Flame-retardant and electromagnetic interference attenuating thermoplastic resin compsn

A thermoplastic resin and composition technology, applied in the field of flame retardant and electromagnetic wave shielding thermoplastic resin composition, can solve the problem of inability to obtain flame retardancy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

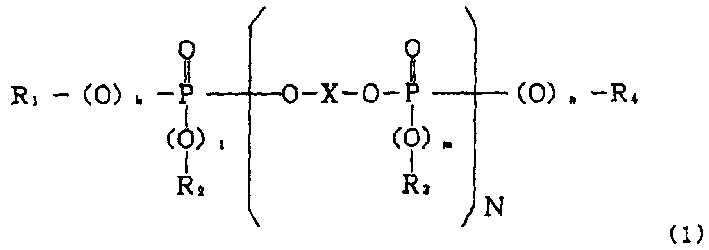

Method used

Image

Examples

Embodiment 1-5 and comparative Embodiment 1-7

[0061] The above components (A) to (E) were mixed in respective ratios shown in Table 1, and the mixture was melted and kneaded with a twin-screw extruder to obtain pellets. The obtained pellets were molded into each test piece with an injection molding machine, and then each evaluation was performed. The results are given in Table 1.

[0062] Example

[0063] As mentioned above, the flame retardant and electromagnetic wave shielding thermoplastic resin composition of the present invention has excellent flame retardancy, good appearance, and excellent molding fluidity, so it can be suitable for fields requiring flame retardancy and electromagnetic wave shielding performance, Used in such as household appliances, OA equipment and electric or electronic equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com