Patents

Literature

62results about How to "Good shedding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano composition with hair loss preventing, hair growing, hair fixing and hair blackening functions as well as preparation method and application thereof

PendingCN112516006ASingle anti-off mechanismPoor anti-shedding effectCosmetic preparationsHair cosmeticsCholesterolPolythylene glycol

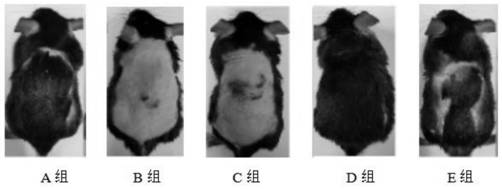

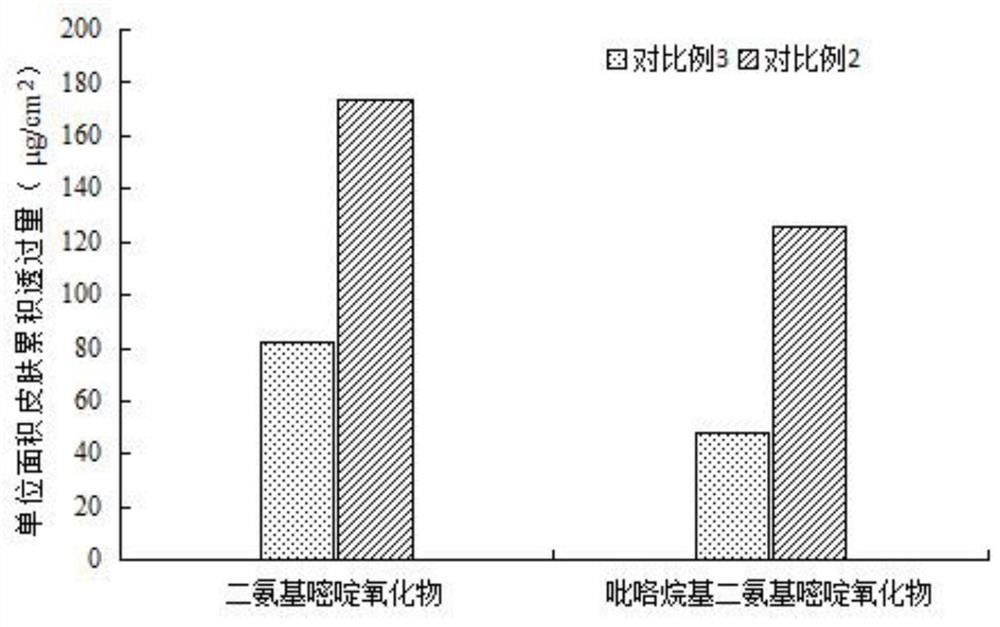

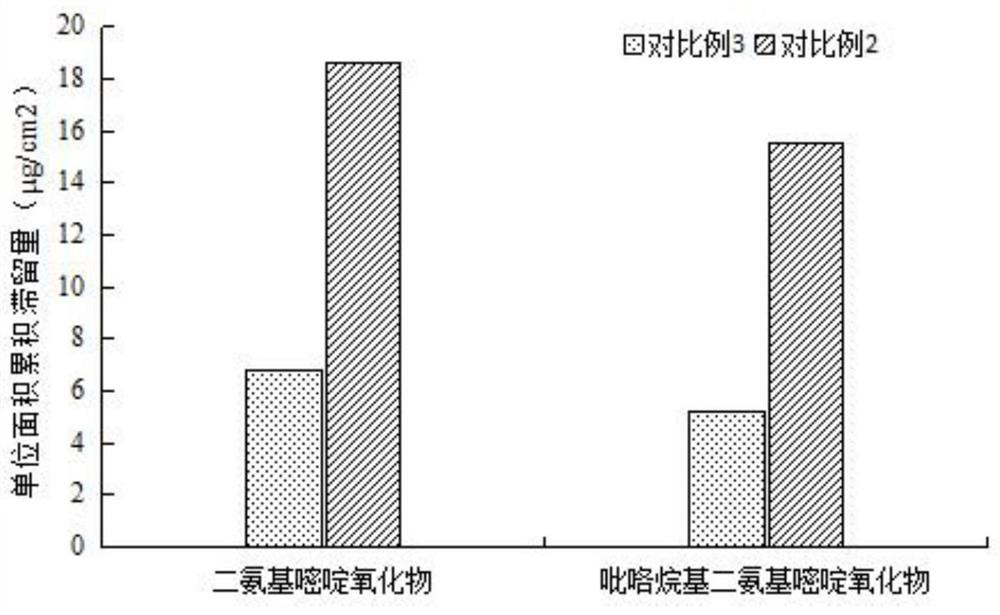

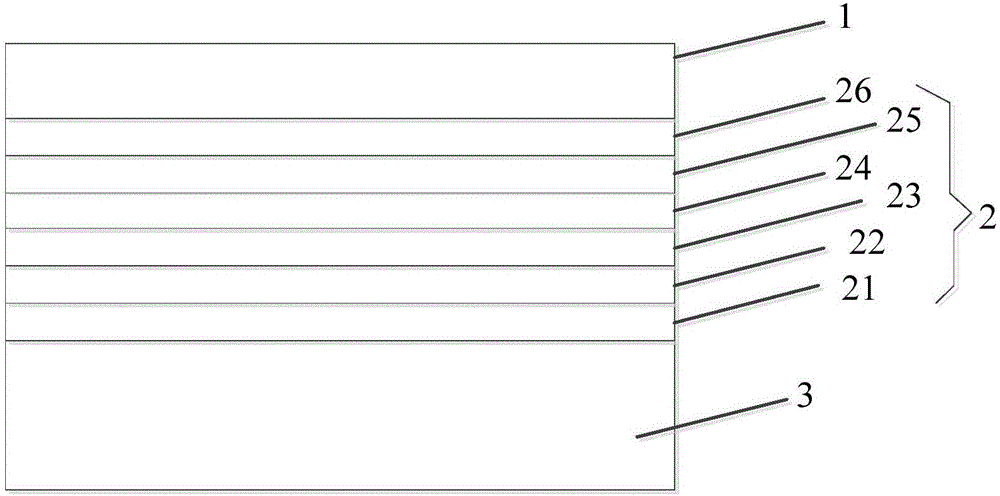

The invention provides a nano composition with hair loss preventing, hair growing, hair fixing and hair blackening functions as well as a preparation method and application thereof, and relates to thetechnical field of cosmetics with special functions. The nano composition comprises diaminopyrimidine oxide, pyrrolidinyl diaminopyrimidine oxide, hair growing peptide, hair fixing peptide, hair blackening peptide, a cell penetrating agent, vitamin E, polydiethylene glycol succinate, phospholipid, cholesterol, polyhydric alcohol and water. The nano composition is good in transdermal performance,improves the adsorption capacity of a preparation on scalp, deeply permeates into hair follicles, can be retained in the hair follicles for a long time, can be maintained at an effective concentrationfor a long time, improves the bioavailability, reduces the use amount of active ingredients, and enables low-content and anti-hair-loss active matter to play an excellent anti-hair-loss effect.

Owner:WUHAN BEST CARRIER NANO TECH

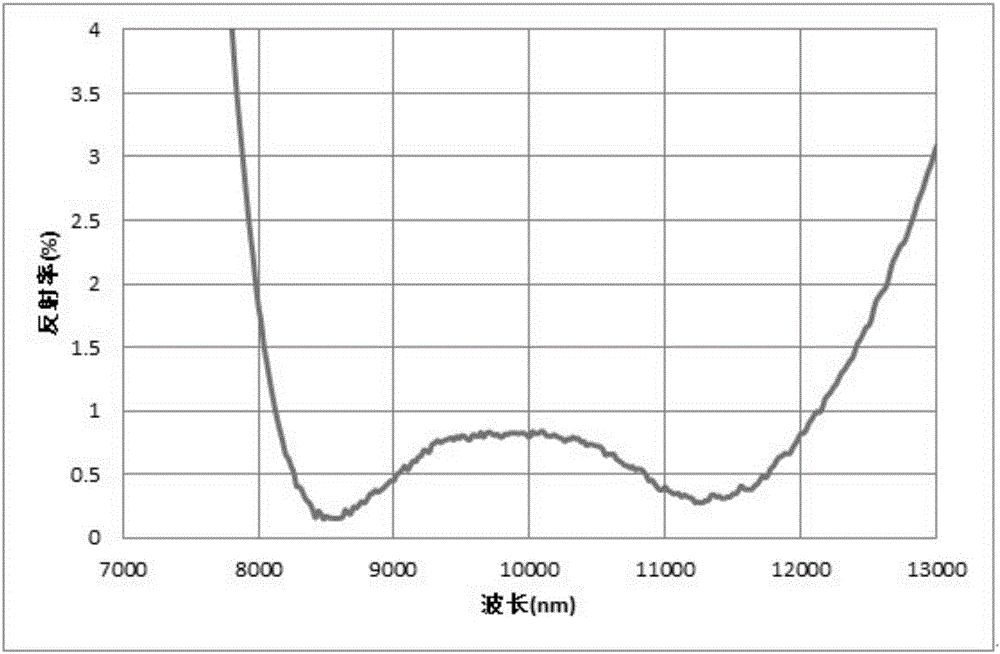

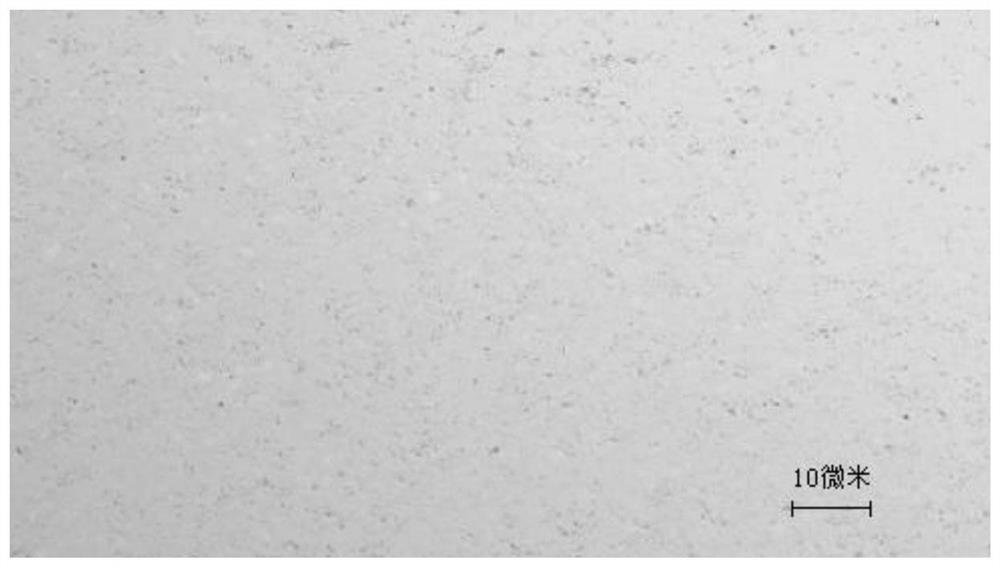

Antireflection coating plated on infrared glass and preparation method thereof

InactiveCN105911616AReduce thicknessImprove anti-reflectionVacuum evaporation coatingSputtering coatingReflectivityOptoelectronics

The invention relates to the technical field of coating, and particularly relates to an antireflection coating plated on infrared glass, which comprises a DLC (Diamond-Like-Carbon) film layer and a bonding layer, wherein the DLC film layer is bonded on an infrared glass substrate via the bonding layer; the bonding layer comprises a first ZnSe layer, a first Ge layer, a second ZnSe layer, a second Ge layer, a third ZnSe layer and a third Ge layer arranged alternatively in sequence. The single-face average reflectivity of the antireflection coating plated on the infrared glass is smaller than 1.5%, the thickness is small, and the antireflection performance is high; and the problem of adhesion strength of plating the DLC film on the infrared glass is solved, the final obtained infrared glass has good scraping-resisting performance, and the service life of the infrared glass is effectively prolonged.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD +1

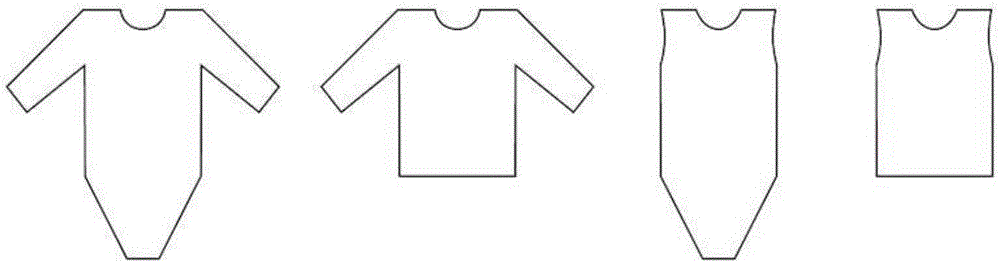

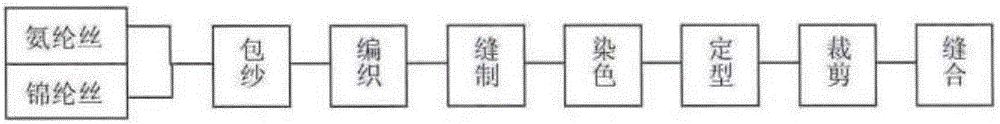

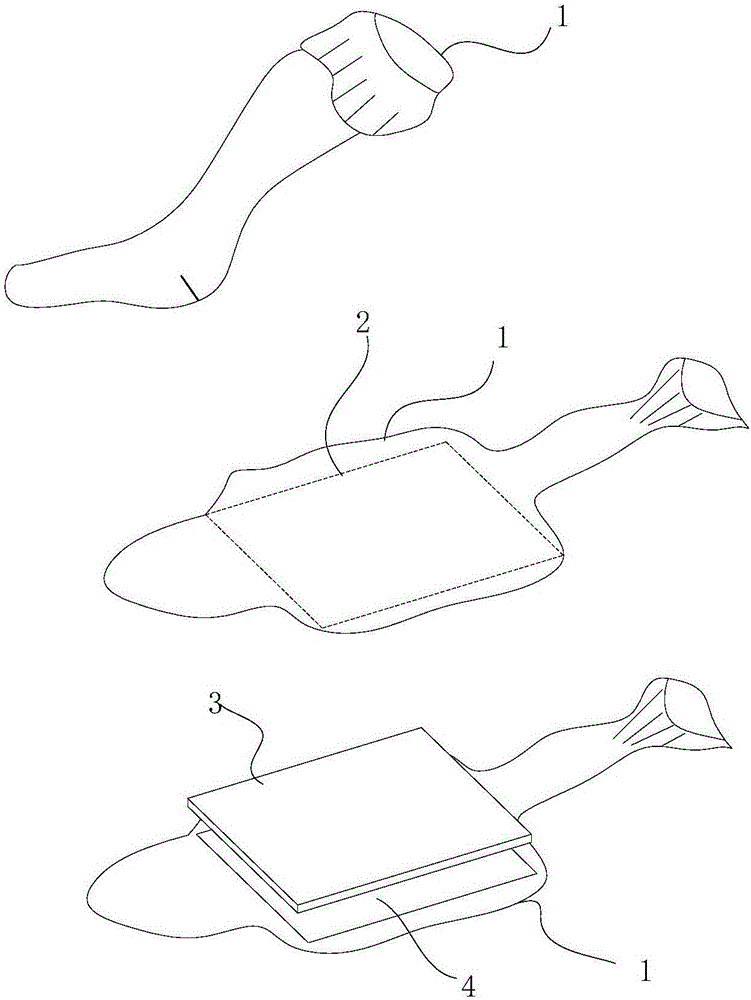

Ultra-thin run-resistant underwear produced by adopting cylinder loom and production process of ultra-thin run-resistant underwear

ActiveCN106263100AExtended service lifeCost-effectiveWeft knittingShaping/stretching tubular fabricsResistYarn

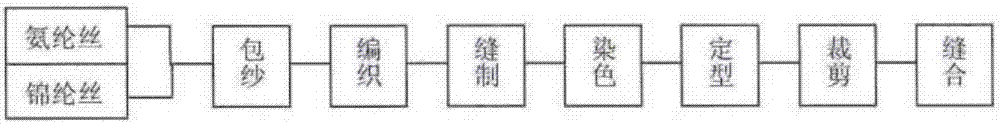

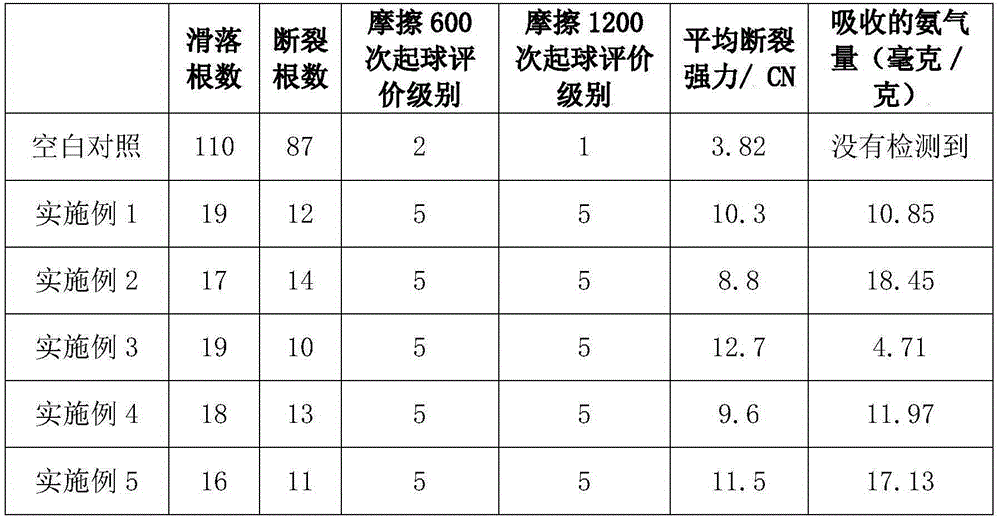

The invention provides ultra-thin run-resistant underwear produced by adopting a cylinder loom and a production process of the ultra-thin run-resistant underwear. The production process comprises the following steps: (1) wrapping by taking spandex as inner-wrapped silk and taking polyamide as outer-wrapped silk to obtain a wrapped yarn; (2) weaving: weaving the wrapped yarn by adopting the cylinder loom comprising a stocking machine to obtain a stocking blank; (3) sewing: cutting and sewing the socking blank to obtain stockings, so as to facilitate subsequent dyeing and sizing; (4) dyeing: bagging and dyeing the stockings to obtain colorful stockings; (5) sizing: sizing the colorful stockings by adopting an underwear sizing plate and endowing the colorful stockings with run-resist functions; (6) cutting: cutting the sized stockings according to a sample plate and cutting each of the stockings into two sleeveless underwear bodies; (7) sewing. In addition, the invention further provides the underwear produced by the production process. On the premise of not increasing the novel equipment investment, an ordinary cylinder loom (comprising the stocking machine) is directly adopted for producing the underwear, so that high quality and inexpensiveness are realized.

Owner:深圳市润薇服饰有限公司

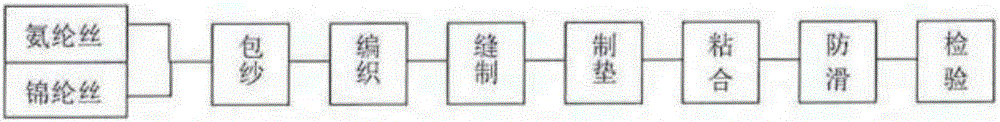

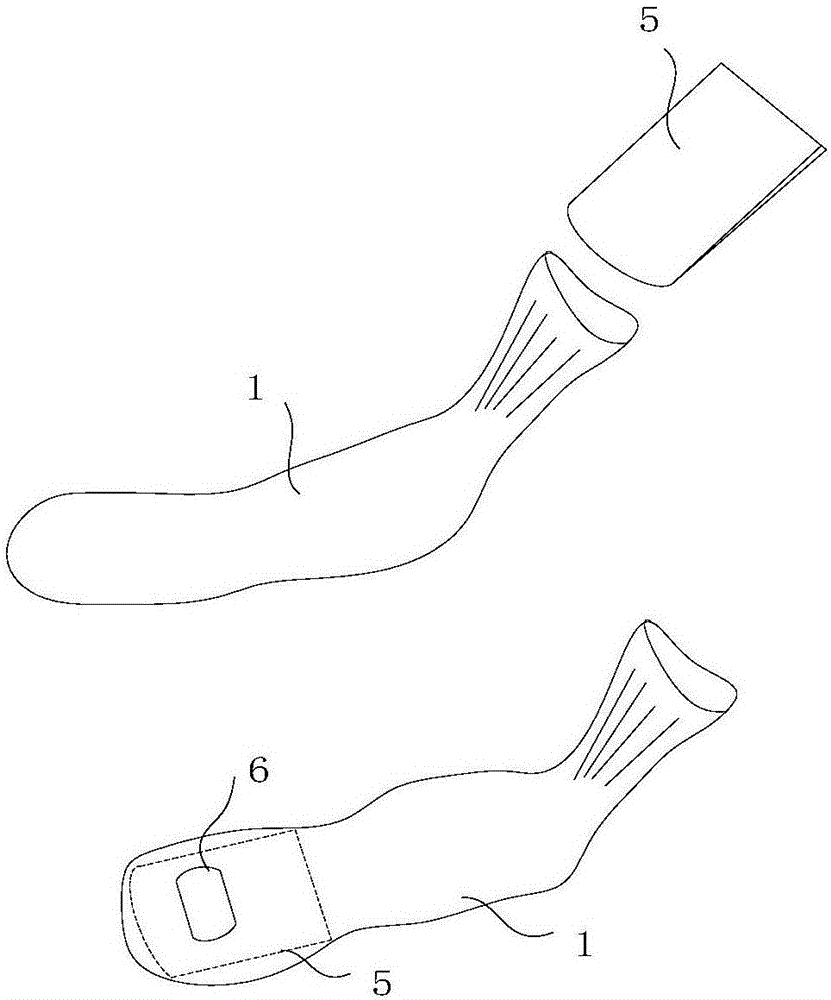

Sports socks produced by virtue of bonding technology and having effect of cushioning heels and production process of sports socks

ActiveCN106510011APlay a supporting rolePlay a bufferWeft knittingSynthetic resin layered productsSOCKSYarn

The invention provides a production process of sports socks having an effect of cushioning heels. The production process comprises the following steps: (1) covering yarns; (2) conducting knitting; (3) conducting sewing; (5) conducting bonding; (6) applying non-slip tapes; and (7) conducting inspection: inspecting bonded positions and an effect. According to the production process provided by the invention, under the precondition of not increasing the investment of novel equipment, socks, which are produced by virtue of a normal cylindrical weaving machine, are locally bonded with shape pads through the novel bonding technology, so that effects of supporting, cushioning and protecting are achieve. In accordance with users' demands, the heel pads (the shape pads) can be made into different shapes, and inner pads, made from various materials, can be selected. In addition, the invention also provides the sports socks produced by the production process.

Owner:LUSHAN HUAMEI COVERED YARN CO LTD

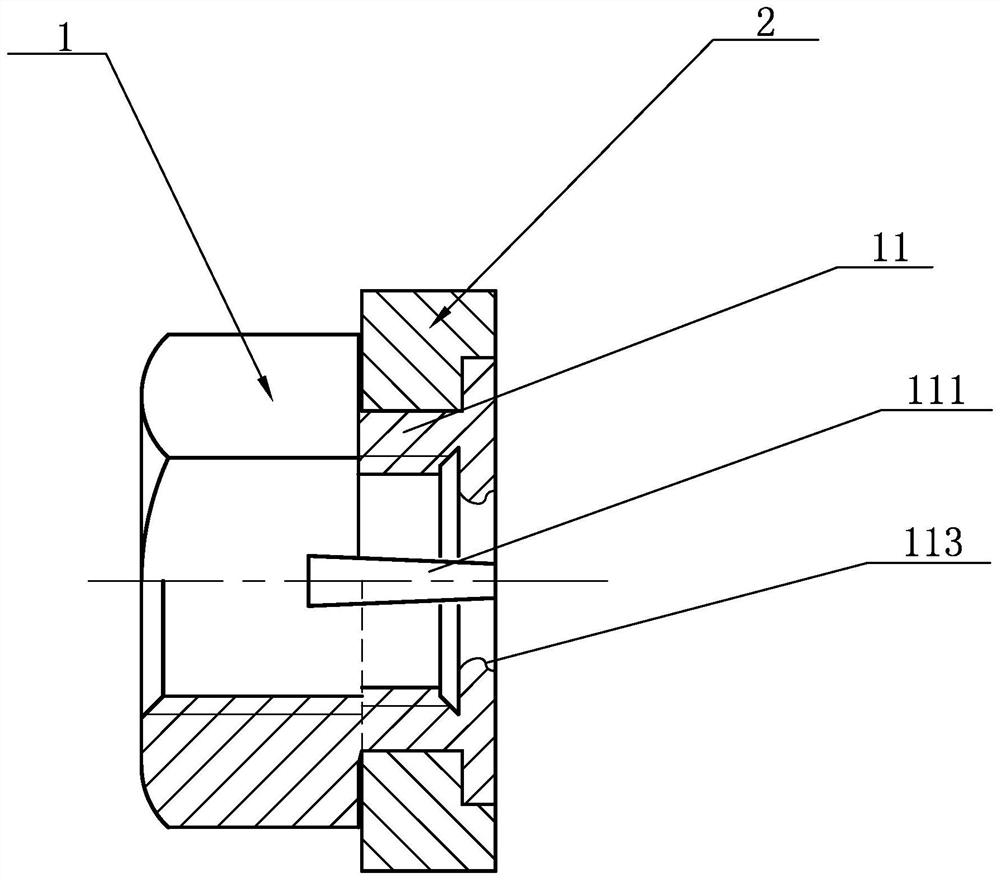

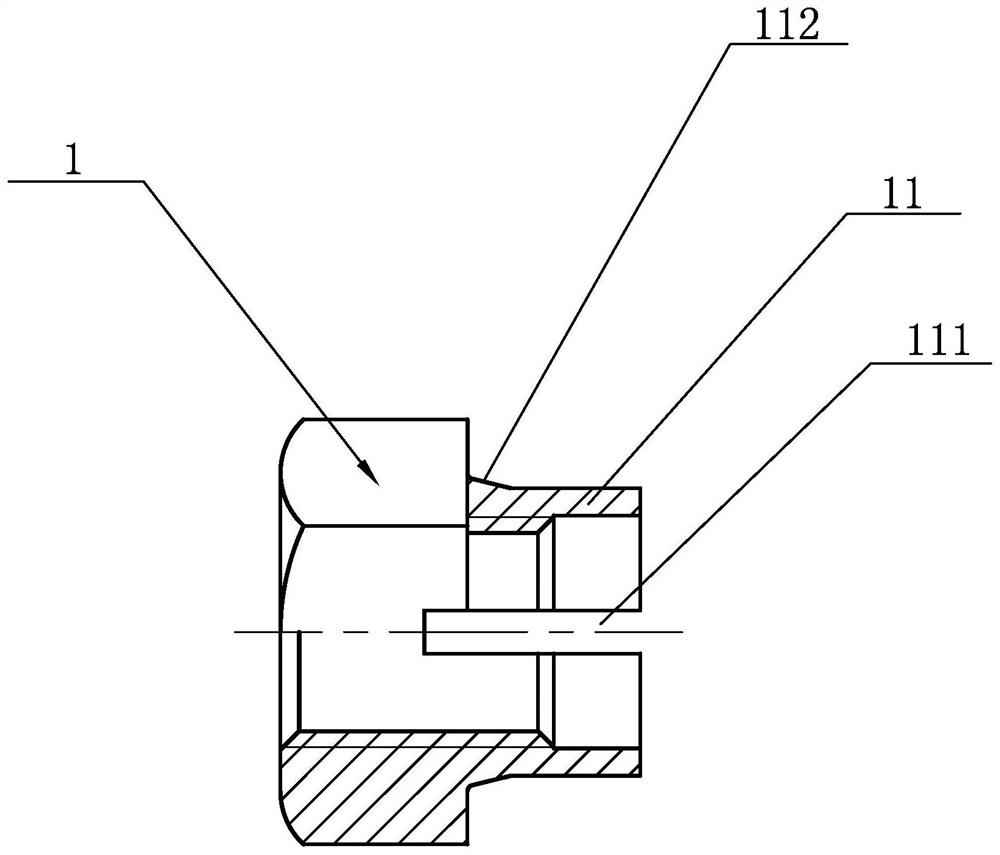

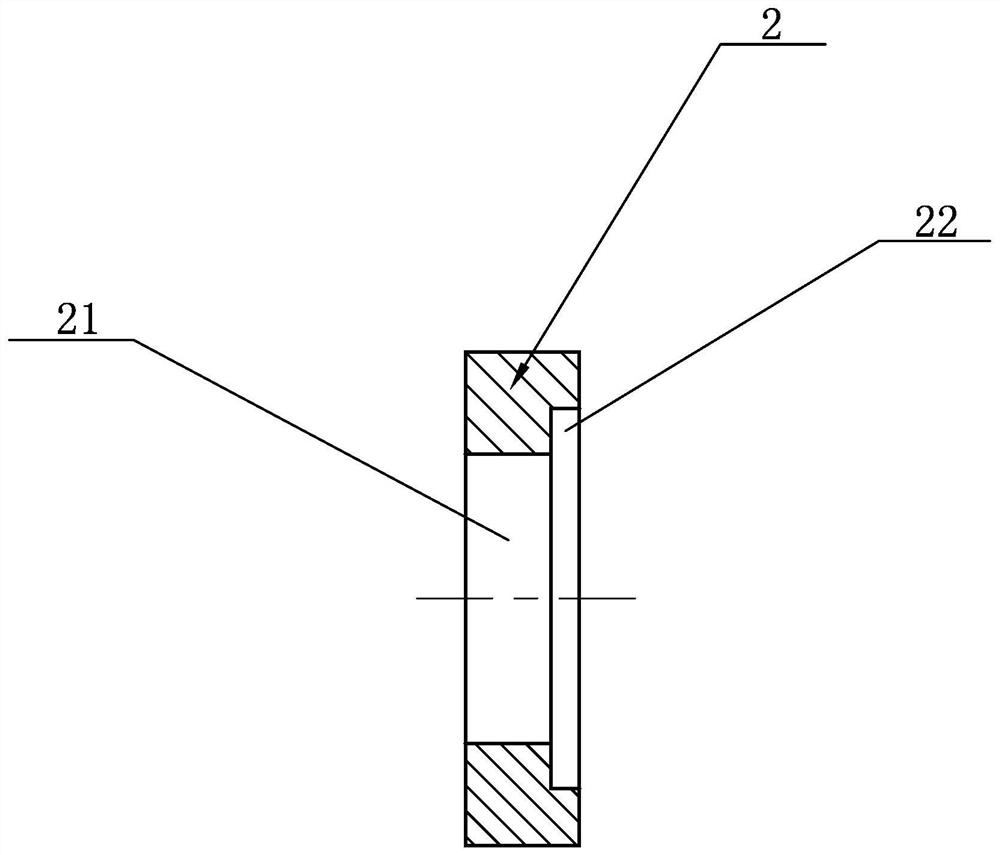

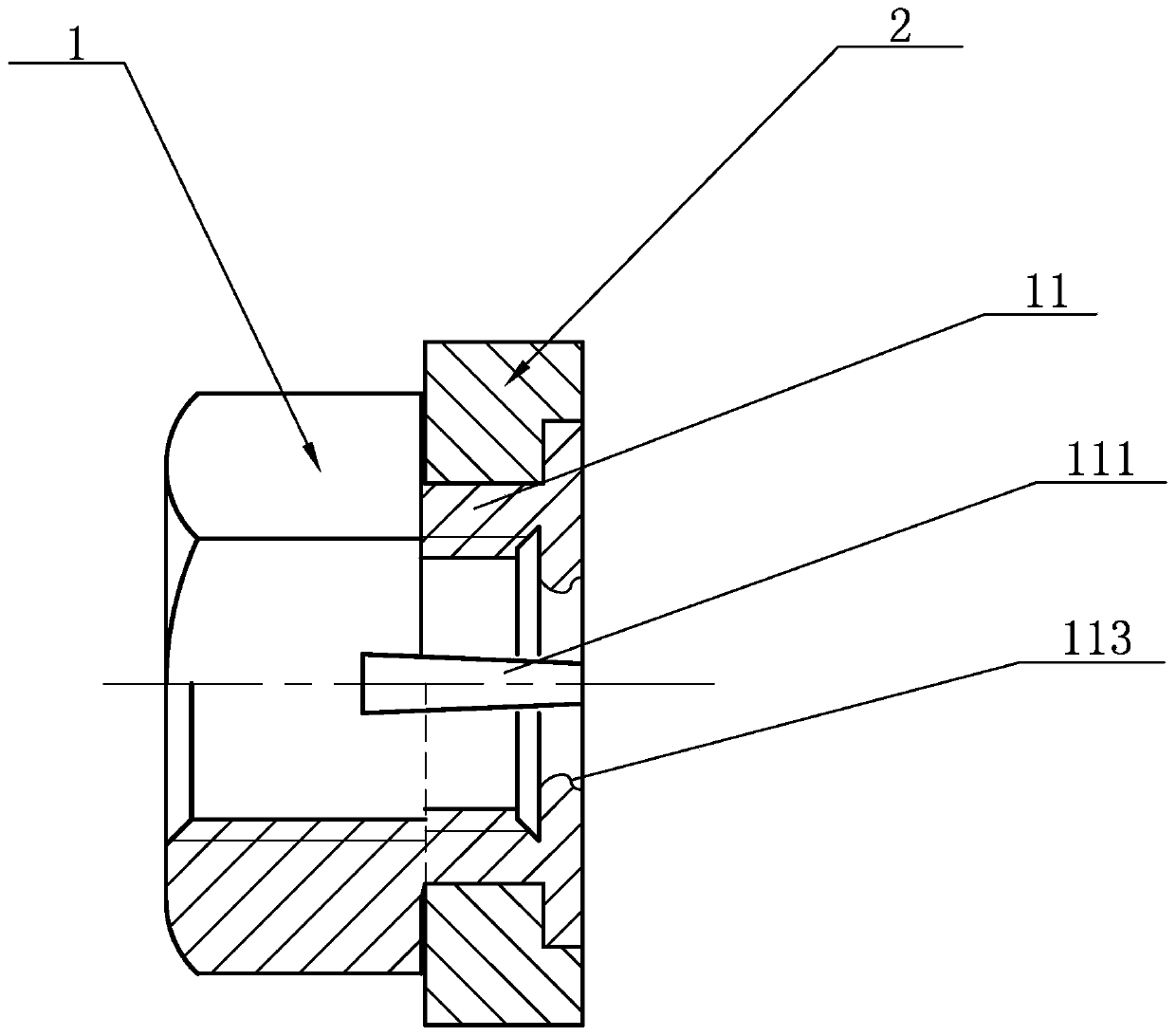

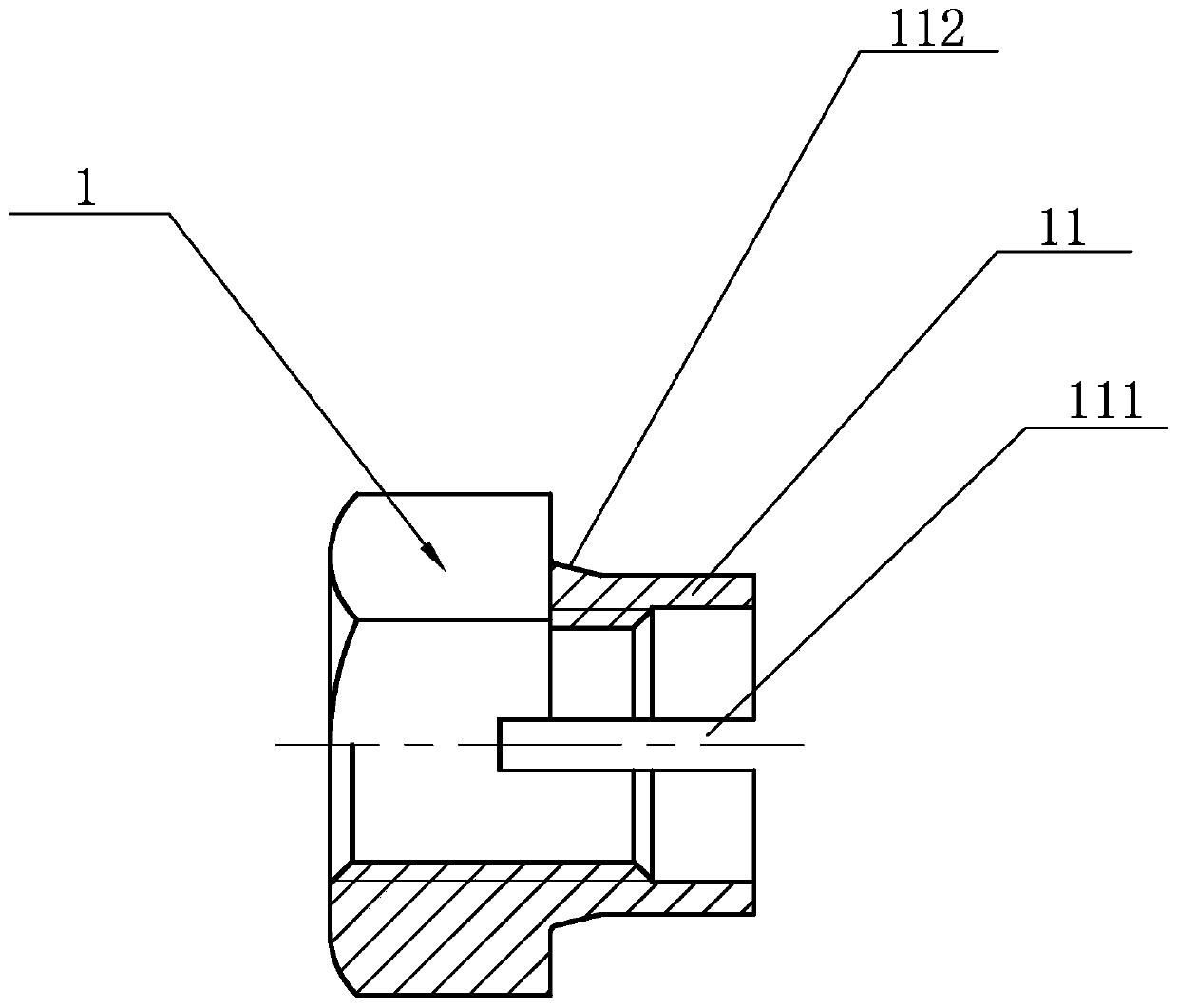

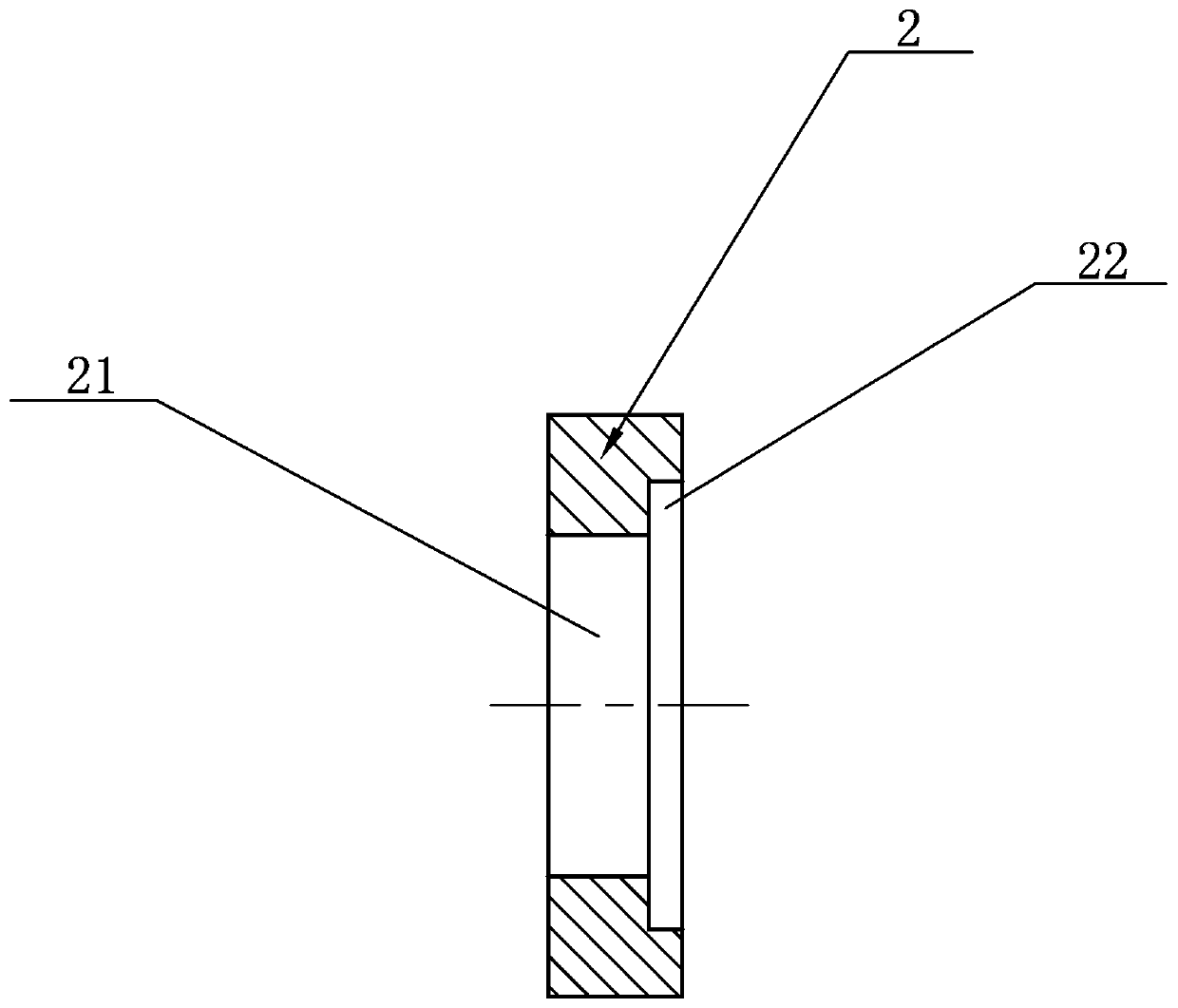

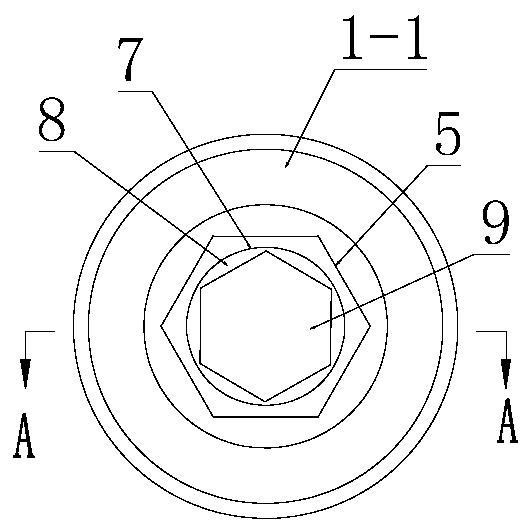

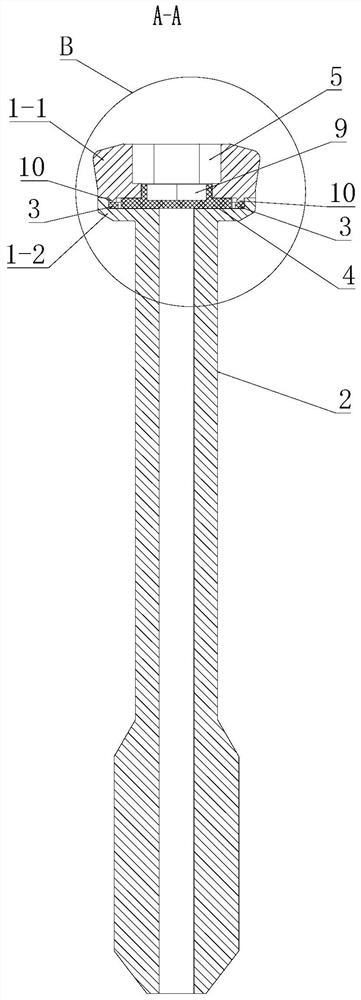

Anti-falling seal ring and corresponding lamp seal structure

InactiveCN102720837AEasy to installGuaranteed tightnessEngine sealsGas-tight/water-tight arrangementsEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

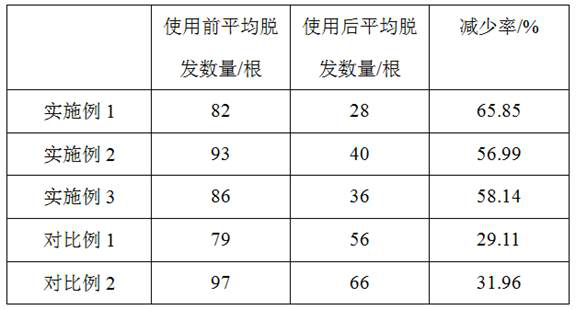

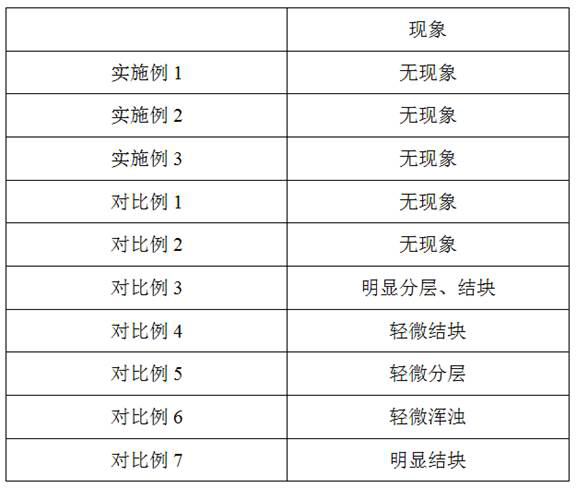

Hair-loss-prevention shampoo and preparation method thereof

PendingCN111956580AGood shedding resistanceImprove anti-shedding effectCosmetic preparationsHair cosmeticsGlycerolGuar gum

The invention discloses hair-loss-prevention shampoo. The hair-loss-prevention shampoo is prepared from the following raw materials: an anionic surfactant, a nonionic surfactant, a zwitterionic surfactant, a cationic surfactant, a traditional Chinese medicine extract, a hair-loss-prevention composition, glycerol, panthenol, cetostearyl ethyl hexanoate, xanthan gum, guar gum hydroxypropyl trimethylammonium chloride, sodium benzoate, citric acid, ethylenediamine tetraacetic acid disodium salt and deionized water. The hair-loss-prevention shampoo disclosed by the invention has a good hair-loss-prevention effect; through addition of the hair-loss-prevention composition and the traditional Chinese medicine extract, the hair loss prevention effect can be significantly improved; the hair-loss-prevention shampoo is good in high-temperature stability; and the traditional Chinese medicine extract is low in hygroscopicity and stable in quality.

Owner:GUANGZHOU KEYING COSMETICS CO LTD

Hair loss prevention hair conditioner and preparation method thereof

InactiveCN105055209AGood effectGood shedding resistanceCosmetic preparationsHair cosmeticsMechanical crushingMedicine

The invention relates to a hair loss prevention hair conditioner and a preparation method thereof. The hair loss prevention hair conditioner is prepared by carrying out infrared heating and drying, and mechanical crushing on Chinese herbal medicines. The hair loss prevention hair conditioner comprises the following Chinese herbal medicines according to weight: 8-15 parts of old ginger, 3-9 parts of pseudo-ginseng, 4-8 parts of almond, 6-15 parts of scallops, 3-7 parts of cassia twig, 5-12 parts of black sesame, 1-6 parts of ligusticum chuanxiong hort, 2-5 parts of Chinese wolfberry, 2-4 parts of a cationic surfactant, 1-2 parts of amino acid, 0.1-0.5 part of essence, 200-600 parts of water, 2-4 parts of grassleaf sweelflag rhizome, 1-3 parts of radix cyathulae and 3-6 parts of sesame oil. The prepared hair conditioner has good hair protection and hair loss prevention effects.

Owner:JIANGSU QILIKANG SKIN PHARMA

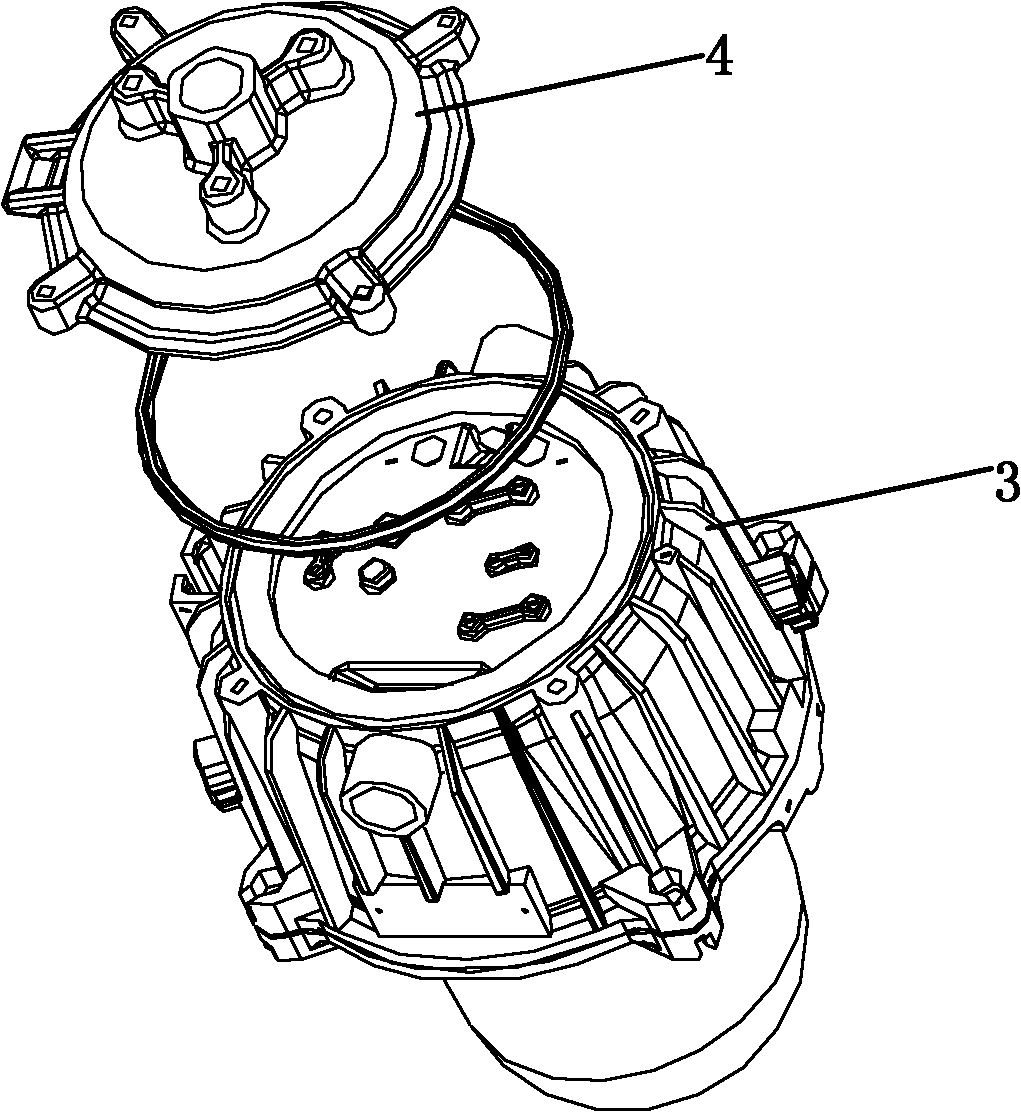

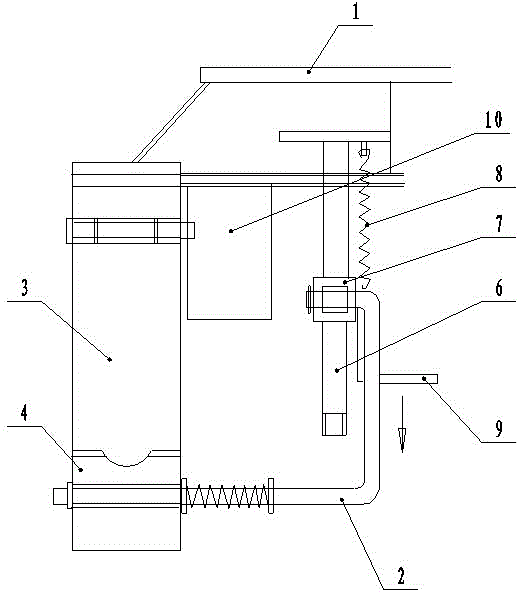

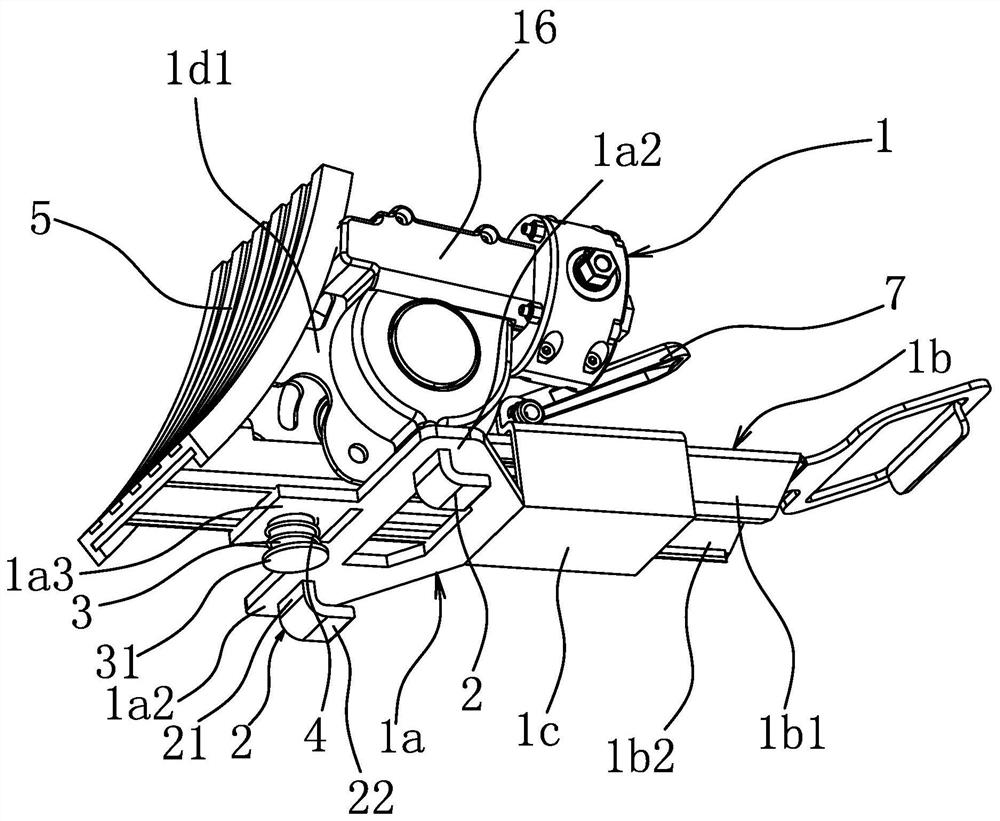

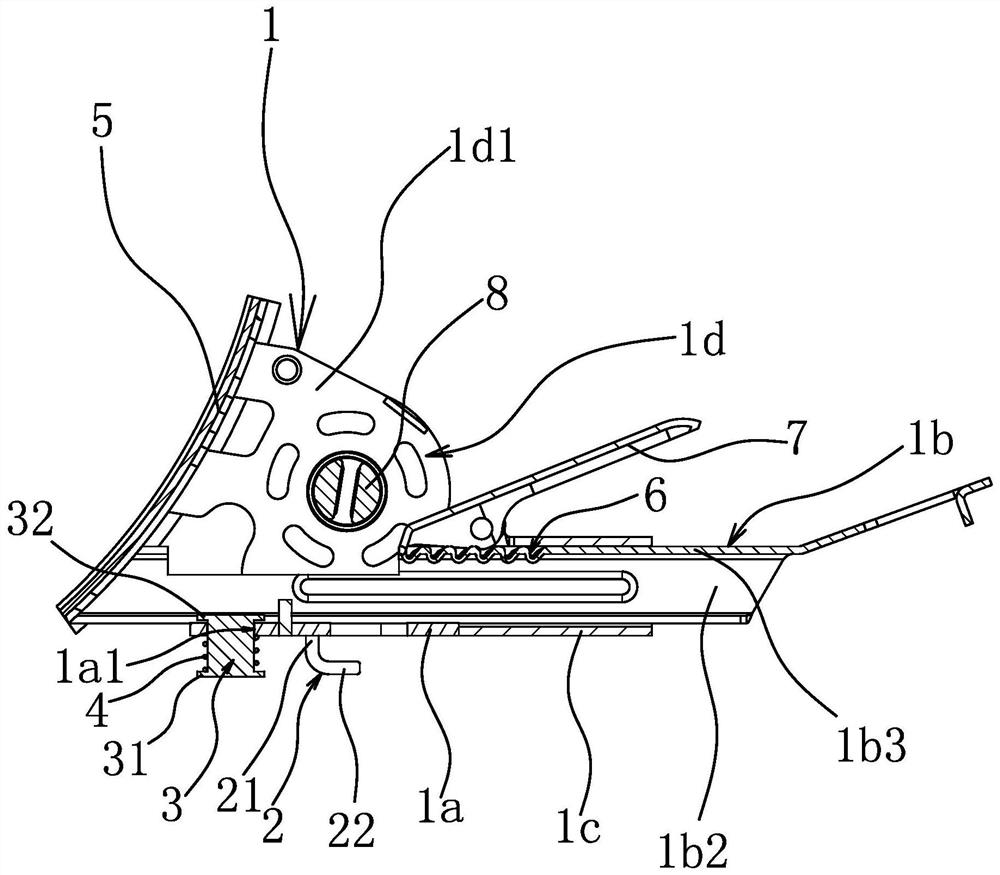

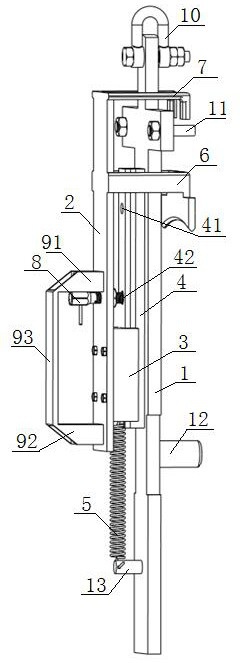

Anti-falling device of tightening element of small box fastener for electrolytic aluminum multifunctional crown block

The invention relates to an anti-falling device of a tightening element of a small box fastener for an electrolytic aluminum multifunctional crown block and belongs to the technical field of the electrolytic aluminum multifunctional crown block. The anti-falling device of the tightening element of the small box fastener for the electrolytic aluminum multifunctional crown block comprises a fastener tightening base, a folding and unfolding connecting rod and an arm type grab plate, wherein the fastener tightening base is slidably connected with one end of the arm type grab plate through the folding and unfolding connecting rod while the other end of the arm type grab plate is slidably connected with the fastener tightening base; a hook plate slot is formed in a connected part of the folding and unfolding connecting rod and the arm type grab plate; a groove for placing the small box fastener is formed on the hook plate slot; a sliding shaft lever is fixedly arranged on the fastener tightening base; the lower end of the sliding shaft lever is slidably connected with the folding and unfolding connecting rod through a double-lug moving main shaft sleeve; a pull ring is arranged at the upper end of the sliding shaft rod and is connected with the double-lug moving main shaft sleeve. The device provided by the invention is mainly applied to the electrolytic aluminum multifunctional crown block.

Owner:广西德保百矿铝业有限公司

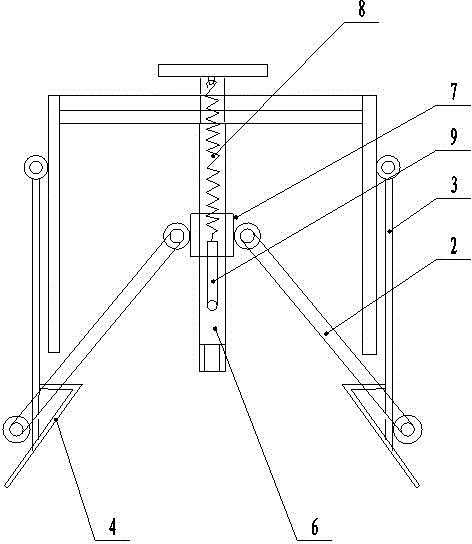

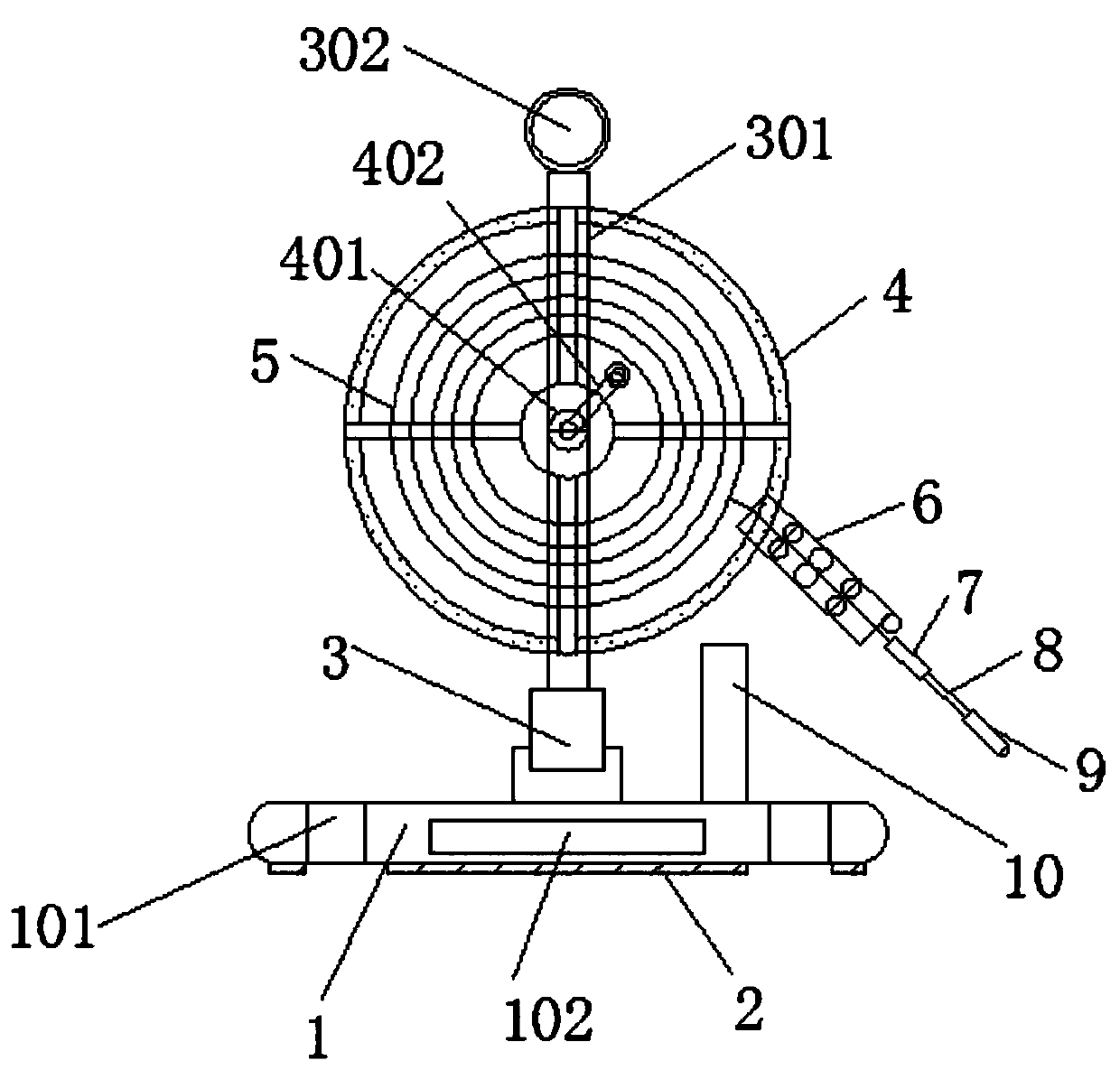

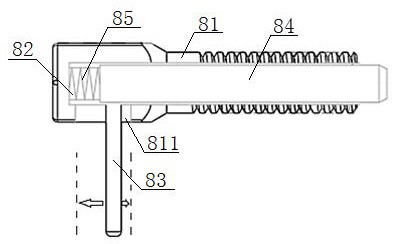

Threading structure for urban electric power engineering construction

ActiveCN110940252AKeep abreast of the progressStop laying outMechanical measuring arrangementsApparatus for laying cablesEngineeringStructural engineering

The invention discloses a threading structure for urban electric power engineering construction. The threading structure includes a base, a supporting frame is rotationally connected to the upper portion of the base. The inside of the supporting frame is fixedly connected with a winding disc. A steel wire is mounted in the winding disc; one end of the steel wire is fixedly connected with the guidehead through the traction head and the spring; one side of the winding disc is movably connected with a measuring device through a locking wheel; the design is novel, the base is rotationally connected to the lower portion of the supporting frame outside the winding disc. A lifting ring is welded at the top end of the supporting frame, the winding disc can be conveniently fixed at the initial position of paying off through the base or the lifting ring; the pay-off length is monitored in real time through a distance measuring wheel of the measuring device; a wire groove is formed in the surface of the traction head, so that a wire is conveniently clamped and fixed, the stability is improved, the top end and the two side walls of the guide head are rotationally connected with rollers, the guide head is guided, the pay-off smoothness is improved, abrasion is reduced, and the traction head and the guide head are conveniently stored by arranging a U-shaped clamping plate.

Owner:天津华烁电力技术开发有限公司

Glass slide for medical detection and preparation method thereof

InactiveCN111621053AEasy to prepareImprove preparation efficiencyPreparing sample for investigationSurface modificationVinylbital

The invention discloses a preparation method of a glass slide for medical detection, which is characterized by comprising the following steps: S1, preparing vinyl-terminated hyperbranched polyether ketone, S2, forming a glass slide, and S3, carrying out surface modification. The invention also provides the glass slide for medical detection, which is prepared by the preparation method of the glassslide for medical detection. The glass slide for medical detection disclosed by the invention is excellent in comprehensive performance, good in hydrophilicity, good in anti-falling effect and excellent in mechanical property.

Owner:王剑

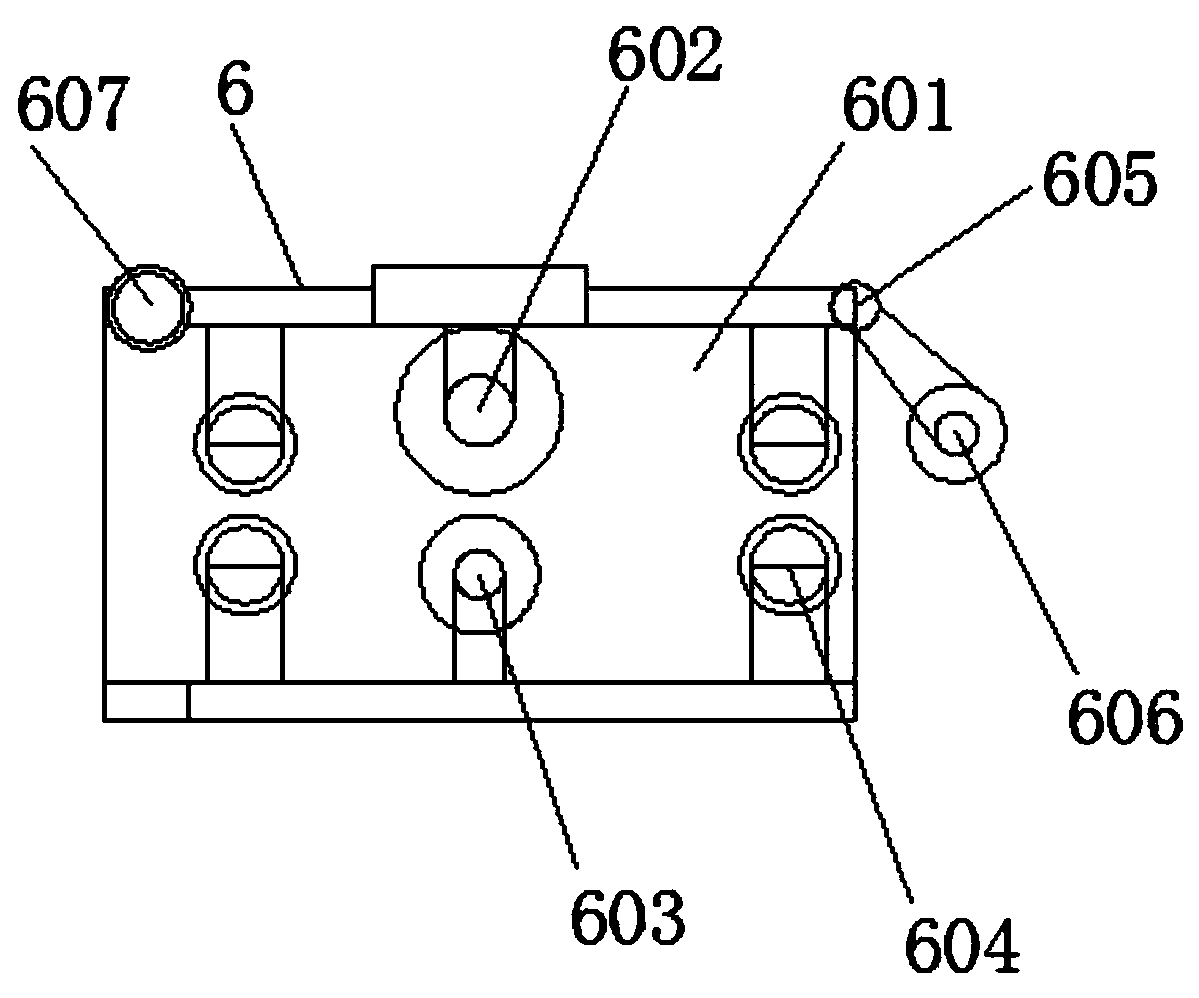

Logistics cargo fixing device

ActiveCN110963161AGood shedding resistanceImprove convenienceInternal fittingsLogistics managementMechanical engineering

The invention provides a logistics cargo fixing device, belongs to the technical field of logistics transportation equipment, and solves a problem that a connecting hook of a logistics cargo fixing device in the prior art is easy to unhook. The logistics goods fixing device comprises a base body, wherein a goods fixing structure used for positioning goods is arranged on the base body, the connecting hook is arranged on a bottom face of the base body, a jacking element capable of stretching out and drawing back in the vertical direction is further arranged at the bottom of the base body, and the jacking element can automatically rebound downwards without being affected by external force after stretching out and drawing back upwards. The goods fixing device is advantaged in that in the hooking process of the connecting hook, the jacking element can apply the upward force to the base body, so the connecting hook on the base body has the upward moving trend and is tightly hooked in a hooking hole of a hole plate, and the connecting hook has good anti-disengaging performance.

Owner:安吉汽车物流(上海)有限公司 +1

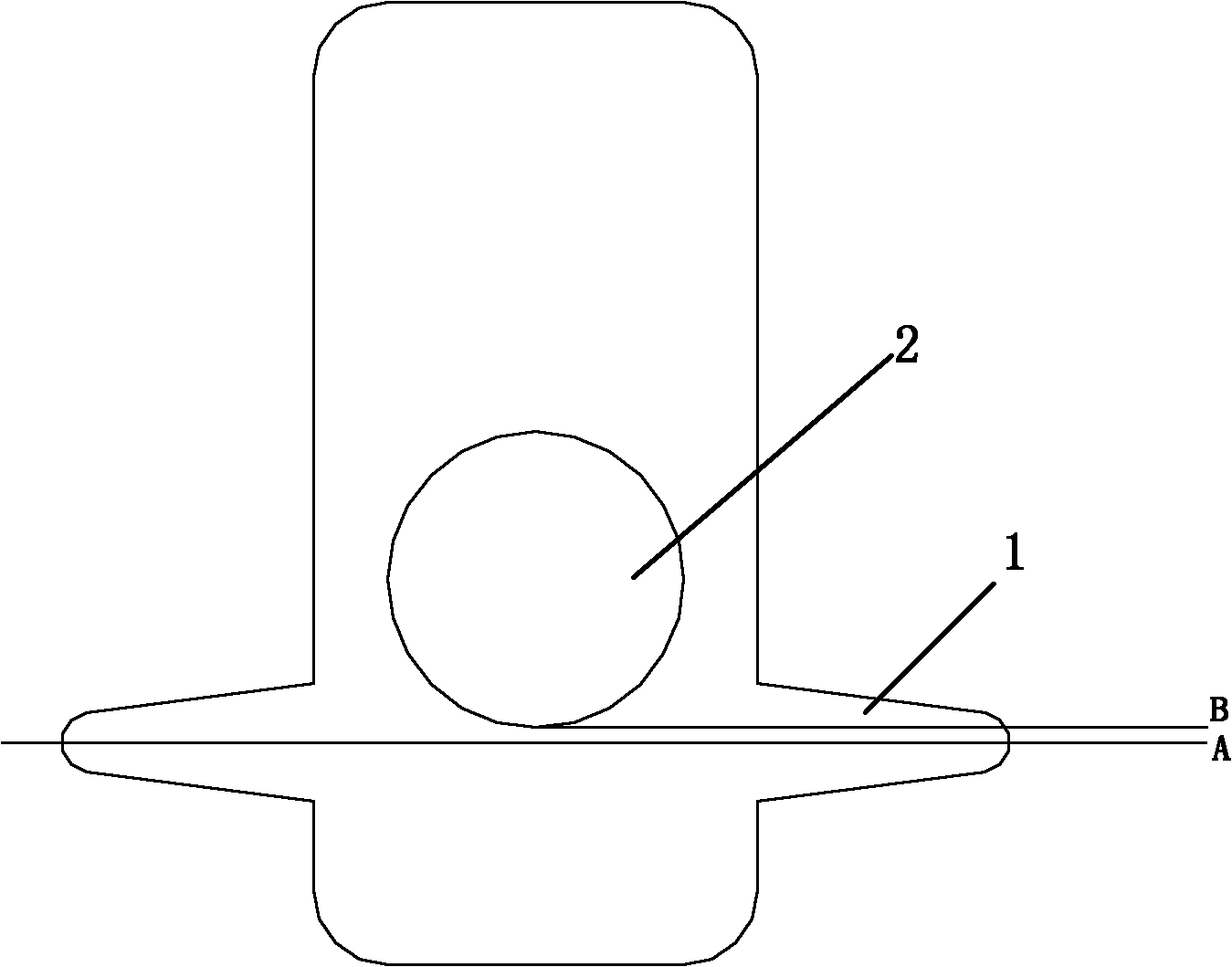

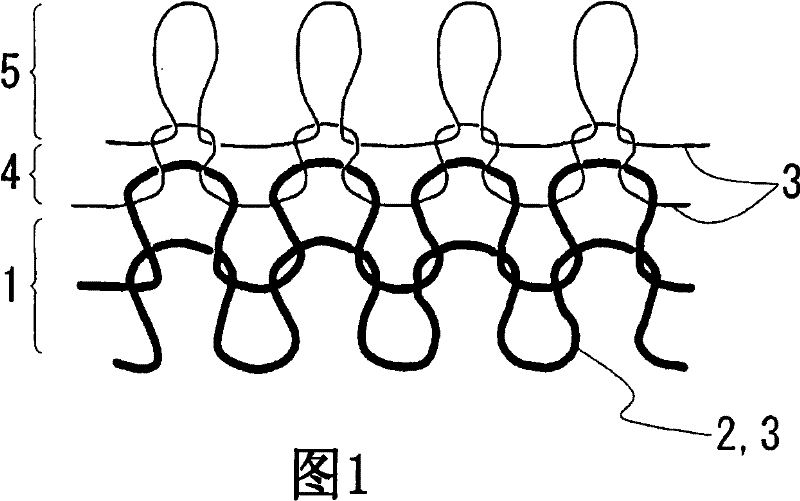

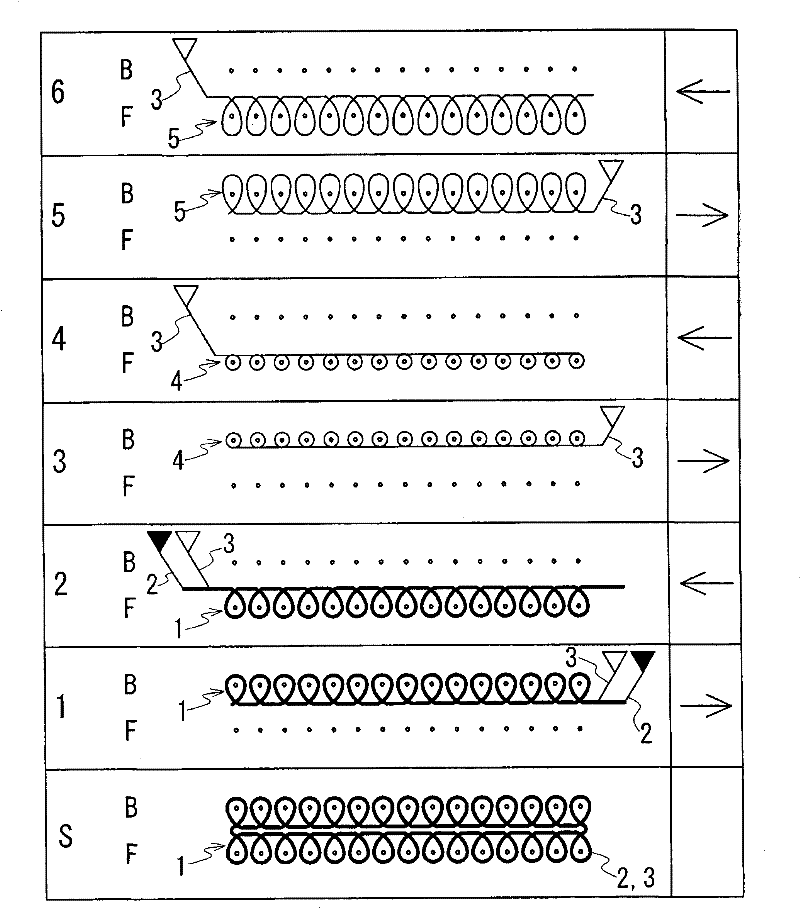

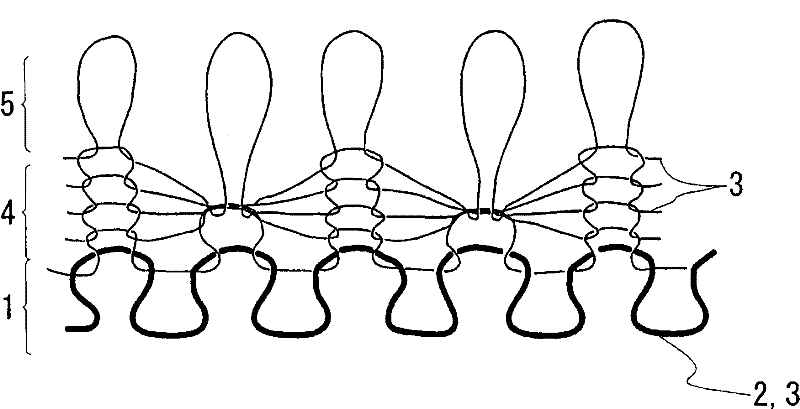

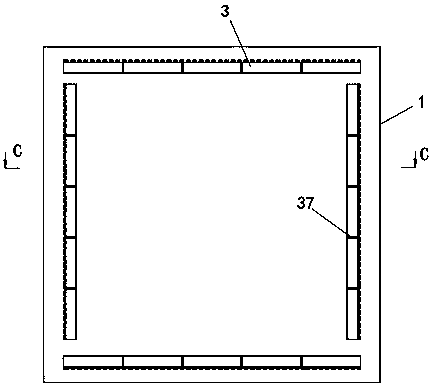

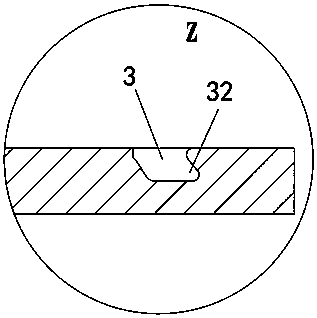

Tubular knitted fabric having opening portion in knitting terminal side and knitting method

The present invention provides a tubular knitted fabric with a peristome at the knitting terminal side and the knitting method, the quality and the style of which are excellent, it uses the cheap elastic yarn used in the yarn plating and knitting and it can reliably prevent the wire off of the open end part while the yarn feeding hole is not increased. The tubular knitted fabric of the invention is a tubular knitted fabric which is knitted by the flat-bed machine and is provided with a peristome at the knitting terminal side. The woven fabric main body (1) of the tubular knitted fabric simultaneously feeds the main yarn (2) and the plated yarn (3) provided with elasticity to the knitting needle and the knitted plating yarn is formed to be tubular. The peristome formed at the knitting terminal side of the knitted fabric body (1) is composed of a terry knitted fabric part (4) and a final coil horizontal arranging part (5), wherein, the terry knitted fabric part (4) is horizontally arranged contacting to the knitting coil knitted by the main yarn (2) and the plating yarn (3), is formed by horizontally arranging the plating yarn (3) and is at least knitted for one coil with the stitchdensity value which is smaller than the stitch density when do plating yarn knitting and it is formed by the terry and the coil of which is small; the final coil horizontal arranging part (5) next tothe terry knitted fabric part (4) is knitted using the plating yarn (3) with the stitch density value which is larger than the stitch density value when knits the terry knitted fabric part (4).

Owner:SHIMA SEIKI MFG LTD

Maintenance paint for ships

ActiveCN108752997BExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxyEmulsion

The invention discloses a ship maintenance paint. Each portion of the ship maintenance paint is composed of, by mass, 25 to 35 parts of butyl acrylate, 20 to 30 parts of epoxy resin, 15 to 25 parts ofpolyacrylic acid vinyl ester emulsion, 10 to 20 parts of mica powder, 10 to 20 parts of an anti-rust paint, 20 to 25 parts of an anti-corrosive filling material, 20 to 30 parts of deionized water, and 10 to 20 parts of an auxiliary agent. The ship maintenance paint possesses excellent anti-corrosive effect, and obvious anti-shedding effect, is excellent in comprehensive performance, is capable ofprolonging ship service life; the preparation conditions are mild; the preparation method is simple; operation is easy; and certain popularization value is achieved.

Owner:广州市泰诚船舶工业有限公司

Ship maintenance paint

ActiveCN108752997AExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxyEmulsion

The invention discloses a ship maintenance paint. Each portion of the ship maintenance paint is composed of, by mass, 25 to 35 parts of butyl acrylate, 20 to 30 parts of epoxy resin, 15 to 25 parts ofpolyacrylic acid vinyl ester emulsion, 10 to 20 parts of mica powder, 10 to 20 parts of an anti-rust paint, 20 to 25 parts of an anti-corrosive filling material, 20 to 30 parts of deionized water, and 10 to 20 parts of an auxiliary agent. The ship maintenance paint possesses excellent anti-corrosive effect, and obvious anti-shedding effect, is excellent in comprehensive performance, is capable ofprolonging ship service life; the preparation conditions are mild; the preparation method is simple; operation is easy; and certain popularization value is achieved.

Owner:广州市泰诚船舶工业有限公司

Plywood veneer overlaying and painting process

InactiveCN105382903AQuality improvementGood shedding resistanceWood veneer joiningWork in processEngineering

The invention relates to a plywood veneer overlaying and printing process. According to the plywood veneer overlaying and painting process, a base material and a veneer are included. The process comprises the following steps that the base material qualified in appearance is screened; the water content of the base material is detected, the next step is directly carried out on the base material with the water content of 8-10%, and dewatering treatment is conducted on the base material with the water content higher than 10%; the base material with the water content of 8-10% is put for a certain time and recovers balanced, and the base material is polished and ground, so that the thickness of the base material is basically consistent; the face, to be attached to the veneer, of the base material is coated with wood grain masking agents; the face, to be attached to the veneer, of the base material is coated with gum; the base material and the veneer are attached; a semi-finished plywood composed of the base material and the veneer is subjected to hot-pressing; and paint is sprayed on the plywood, and then baking, hot air blowing and baking are sequentially carried out. The process does not need use valuable wood as the base material, the machined plywood is good in quality and achieves the high-end wood sense, and the paint and the base material are high in binding stability and good in anti-disengagement performance.

Owner:YIBIN LIXING WOOD IND CO LTD

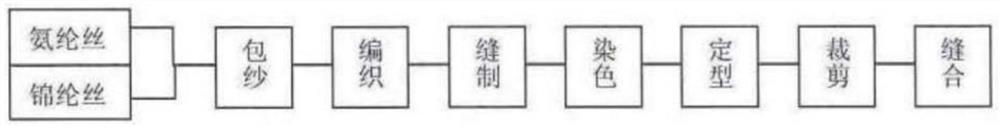

Production process of run-resistant anti-snagging underwear, and seamless underwear

InactiveCN111809299AExtended service lifeCost-effectiveWeft knittingGirdlesEngineeringMechanical engineering

The invention relates to a production process for producing a run-resistant anti-snagging underwear by adopting a cylinder loom. The production process comprises the following steps of covering yarns;weaving; sewing; dyeing; shaping; clipping and stitching. According to the production process provided by the invention, without increasing the input of novel equipment, the underwear is produced bydirectly adopting a common cylinder loom; and in accordance with the principle of attractiveness in price and quality, the breathable and warm underwear capable of being worn for all seasons, coveringthe body wrinkles and spots, and tightening skin can be manufactured. Secondly, the underwear gives the body light shape and balances the body curve. Again, the underwear has anti-snagging and run-resistant functions, the service life of the underwear is prolonged, and the cost performance of the underwear is further improved.

Owner:浙江艾恋针织服饰有限公司

A kind of ultra-thin anti-off underwear produced by cylinder loom and its production process

ActiveCN106263100BExtended service lifeCost-effectiveWeft knittingShaping/stretching tubular fabricsYarnResist

The invention provides ultra-thin run-resistant underwear produced by adopting a cylinder loom and a production process of the ultra-thin run-resistant underwear. The production process comprises the following steps: (1) wrapping by taking spandex as inner-wrapped silk and taking polyamide as outer-wrapped silk to obtain a wrapped yarn; (2) weaving: weaving the wrapped yarn by adopting the cylinder loom comprising a stocking machine to obtain a stocking blank; (3) sewing: cutting and sewing the socking blank to obtain stockings, so as to facilitate subsequent dyeing and sizing; (4) dyeing: bagging and dyeing the stockings to obtain colorful stockings; (5) sizing: sizing the colorful stockings by adopting an underwear sizing plate and endowing the colorful stockings with run-resist functions; (6) cutting: cutting the sized stockings according to a sample plate and cutting each of the stockings into two sleeveless underwear bodies; (7) sewing. In addition, the invention further provides the underwear produced by the production process. On the premise of not increasing the novel equipment investment, an ordinary cylinder loom (comprising the stocking machine) is directly adopted for producing the underwear, so that high quality and inexpensiveness are realized.

Owner:深圳市润薇服饰有限公司

New process for modifying rabbit hair fiber grafted silk protein

InactiveCN105401427AReduce harmReduce consumptionBiochemical fibre treatmentAnimal fibresFiberProteinase activity

The invention discloses a new process for modifying rabbit hair fiber grafted silk protein. The process does not use protease, is harmless to fiber, is natural and environment-friendly, and does not use a chemical raw material. The rabbit hair cloth produced through the process is relatively soft and delicate in hand feeling, and low in possibility of pilling, and also has particular glossiness. The anti-pilling grade of the produced rabbit hair cloth can reach 4-5, and the possibility of pilling is low.

Owner:浙江德清华丝纺织有限公司

Anti-shedding tile

The invention discloses an anti-shedding tile. The anti-shedding tile comprises a tile base, one side of the tile base is a decorative surface, and the other side of the tile base is an adhesive surface; the adhesive surface is provided with anti-shedding grooves, each anti-shedding groove comprises two symmetrical inclined grooves which form a splay structure with the cross section in a splay shape, and the inclination direction of each inclined groove and the groove bottom form an acute bottom angle which is a fillet angle; and the number of the inclined grooves is at least four, and the four inclined grooves are perpendicular to one another and arrayed in a square shape. The anti-shedding grooves form a square array through the two perpendicular splay structures, four-sided stress supporting is realized, anti-shedding fixing is facilitated, and the firing and external shape of the tile are not affected; and meanwhile, the inclined grooves have the acute bottom angles which are arc angles, deformation caused by sintering stress is effectively prevented, and the bottom corners effectively achieve an anti-shedding effect.

Owner:佛山市星力环保设备有限公司

Method for preparing tungsten carbide coating on surface of roller for lithium battery production

PendingCN113699478AReduce decarbonizationLower flame temperatureMolten spray coatingRollsAdhesive beltCombustion chamber

The invention relates to a method for preparing a tungsten carbide coating on the surface of a roller for lithium battery production. The method comprises the following steps of (1) carrying out visual inspection and magnifying glass inspection on the surface of the roller for lithium battery production; (2) after the surface of the roller is subjected to oil removal, impurity removal and purification, conducting rough grinding and texturing treatment on the surface of the roller through a rough polishing machine; (3) carrying out protection treatment on the non-spraying surfaces at the two ends of the roller subjected to rough grinding and texturing by adopting a high-temperature-resistant adhesive tape and a tool; and (4) using liquid-phase propane as a main combustion gas, using compressed air as a combustion-supporting gas, using nitrogen as a carrier gas powder feeding gas, inputting all the gases into a combustion chamber through a porous ceramic sheet, initially igniting by a spark plug for high-pressure combustion, generating high-velocity flames with the flame flow speed being more than 7 times of the sound velocity, spraying tungsten carbide powder on the surface of the roller to be sprayed by adopting a powder flame spraying technology, and rapidly cooling and solidifying to form the tungsten carbide coating; and (5) carrying out fine polishing treatment on the surface of the roller sprayed with the tungsten carbide coating by adopting a fine polishing machine.

Owner:宁德市福能新能源科技有限公司

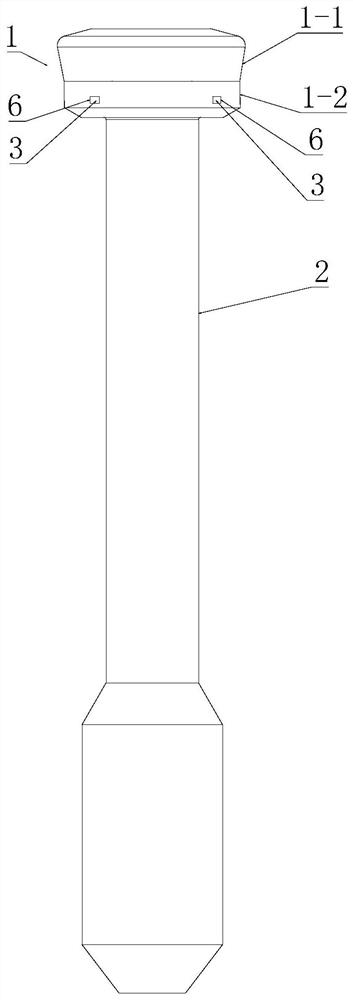

Self-locking anti-loosening nut

The invention discloses a self-locking anti-off nut, which comprises a nut body. An anti-off strip is integrally provided at one end of the nut body. A self-locking groove is axially arranged on the anti-off strip. The anti-off strip is close to the nut body. A self-locking tapered surface is provided at the end; the anti-off belt is covered with a lock pad, and a lock pad through hole is arranged axially in the middle of the lock pad, and a positioning recess is provided axially at the end of the lock pad away from the nut body The positioning groove communicates with the through hole of the lock washer; when the nut body is locked, the lock washer and the self-locking cone are locked together. The above-mentioned technical scheme has reasonable structural design, simple structure, convenient installation, reliable connection, good detachment prevention performance, good anti-theft effect and good practicability.

Owner:刘克良

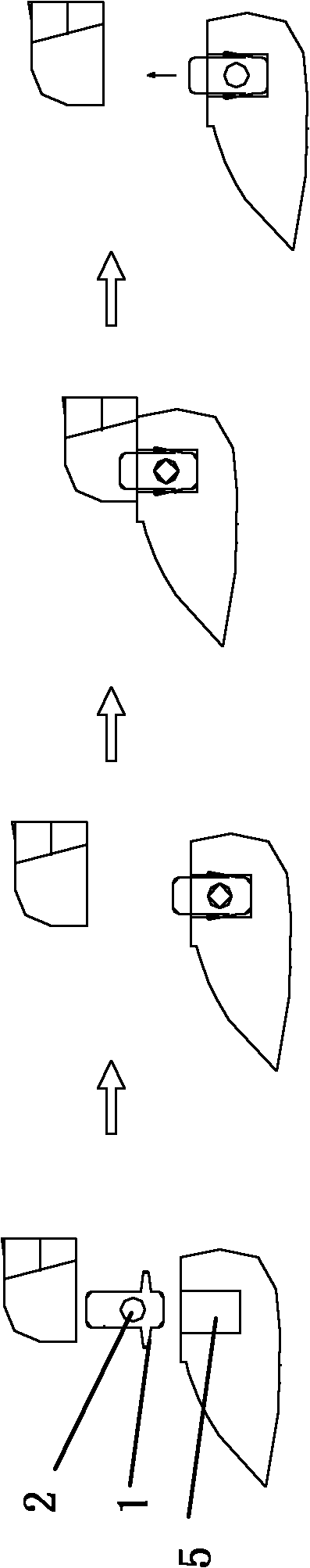

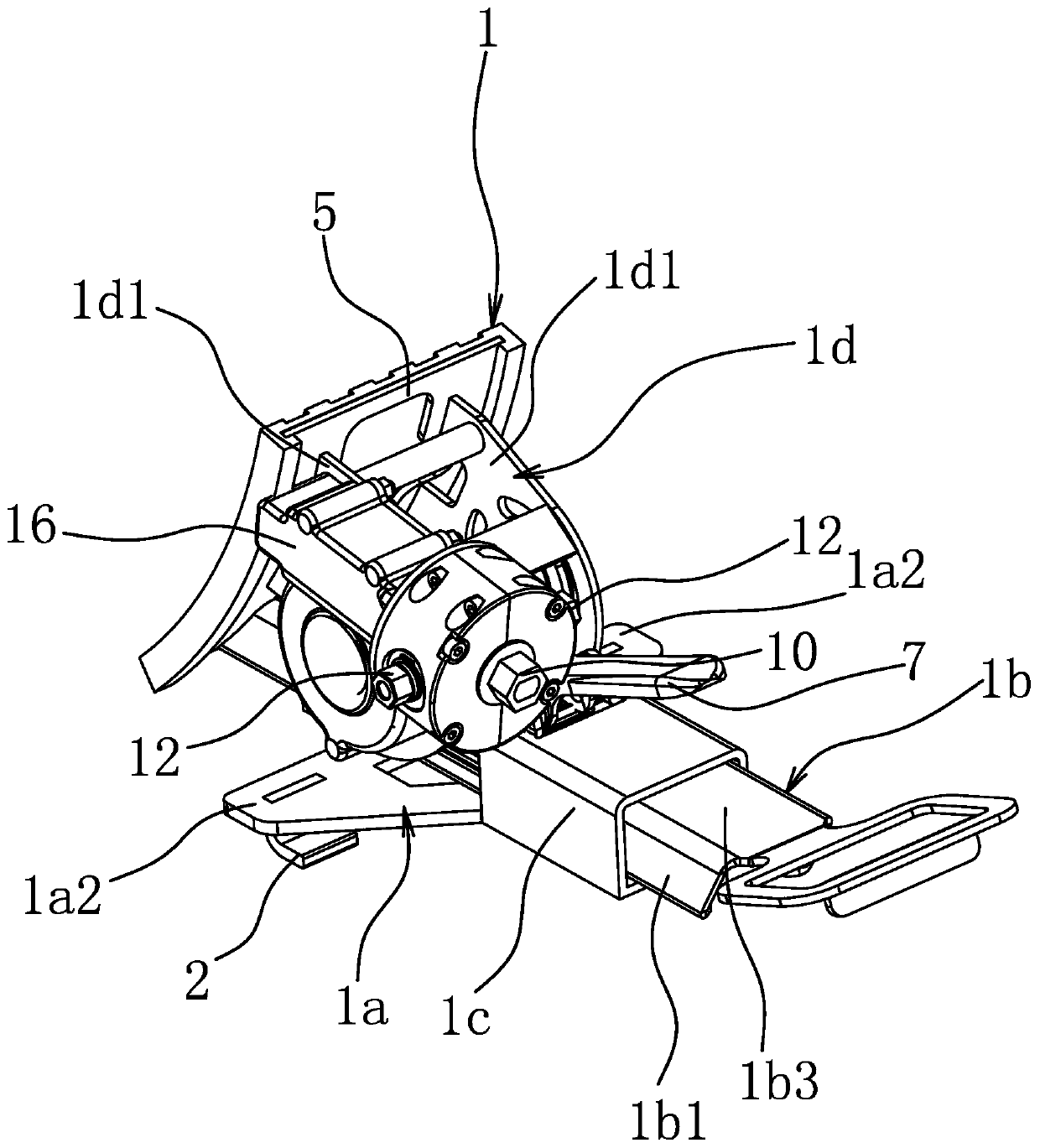

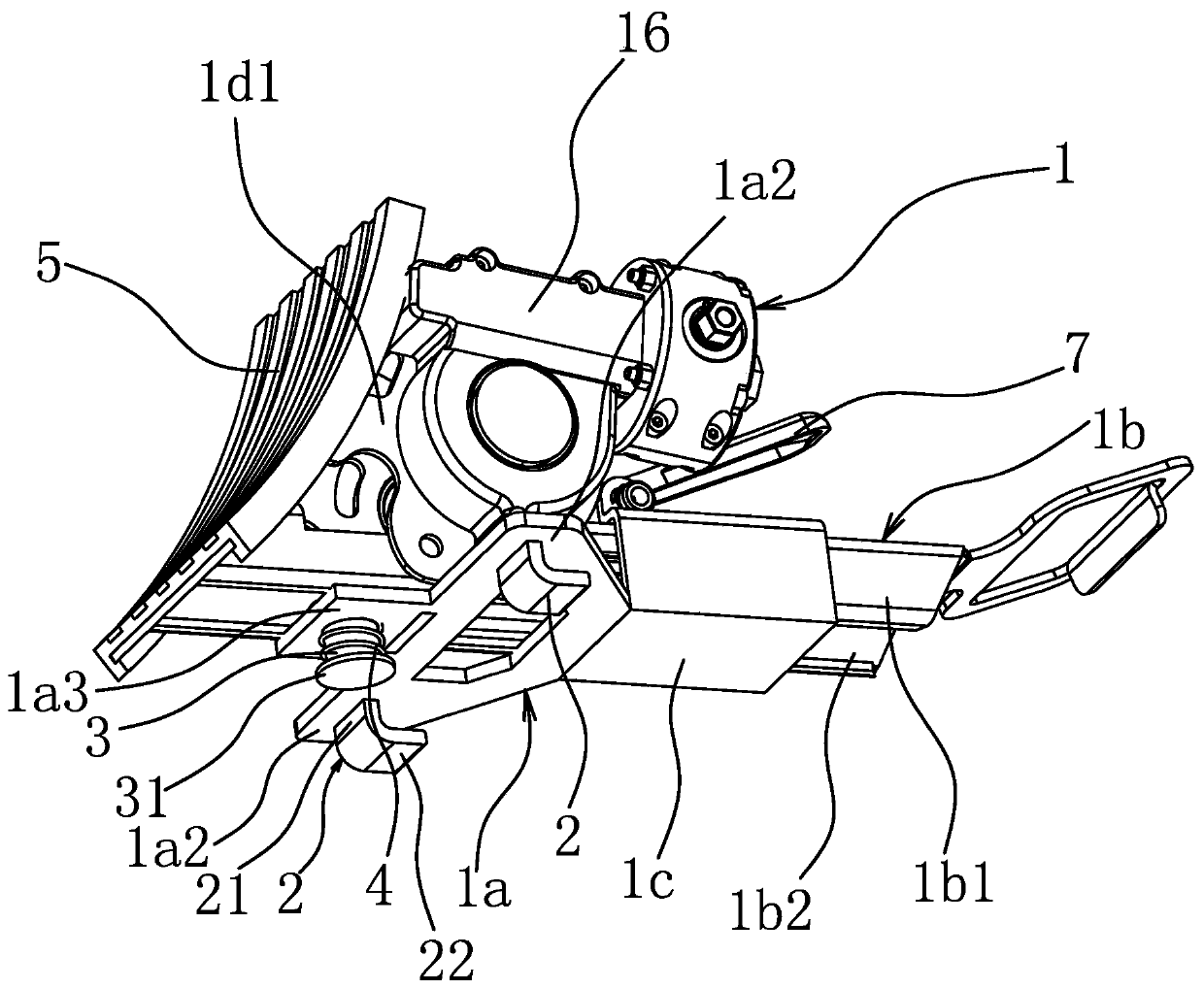

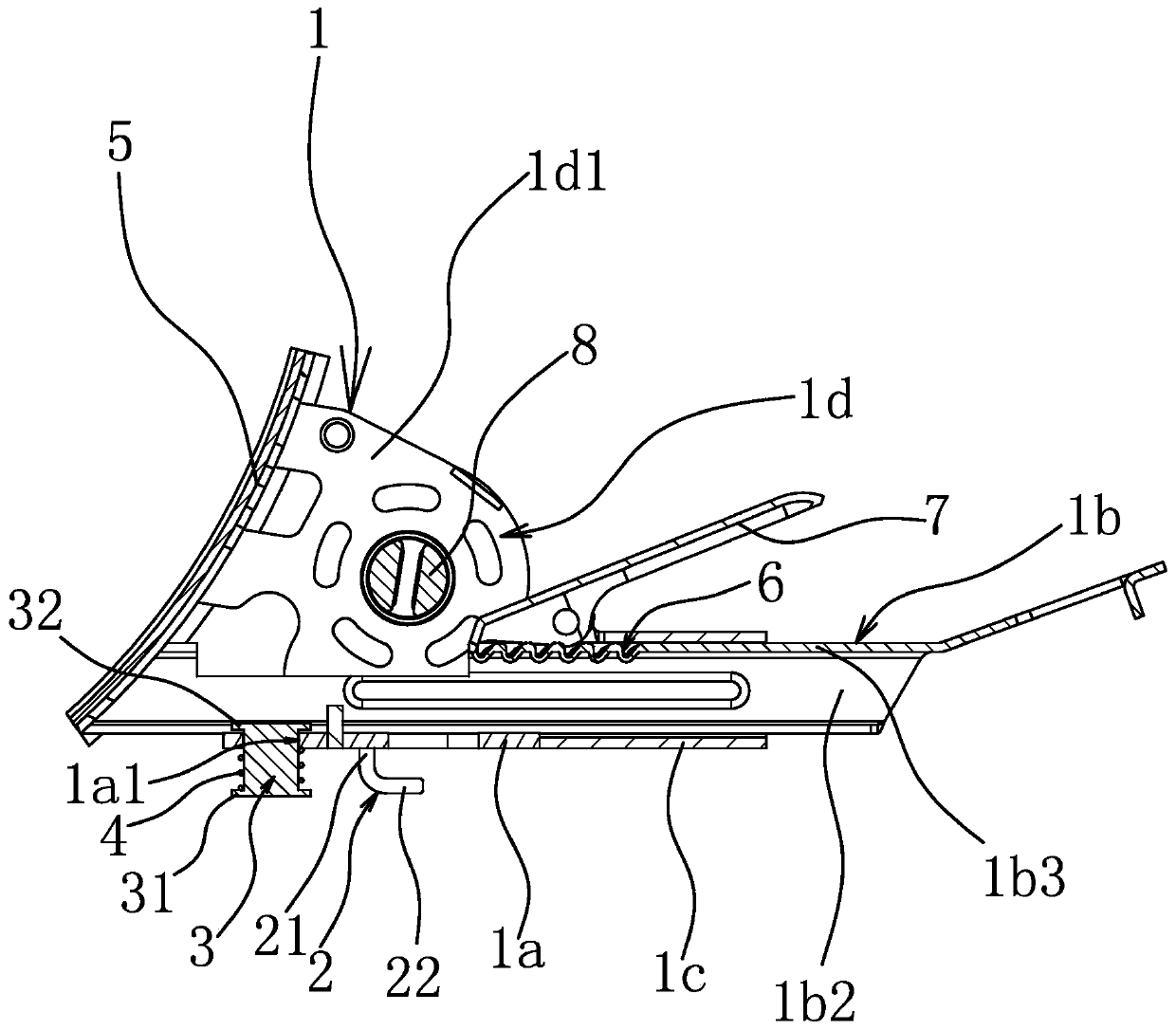

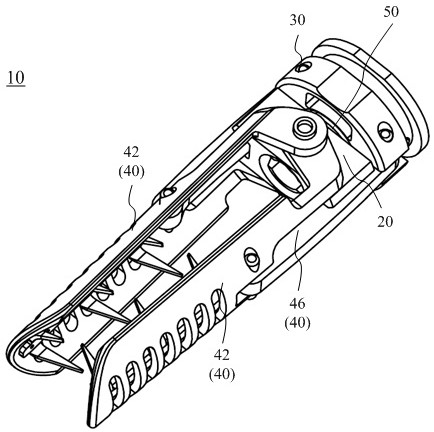

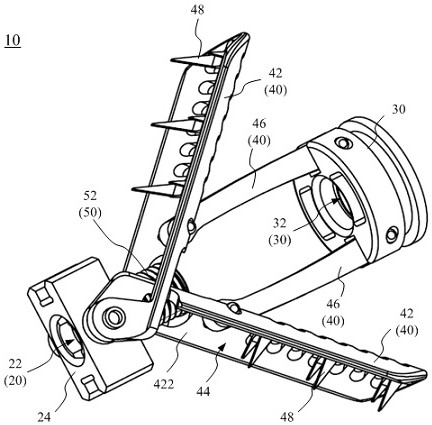

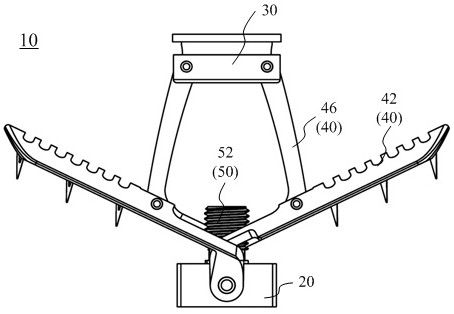

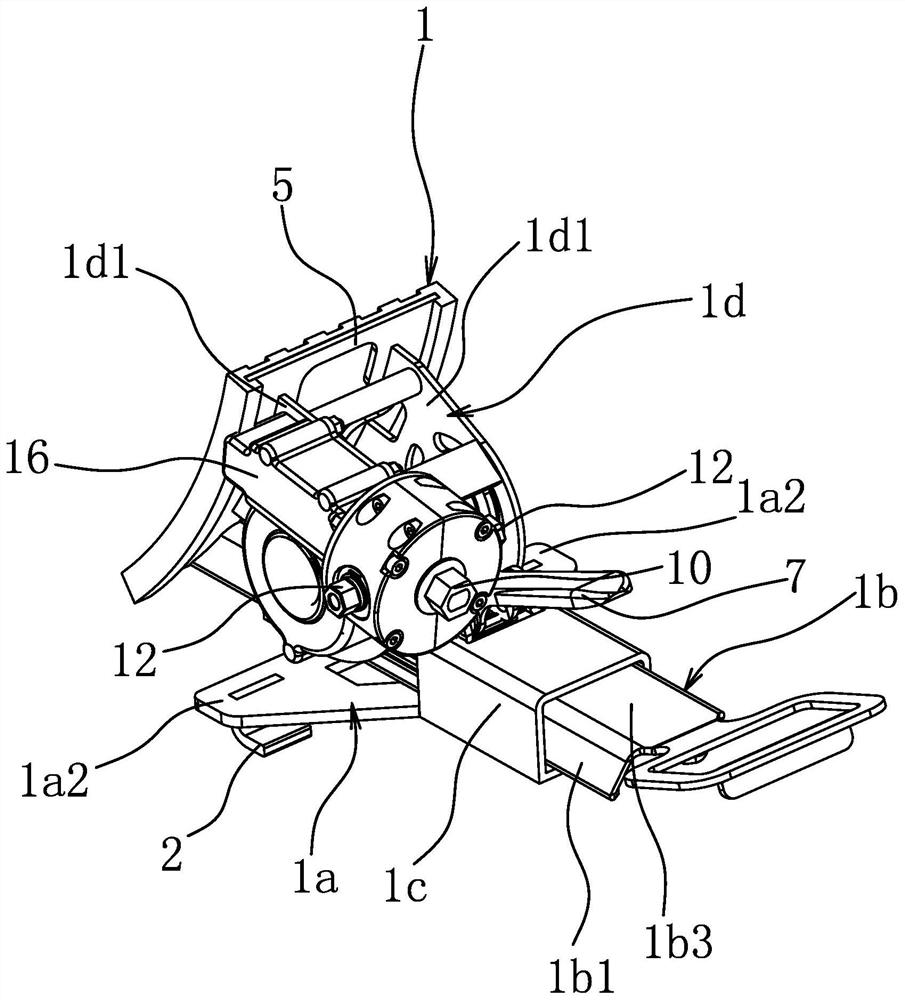

Gripping instruments

ActiveCN113425461BImprove operational convenienceIncrease contact areaAnnuloplasty ringsMechanical engineeringPhysics

The application provides a clamping device, which mainly includes a clamping base, a driving base, a clamping structure with different clamping angles formed according to the distance between the clamping base and the driving base, and a fine adjustment member, wherein the fine adjustment can be made by The parts and the driving seat are dissociated or connected to each other, so that the driving seat can move quickly or step by step relative to the clamping seat, so as to achieve the purpose of quickly adjusting or finely adjusting the clamping angle of the clamping structure. Accordingly, the application not only It can improve the operation convenience of the clamping instrument, and can provide precise clamping force control effect.

Owner:SHANGHAI HUIHE MEDICAL CO LTD +1

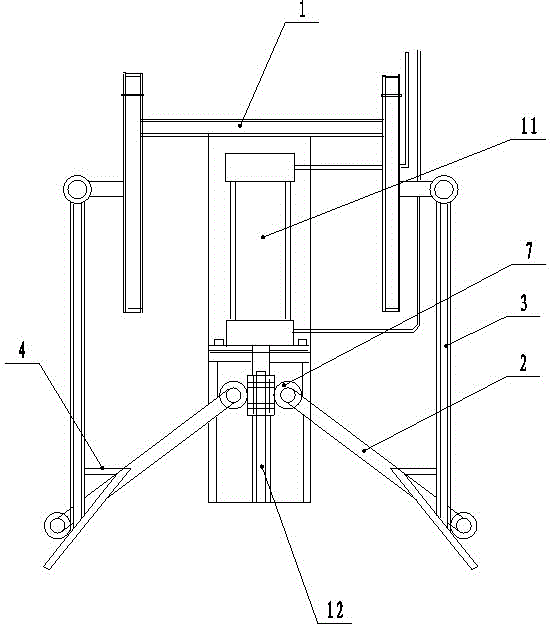

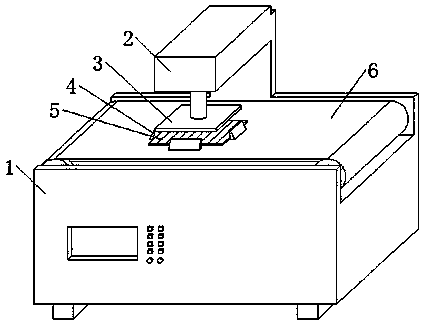

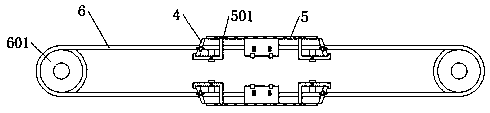

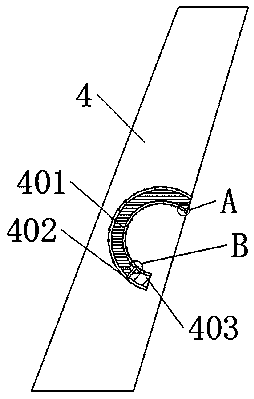

A cardboard fixing mechanism for paper printing

ActiveCN109677008BEasy to fixAffect printing qualityPaper-makingBox making operationsPaperboardElectric machinery

Owner:浙江骏驰纸制品有限公司

Self-locking anti-disengagement nut

Owner:刘克良

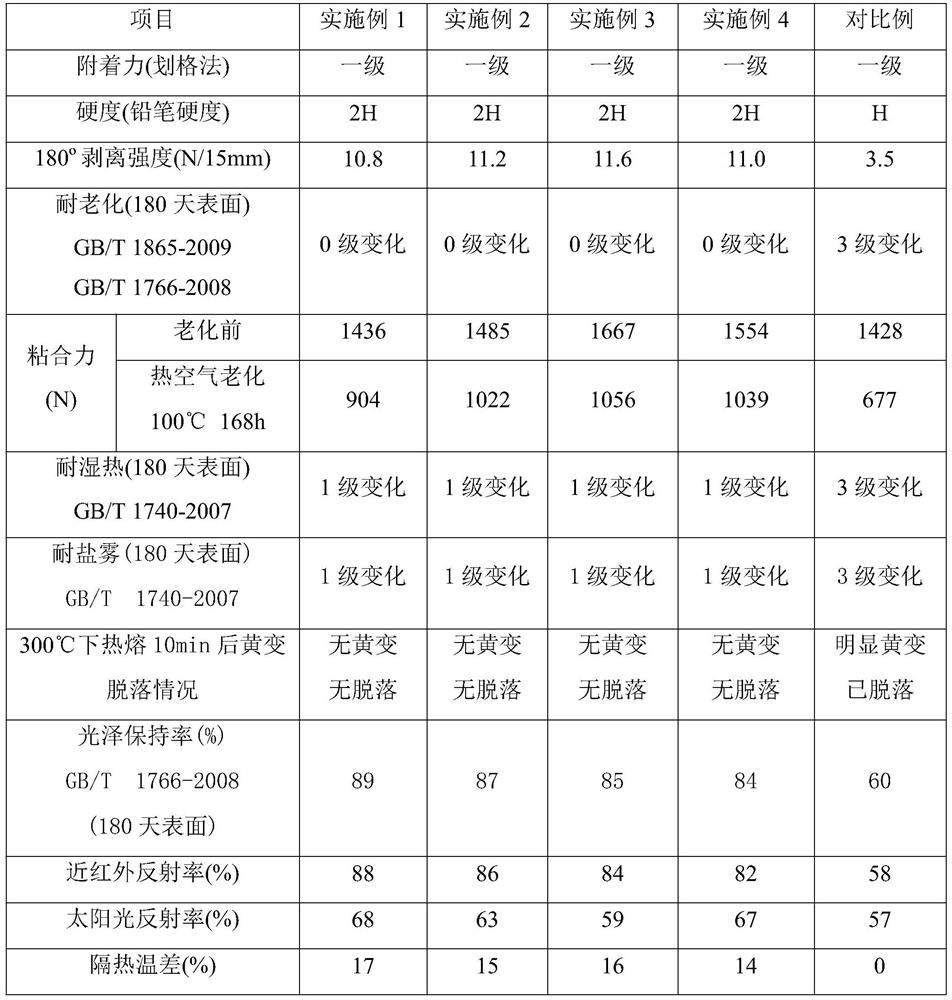

Cold roof prepared from PET modified film

InactiveCN112048252ANon-toxicHeat resistantRoof covering using slabs/sheetsNon-macromolecular adhesive additivesAdhesive cementPolymer science

The invention relates to a cold roof prepared from a PET modified film comprising a base material plate and a PET modified film compounded on the upper surface of the base material plate through hot pressing. The preparation method of the cold roof prepared from the PET modified film comprises the following steps: (1), pretreating a base material plate; (2), modifying PET (Polyethylene Terephthalate) through nano SiO2 particles to obtain modified PET; carrying out pre-crystallization and drying treatment on a modified PET raw material, feeding the material into an extruder for melting and plasticizing, and carrying out die head treatment through a pre-filter, a metering pump and a main filter; and pressing the material on a quenching wheel by an electrostatic adsorption device, rapidly performing cooling to form a cast sheet, and then sequentially stretching the sheet longitudinally and transversely. enabling the base film to be subjected to shaping, cooling, thickness measurement, edge cutting, static elimination treatment and online rolling to obtain the PET modified film; and (3), covering the pretreated base material plate with a PET modified film, and feeding the base materialplate into a hot press for hot press molding. According to the invention, the PET film is modified through the nano SiO2 particles, so that the PET film does not need to be coated with an adhesive ofa middle layer while being laminated with a metal plate, and the PET film can play a role in laminating and also can play a role in gluing.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

a logistics container

ActiveCN110963161BGood shedding resistanceImprove convenienceInternal fittingsLogistics managementStructural engineering

The invention provides a logistics cargo container, which belongs to the technical field of logistics transportation equipment. The utility model solves the problem that the connecting hook is easy to be decoupled in the existing logistics solid cargo container. This logistics cargo container includes a base body, the base body is provided with a cargo fixing structure for positioning the cargo, the bottom surface of the base body is provided with a connecting hook, and the bottom of the base body is also equipped with a It is a telescopic pressing element, and the pressing element can rebound downward by itself without the action of external force after upward contraction. During the hooking process of the connecting hook of the present invention, the pressing element will apply an upward force to the base body, so that the connecting hook on the base body has a tendency to move upwards and is tightly hooked into the hooking hole of the perforated plate. Therefore, the connecting hook has better detachment prevention performance.

Owner:安吉汽车物流(上海)有限公司 +1

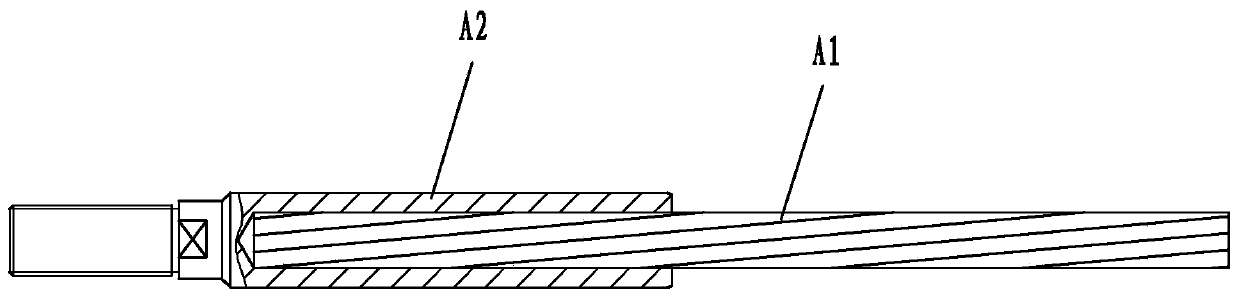

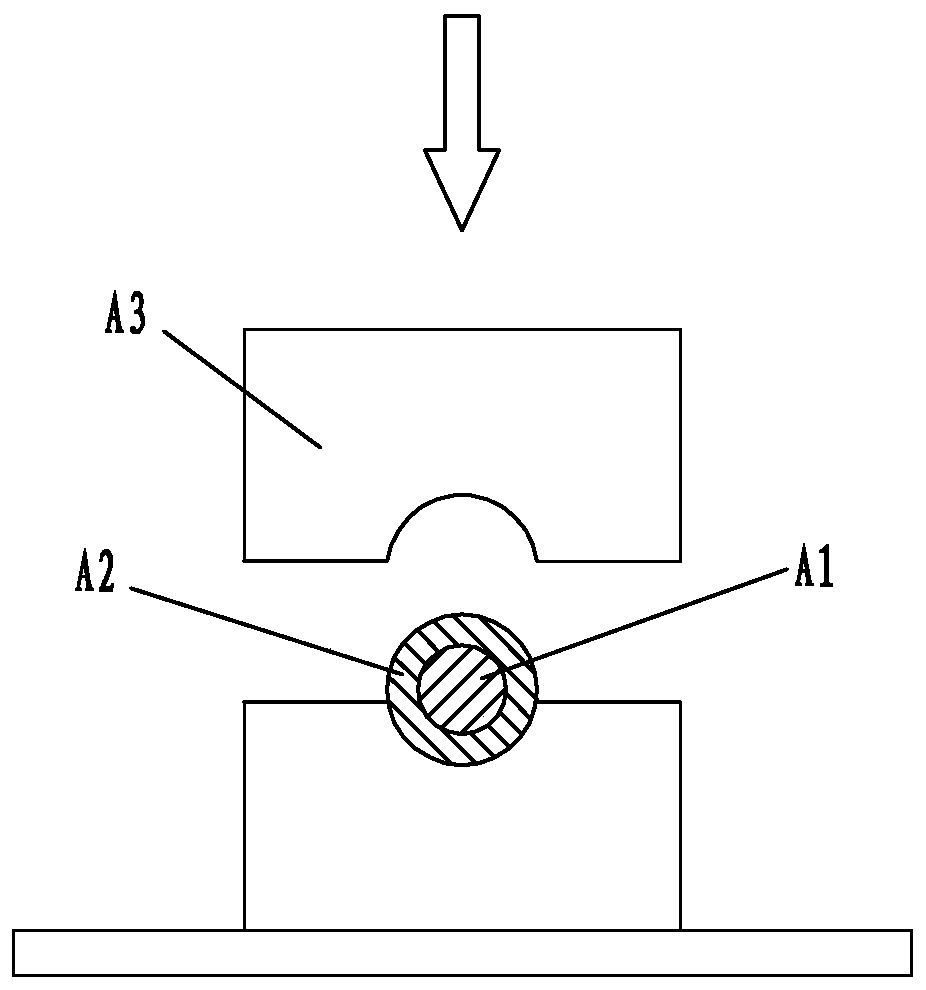

Large-diameter stainless steel cable and method of making the same

ActiveCN108262410BGood shedding resistanceCrimp firmlySlide fastenersStructural engineeringSS - Stainless steel

Owner:柳州豪姆机械有限公司

A kind of inorganic bonding system for water-based environment-friendly brazing flux and its application

ActiveCN112247400BImprove adhesionPromote environmental protectionWelding/cutting media/materialsSoldering mediaEnvironmental engineeringFiller metal

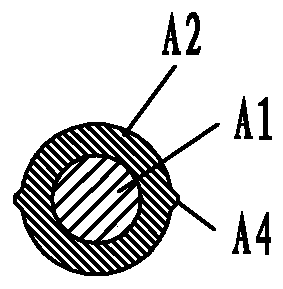

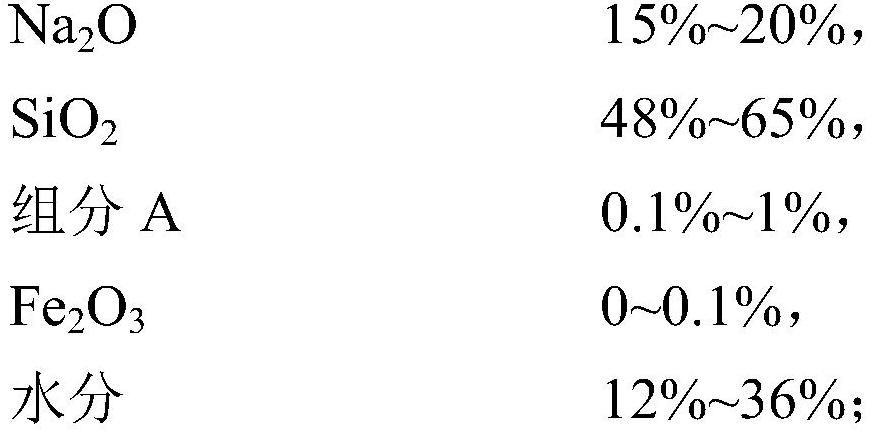

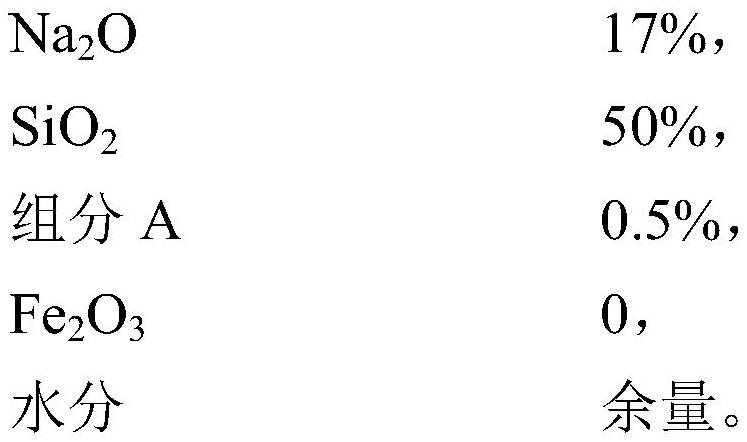

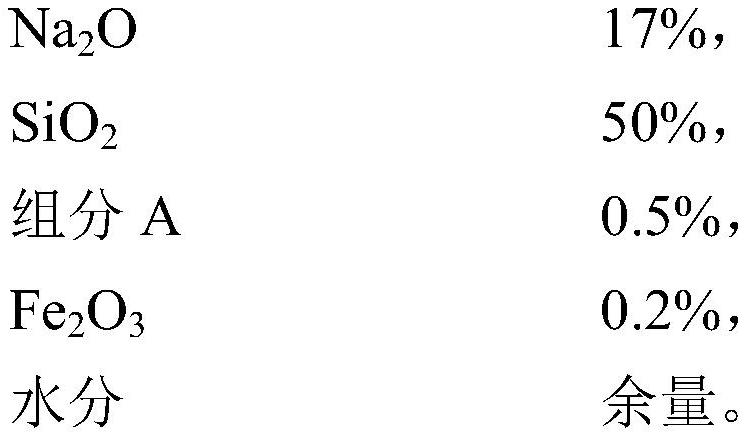

The invention discloses an inorganic bonding system for water-based environment-friendly brazing flux, which comprises the following components in terms of mass percentage: Na 2 O 15%~20%, SiO 2 48%~65%, component A 0.1%~1%, Fe 2 o 3 0-0.1%, moisture 12%-36%; the component A includes CaO and MgO, and the mass ratio of CaO and MgO is 1:0.5-2. The invention also discloses the application of the inorganic bonding system for the water-based environment-friendly brazing flux in the preparation of coated brazing filler metal. The invention also discloses a coating composition for brazing material, which includes brazing flux and the inorganic bonding system for the water-based environment-friendly brazing flux. The invention also discloses a sheathed brazing material, which comprises a brazing material as an inner core and a sheath covering the brazing material, spraying the brazing material coating composition onto the surface of the brazing material and drying That is, the covered brazing filler metal is obtained.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

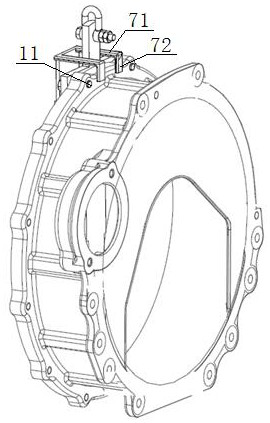

A flywheel housing and flywheel mounting sling and method of using the same

ActiveCN112664617BReduce labor intensityReduce the difficulty of operationVibration suppression adjustmentsLoad-engaging elementsStructural engineeringFlywheel

Owner:DONGFENG AUTOMOBILE COMPANY

Anti-falling bone screw

PendingCN112807068AEasy to useGood shedding resistanceInternal osteosythesisFastenersBone qualityEngineering

The invention relates to an anti-falling bone screw. The bone screw comprises a screw head and a screw rod at the bottom of the screw head, wherein a device inner cavity and a telescopic tooth piece device installed in the device inner cavity are arranged in the screw head; the telescopic tooth piece device comprises a telescopic tooth piece and a gear for driving the telescopic tooth piece; the gear and the screw rod are coaxially arranged; the telescopic tooth piece is provided with a tooth structure meshed with the gear; the rotation action of the gear drives the telescopic tooth piece to stretch out or retract from the side face of the screw head; a guide structure is arranged in an inner cavity of the screw head and guides stretching and retracting of the telescopic tooth piece; and a gear through hole communicating with the device inner cavity is formed in the front face of the screw head and used for rotating the gear. The bone screw has the beneficial effects that when the bone screw is used for old people, osteoporosis patients and the like, the bone screw can be tightly clamped with the bone by stretching out the telescopic tooth piece, so that the bone screw cannot fall off; the bone screw can be normally taken out of the bone by retracting the telescopic tooth piece; and the use is convenient, and the anti-falling effect is remarkable.

Owner:常州市南翔医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com