Technology for preparing phosphine by reacting aluminium phosphide with sulfuric acid

A technology of aluminum phosphide and sulfuric acid, applied in the direction of phosphine, etc., can solve problems such as pollution, and achieve the effect of convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

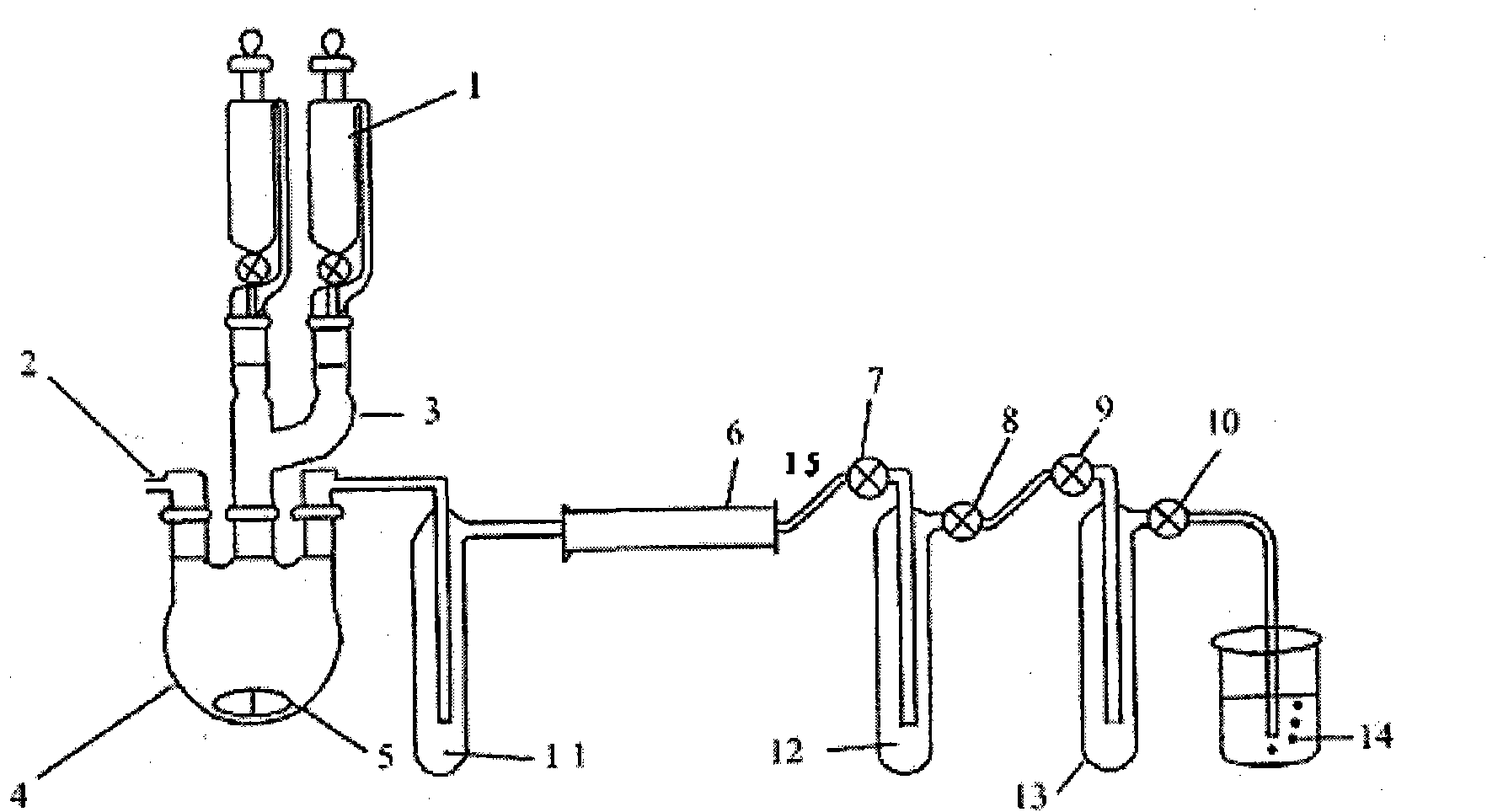

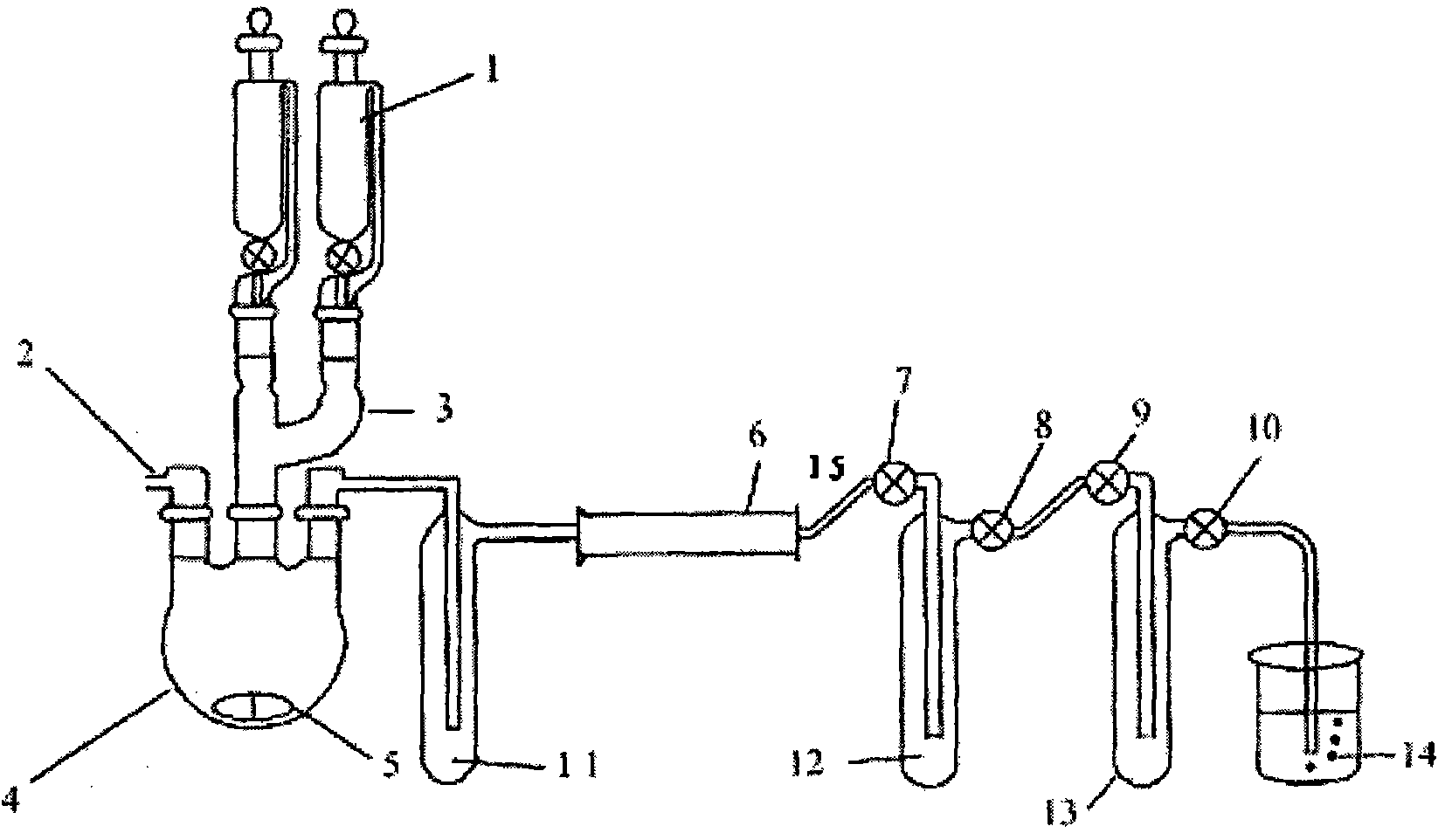

[0010] refer to figure 1 , the upper end of the integrated flask (4) is connected and installed with a constant pressure feeding funnel (1) through a connecting pipe (3), and a nitrogen inlet pipe (2) is connected and installed at the same time, and an electromagnetic heating stirrer ( 5), then, connect the KOH drying pipe (6), 1# piston (7), 2# piston (8), 3# piston (9), 4# piston (10), 1# through the connecting pipe (15) in sequence Catcher (11), 2# trap (12), 3# trap (13) and constitute.

[0011] When in use, an adapter (3) is installed on the flask (4) equipped with an electromagnetic heating stirrer (5), on which two constant-pressure feeding funnels (1) are inserted into aluminum phosphide, and then installed on the flask (4). The connected nitrogen inlet pipe (2) connects the pure nitrogen cylinder to supply nitrogen, and connects the gas outlet pipes of several cold traps through the connecting pipe (15). The first 1# catcher (11) cold trap is -78 ℃ (dry ice-acetone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com