Loctofen preparation method

A kind of technology of lactofaprin and preparation method, which is applied in the field of preparation method of the original medicine of lactofaprin, and achieves the effects of easy realization, high yield and high content of the original drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

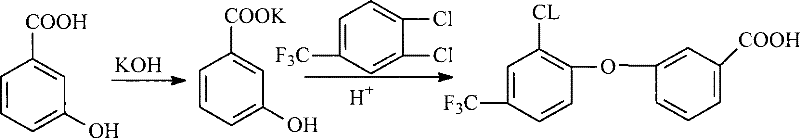

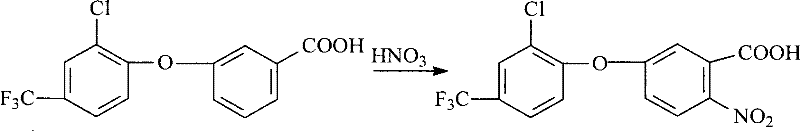

[0037] 1) Preparation of 3-[2-chloro-4-(trifluoromethyl)phenoxy]benzoic acid

[0038] In a 100L reactor, add 38.60Kg dimethyl sulfoxide (99%, 490mol) and put it into the reactor after metering, and add 10.10Kg potassium hydroxide (93%, 168mol) and 10.45Kg m-hydroxybenzene while stirring Formic acid (98%, 74.2 mol) was heated to 110° C. for a salt-forming reaction for 3 hours, and the water and part of the solvent generated by the reaction were removed under reduced pressure. Then add 3.45Kg anhydrous potassium carbonate (98%, 24.5mol) and 15.28Kg 3.4-dichlorobenzotrifluoride (98.5%, 70mol) in still, continue to heat up to 152-158 ℃, carry out condensation reaction, condensation reaction 20 -22 hours, the solvent dimethyl sulfoxide was removed. Add water to dissolve the remaining solids in the kettle, add concentrated hydrochloric acid dropwise to the solution for acidification to make PH=1-2, after the acidification is completed, carry out centrifugation, dry the wet product ...

Embodiment 2

[0045] 1) Preparation of 3-[2-chloro-4-(trifluoromethyl)phenoxy]benzoic acid

[0046] In a 100L reactor, add 38.60Kg dimethyl sulfoxide (99%, 490mol) and put it into the reactor after metering, and add 10.10Kg potassium hydroxide (93%, 168mol) and 10.45Kg m-hydroxybenzene while stirring Formic acid (98%, 74.2 mol) was heated to 110° C. for a salt-forming reaction for 3 hours, and the water and part of the solvent generated by the reaction were removed under reduced pressure. Then add 3.45Kg anhydrous potassium carbonate (98%, 24.5mol) and 15.28Kg 3.4-dichlorobenzotrifluoride (98.5%, 70mol) in still, continue to heat up to 152-158 ℃, carry out condensation reaction, condensation reaction 20 -22 hours, the solvent dimethyl sulfoxide was removed. Add water to dissolve the remaining solids in the tank, add concentrated hydrochloric acid dropwise to the solution for acidification to make PH = 1-2, after the acidification is completed, perform centrifugation, and dry the cake to ob...

Embodiment 3

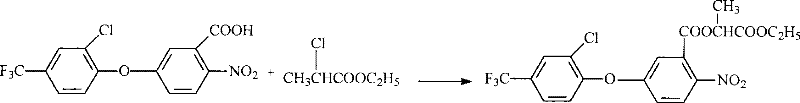

[0053] Repeat the same steps as described in Example 1, but from step 3): the preparation of lactofen-methyl: in a 100L reactor, add 73.25Kg2- ethyl chloropropionate (99%, 530mol), in Add 19.86Kg of 5-[2-chloro-4-(trifluoromethyl)phenoxy]-2-nitrobenzoic acid (91.0%, 50mol) under stirring, and heat up to 80-85°C to obtain solution A. In the reaction kettle, add 43.95Kg ethyl 2-chloropropionate (99%, 320mol) and 9.15Kg potassium carbonate (99%, 65mol), stir and heat up at 80-85°C to obtain solution B, and at 80-85°C, dissolve A solution Drop into solution B, add 0.2Kg tetrabutylammonium bromide at 90-95°C after the dropwise addition, and keep warm at 90-95°C for 6-8 hours, measure the reaction end point by HPLC, filter, and wash the filtrate with water To neutrality, the water layer was separated, and the excess ethyl 2-chloropropionate was removed from the oil layer to obtain 24.4Kg lactoforin, with a content of 87.3%, and a yield of 92.3%, based on 3.4-dichlorotrifluorotoluene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com