Carbon-sulfur composite material, preparation method thereof and lithium-sulfur battery

A technology of composite materials and composite methods, which is applied in the field of sulfur-carbon composite materials and their preparation, can solve problems such as poor electrical properties, achieve good adsorption and catalytic functions, increase sulfur loading capacity, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

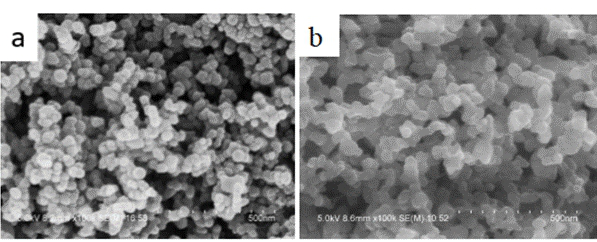

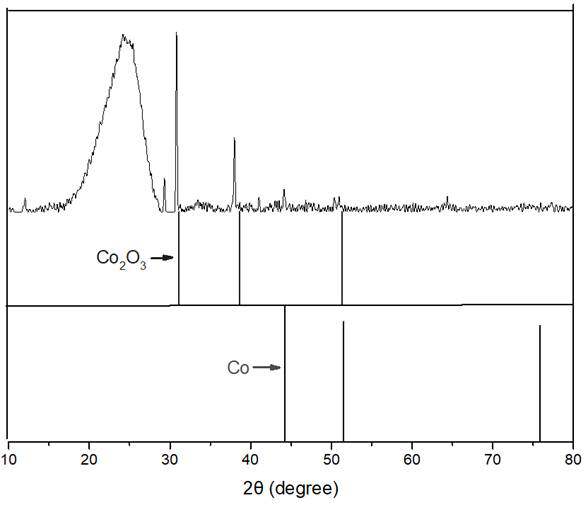

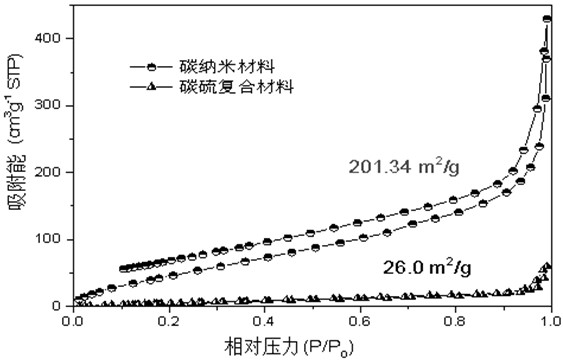

[0058] A carbon-sulfur composite material, comprising a porous carbon matrix and sulfur particles supported in situ with metals and their compounds, composed of figure 1 It can be seen that the porous carbon matrix is composed of interconnected nano-carbon particles, and the sulfur particles are dispersed among the nano-carbon particles, and the sulfur particles are partially filled in the pores of the porous carbon matrix and partially covered on the surface of the nano-carbon particles; it can be seen from the XRD analysis ( figure 2 ), the metals and their compounds are Co and Co 2 O 3 A mixture of Co and Co 2 O 3 The particle size of the sulfur particles is 50-80nm, and the weight content of the sulfur particles in the carbon-sulfur composite material is 90%; the particle size of the nano-carbon particles is 20-50nm; the porous carbon The matrix is a hierarchical porous carbon matrix; the porous structure of the hierarchical porous carbon matrix is mainly mesopor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com