Method for selectively recycling lithium in waste lithium ion battery positive electrode material

A technology for lithium-ion batteries and cathode materials, which is applied in the field of selective recycling of lithium in the cathode materials of waste lithium-ion batteries, can solve the problems that qualified lithium carbonate products cannot be obtained and are not suitable for recycling, and achieve industrial processes that are easy to implement and difficult to remove Small, selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for selectively reclaiming lithium in waste lithium-ion battery cathode materials, comprising the steps of:

[0042] (1) Put the waste lithium iron phosphate cathode material in a high-temperature kiln at 1300°C into the air as an oxidant reaction, the iron in it is oxidized to trivalent, and add 50% of the waste cathode powder as a sodium sulfate additive during high-temperature oxidation , to realize the decomposition of the structure of the positive electrode material of the lithium ion battery;

[0043] (2) Leach the high-temperature oxide material obtained in step (1) in water, and obtain a lithium-rich solution and other element precipitates (iron phosphate precipitation) after filtering.

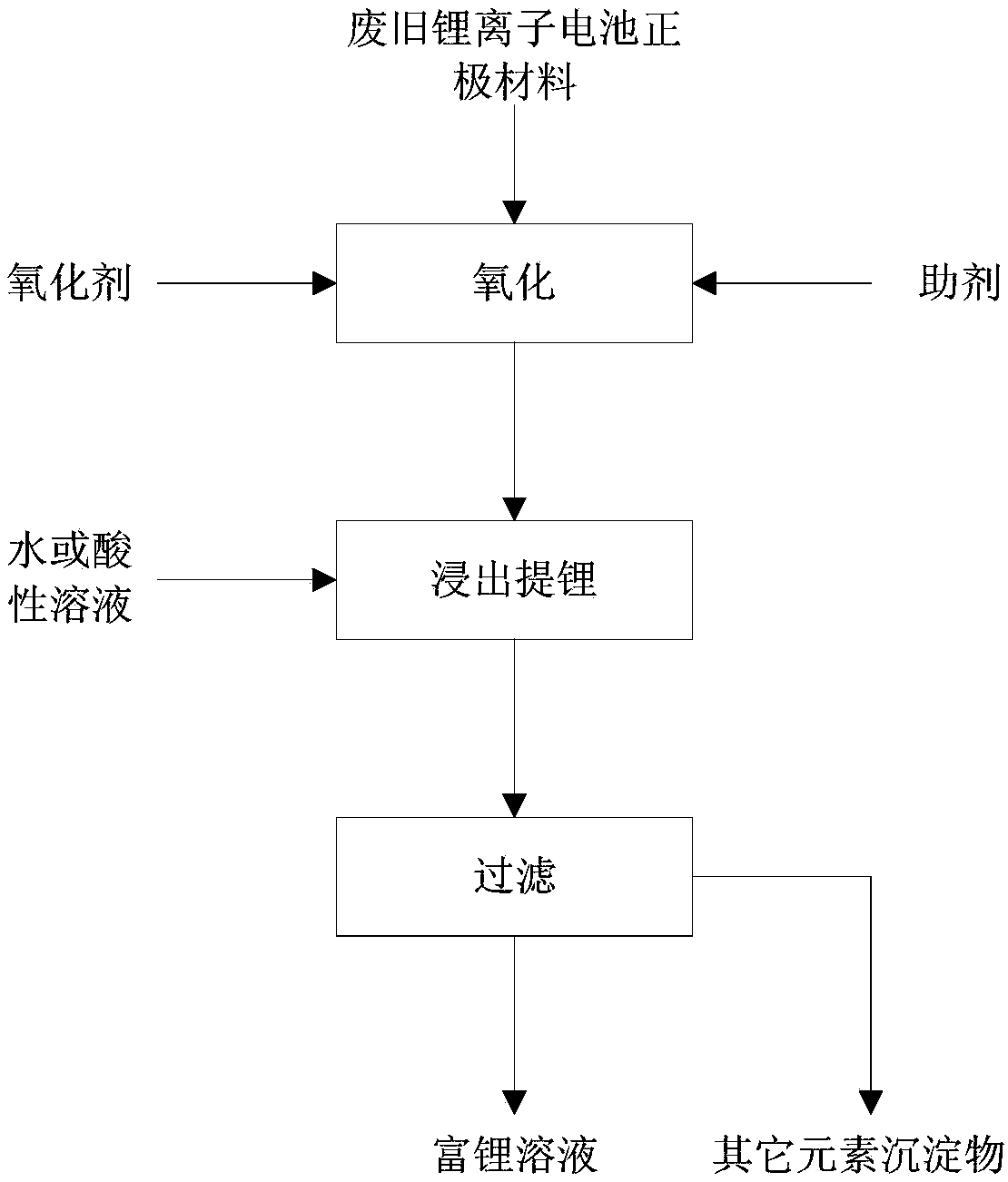

[0044] The process flow chart of the selective recovery of lithium in the positive electrode material of waste lithium-ion batteries provided by this embodiment is as follows figure 1 shown.

[0045] After sampling and diluting the lithium-rich solution, use inductiv...

Embodiment 2

[0047] A method for selectively reclaiming lithium in waste lithium-ion battery cathode materials, comprising the steps of:

[0048] (1) Feed the waste lithium iron phosphate positive electrode material into oxygen at 800°C and adopt a high-temperature solid-phase reaction, wherein the iron is oxidized to trivalent, and add potassium sulfate additive with 50% of the waste positive electrode powder during high-temperature oxidation, Realize the decomposition of the cathode material structure of lithium-ion batteries;

[0049] (2) Leaching the high-temperature oxide material obtained in step (1) in a hydrochloric acid solution with a pH value of 3, and filtering to obtain a lithium-rich solution and iron phosphate precipitation.

[0050] After sampling and diluting the lithium-rich solution, use inductively coupled plasma atomic emission spectrometry to measure the lithium concentration in the solution to be 10.5g / L, and iron and phosphorus are less than 0.5g / L; The content of ...

Embodiment 3

[0052] A method for selectively reclaiming lithium in waste lithium-ion battery cathode materials, comprising the steps of:

[0053] Mix the waste lithium iron phosphate cathode material with a certain amount of water, and add ammonium persulfate as the oxidant to react at 80°C by the liquid phase method to realize the coupling of iron oxidation and lithium leaching, and add sulfuric acid with 5% mass of the cathode material Ammonium is used as an auxiliary agent, the structure of the positive electrode material of the lithium-ion battery is decomposed, and lithium is leached; the reacted material is filtered to obtain a lithium-rich solution and iron phosphate precipitation.

[0054] After sampling and diluting the lithium-rich solution, use inductively coupled plasma atomic emission spectrometry to measure the concentration of lithium in the solution to be 12g / L, and iron and phosphorus are less than 0.5g / L; It is determined that the lithium content is less than 0.1%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com