Nb-position Cr/Mo codoped bismuth-calcium niobate high-temperature piezoelectric ceramic material and preparation method therefor

A technology of calcium bismuth niobate and high temperature piezoelectricity is applied in the field of piezoelectric ceramic materials to achieve the effects of excellent piezoelectric performance, improved piezoelectric performance and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

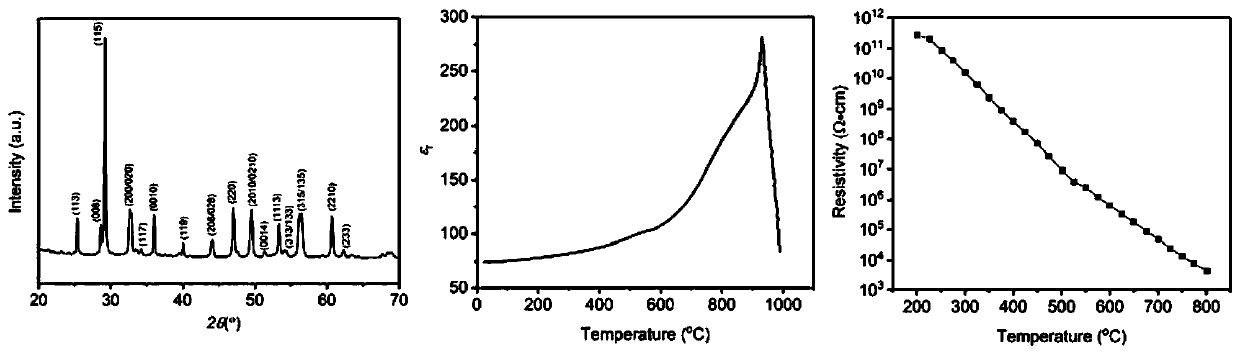

Embodiment 1

[0041] Prepare CaBi in accordance with chemical composition 2 Nb 2-x (Mo 2 / 3 Cr 1 / 3 ) x O 9 , X = 0.03 Cr / Mo co-doped modified calcium bismuth niobate (CaBi 2 Nb 2 O 9 ) Lead-free piezoelectric ceramics, including the following steps:

[0042] (1) Ingredients: CaCO 3 Powder, Bi 2 O 3 Powder, Nb 2 O 5 Powder, Cr 2 O 3 Powder and MoO 3 The powder is the raw material, and the ingredients are mixed according to the stoichiometry of Ca, Bi, Nb, Cr and Mo in the general formula;

[0043] (2) One-time ball milling: Add the same amount of absolute ethanol as the mixture to the above mixture, and continue the ball milling for 12 hours to mix the powder uniformly to form a slurry, which can further improve the bismuth calcium niobate high-temperature piezoelectric ceramic material Comprehensive performance;

[0044] (3) Drying: Put the above slurry in a constant temperature oven to bake, remove the absolute ethanol, and grind in a mortar to obtain a powder;

[0045] (4) Pre-burning of pressed t...

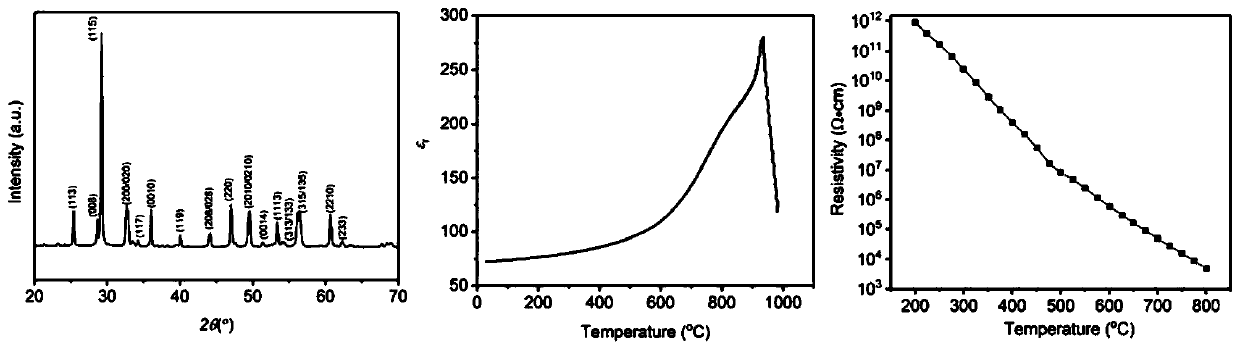

Embodiment 2

[0057] Prepare CaBi in accordance with chemical composition 2 Nb 2-x (Mo 2 / 3 Cr 1 / 3 ) x O 9 , X=0.04 Cr / Mo co-doped modified calcium bismuth niobate (CaBi 2 Nb 2 O 9 ) Lead-free piezoelectric ceramics, including the following steps:

[0058] (1) Ingredients: CaCO 3 Powder, Bi 2 O 3 Powder, Nb 2 O 5 Powder, Cr 2 O 3 Powder and MoO 3 The powder is the raw material, and the ingredients are mixed according to the stoichiometry of Ca, Bi, Nb, Cr and Mo in the general formula;

[0059] (2) One-time ball milling: Add the same amount of absolute ethanol as the mixture to the above mixture, and continue the ball milling for 12 hours to mix the powder uniformly to form a slurry, which can further improve the bismuth calcium niobate high-temperature piezoelectric ceramic material Comprehensive performance;

[0060] (3) Drying: Put the above slurry in a constant temperature oven to bake, remove the absolute ethanol, and grind in a mortar to obtain a powder;

[0061] (4) Pre-burning of pressed tab...

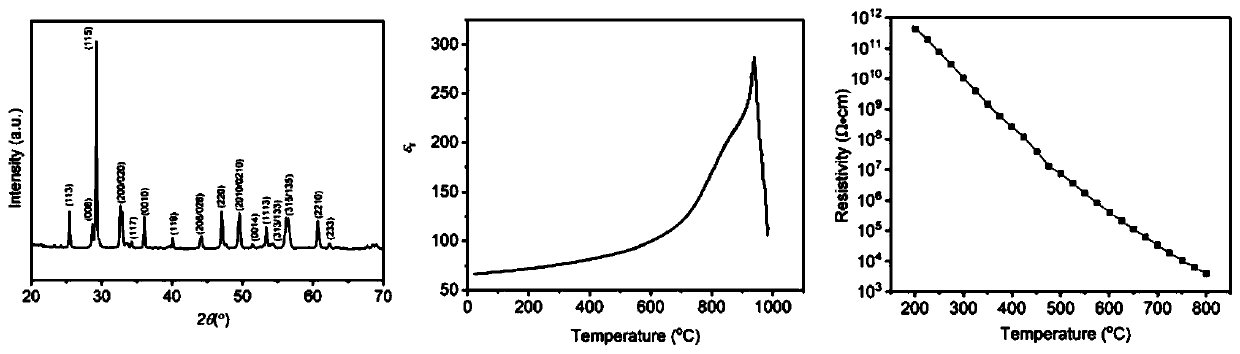

Embodiment 3

[0073] Prepare CaBi in accordance with chemical composition 2 Nb 2-x (Mo 2 / 3 Cr 1 / 3 ) x O 9 , X=0.05 Cr / Mo co-doped modified calcium bismuth niobate (CaBi 2 Nb 2 O 9 ) Lead-free piezoelectric ceramics, including the following steps:

[0074] (1) Ingredients: CaCO 3 Powder, Bi 2 O 3 Powder, Nb 2 O 5 Powder, Cr 2 O 3 Powder and MoO 3 The powder is the raw material, and the ingredients are mixed according to the stoichiometry of Ca, Bi, Nb, Cr and Mo in the general formula;

[0075] (2) One-time ball milling: Add the same amount of absolute ethanol as the mixture to the above mixture, and continue the ball milling for 12 hours to mix the powder uniformly to form a slurry, which can further improve the bismuth calcium niobate high-temperature piezoelectric ceramic material Comprehensive performance;

[0076] (3) Drying: Put the above slurry in a constant temperature oven to bake, remove the absolute ethanol, and grind in a mortar to obtain a powder;

[0077] (4) Pre-burning of pressed tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com