Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

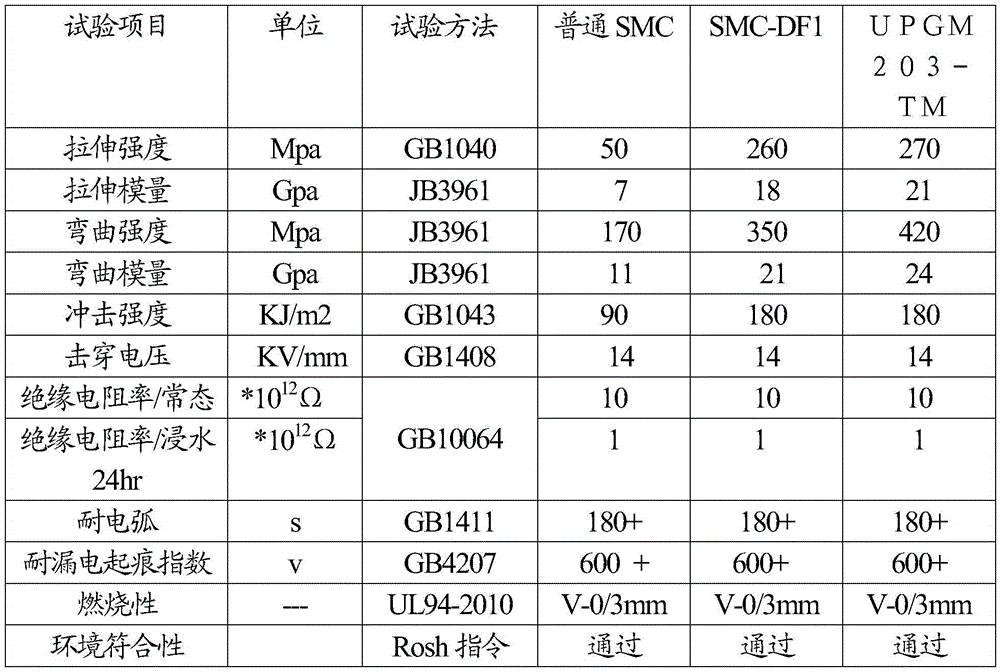

A sheet molding compound, polyester resin technology, applied in the field of composite materials, can solve the problems of low tensile strength, bending strength and impact strength, poor mechanical properties, can not effectively meet application requirements, etc., to improve mechanical properties, shrink Insulation distance, excellent unidirectional high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

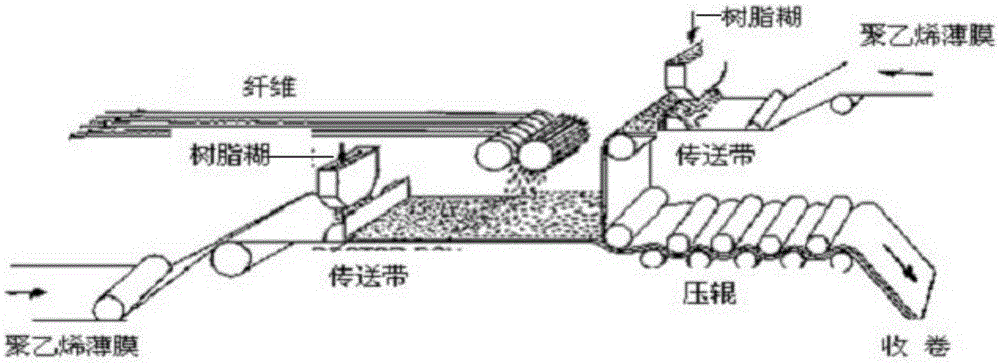

[0032] Such as figure 1 Shown, a kind of unsaturated polyester resin fiber reinforced sheet molding compound preparation method is characterized in that, preparation step comprises:

[0033] A. Filler modification: Put the aluminum hydroxide powder into the high-speed mixer, spray one or more of silane coupling agent, aluminate coupling agent, and wetting and dispersing agent, and the speed of the high-speed mixer is 2000~ 4000r / min, keep mixing for 10-15min, the temperature rises to 125°C and keep warm for 10min, then pack into bags for later use to obtain the filler of modified aluminum hydroxide;

[0034] B. Preparation of resin paste: Add unsaturated polyester resin, low shrinkage agent, auxiliary agent, and curing agent into the mixing tank and stir evenly, then add filler, flame retardant synergist, thickener, release agent, reinforcement in step A Materials and colorants are dispersed at high speed, and the viscosity is controlled not to exceed 80,000 centipoise to obt...

Embodiment 1

[0038] Formula: 10-20 parts of phthalic resin, 5-10 parts of polystyrene low-shrinkage agent, 0.3 parts of tert-butyl peroxybenzoate, 1-2 parts of zinc stearate, 40-50 parts of aluminum hydroxide, BYK One part of wet dispersant 9010, 0.5 part of magnesium oxide, 30-60 parts of 1-inch alkali-free chopped glass fiber.

[0039] Process: According to the formula, add o-phthalic resin, polystyrene low shrinkage agent, BYK wetting and dispersing agent 9010, tert-butyl peroxybenzoate to disperse for 1-3min, add zinc stearate, hydroxide at 500-900r / min Aluminum 20min, add magnesium oxide 1200r / min to disperse for 3min. Put the uniformly dispersed resin paste into the upper and lower slots of the SMC unit, evenly scrape it on the polyethylene film that is loaded up and down, evenly sprinkle 1 inch chopped glass fiber on the resin paste, and send it into the pressure roller to press and soak , rewinding and sent to the aging room at 45°C, aging for 24-72 hours until it is not sticky an...

Embodiment 2

[0042] Formula: 10-20 parts of m-benzene resin, 5-10 parts of polystyrene low-shrinkage agent, 0.3 parts of tert-butyl peroxybenzoate, 1-2 parts of zinc stearate, 40-50 parts of aluminum hydroxide, MC resistance 2-8 parts of fuel, 1 part of BYK wetting and dispersing agent 9010, 0.5 parts of magnesium oxide, 30-60 parts of 1-inch alkali-free chopped glass fiber.

[0043] Process: According to the formula, add isophthalic resin, polystyrene low shrinkage agent, BYK wetting and dispersing agent 9010, tert-butyl peroxybenzoate to disperse for 1-3min, add zinc stearate, hydroxide at 500-900r / min Aluminum and MC flame retardant for 20 minutes, adding magnesium oxide 1200r / min to disperse for 3 minutes. Put the uniformly dispersed resin paste into the upper and lower slots of the SMC unit, evenly scrape it on the polyethylene film that is loaded up and down, evenly sprinkle 1 inch chopped glass fiber on the resin paste, and send it into the pressure roller to press and soak , rewin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com