Green method for recycling lithium in cathode materials

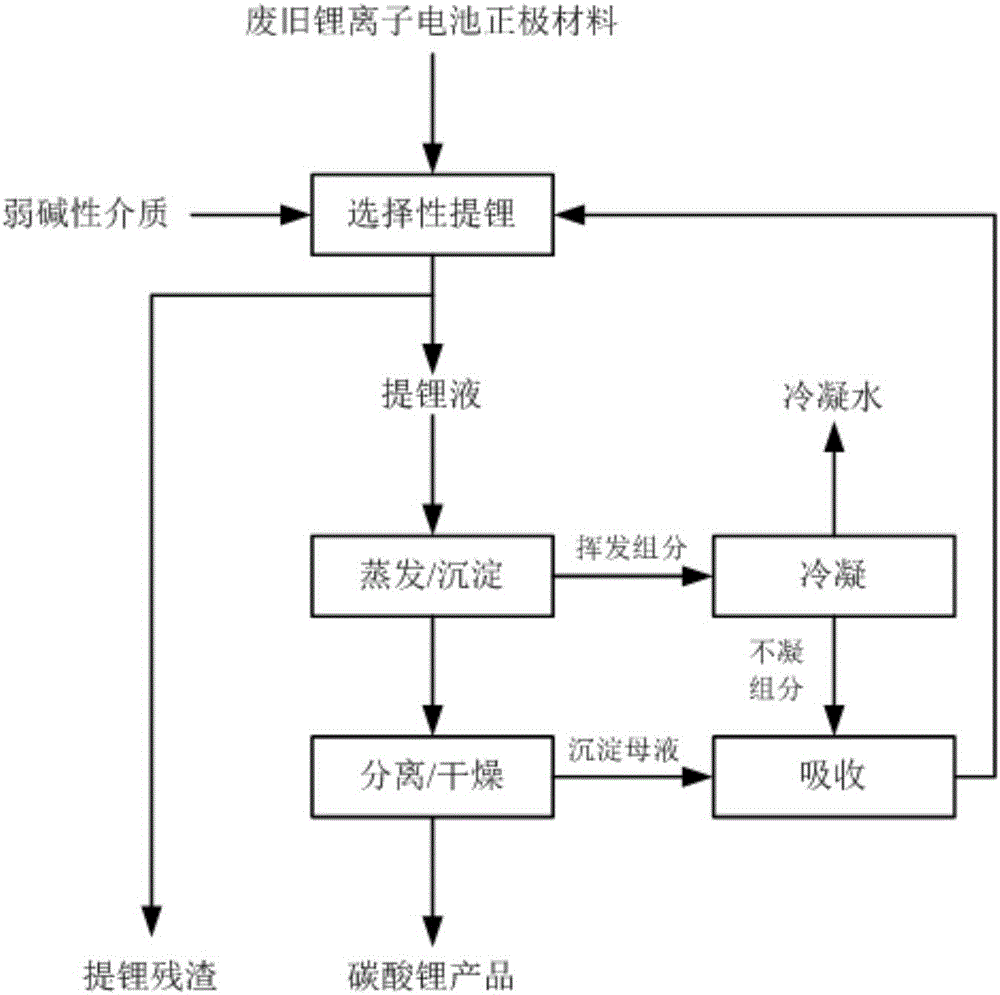

A technology for positive electrode materials and materials, which is applied in the field of lithium in the positive electrode materials of clean and recycled waste lithium ion batteries, can solve the problems that qualified lithium carbonate products cannot be obtained and are not suitable for recycling, and it is difficult to achieve deep purification, small removal difficulty, and transformation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for reclaiming lithium in waste lithium iron phosphate cathode material, comprising the steps of:

[0039] (1) Mix the waste lithium iron phosphate positive electrode material separated from the aluminum current collector with water, add ammonium bicarbonate under stirring conditions, so that the concentration of ammonium bicarbonate after mixing is 50g / L, and the volume-to-mass ratio of liquid to solid (L / kg) is 15; after the above operations are completed, the reactor is closed, carbon dioxide gas is introduced, and the leaching of lithium in the positive electrode material is realized under the condition that the pressure of the reactor is 0.2 MPa and the reaction temperature is 15 ° C, and the liquid-solid separation of the material after the reaction is carried out. Obtain lithium extraction solution and lithium extraction residue;

[0040] (2) Evaporate the lithium extraction solution at 60°C, and when the volatile components escape, lithium carbonate is ...

Embodiment 2

[0043] A method for reclaiming lithium in waste nickel-cobalt lithium manganese oxide positive electrode material, comprising the steps:

[0044] (1) Mix the waste nickel-cobalt-lithium-manganese-manganese-oxide positive electrode material separated from the aluminum current collector with water, add sodium bicarbonate under stirring conditions, so that the concentration of sodium bicarbonate after mixing is 250g / L, and the volume-to-mass ratio of liquid to solid (L / kg) is 5; after the above operations are completed, the reactor is closed, carbon dioxide gas is introduced, and the leaching of lithium in the positive electrode material is realized under the condition that the pressure of the reactor is 0.5MPa and the reaction temperature is 40°C, and the liquid-solid separation of the material after the reaction is carried out. , to obtain the lithium extraction solution and the lithium extraction residue respectively;

[0045] (2) Evaporate the lithium extraction solution at ...

Embodiment 3

[0048] A method for reclaiming lithium in spent lithium cobalt oxide cathode materials, comprising the steps of:

[0049] (1) Mix the waste lithium cobaltate positive electrode material separated from the aluminum current collector with water, add ammonia water under stirring conditions, so that the concentration of ammonia water after mixing is 100g / L, and the liquid-solid volume-to-mass ratio (L / kg) is 10; complete After the above operation, the reactor is closed, carbon dioxide gas is introduced, and the lithium in the positive electrode material is leached under the conditions of the reactor pressure of 0.8MPa and the reaction temperature of 90°C, and the liquid-solid separation of the reacted material to obtain the lithium extraction solution respectively. and lithium extraction residue;

[0050] (2) Evaporate the lithium extraction solution at 100°C. When the volatile components are released, lithium carbonate is precipitated synchronously. Lithium carbonate is separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com