorbed by exhaust can be reused for hydrolyzing agent preparation.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Rat-killing method for outdoor rat cave

A rat-killing method for outdoor rat cave includes putting aluminium phosphide as rodenticide at the deep place in rat cave, putting a silt barrier in the rate cave, pouring initiator for speeding up reaction of aluminium phosphide, blocking the cave by clay, feeding oxidant in the cave, and sealing the cave by stone, brick and concrete. Its advantages are high effect, and no environment pollution.

Owner:XINTIANDI INSECTICIDAL SERVICE GUANGZHOU

Method of preparing active aluminium oxide from aluminium phosphide

InactiveCN1597522ASimple production processReduce energy consumptionAluminium oxides/hydroxidesWater vaporHydrogen phosphide

A process for preparing active aluminium oxide from aluminium phosphide by intermittent hydrolysis method or continuous hydrolysis method is disclosed. Said intermittent hydrolysis method includes such steps as adding excessive water to reactor, adding aluminium phosphide powder, reacting while stirring, collecting hydrogen phosphide gas, filtering solution, drying filtered cake, pulveriznig and calcining.

Owner:TIANJIN UNIV

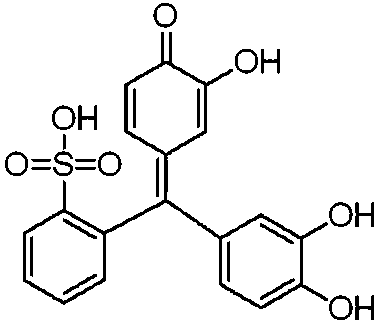

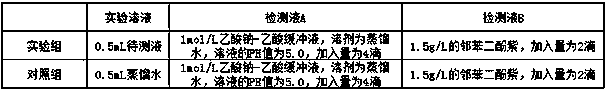

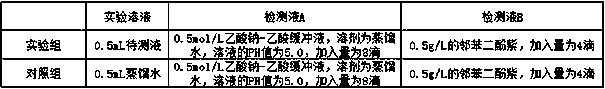

Kit and detection method for quickly detecting aluminium phosphide in edible mushroom and cereals

InactiveCN108827959ACreate pollutionEasy to commoditizeMaterial analysis by observing effect on chemical indicatorSodium acetateBottle

The invention discloses a kit and a detection method for quickly detecting aluminium phosphide in edible mushroom and cereals. The kit comprises: a detection solution A bottle filled with a 0.2-4 mol / L sodium acetate-acetic acid buffer solution, a detection solution B bottle filled with a 0.2-5 g / L pyrocatechol violet liquid, a centrifugal tube, and a sample cup. The detection method includes thesteps of: extracting the aluminium phosphide with water to decompose the aluminium phosphide into hydrogen phosphide and Al(OH)3, wherein the Al(OH)3 can form a violet complex with the pyrocatechol violet when pH is 5.0, and according to different concentrations, the violet complex shows a red color, a purple color or a violet color in a solution; and determining whether the sample contains the aluminium phosphide or not by observing the color of the solution after the reaction. The kit for quickly detecting aluminium phosphide in edible mushroom and cereals employs low-cost and accessible consumable reagents, is free of environmental pollution, is easy and convenient to use, and has high sensitivity and intuitive results.

Owner:郑州华洲集团股份有限公司

Rat-killing method for outdoor rat cave

A rat-killing method for outdoor rat cave includes putting aluminium phosphide as rodenticide at the deep place in rat cave, putting a silt barrier in the rate cave, pouring initiator for speeding upreaction of aluminium phosphide, blocking the cave by clay, feeding oxidant in the cave, and sealing the cave by stone, brick and concrete. Its advantages are high effect, and no environment pollution.

Owner:XINTIANDI INSECTICIDAL SERVICE GUANGZHOU

Fumigation insecticide, preparation method of fumigation insecticide and disinfection and killing method adopting fumigation insecticide

InactiveCN112237204ASmooth sustained releaseLong-lasting insect repellentBiocideAnimal repellantsPolyolPolythylene glycol

The invention relates to a fumigating insecticide, a preparation method of the fumigating insecticide and a disinfection and killing method adopting the fumigating insecticide. The fumigating insecticide is prepared from the following components in parts by weight: aluminum phosphide, cyhalothrin, chlorantraniliprole, ethanol, polyethylene glycol, phenolic resin, guar gum, calcium alginate and castor oil polyether polyol. The preparation method of the fumigating insecticide comprises the following steps: mixing and stirring all the raw materials at the temperature of 55-65 DEG C, then rapidlycondensing, and drying at the temperature of 40-50 DEG C to obtain the fumigating insecticide. The disinfecting and killing method adopting the fumigating insecticide comprises the following steps: atthe temperature of 20-25 DEG C and the humidity of 30-33RH%, putting the fumigating insecticide into a closed space at the usage amount of 6-10g / m < 3 >; the fumigating insecticide has the effect ofstably and durably releasing hydrogen phosphide, so that the effect of durably preventing and killing insects can be achieved by using a relatively small amount of fumigating insecticide, and the costof the disinfecting and killing process is saved.

Owner:河南省紫风养护发展有限公司

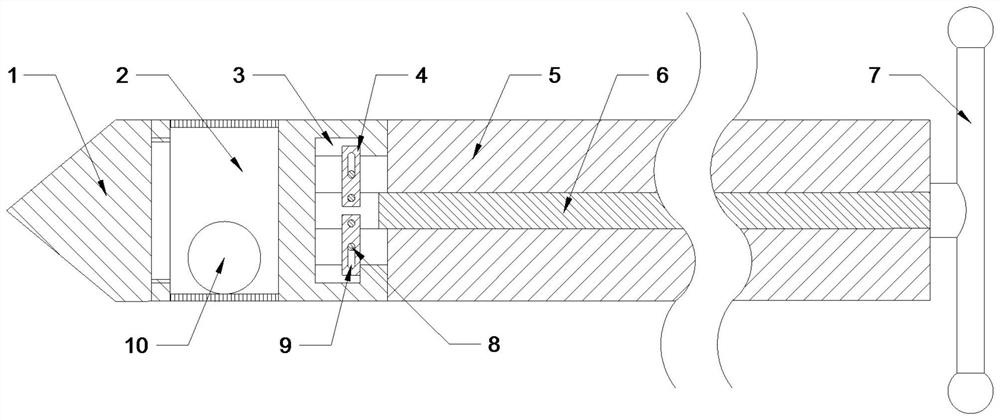

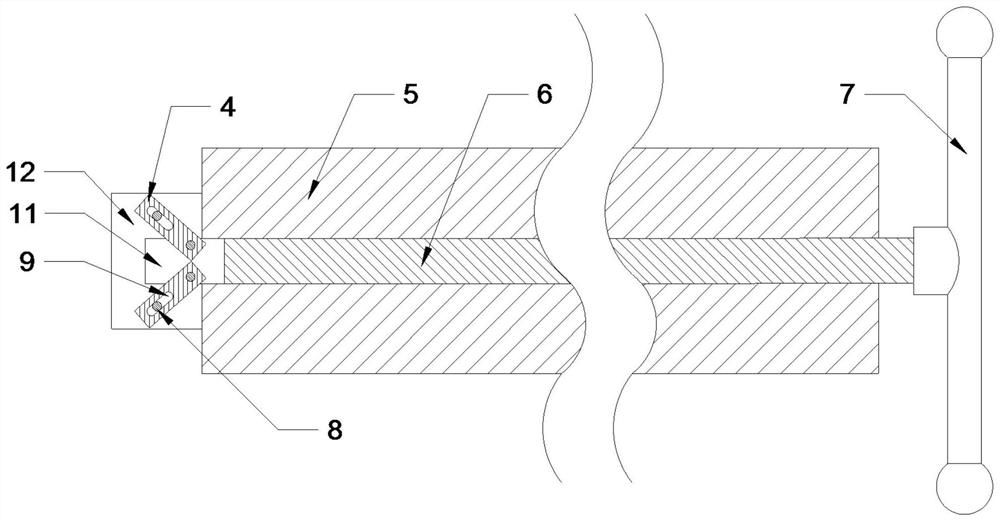

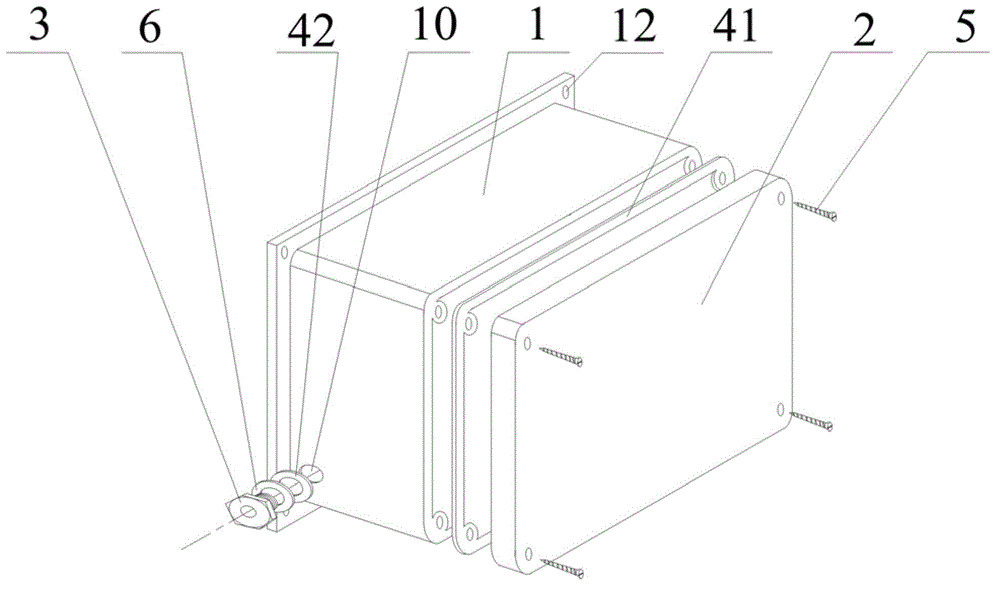

A granary fumigation and insecticide dosing mechanism

ActiveCN109362365BEasy to useGuaranteed distributionAgriculture tools and machinesHarvested fruit hanging devicesAnimal scienceMedicine

The invention relates to the technical field of grain storage equipment, and discloses a granary fumigation and deworming dosing mechanism, which includes an insertion rod, a through hole is provided on the central axis of the insertion rod, an opening slot 1 is provided at the front end of the insertion rod, and a limit post is provided in the opening slot 1 There is a push-pull rod inside the through hole, the front end of the push-pull rod is provided with an opening slot 2, the front end of the push-pull rod and one end of the bayonet pin are hinged in the opening slot 2, the bayonet pin is provided with a sliding groove, and the limit column is stuck in the sliding groove; the insertion rod The front end is inserted into the interface groove at the rear end of the drug injection barrel and connected with the drug injection barrel, and the inner wall of the interface groove is provided with a card slot for bayonet insertion. It solves the problem that aluminum phosphide tablets cannot be put into the deep part of the granary when aluminum phosphide is used to fumigate and eliminate insects in the existing family granary, and the generated phosphine insecticidal gas cannot effectively cover the entire granary and effectively eliminate insects.

Owner:郑州中锣科技有限公司

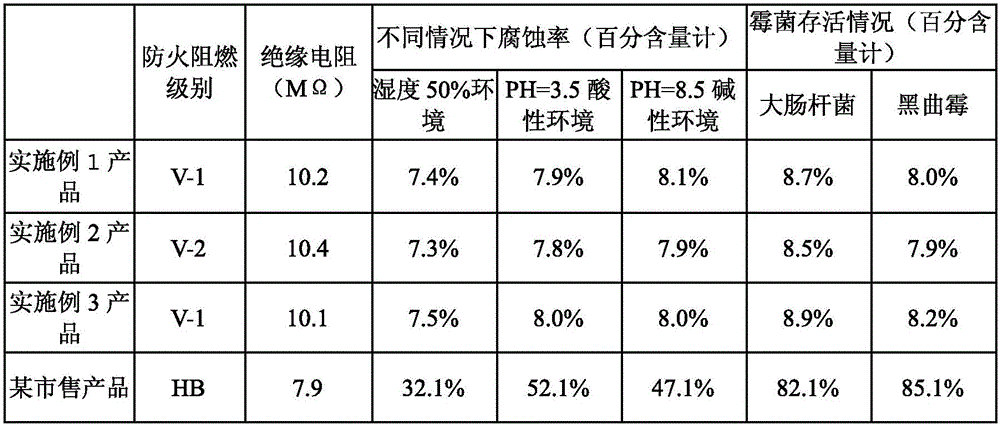

Modified additive of lubricating oil

InactiveCN106085555AExcellent flame retardantGood acid and alkali resistanceAdditivesPolyvinyl chloridePotassium

The invention relates to a modified additive of lubricating oil. The modified additive is prepared from the following components of diphenyl-methane-diisocyanate, PVC (polyvinyl chloride) resin powder, styrene-butadiene-styrene block copolymer, ammonium polyphosphate, triethylene glycol di-2-ethylhexoate, p-cresol, polythiophene, benzalkonium chloride, oxazolidinone, aluminium phosphide, nanometer chitin, nano-silver, bamboo pulp, trisodium phosphate, dolomite powder, camellia pollen, sodium iodoacetate, clove, honey, potassium fluotitanate, modified attapulgite powder, olivine powder, pure acrylic emulsion, acetic styrene-acrylic emulsion, n-butyl acetate, 2-benzothiazolethiol, 2-hydroxy-4-methoxybenzophenone, 2-tert-butylhydroquinone, 4,4'-diaminodiphenyl, and sodium allysulfonate. The modified additive has the advantages that the flame-retardant, acid and alkaline-resistant, anti-mildewing and anti-bacterial properties are excellent, and the product property is improved.

Owner:余志娟

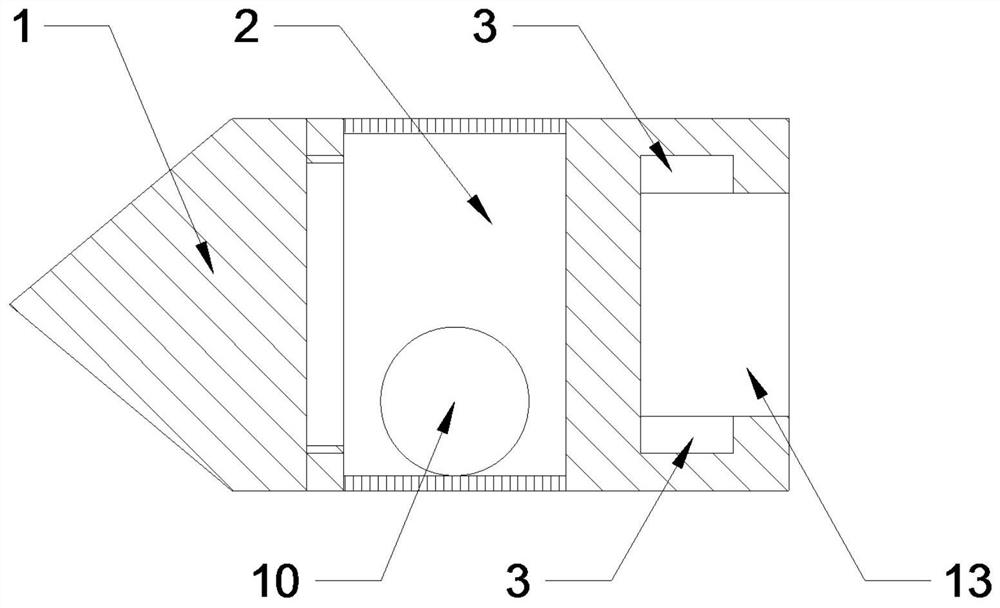

Control interface protection device

InactiveCN104158020AImprove sealingEffective protectionCoupling device detailsEngineeringMechanical engineering

The invention relates to a control interface protection device. The control interface protection device specifically includes: a shell used for accommodating a control interface and having a wire inlet hole; a cover body sealed together with the shell to be a whole through a first sealing gasket; and a lock nut locked and connected to the wire inlet hole through a second sealing gasket and used for sealing a line entering through the wire inlet hole. The shell, the first sealing gasket, and the cover body are sealed and connected through screws. The control interface protection device further comprises a flat gasket cushioned and connected to the lock nut. The shell and the cover are both made of plastics. The shell is provided with mounting holes. Therefore, the control interface protection device of the invention can effectively seal and protect the control interface, prevent the control interface from being eroded during aluminium phosphide fumigation, and guarantee the normal work of the control interface and a fire extinguishing system.

Owner:SHAANXI LANDE SENMAO FIRE CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com