Organism single layer protecting metal-group foam material, and its preparing method

A technology of foam materials and organic matter, which is applied in the field of organic single-layer protective gold cluster foam materials and its preparation, can solve the problems of foam material doping uniformity, metal powder aggregation, etc., and achieve easy control, peaceful process conditions, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] First, 1 part of water-soluble mercaptosuccinic acid-protected gold MPC was dissolved in 10 parts of distilled water, and then the gold MPC aqueous solution was cast into a mold, and left at room temperature for 0.5 hours. Use liquid nitrogen vapor to freeze the gold MPC aqueous solution sample in the mold axially from the bottom up. After 30 minutes, put the frozen sample into the freezer chamber (about -20°C) of the freeze dryer instrument to maintain the frozen state, and lower the freeze dryer instrument. After reaching 100 Pa, keep the vacuum of the freezer for 30 minutes; keep the vacuum of the freezer constant, raise the temperature to room temperature at a rate of 1°C / min, and keep it for 7 days to ensure that the solvent in the foam system is completely dry. The dried foam material is demoulded to obtain a water-soluble organic single-layer protected gold cluster foam material. The resulting foam has poor density uniformity and is relatively dense at the bottom...

Embodiment 2

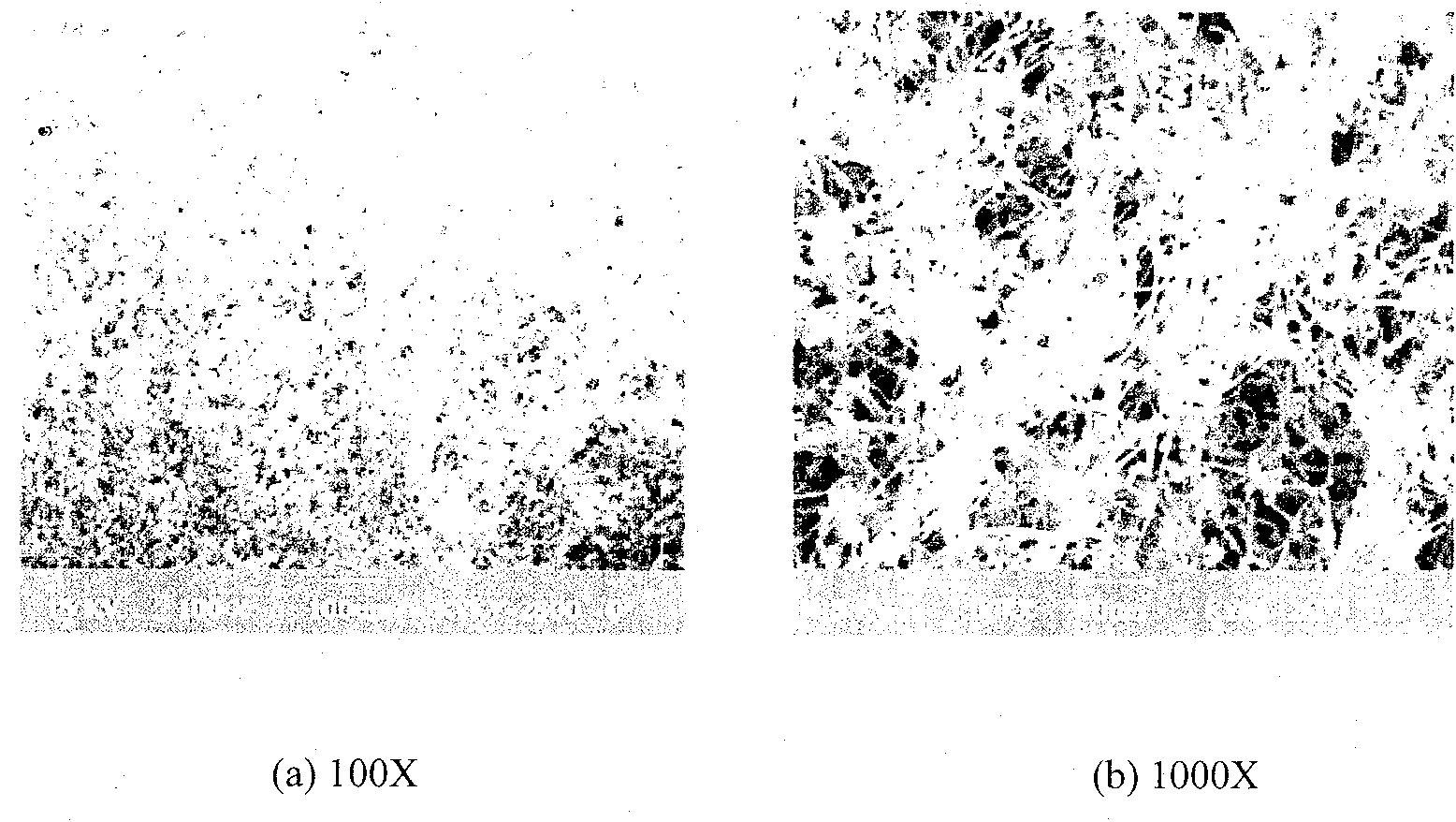

[0045] Firstly, 1 part of water-soluble mercaptosuccinic acid-protected gold MPC was dissolved in 14 parts of distilled water, and then the gold MPC aqueous solution was cast into a mold and left at room temperature for 5 hours. Use liquid nitrogen vapor to freeze the gold MPC aqueous solution sample in the mold axially from the bottom up. After 30 minutes, put the frozen sample into the freezer chamber (about -20°C) of the freeze dryer instrument to maintain the frozen state, and lower the freeze dryer instrument. After reaching 100 Pa, keep the vacuum of the freezer for 30 minutes; keep the vacuum of the freezer constant, raise the temperature to room temperature at a rate of 1°C / min, and keep it for 7 days to ensure that the solvent in the foam system is completely dry. The dried foam material is demoulded to obtain a water-soluble organic single-layer protected gold cluster foam material. The resulting foam has a bulk density of approximately 74 mg / cm 3 , the uniformity o...

Embodiment 3

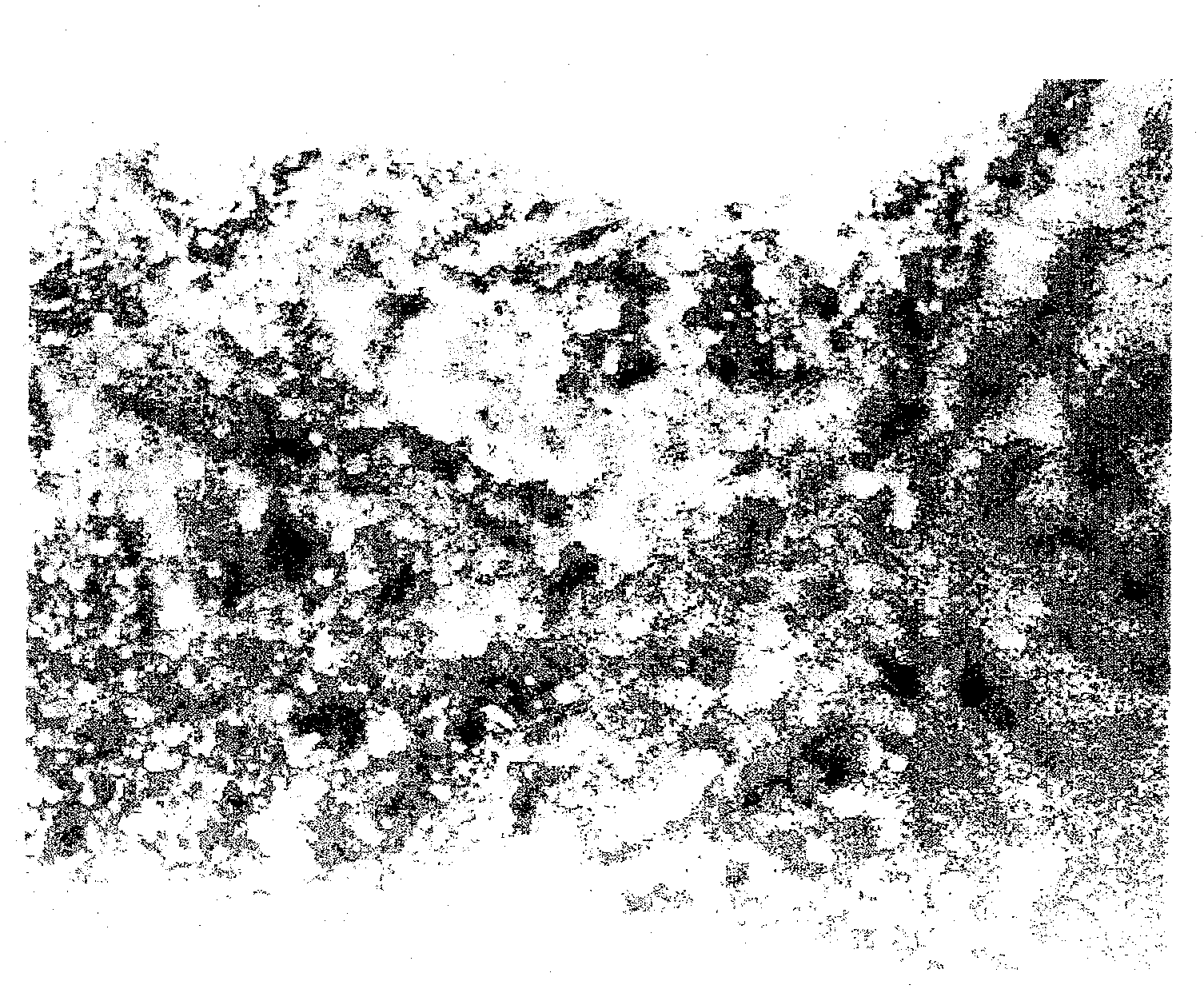

[0047] Firstly, 1 part of water-soluble mercaptosuccinic acid-protected gold MPC was dissolved in 20 parts of distilled water, and then the gold MPC aqueous solution was cast into a mold and left at room temperature for 10 hours. Use liquid nitrogen vapor to freeze the gold MPC aqueous solution sample in the mold axially from the bottom up. After 30 minutes, put the frozen sample into the freezer chamber (about -20°C) of the freeze dryer instrument to maintain the frozen state, and lower the freeze dryer instrument. After reaching 100 Pa, keep the vacuum of the freezer for 30 minutes; keep the vacuum of the freezer constant, raise the temperature to room temperature at a rate of 1°C / min, and keep it for 7 days to ensure that the solvent in the foam system is completely dry. The dried foam material is demoulded to obtain a water-soluble organic single-layer protected gold cluster foam material. The resulting foam has a bulk density of approximately 54 mg / cm 3 , good density un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com