Method for preparing tetrahedral light-emitting indium phosphide/zinc sulfide core-casing quantum dots

A technology of core-shell structure and quantum dots, which is applied in the field of chemical synthesis of tetrahedral indium phosphide/zinc sulfide core-shell structure quantum dots, which can solve adverse reactions, safety control, controllable reactions, unstable raw materials, and raw material costs Advanced problems, to achieve the effect of ensuring fluorescence quantum yield, storage and use safety, mild reaction and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

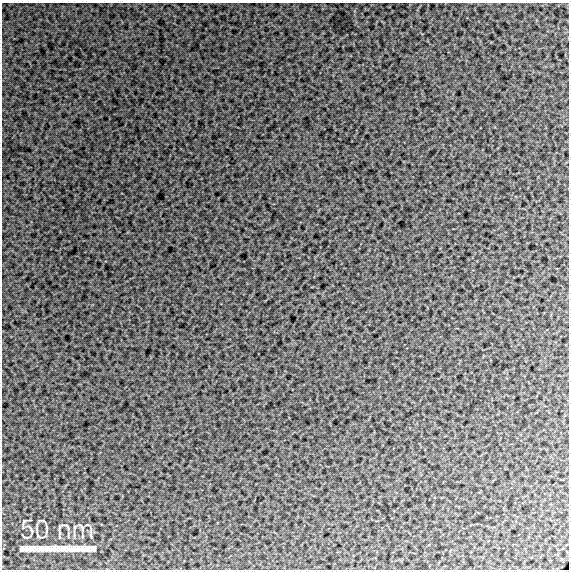

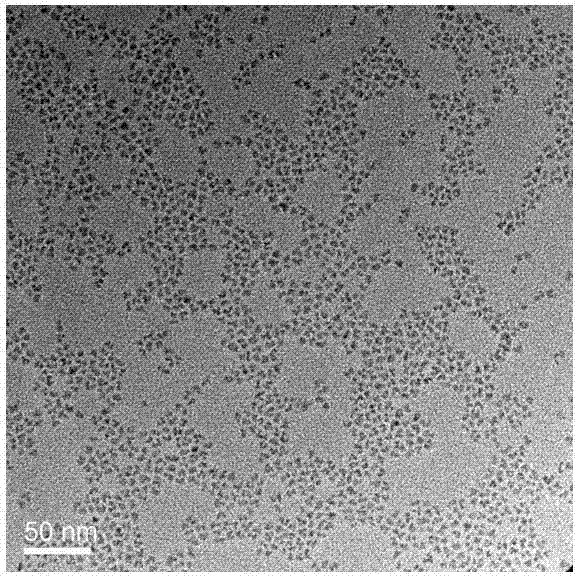

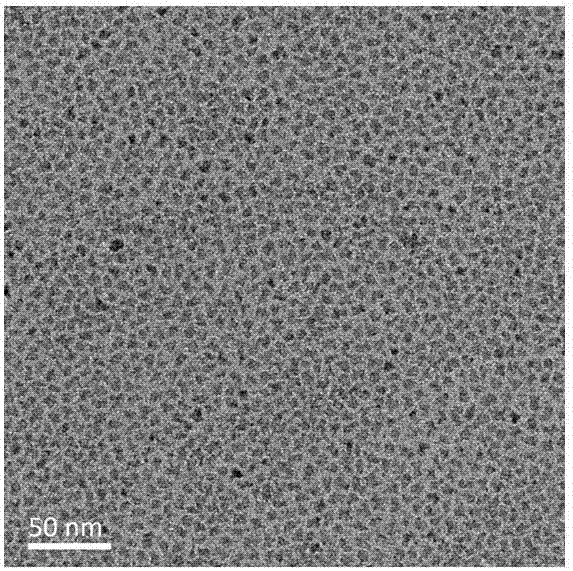

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of blue InP / ZnS core-shell quantum dots

[0040] (1) Mix 24 mmol tris(dimethylamino)phosphine and 60 mmol oleylamine at room temperature. The system was evacuated, stirred and heated to 80 o C, and maintain the reaction temperature for 30 min to obtain tris(dioleylamino)phosphine.

[0041] (2) Preparation of InCl 3 and ZnI 2 The oleylamine solution makes InCl 3 and ZnI 2 The concentrations are 0.068 and 0.440mol / L, respectively. The solution was stirred and heated to 150°C under vacuum o C, and maintain this temperature for 2 h.

[0042] (3) to the InCl 3 and ZnI 2 Inject inert gas in the reaction bottle of oleylamine solution, and system temperature is raised to 200 o C. Rapidly inject tris(dioleylamino)phosphine, and keep the molar ratio of indium halide to tris(dioleylamino)phosphine at 7:1, and maintain the temperature for 20 min.

[0043] (4) After preparing the InP quantum dot core, immediately inject the octadecene solution of n-...

Embodiment 2

[0050] Example 2: Preparation of green InP / ZnS core-shell quantum dots

[0051] (1) Mix 24 mmol tris(dimethylamino)phosphine and 60 mmol oleylamine at room temperature. The system was evacuated, stirred and heated to 80 o C, and maintain the reaction temperature for 30 min to obtain tris(dioleylamino)phosphine.

[0052] (2) Preparation of InCl 3 and ZnI 2 The oleylamine solution makes InCl 3 , ZnI 2and ZnCl 2 The concentrations are 0.068, 0.136 and 0.306mol / L, respectively. The solution was stirred and heated to 150°C under vacuum o C, and maintain this temperature for 2 h.

[0053] (3) to the InCl 3 and ZnI 2 Inject inert gas in the reaction bottle of oleylamine solution, and system temperature is raised to 200 o C. Rapidly inject tris(dioleylamino)phosphine, and keep the molar ratio of indium halide to tris(dioleylamino)phosphine at 7:1, and maintain the temperature for 20 min.

[0054] (4) After the InP quantum dot core is prepared, the octadecene solution of n-...

Embodiment 3

[0061] Example 3: Preparation of red InP / ZnS core-shell quantum dots

[0062] (1) Mix 24 mmol tris(dimethylamino)phosphine and 60 mmol oleylamine at room temperature. The system was evacuated, stirred and heated to 80 o C, and maintain the reaction temperature for 30 min to obtain tris(dioleylamino)phosphine.

[0063] (2) Preparation of InCl 3 and ZnI 2 The oleylamine solution makes InCl 3 , ZnCl 2 The concentrations are 0.068 and 0.440mol / L, respectively. The solution was stirred and heated to 150°C under vacuum o C, and maintain this temperature for 2 h.

[0064] (3) to the InCl 3 and ZnI 2 Inject inert gas in the reaction bottle of oleylamine solution, and system temperature is raised to 200 o C. Rapidly inject tris(dioleylamino)phosphine, and keep the molar ratio of indium halide to tris(dioleylamino)phosphine at 7:1, and maintain the temperature for 20 min.

[0065] (4) After the InP quantum dot core is prepared, the octadecene solution of n-dodecyl mercaptan a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com