Safe production technique for manufacturing high-purity phosphine on large scale

A technology for phosphine trihydrogen and safe production, applied in the direction of sustainable manufacturing/processing, chemical industry, phosphine, etc., to achieve the effect of reducing the entry of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

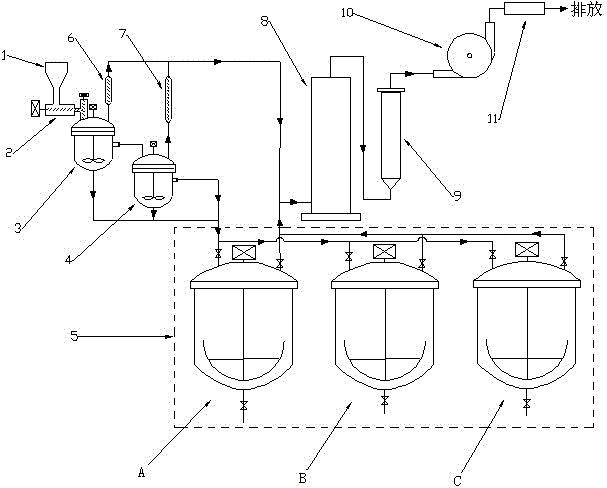

[0031] The processing steps of adopting above device to produce phosphine trihydride are as follows:

[0032] (1) Preparation for driving:

[0033] a) The low-temperature and low-pressure trapping purifier 8 is put into liquid nitrogen to keep its dehydration tank at -60°C and its storage tank at -150°C.

[0034] b) Put 6000 grams of aluminum phosphide powder into hopper 1, and use high-purity N 2 Replace to oxygen content <3PPM.

[0035] c) Inject deionized water into the first-stage reactor 3 and the second-stage reactor 4 to the overflow port, and start stirring.

[0036] (2) The reaction to produce phosphine trihydride:

[0037] a) Raise the temperature of the first-stage reactor 3 and the second-stage reactor 4 to 50°C, and start the vacuum pump 10 to control the first-stage reactor 3, the second-stage reactor 4 and the third-stage reactor 5 to 500-550mmHg.

[0038] b) Start the screw solid feeder 2, and feed aluminum phosphide with a purity greater than 85% into the ...

Embodiment 2

[0076] Adopt the safe production process device of large-scale preparation of phosphine trihydrogen of embodiment 1 to prepare phosphine trihydrogen, control the vacuum degree of the three-stage series reactor to be 500-600mmHg, wherein the first-stage reactor 3, the second-stage reactor 4 The temperature is 45-55°C, the temperature of the third-stage reactor 5 is 25°C, and the operating condition of the low-temperature and low-pressure trapping purifier 8 is an operating pressure of 500-600mmHg; operating temperature: purifier: -55°C; receiver: - 100°C; trap: -155°C, other control conditions are the same as in Example 1. The yield of the solid-state phosphorus trihydride trapped by the cryogenic trap is calculated by the same method as in Example 1: between 88-91% (weight).

Embodiment 3

[0078] The safety production process device of the large-scale preparation of high-purity phosphine trihydrogen in Example 1 is used to prepare phosphine trihydrogen,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com