A kind of inorganic bonding system for water-based environment-friendly brazing flux and its application

An inorganic bonding and brazing flux technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as easy to produce open flame bonding force, easy volatilization of organic matter, poisonous human body, etc., and achieve strong bonding force and environmental protection Good performance, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

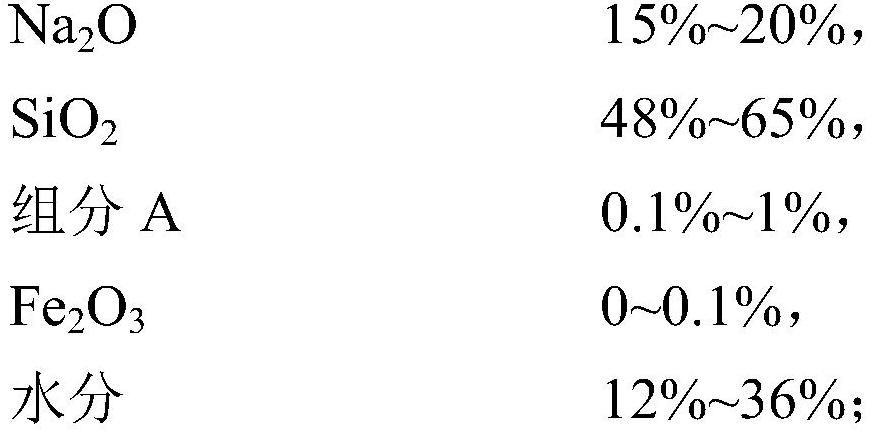

[0037] With the total mass of 100%, the inorganic bonding system with aqueous environmentally friendly flux includes the following components:

[0038]

[0039] Components A include CaO and MgO, the mass ratio of CaO and MgO is 1: 1.

[0040] The above components are uniformly mixed with the inorganic bonding system of the aqueous environmental flux.

[0041] The inorganic bonding system of the FB101 flux (JB / T 6045-2017) and the water-based greening agent is mixed with a mass ratio of 1: 2.

[0042] The above solder was sprayed to the surface of the solder surface and dried at 120 to 140 ° C. The thickened skin thickness of the obtained pharmaceutical solder was 0.25 mm, and the mass percentage of the powder of the solder was 8% to 12%.

Embodiment 2

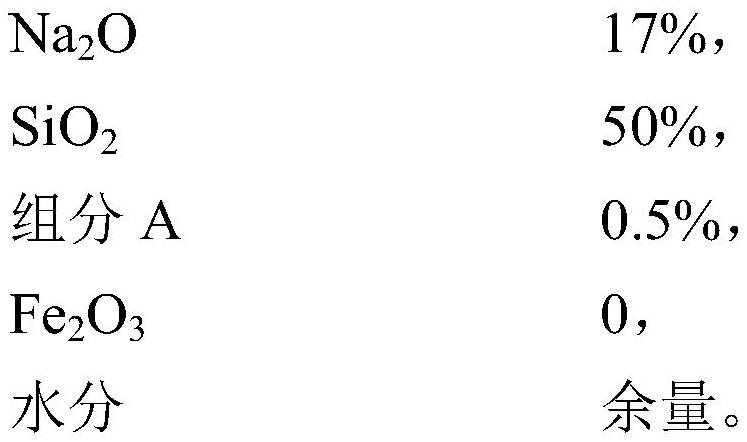

[0051] With the total mass of 100%, the inorganic bonding system with aqueous environmentally friendly flux includes the following components:

[0052]

[0053] Components A include CaO and MgO, the mass ratio of CaO and MgO is 1: 1.

[0054] The above components are uniformly mixed with the inorganic bonding system of the aqueous environmental flux.

[0055] The inorganic bonding system of the FB101 flux (JB / T 6045-2017) and the water-based greening agent is mixed with a mass ratio of 1: 2.

[0056] The above solder was sprayed to the surface of the solder surface and dried at 120 to 140 ° C. The thickened skin thickness of the obtained pharmaceutical solder was 0.35 mm, and the mass percentage of the powder of the solder was 12% to 15%.

Embodiment 3

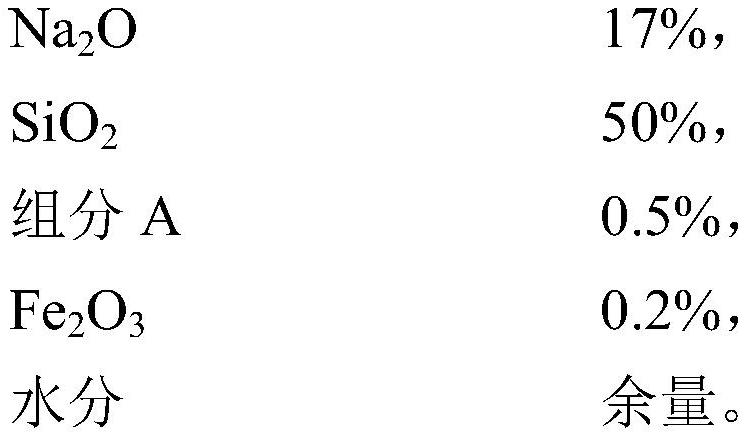

[0066] With the total mass of 100%, the inorganic bonding system with aqueous environmentally friendly flux includes the following components:

[0067]

[0068] Component A includes CaO and MgO, the mass ratio of the CaO and MgO is 1: 2.

[0069] The above components are uniformly mixed with the inorganic bonding system of the aqueous environmental flux.

[0070] The inorganic bonding system of the FB101 flux (JB / T 6045-2017) and the water-based greening agent is mixed with a mass ratio of 1: 2.

[0071] The above solder was sprayed to the surface of the solder surface and dried at 120 to 140 ° C. The thickened skin thickness of the obtained pharmaceutical solder was 0.25 mm, and the mass percentage of the powder of the solder was 8% to 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com