Comprehensive recycling method of solid polymer electrolyte water-electrolysis membrane electrode

A solid polymer, electrolyzed water technology, used in recycling technology, fuel cell disposal/recycling, battery recycling, etc., can solve the problems of environmental pollution, reagent pollution, cumbersome process, etc. The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

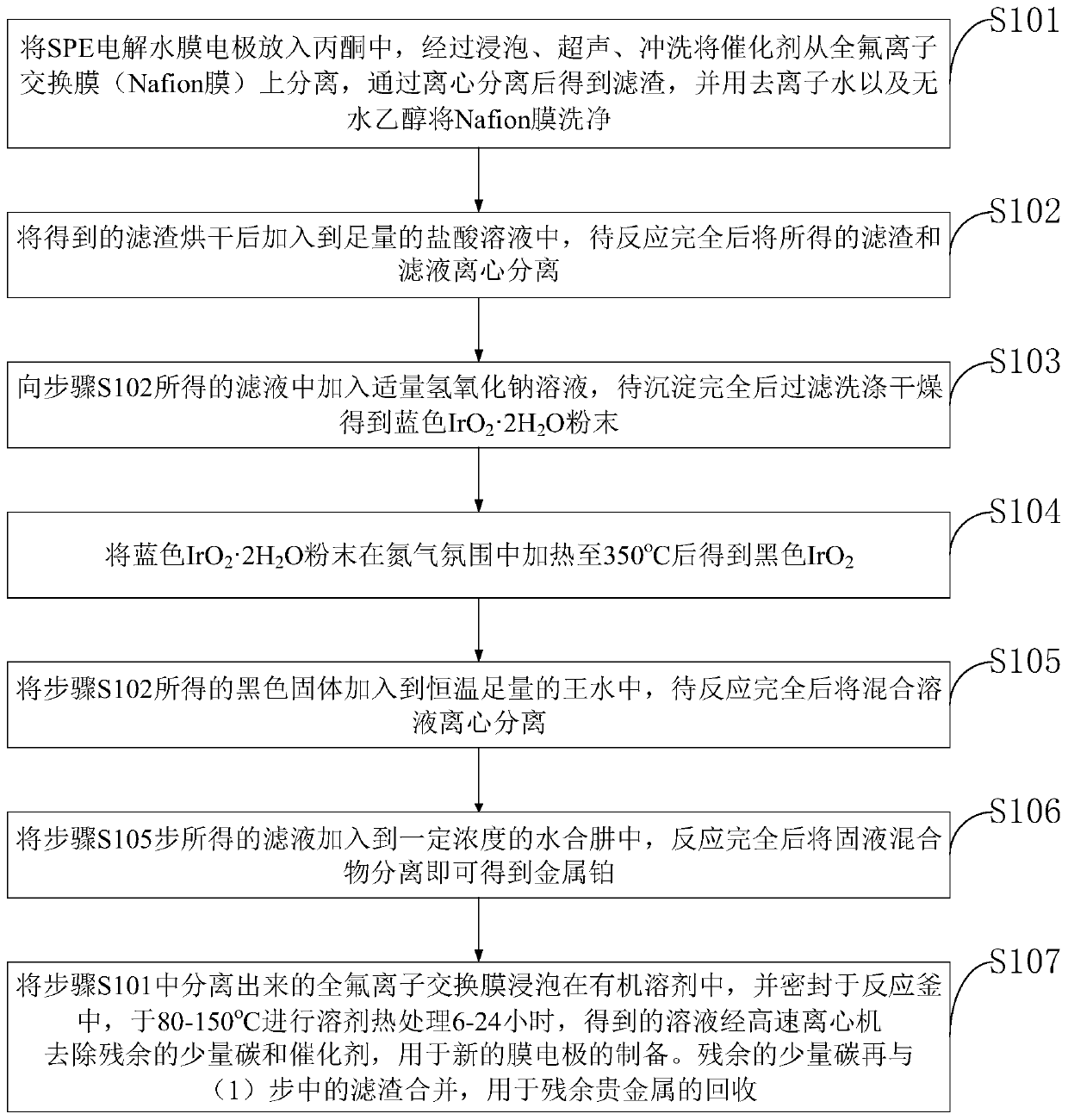

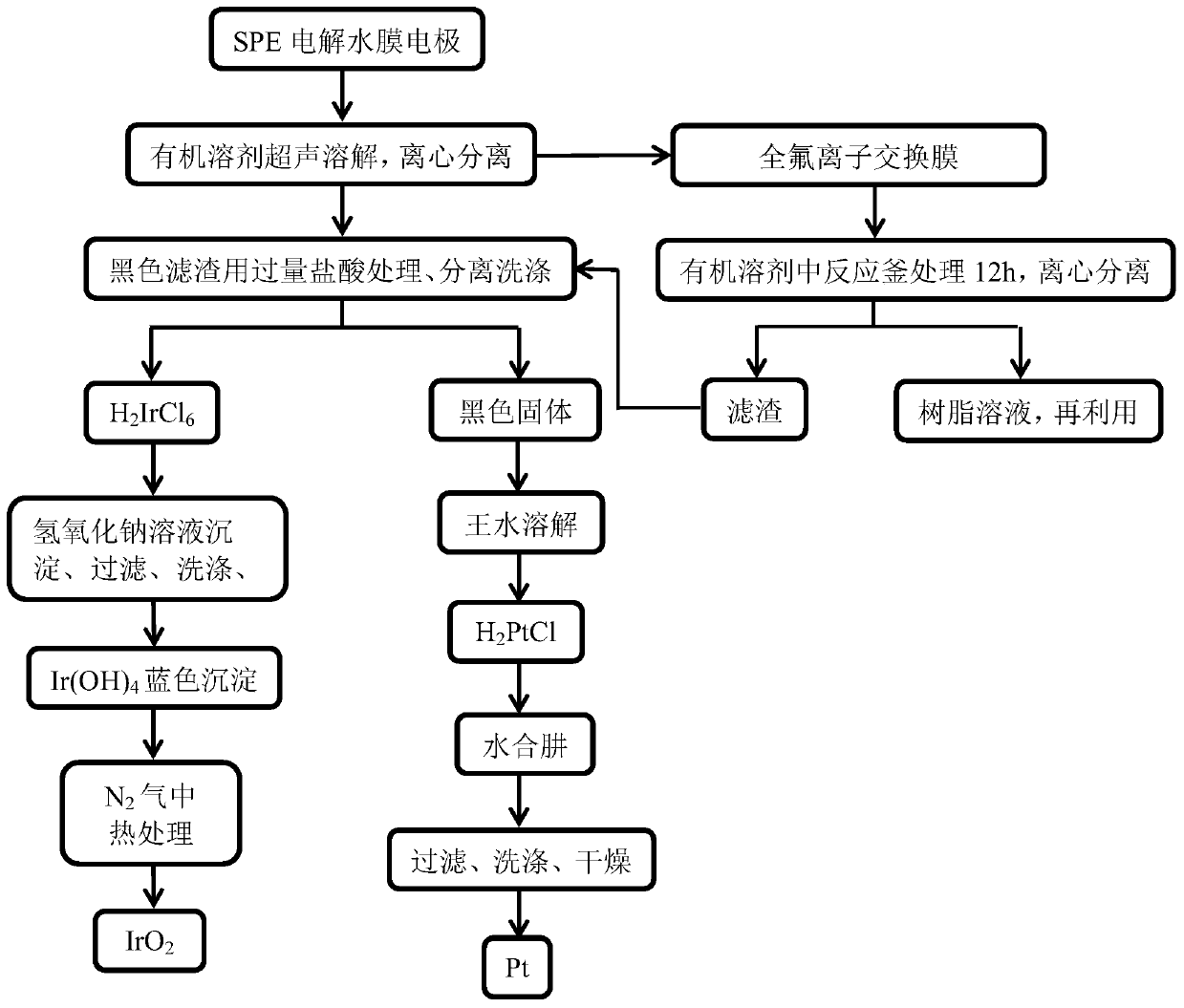

Method used

Image

Examples

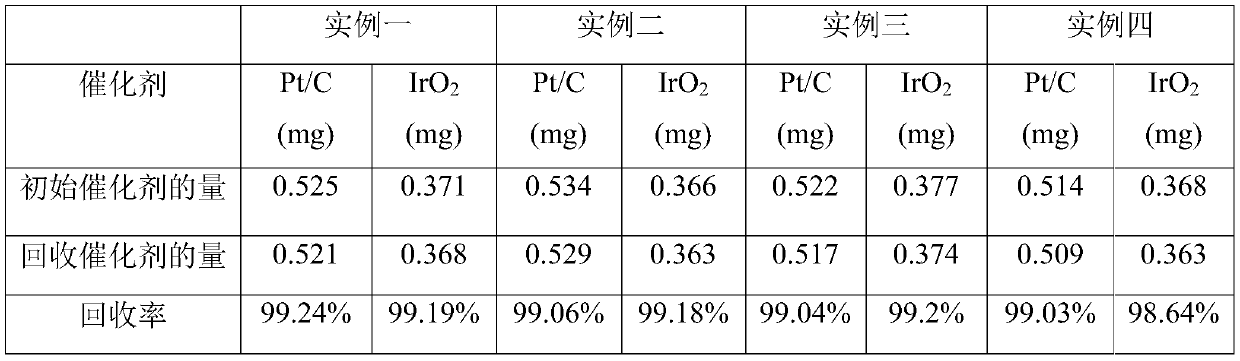

example 1

[0061] Soak the disassembled SPE electrolytic water membrane electrode in acetone for 2 hours, ultrasonic for 30 minutes, wait until the catalyst on the cathode and anode completely falls off the Nafion membrane, and obtain the filter residue by centrifugation. Wash the filter residue with water and ethanol, and dry the washed filter residue in a blast oven for standby use, the drying temperature is 60° C., and the drying time is 3 hours.

[0062] Add the dried filter residue to 6mol L -1 In the hydrochloric acid solution, the molar mass of hydrochloric acid is 8 times that of the filter residue. After fully reacting for 1 hour, the unreacted filter residue and the filtrate are centrifuged and separated. The filter residue produced in this step is also washed with deionized water and absolute ethanol. Dried in an air oven for subsequent use, the same drying temperature was 60°C, and the drying time was 3 hours.

[0063] Slowly add sodium hydroxide solution dropwise in the fil...

example 2

[0067] Soak the disassembled SPE water electrolysis membrane electrode in acetone for 1.5 hours, ultrasonic for 45 minutes, wait until the catalyst on the cathode and anode completely falls off the Nafion membrane, obtain the filter residue by centrifugation, use deionized water and anhydrous Wash the filter residue with water and ethanol, and dry the washed filter residue in a blast oven for standby use, the drying temperature is 70° C., and the drying time is 2.5 hours.

[0068] Add the dried filter residue to 5mol L -1 In the hydrochloric acid solution, the molar mass of hydrochloric acid is 10 times that of the filter residue. After fully reacting for 1 hour, the unreacted filter residue and the filtrate are centrifuged and separated. The filter residue produced in this step is also washed with deionized water and absolute ethanol. Dried in an air oven for subsequent use, the same drying temperature was 70°C, and the drying time was 2.5 hours.

[0069] Slowly add sodium h...

example 3

[0073] Soak the disassembled SPE electrolytic water membrane electrode in acetone for 1 hour, and ultrasonicate for 60 minutes. After the catalyst on the cathode and anode completely falls off from the Nafion membrane, obtain the filter residue by centrifugation, and use deionized water and anhydrous Wash the filter residue with water and ethanol, and dry the washed filter residue in a blast oven for standby use, the drying temperature is 80° C., and the drying time is 2 hours.

[0074] Add the dried filter residue to 4mol L -1 In the hydrochloric acid solution, the molar mass of hydrochloric acid is 12 times that of the filter residue. After fully reacting for 1 hour, the unreacted filter residue and the filtrate are centrifuged. The filter residue produced in this step is also washed with deionized water and absolute ethanol, and then the Dried in an air oven for subsequent use, the drying temperature was also 80° C., and the drying time was 2 hours.

[0075] Slowly add sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com