Ultrahigh-wear-resistant sole material and manufacturing method thereof

A technology for shoe sole materials and manufacturing methods, which can be applied to shoe soles, footwear, applications, etc., and can solve the problems of difficult recycling and reuse of raw materials, insufficient resilience, and high specific weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

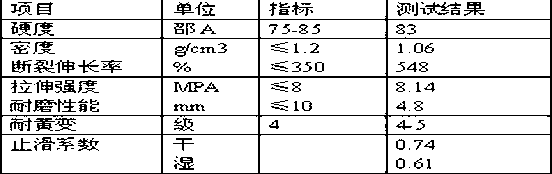

[0055] In the preferred embodiment of the super wear-resistant shoe sole material proposed by the present invention, the manufacture of the super wear-resistant shoe sole material may include but not limited to the raw materials of the following components by weight:

[0056] EPDM rubber: 65-70 parts;

[0057] Melting rubber: 25-30 parts;

[0058] White carbon black: 30-40 parts;

[0059] Softening oil: 5-10 parts;

[0060] Stearic acid: 1.5-2 parts;

[0061] Polyethylene glycol: 3-4 parts;

[0062] Antioxidant: 0.5 parts;

[0063] Black smoke glue: 15-20 parts;

[0064] High-performance wear-resistant agent: 4-6 parts;

[0065] Zinc oxide powder: 4-5 parts

[0066] Dicumyl peroxide: 1.5-2 parts;

[0067] Auxiliary cross-linking agent: 5-7 parts.

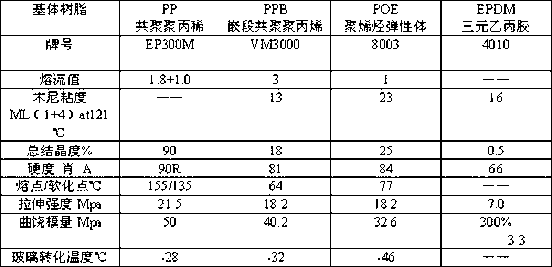

[0068] Among them, the composition of melted rubber:

[0069] Homopolypropylene: 300M 10 parts;

[0070] Block copolymerized polypropylene: 40 parts;

[0071] Ethylene octene copolymer: 50 parts.

[0072] Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com