Modified additive of lubricating oil

A lubricating oil and additive technology, applied in the field of lubricating oil, can solve the problem of single performance, achieve anti-mildew and antibacterial performance, superior flame retardancy, and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

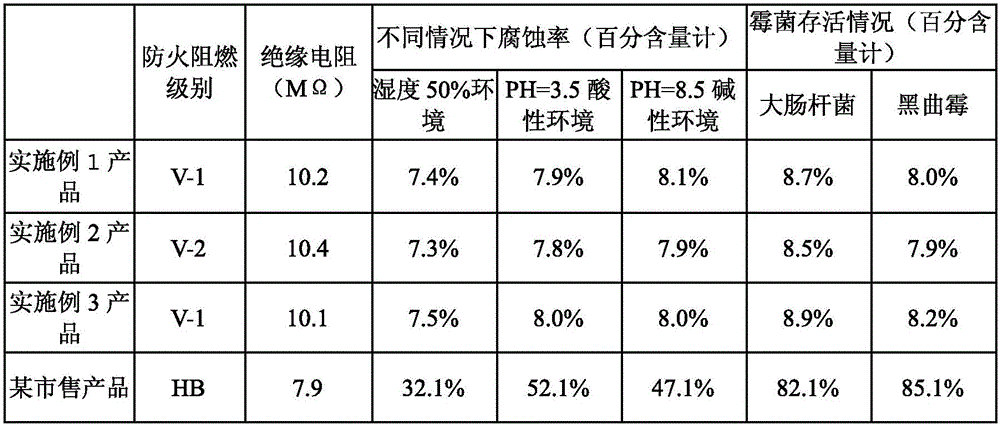

Examples

Embodiment 1

[0016] The lubricating oil modification additive in this embodiment consists of the following components in parts by mass: 14 parts of diphenylmethane diisocyanate, 12 parts of PVC resin powder, 12 parts of styrene-butadiene-styrene block copolymer 10 parts of ammonium polyphosphate, 12 parts of triethylene glycol diisocaprylate, 12 parts of p-cresol, 10 parts of polythiophene, 12 parts of benzalkonium chloride, 12 parts of oxazolidinone, 10 parts of aluminum phosphide , 10 parts of nano-chitin, 10 parts of nano-silver, 12 parts of bamboo pulp, 10 parts of trisodium phosphate, 8 parts of dolomite powder, 12 parts of camellia powder, 10 parts of sodium iodoacetate, 8 parts of clove, 10 parts of honey, fluorine titanium 8 parts of potassium acid potassium, 8 parts of modified attapulgite powder, 10 parts of olivine powder, 10 parts of pure acrylic emulsion, 10 parts of vinegar acrylic emulsion, 10 parts of butyl acetate, 10 parts of 2-mercaptobenzothiazole, 2 -10 parts of hydrox...

Embodiment 2

[0022] The lubricating oil modification additive in this embodiment consists of the following components in parts by mass: 16 parts of diphenylmethane diisocyanate, 14 parts of PVC resin powder, 14 parts of styrene-butadiene-styrene block copolymer 12 parts of ammonium polyphosphate, 14 parts of triethylene glycol diisocaprylate, 14 parts of p-cresol, 12 parts of polythiophene, 14 parts of benzalkonium chloride, 14 parts of oxazolidinone, 12 parts of aluminum phosphide , 12 parts of nano-chitin, 12 parts of nano-silver, 14 parts of bamboo pulp, 12 parts of trisodium phosphate, 10 parts of dolomite powder, 14 parts of camellia powder, 12 parts of sodium iodoacetate, 10 parts of clove, 12 parts of honey, fluorine titanium 10 parts of potassium acid potassium, 10 parts of modified attapulgite powder, 12 parts of olivine powder, 12 parts of pure acrylic emulsion, 12 parts of vinegar acrylic emulsion, 12 parts of butyl acetate, 12 parts of 2-mercaptobenzothiazole, 2 12 parts of -hy...

Embodiment 3

[0028] The lubricating oil modification additive in this embodiment consists of the following components in parts by mass: 18 parts of diphenylmethane diisocyanate, 16 parts of PVC resin powder, 16 parts of styrene-butadiene-styrene block copolymer 14 parts, ammonium polyphosphate 14 parts, triethylene glycol diisocaprylate 16 parts, p-cresol 16 parts, polythiophene 14 parts, benzalkonium chloride 16 parts, oxazolidinone 16 parts, aluminum phosphide 14 parts , 14 parts of nano-chitin, 14 parts of nano-silver, 16 parts of bamboo pulp, 14 parts of trisodium phosphate, 12 parts of dolomite powder, 16 parts of camellia powder, 14 parts of sodium iodoacetate, 12 parts of clove, 14 parts of honey, fluorine titanium 12 parts of potassium acid potassium, 12 parts of modified attapulgite powder, 14 parts of olivine powder, 14 parts of pure acrylic emulsion, 14 parts of vinegar acrylic emulsion, 14 parts of butyl acetate, 14 parts of 2-mercaptobenzothiazole, 2 14 parts of -hydroxy-4-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com